CNC Kit 3 Axis Breakout Board And M542 Drivers For CNC Router/Mill/Plasma DIY

| |||||||||

Descriptions

3 Axis CNC Kit For Nema17/23/24/34 Stepper Motor

3rd Generation 5 Aixs Breakout Board With Display and Keypad(Professional Version) + 3 Pcs M542 Stepper Motor Drivers

The latest 3rd generation breakout board has been upgraded to the intelligent, professional and industrial-level interface board set by re-designing the PCB board and upgrading the external manual control tools (control pad and display panel). The re-designed PCB board makes the breakout board control the microstep drivers more smoothly with lower noise. Besides, the 3rd generation breakout board set has two types of versions, one is the Standard version, another one is the Professional version. Compare to the standard version, the professional version mainly has two more functions than the standard version: "computer G-code recording function" and "manual programing function". Except these two functions, these two types of versions have no other differences. This item contains Professional Version.

The M542 Stepper Driver Board Controller is a high performance microstepping driver based on pure-sinusoidal current control technology. With this technology and the self-adjustment technology (self-adjust current control parameters) for different motors, the drive motors can run with less noise, lower heating, smoother movement and have better performances at higher speed than most of the drivers in the market. It can work with 2-phase and 4-phase hybrid stepper motors, suits for Nema17--Nema34 stepper motors with 1.0A-4.5A current.

This item contains 1Pcs Breakout Board (Professional Version)and 3Pcs M542 Stepper Drivers. If you need the standard versoin or more drivers or stepper motor, please feel free to contact us for quotation.

It has professional DRO(digital read out), which can show real-time numerical value of 4axis(X, Y, Z, A), you can also set the motor speed, microstep and other parameter etc for manual control.

For more detailed information about display, you can click here to check Display Specification

|

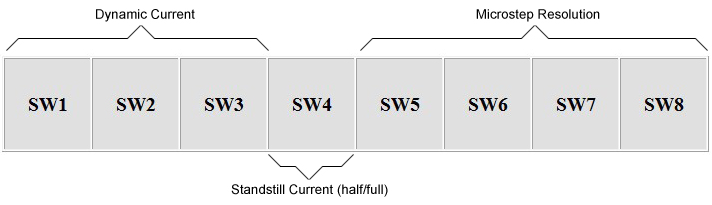

Dynamic current setting

|

||||

|

Peak Current

|

AVG Current

|

SW1

|

SW2

|

SW3 |

| 1.5A | 1.0A | ON | ON | ON |

| 2.0A | 1.4A | OFF | ON | ON |

| 2.4A | 1.7A | ON | OFF | ON |

| 2.8A | 2A | OFF | OFF | ON |

| 3.2A | 2.3A | ON | ON | OFF |

| 3.7A | 2.6A | OFF | ON | OFF |

| 4.2A | 3A | ON | OFF | OFF |

| 4.5A | 3.2A | OFF | OFF | OFF |

| Auto Half-Current-Reduction Setting | ||||

| SW4 | ON | OFF | ||

| Work-Full | Standstill-Full | Work-Full | Standstill-Full | |

| Mirostep Resoltion Selection | |||||

| Mirostep | Step/Rev.(1.8° motor) | SW5 | SW6 | SW7 | SW8 |

| 2 | 400 | ON | ON | ON | ON |

| 4 | 800 | ON | OFF | ON | ON |

| 8 | 1600 | ON | ON | OFF | ON |

| 16 | 3200 | ON | OFF | OFF | ON |

| 32 | 6400 | ON | ON | ON | OFF |

| 64 | 12800 | ON | OFF | ON | OFF |

| 128 | 25600 | ON | ON | OFF | OFF |

| 256 | 51200 | ON | OFF | OFF | OFF |

| 5 | 1000 | OFF | ON | ON | ON |

| 10 | 2000 | OFF | OFF | ON | ON |

| 25 | 5000 | OFF | ON | OFF | ON |

| 50 | 10000 | OFF | OFF | OFF | ON |

| 125 | 25000 | OFF | ON | ON | OFF |

| 250 | 50000 | OFF | OFF | ON | OFF |

Suitable for small-and-medium automatic machine equips with CNC controller, such as CNC router, CNC mill, CNC lathe, X-Y-Z tables, labeling machines, laser cutters and pick-place devices etc.

