Overview

- Suitable for people who have little or no experience

with PLCs.

- High definition full motion video (1920x1080).

- Clear, concise, organized, detailed and easy to understand.

- 5 hours of training.

- Proven training curriculum.

- This listing is for 1 DVD that contains

1. Ladder Diagram Training Course.

2. PLC Hardware Training Course.

3. PLC Programming Training Course.

4. Bonus PLC ebooks (+1000 pages).

- Please note that this listing does not include

any PLC hardware.

|

|

Why buy this training course?

- Risk free. We offer a 30 days money back return policy!

- Give yourself a competitive edge in the job market by learning a new skill.

- Increase your worth to your employer and move up the career ladder.

- Good value. An equivalent training course can cost over $500.

- We have been selling since 2012 and have thousands of satisfied customers.

|

Road Map To PLC Mastery:

Ladder Diagram Training Course

- The road map to PLC mastery starts with learning how to read electrical schematics. Programmers need this skill to see how PLC programs interact with the hardware that are in a system. This training course teaches electrical schematic reading and electrical components that are commonly found in PLC based systems.

PLC Hardware Basics Training Course

- The next stop of the road to PLC mastery is learning the basics of PLC hardware. PLC hardware knowledge is needed to design PLC systems that conform to technical specifications. This training course teaches PLC hardware that are typically used in PLC systems such as digital I/O module, analog I/O module, processor modules and power supply module.

PLC Programming Basics Training Course

- The final stop of the road to PLC mastery is learning the basics of PLC programming. The PLC Programming Basics Training Course teaches the fundamental of PLC programming. One of the training course's goal is to give you a solid foundation in PLC programming. Some of the programming concepts required to build a solid foundation can be hard to grasp. This training course has several features and characteristics that make learning easier. Programming concepts are explained with the aid of animations and demonstrations with actual PLC. This training course is not a boring text book!

- At the end of this training course, you will have the skill to develop PLC programs that are moderately complex.

Beyond the road map to PLC mastery

- In addition to three training courses, you will also get three bonus PLC ebooks that have a total of more than 1000 pages. The three bonus PLC ebooks supplement the PLC hardware and PLC programming concepts presented by the three training courses. Use the ebooks to progress your understanding of PLCs.

|

Topics of the PLC Training Course

Ladder Diagram Training Course

- Training Course Introduction

- Prerequisite / required hardware

- Indicator Lights

- Intro / Electrical symbol

- Switches

- Intro/ Push buttons / Contacts / Selector Switches / Limit Switches / Electrical symbols

- Transformers

- Control Transformer / Primary winding / Secondary Winding / Electrical Symbol

- Fuses

- Intro / Electrical Symbol

- Relays

- Intro / Anatomy of a Relay / Wiring / Electrical Schematic usage / Electrical Schematic Naming Convention / Electrical Symbol

- Ladder Diagram Framework

- Components of Ladder Diagrams / Wire Labels / Component Labels / Adding Components to Ladder Diagrams / Components Name Prefixes / Practical Example

- Practical Exercise

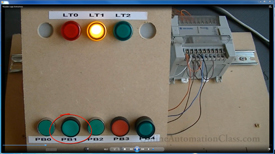

- Intro / Required Hardware / 3 Wire Start/Stop control circuit design using ladder diagram / 3 Wire Start/Stop circuit construction / Testing

PLC Hardware Training Course

- Intro / Prerequisites / Objectives /

- What is a PLC? / PLCs Form Factor / Stand Alone / Modular / Form Factors Cost and Capabilities

PLC Chassis

- Physical Features / Backplane PCB / Module Installation/ Chassis Selection guide/ Allen Bradley SLC 500 Chassis

PLC Power Supply

- What is a PLC Power Supply? / Physical Features / Output Power / Sizing Allen Bradley 1746-P1 Power Supply

PLC Digital Input and Output Channels

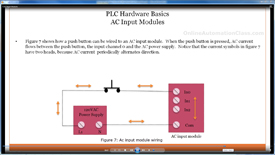

- What are Input and Output Channels? / Digital I/O Module / Operating Voltage Range / Allen Bradley SLC 500 I/O Modules / Digital I/O Module / Physical Features / Digital Input Channels Wiring / Sinking and Sourcing Input Wiring / Input Channels Wiring Demo / What are transistors Output Channels? / Transistor Output Channels Current Rating / Number of Channels / Transistor Sinking and Sourcing Output Channels Wiring / Output Channels Operating Voltage Range / Transistor Output Channel Wiring Demonstration

PLC Contact Output Channels

- What Are Contact Output Channels / Contact Types: Form A, Form B, Form C / Contact Output Module Internal Connection / Voltage and Current Rating / Sourcing and Sinking / Contact Output Channels Wiring Demonstration.

