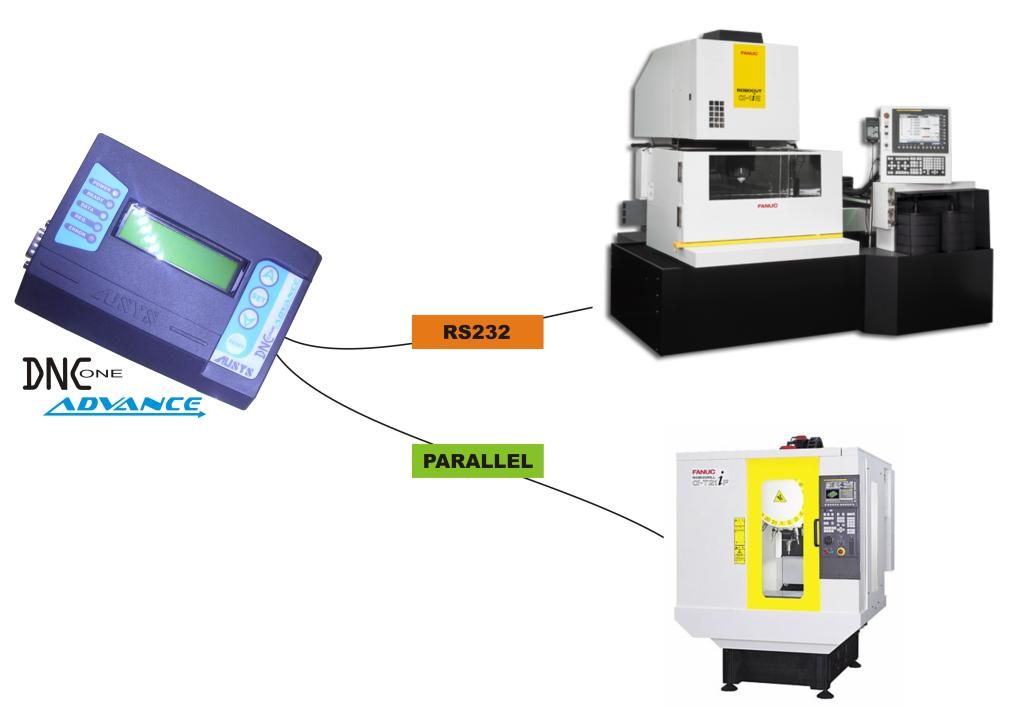

CNC Program Transfer between USB & CNC control via Serial (RS232) / Parallel Port

This reader will read cnc files on USB flash drive, then transfer to CNC machines via TAPE port or COM port (RS232).

This READER is used to transfer program to / from CNC machine via parallel port (FANUC 50pins) or serial port (RS-232) for almost CNC machines.

Compatible USB 2.0 Compatible

File extention *.NC, *.TAP and *.TXT are supported.

Choose the file name from the list on LCD display easily.

Return automatically to the top of the program .

Parameters setting.

ASCII and EIA codesets are fully supported for old paper tape punch machines.

Package include: 1x Reader, 1x RS232 cableDNC One specifications

- DNC-one tool is used to transfer/drip feed a NC program (G, M codes) to CNC machines from USB flash drive (replacing PC) by the parallel port (50pins) or serial port (RS-232C), it also receives programs, parameters in CNC machine and saves to USB.

- DNC-one compatible with almost CNC machines such as: Fanuc, Okuma, Mitsubishi, Yasnac, Haas...

- Read the USB 2.0 of all brands and different capacities.

- Read the file names is long up to 255 characters and the files can be stored in a directory and subdirectories (this feature starting Version 6.0 onwards).

- Select the file on the LCD screen.

- Equipped with 2 USB ports.

- Set the communication parameters by pressing the button on theDNC-one.

- The baudrate in serial mode is up to 115.200bps (4800, 9600, 19200, 38400, 57600, 115200) Change the speed of data transfer for parallel port communication.

- Return automatically to the top of the program after transferring finishes.

- The warranty period is 2 years.

DNC-one usually considered to be similar the internal memory of the CNC machine: Return automatically to the top of program after a program finishes or RESET button pressed in the CNC machine side (in parallel mode, CNC machine always outputs the RESET signal if RESET button pressed, but sometimes RESET signal is not output by serial port).

Traditional solution of DNC drip-feeding for CNC machines is using computers have been installed a dedicated DNC software (like CIMCO Edit, Dostek DNC, etc) to send or receive G,M-code programs.

But this solution has some drawbacks:

- Placing a computer near CNC causes to be waste workshop area.

- Manipulating on the computer takes a lot of time and many stages (booting the computer, launch the software, installation, selection, etc).

- Computers sometimes fail or suffer from virus attack, which causes delay jobs, reducing productivity.

- RS232 port of the computer sometimes damage the data transmission board of the CNC machine.

- You have to operate on PC after every time finishing a program

With the above drawbacks of the traditional solution, we have researched the functional integration necessary to target the most compact product manipulation and optimal operation, in order to improve productivity and economic performance in process using CNC machine, so the DNC One product to Send/Receive G-code for CNC machine was born.

- Demensions: 140x100x30mm

- Weight: 320g

- Plastic box

- 04 magnet nuts to mounting on CNC machine

- 01 DC power supply port

- 02 USB socket

- 01 RS232 port (9 pins)

- 01 parallel port (50 pins)

- 05 LEDs indicator: POWER, READY, DATA, REQUEST, ERROR.

- 04 function buttons:

▲: go up

▼: go down

SET: select

RESET: restart the DNC One

- LCD16x2 screen: display status, files list, setting parameter, alarm, ect.

Supply power for the DNC One in several ways:

Note: At the same time just choose one way to supply the power. |

|

| Some types of CNC can use DNC One |

Note: The DNC is allowed only for machines having the mainboard support. |

| Features |

(*)The feature is in testing phase.

Note: You should use good quality USB. |

| Version information |

|

| Duration of warranty | 24 months |