Up for auction are FirstLook engine diagnostic sensors - model ADS ES 100 by SenX Technology (you can find information about this tool on the web, just search for SenX Technology or go to their website at http://senxtech.com/ ). These sensors are used but virtually indestructible. All sensors have been tested and perform as new. Includes 8 ft male to male bnc cable. This tool requires a lab scope which is not included.

FirstLook: How It Works

This section will explain how the FirstLook® sensor works. You can also read the manuals for the ADS ES 100 sensor. To make the understanding easy, you can view the video demonstrations at http://senxtech.com/how-it-works/#tab3-works . If you are one of those who prefer visualization than just reading the articles, then it will show you how easy it is for you to use FirstLook® sensors in your day-to-day operations. You can also go through case studies to get a better understanding of the FirstLook® operation.

FirstLook® Theory of Operation:

The FirstLook® sensor looks at the pulse waves generated by the normal operation of an internal combustion engine.

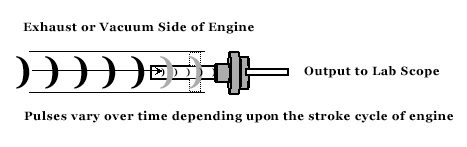

The Engine air flow produces a series of high pressure pulses separated by low pressures. Intake valves and exhaust valves open and close in a specified order with a specified timing. A ‘pulse’ of high pressure air is pushed into the exhaust system every time a cylinder’s exhaust valves open. The sensor detects these pulse waves through either the exhaust or vacuum side of the engine, or through the oil level indicator tube where pressure changes can be caused by ‘blow-by’ around the cylinders and rings. The pressure signature shows the events that occur during the 4-stroke cycle and when in the cycle those events occur. In a perfect engine, the pressure pulses will all look the same and be equally spaced. Engine problems will show in the pressure signature. Abnormal pressure pulses will jump out at you. And the shape of the pulse will tell you what is wrong.

The key to this is FirstLook®’s unique pressure sensor design. This consists of a piezoelectric material in a patented protective housing assembly. The piezoelectric material “measures” the pressures in the air flow in which it is placed.

Why It Works

All materials deform under a load. They compress or bend when the pressure on them increases. They expand or relax when the pressure on them decreases. Some materials, such as rubber, deform easily. Other materials are harder to deform, but they still deform.

Piezoelectric materials produce an electric charge as they are deforming. This electric charge is approximately proportional to the pressure on the material. As the pressure increases, the deformation increases and so does the electric charge.

Piezoelectric materials can only be used to measure dynamic pressures, pressures that are changing. They cannot measure static pressures. The material stops deforming once the pressure becomes static, or constant. Now, the material is no longer producing an electric charge. And the electric charge that was produced bleeds away to zero because of the conductivity of the material. Fortunately for us, air pressures in a running engine are continuously changing.

Internal combustion engines produce a predictable pattern of these pulses which can easily be displayed on most commercially available lab scopes when connected to FirstLook®. This pulse wave is sensed and the voltage is output for display by the lab scope. Any change or irregularity in this predictable pattern can be traced back to problems in the engine. The pulse wave can also be affected by unburned fuel in the exhaust and this abnormality is also detected and displayed. The FirstLook® sensor does not require any external source of power, so you never need to purchase or replace batteries.