PLC Analog Input Channels

- What are Analog Input Channels? / Examples of Practical Usage / Types of Analog Signals / Examples of Analog Input Channels Usage / Operating Voltage Range / Allen Bradley Analog Input Module / Measurement Accuracy / Module Resolution / Voltage Resolution Calculation / Total Counts Calculation / Analog Input Module Usage Demonstration.

PLC Analog Output Channels

- What are Analog Output Channels? / Examples of Practical Use / Physical Features / Operating Voltage Range / Module Resolution / Accuracy / >Usage Demonstration / Voltage Resolution Calculation / Counts Calculation / Analog I/O Channels Wiring / Electrical Noise Prevention / Cable Shielding

PLC Processor

- What is a PLC Processor? / Examples of PLC Processors / Physical Features of PLC Processors / Indicator LEDs and Keylock / Communication Ports / Programming Cable / Memory Type: ROM, RAM, EEPROM / Memory Structure / Memory Capacity Selection / User Programs and Firmware / >Scan Cycle / Scan Cycle Analogy. / Scan Time

Powering PLCs

- Power Requirement / What is a Control Transformer? / Control Transformer Terminal Name / Step Down Control Transformer / Control Transformer Sizing / Volt-Amp Rating / PLC Rating Label / PLC Power / Control Transformer Fuse Sizing

Programming PLCs

- PLC Interface Software: RSLOGIX 500 and DirectSOFT / PLC Program Upload and Download / Interface Software Function / RSLOGIX 500 Pro Quick Tour / PLC Communication interfaces: RS232, RS485 and Ethernet / Handheld PLC Programmers

PLC Programming

- Training course introduction

- PLC Memory

- Introduction / PLC Memory Usage / Data Types / Integer, Boolean, Floating Point, counter and timer / Data Type Usage / Boolean Data Type / Boolean Data Type Block / Integer Data Type / Integer Data Type Block / Memory Addressing / Allen Bradley Memory Addressing Convention / RSLOGIX 500 Binary Data File

- PLC Program Overview

- Introduction / Why some machines require PLC programs? / PLC Program Inputs and Outputs / PLC Programs Instructions / PLC Program Development Software / Ladder Logic Programming Language / Ladder logic Instructions / Reference Memory Address / Ladder Logic Instruction Symbol Name / Ladder Logic Comments / Ladder Logic Rungs / Ladder logic Rungs State / Ladder Logic Branches / PLC Program Scan / PLC Program Execution / Ladder Logic Program VS Electrical Ladder Logic Diagram

- "RSS" RSLOGIX 500 Project Files

- RSLOGIX Micro Starter Lite Installation / Open RSS project file with RSLOGIX Micro Starter Lite

- Ladder Logic Instructions

- Ladder Relay Instructions

- Introduction / Normally open contact instruction / Normally closed contact instruction / Output coil instruction / Normally open, normal closed and output coil instruction demonstration / Transitional contact instruction Demonstration / Latch output coil instruction / Unlatch output coil instruction / Latch and unlatch output coil instruction demonstration.