Suitable for small-and-medium automatic machine equips with CNC controller, such as CNC router, CNC mill, CNC lathe, X-Y-Z tables, labeling machines, laser cutters and pick-place devices etc.

Suitable for a wide range of stepping motors, from NEMA size 17 to 34

Suitable for a wide range of stepping motors, from NEMA size 17 to 34

Nema17 Motor: 24V Power Supply

Nema17 Motor: 24V Power Supply

Nema23/24 Motor: 36V Power Supply

Nema23/24 Motor: 36V Power Supply

Small size Nema34 Motor: 48V Power Supply

Small size Nema34 Motor: 48V Power Supply

Guide: Choose the voltage according to motor size, choose current according to the rated current of motor.

Guide: Choose the voltage according to motor size, choose current according to the rated current of motor.

Example: 3Pcs Nema23 with 3A, then the power supply should output 3*3A=9A at least, so you can use 36V 10A PSU.

Example: 3Pcs Nema23 with 3A, then the power supply should output 3*3A=9A at least, so you can use 36V 10A PSU.

If need power supply for this kit, please contact us with the model of motor, we will recommend suitable power supply for you.

Do not plug/unplug any connectors when the board or driver is powered on.

Do not plug/unplug any connectors when the board or driver is powered on.

Do not use the power supply higher than rated voltage of the kit.

Do not use the power supply higher than rated voltage of the kit.

Do not disassemble the product without the guidence of professional person.

Do not disassemble the product without the guidence of professional person.

Please do bench test this system before installing it.

Please do bench test this system before installing it.

Please assemble the kit according to the instruction.

Please assemble the kit according to the instruction.

Descriptions

| 5 Axis Breakout Board | |

|

Model

|

Professional Version |

| Input Power | USB Port or External 5V DC Power |

| Drive Type | Pulse + Direction + Enable Signal |

| Suitable Stepper Driver | 2 Phase, 4 Phase Stepper Driver |

| Cooling Method | Natural Cooling or Fan Forced Cooling |

| Operating Environment | Avoid dust, oil fog, corrosive gas |

| Operating Temperature | Max 70°C |

| Operating Humidity | 40%RH ~ 90%RH |

| Weight | 275G |

| Dimension | 110*110*25mm |

| M542 Stepper Driver | |

| Model | M542 |

| Output current | 1.0A-4.5A |

| Supply Voltage | 24-50V DC |

| Pulse Input Frequency | 0-300KHZ |

| Isolation Resistance | 500 MΩ |

| Cooling Method | Natural Cooling or Fan Forced Cooling |

| Operating Temperature | Max 70°C |

| Dimension | 118*86*36(mm) |

| Weight | 370G |

| Suitable Stepper motor | Nema17-Nem34 Stepper motor(1.0-4.5A) |

| Estimated Delivery Time (subjects to stock availability) | ||

|---|---|---|

| USA (excl. Alaska, Hawaii, Puerto Rico) | USPS First-Class Package/UPS SurePost/UPS Ground | 3-7 business days |

| Other Countries (May depart from other stock location) | International Airmail Service | 12-21 business days |

Please DO CONTACT AND CONFIRM with us BEFORE you bid IF you:

- need the item urgently.

- require that the item should be delivered within a certain time.

- have any other questions/requirements about delivery.

Remarks:

*Usually, your order will be dispatched before the next working day after the full payment is cleared when stock lasts.

*Notification will be sent after your order is dispatched, please check you email or ebay order records for date of dispatch.

*It is not guaranteed that parcel should arrive within the time stated above. However, 95%+ parcels will be delivered within the reference time.

*Please contact us if you have any trouble in receiving your orders. We will help you to track them.