We are one of the most popular suppliers of linear actuators in the United Kingdom, with full product support and user advice available.

We are one of the most popular suppliers of linear actuators in the United Kingdom, with full product support and user advice available.Please contact us if you are ordering from a VAT-registered business in an EU country (excluding the UK) or from a country outside of the EU.

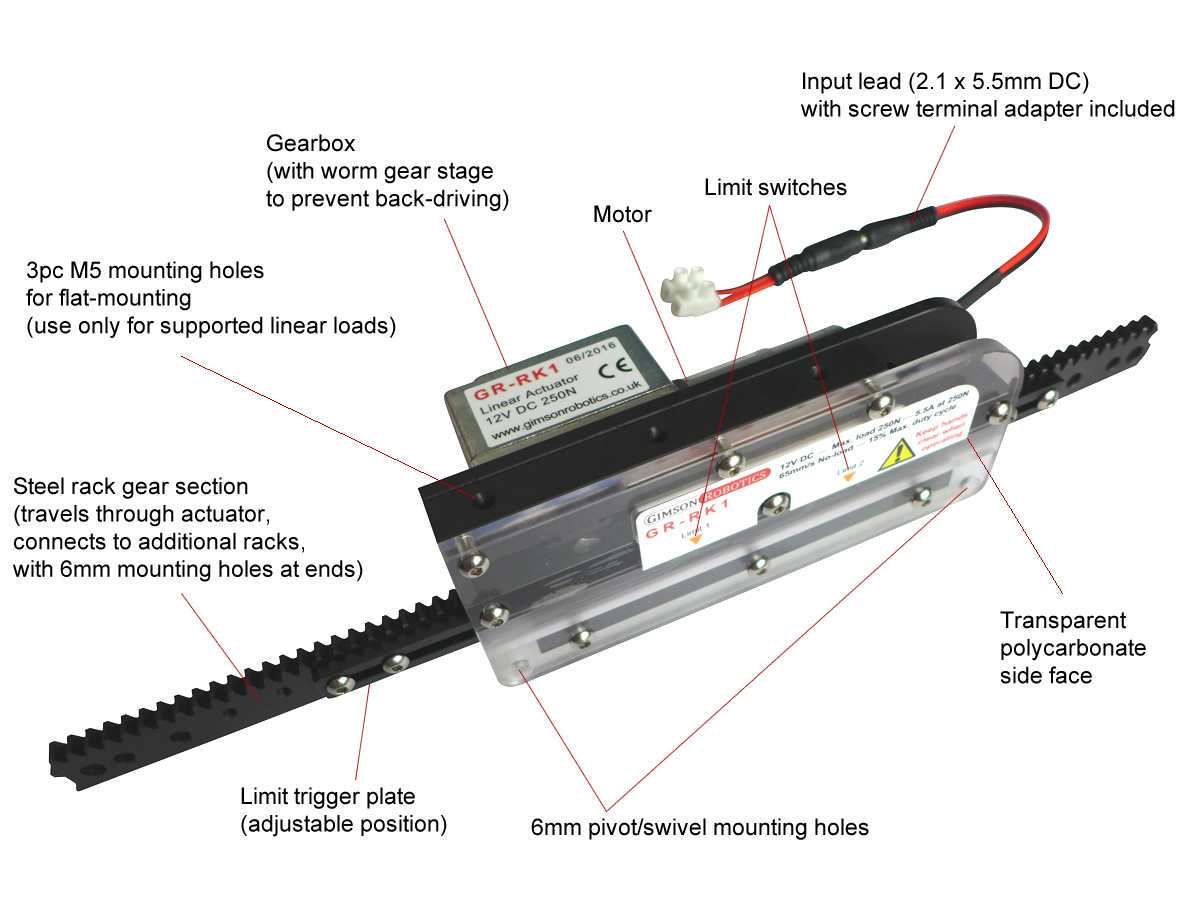

The GR-RK1 actuator on this listing is unlike any linear motor we have stocked before, offering adjustable mounting length and travel distance through a unique modular design. Rather than using the typical screw-based mechanism this device employs a rack and pinion slider which travels through the motor assembly. The steel rack sections, which come in two sizes, are designed to attach end-to-end meaning that you can add and remove pieces to reach the optimal size for your application.

The actuator motor is rated for a nominal 12V DC and is suitable for pushing and pulling loads up to 250N (25.5kg, 56lbs). The no-load travel speed is a relatively fast 65mm/s, decreasing to 35mm/s under the full rated load. Loads should be reduced if running a combined rack length of 1m or more.

Please see below for more product details.