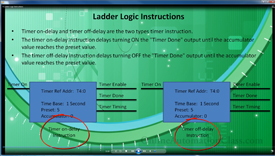

- Timer instructions

- Instruction inputs and outputs/ parameters / Reset / Analogy / Demonstration

- Counter instructions

- Instructions input and outputs / Instructions parameters / Reset instruction / Analogy / Demonstration

- Ladder Logic Programming Tools

- Introduction / Boolean Expression / Boolean Expression to Ladder Logic Circuit Conversion / Sum of Product (SOP) & Product of Sum (POS) Boolean Expression / SOP boolean Expression Conversion Example / POS Boolean Expression Conversion Example / Truth Table Introduction / Truth Table Header / Truth Table Input Columns / Truth Table to Boolean Expression Conversion Example / Karnaugh Map Introduction / Karnaugh Map Vertical and Horizontal Header / Karnaugh Map Output Cells / Karnaugh Map / Gray code / Number of Inputs vs Number of Output Cells / Inputs to Output Cell Mapping / Karnaugh Map Usage Example / Karnaugh Map Grouping Rules / Solving Karnaugh Maps with "Karnaugh Map Minimizer" Software

- Types of PLC Programs

- Introduction / Combinational PLC Program / Combinational PLC Program Characteristics / How Combinational PLC Programs Work / Sequential PLC Programs / Sequential PLC program Characteristics / How Sequential PLC Programs Work / Sequential PLC Program Analogy / Sequential PLC Program Application / Combinational PLC Program Application

- Combinational PLC Program Design

- Introduction / PLC Program Development Cycle / Machine Logic Specification Step / Electrical Schematic Drafting Step / Design & Implementation Step / Expressing Systems Logic with Truth Table / Truth Table to Boolean Expression Conversion / Boolean Expression to Ladder Logic Circuit Conversion / Combinational PLC Program Overview / Testing step / Combination PLC program demonstration

- Sequential PLC Program Design

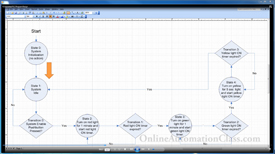

- Introduction / Sequential PLC Program Development Cycle / Machine/System Logic Specification Step / Systems Logic Documentation

- System I/O Documentation / Hardware Schematic Drafting Step / Design & Implementation Step / Sequential PLC Program Logic Overview / State Diagram Design / State Diagram to Ladder Logic Conversion / Testing Step / Sequential PLC Program Demonstration

Topics of the three Bonus PLC Ebooks

Automated Manufacturing System

- Programmable Logic Controllers / PLC Hardware / Logical Sensors / Logical Actuators / Boolean Logic Design / Karnaugh Maps / PLC Operation / Timers, Counters and More / Structured Logic Design / Flowchart Based Design / State Based Design / Numbers and Data / PLC Memory / Ladder Logic Functions / Advanced Ladder Logic Functions / Open Controllers / Instruction List Programming / Structured Text Programming / Sequential Function Charts / Function Block Programming / Analog Inputs and Outputs / Continuous Sensors / Continuous Actuators / Continuous Control / Fuzzy Logic / Serial Communication / Networking Communication / Internet / Human Machine Interfaces (HMI) / Electrical Design / Software Design / Selecting a PLC / Appendix - Function References / Appendix - Glossary / Appendix - References

Dynamic System Modeling and Control

- Introduction / Translation / Solving Differential Equations

- Numerical Methods / Rotation / Transfer Functions / Circuits / Feedback Control Systems and Block Diagram / Phasor Analysis / Bode Plots / Root Locus Plots / Non-linear Systems / Analog IO / Sensors / Actuators / Motion Control Systems / Laplace Techniques / Magnetic Systems / Fluids / Linear Controls with Laplace / Lab Guide / Writing / Math Review Guide / C Programming Review / Units / Materials

Integration and Automation of Manufacturing Systems

- Integrated and Automated Manufacturing / An Introduction to C/C++ Programming / Network Communication / Databases / Communications / Programmable Logic Controllers (PLCs) / PLCs and Networking / Industrial Robotics / Other Industrial Robots / Robot Applications / Spatial Kinematics / Motion Control / CNC Machines / CNC Programming / Data Acquisition / Vision Systems / Integration Issues / Material Handling / Petri Nets / Production Planning and Control / Simulation / Planning and Analysis / References / Appendix - Projects / Appendix - Common References

|

Other Online Automation Class Products

Allen Bradley RSLOGIX 500 Pro Training Course

Allen Bradley Factorytalk View Studio Training Course

(Applicable to version 6/7/8)

|

Sales Policy

- Return within 30 days if not satisfied. Please contact us first before shipping back the item.

- We accept Paypal.

- Contact us through Ebay.

|

|