We have designed this model in response to the many requests we've had for adjustable travel and longer stroke lengths from our linear actuators. The actuator should be suitable for opening/closing windows and doors, moving cameras and special effects equipment, and other similar indoor applications. Some of the main design elements are labelled below:

Each unit is supplied with a range of accessories making it immediately configurable to many different sizes and mounting orientations. In each box is included:

1pc GR-RK1 Base Unit (Motor, Input lead, Limt Switch Assembly)

1pc 72 Tooth rack gear (Steel 1.5 MOD, supplied ready-fitted in the base unit)

2pc 46 Tooth rack gear (Steel 1.5 MOD)

2pc Rack-clamping sets (Including 4pc M5 screws with a 3mm hex-socket size, for attaching one rack to another)

1pc Pivoting aluminium body bracket (with mounting accessories)

1pc Female DC to screw terminal (connector/adapter)

1pc Actuator adjustments guide leaflet (a copy of this is also available here)

Warning: Be sure to make any position or rack mounting adjustments with power removed from the actuator and then keep clear when running the actuator

The 72-tooth rack (supplied already installed in the base unit) has an overall length of 341mm, and immediately allows for a practical stroke length of up-to 160mm. The two 46-tooth racks also included are each 219mm long, if both are added to the 72-tooth rack the total stroke length can be increased to around 580mm. Additional racks beyond those included are available separately, allowing even longer potential travel distances.

Two microswitches built in to the base unit are intended to be used as travel limit switches, to be triggered by adjustable-position plastic blocks attached to the moving rack gears. Each limit trigger plate (as the plastic blocks are called) is fixed to a rack section with two M4 screws, each with a 2.5mm hex-socket head. The transparent side of the actuator body reveals the orange switch plungers and where the trigger plates engage with them, allowing extension adjustments to be made visually, as shown below.

To increase the travel distance of the actuator you can simply remove one of the two limit plates, attach an additional rack section using one of the two included clamping sets (ensuring that the button-heads of the clamping screws are on the transparent side of the actuator body), and then replace the removed limit plate onto the new rack where you would like the actuator to stop. An example of two racks attached to one-another, alongside one of the clamping sets, is pictured below.

An 'adjustments guide' leaflet is included with each actuator to guide you through the process of adjusting the travel limits and adding additional racks, a copy of this is available here (PDF).

Both ends of the steel rack sections have two 5mm holes (used for the clamping plates) and one 6mm hole, which can be used to transmit the load, via a pivoting bracket, by pulling on a cable, or similar.

The included aluminium slot-bracket is designed to fit either of the two 6mm mounting holes on the main body of the actuator, to allow the body to pivot as the rack extends and retracts:

Operating Characteristics

| Motor: | Nominal 12V DC, up to 60W |

| No Load speed: | 65mm/s |

| No Load Current: | 0.7A |

| Full Load Speed: | 35mm/s |

| Maximum load: | 250N (25.5kg) |

| Current for max. load: | 5.5A (do not apply power to the actuator if the load exceeds the maximum rating, this would void the warranty and be likely to damage the gearbox or bearings) |

| Maximum static load: | 1500N (153kg) |

| Noise levels: | < 52dB under no-load |

| Maximum duty cycle: | 15% (this is the maximum proportion of time that the actuator may be in operation for, up to 2minutes during any continuous stretch. The duty cycle should be reduced below 10% for average loads >200N) |

Please be aware that there may some variation in the operating performance from actuator to actuator, as a rule-of-thumb allow for a 5% difference above/below the given values. If intending to use two actuators together to drive the same assembly connect them in parallel to the input current and ensure that the driven assembly is rigid enough to transfer forces between the actuators (so as to prevent twisting if one actuator is slightly faster than the other). | |

Actuator Build Detail

| Size: |  |

| Mounting: | • Two sets of 6mm through-holes for pivoting mounts (and hinged brackets) • Three M5 tapped holes for flat-surface mounting. Only fix the body with these (so that it cannot pivot) if the load is perfectly linear and parallel to the moving rack • One 6mm and two 5mm holes at the end of each rack section |

| Body material: | Polycarbonate (transparent side), Delrin (black side and internal features), with aluminium gearbox housing |

| Rack material: | Hardened carbon steel, with black oxide treatment. It is recommended that oil is applied to the racks and clamp pieces every 4 months or so, this is not needed for mechanical lubrication but will help defend against corrosion (particularly in higher humidity environments). Wiping along the racks with an oiled rag should be sufficient for this purpose |

| Rack gear dimensions: | Please click here for a dimensioned diagram (jpg image) for both rack sizes |

| Operating temperature: | 0°C ~ +35°C |

| Gearbox type: | Three-stage, all metal gears. First stage worm-wheel gears to provide resistance to back-driving, second and third stages spur gears of increasing tooth pitch (output stage 1.25 Mod) |

| Limit switches: | The internal switch circuit is laid out like this, featuring two normally-closed microswitches with two diodes: The two black limit switch trigger plates are used to trigger one of the two microswitches at a time, stopping travel in the direction of motion. |

| Wire length: | 150mm from the motor, the included female DC to screw terminal adapter adds another 50mm |

| Weight: | Base unit (no racks): 850g 46 tooth rack: 160g 72 tooth rack: 250g One complete set (including base unit, one 72T rack, two 46T racks and mounting accessories) as supplied: 1740g |

We keep a spares stock of all actuator components, including rack sections and Delrin slide plates. If you would like any additional information or advice then please contact us.