BEST VIEWED USING GOOGLE OR GOOGLE CHROME BROWSER

MAX MCR BLACK A/B

ELECTRONIC PRINTED CIRCUIT BOARD POTTING COMPOUND

1/2 GALLON OF PART A RESIN

1 QUART OF PART B CURING AGENT

96 OUNCES COMBINED VOLUME

OPAQUE BLACK INSULATING RESIN SYSTEM

ELECTRICAL INSULATING AND ELECTRONIC CIRCUITRY

OR

PERMANENT OPAQUE BLACK MASKING COMPOUND FOR PROPRIETARY ELECTRONICS

CIRCUIT BOARD CONFORMAL COATING

ELECTRICAL POTTING COMPOUND

EMBEDDING OR MASKING COMPOUND

WATERPROOF LOW TO HIGH VOLTAGE CIRCUITS

>2,000,000 CYCLIC ON/OFF TEST WITH NO FAILURE

24 VOLT SOLENOID

VALVE POTTED WITH MAX MCR A/B.

PRODUCT DESCRIPTION

MAX MCR BLACK A/B is an unfilled medium working time casting resin that offers a good balance of performance and cost, making it an excellent resin for electrical insulating applications. It cures to a hard but tough compound that is suitable for small to medium parts without excessive exothermic heat generation (up to 1 pound). It has a 30-minute working time when mixed up to 200-gram mass.

MAX MCR BLACK A/B is low in viscosity and offers a very high gloss finish blemish free surface.

The 2 to 1 mix ratio offers ease of use and easily poured in place or can be adapted for mix meter equipment.

It is suitable for silicone, polyurethane, steel, and wood molds for casting applications.

MAX MCR A/B can also be utilized in many different applications where epoxy resins are typically employed.

It bonds very well to wood, metal, concrete and other composite and plastic substrates.

Other Uses:

Electronic Potting and Encapsulating Compound

Structural Adhesive

Protective Coating

Fiber Glass/Carbon Impregnating And Laminating Resin

Base Binder Resin

MAX MCR A/B

PHYSICAL PROPERTIES

AND

MECHANICAL PROPERTIES

Form And Color | Black Liquid, Self Leveling Other Colors Available |

Viscosity Part A | 2,500 cPs |

Viscosity Part B | 750 cPs |

Mixed Viscosity | 2800 cPs (after induction time) |

Mix Ratio By Weight | (2:1) 100 Parts A to 50 Parts B |

Mix Ratio By Volume | (2:1)100 Parts A to 50 Parts B |

Mixed Density | 1.10 g/cc |

Working Time | 30 minutes (400-gram mass) |

Gel Time | 60 minutes |

Peak Exotherm | 280°F max (400400-gramss) |

Demold Time | 24 hours room temperature |

Accelerated Cure | 2 Hours @ 75°F plus 30 minutes at 200°F |

Shore Hardness | 75 Shore D |

Shrinkage: | <0.30 % |

Compressive Strength | 13,800 psi |

Tensile Strength | 9,900 psi |

Tensile Elongation | 4% |

Heat Distortion Temperature | 190°F |

ELECTRICAL AND THERMAL CONDUCTIVITY PROPERTIES

Volume Resistivity | 4.7 X 1013 Ohms-Cm |

Dielectric Strength | 510 Volts/Mil 60 Cycles |

Dielectric Constant | 4.0 (10 kHz) |

Dissipation Factor | 0.014 (10 kHz) |

Thermal Conductivity (Unfilled) 40°-45°C | 0.25 W/mK |

CIRCUIT BOARD POTTING

WATERPROOFING OF AN ELECTRICAL CIRCUITRY

MAX MCR A/B USED AS THE BLACK PCB ENCAPSULANT

AND

MAX CLR RESIN or MAX 1618 A/B SYSTEM USED IN THE L.E.D CLEAR CASTING

MAX CLR A/B RESIN SYSTEM

Or our newest resin system that demonstrates improved color stability

MAX 1618 CRYSTAL CLEAR RESIN SYSTEM

MAX MCR A/B IS WELL SUITED FOR AUTOMOTIVE ENVIRONMENT

NEED MORE INFORMATION?

Please visit our YouTube Channel to view our video demonstrations

PLEASE VIEW THE VIDEO BELOW FOR THE PROPER MIXING OF EPOXY RESINS. IT DEMONSTRATES THE PROPER TECHNIQUE OF MIXING ANY TYPE OF EPOXY RESIN SYSTEM.

THE PROPER CURE AND FINAL PERFORMANCE OF ANY EPOXY RESIN SYSTEM ARE HIGHLY DEPENDENT ON THE QUALITY AND THOROUGHNESS OF THE MIX.

PROPER EPOXY MIXING TECHNIQUE - Avoid tacky or uncured spots and low air bubble mixing - YouTube

Video will open in a new window

HOW TO REMOVE AIR BUBBLES FROM AN APPLIED EPOXY COATING, ALSO HELPS WITH LEVELING AND FLOW - YouTube

Video will open in a new window

THE RESIN AND CURING AGENT MUST BE MIXED TO HOMOGENEOUS CONSISTENCY

TO ACHIEVE PROPER CURE AND TACK FREE RESULTS.

BATCH SIZE MIXING AND WORKING TIME CORRELATION

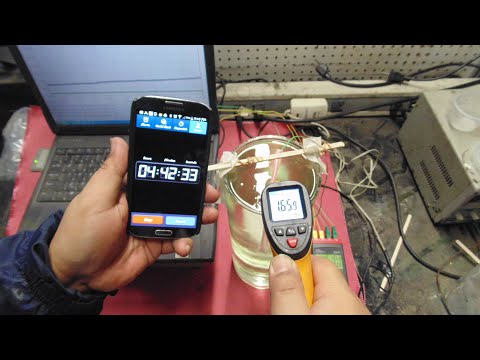

PLEASE VIEW THE FOLLOWING VIDEO DEMONSTRATION REGARDING BATCH SIZE MIXING AND WORKING TIME. THE RESIN SYSTEM USED WAS A BASELINE LABORATORY FORMULATION WHICH WAS SPECIFICALLY COMPOUNDED FOR THIS DEMONSTRATION REACTION.

WHEN MIXED IN LARGE MASS AND ALLOWED TO REACT IN A CONFINED MASS MOST CHEMICAL REACTION THAT PRODUCES EXOTHERMIC HEAT ENERGY THAT CAN CAUSE SIMILAR RESULTS.

THIS VIDEO DEMONSTRATES THE IMPORTANT ASPECTS OF SAFETY FACTORS THAT MUST BE CONSIDERED BEFORE USING ANY REACTIVE CHEMICALS.

AND

AND

DIMENSIONAL STABILITY OF

MAX MCR A/B

MAX MCR A/B IS AN UNFILLED RESIN SYSTEM THAT MAY REQUIRE ADDITION OF A THERMAL CONDUCTIVE FILLER TO IMPROVE ITS THERMAL CONDUCTIVITY AND DIMENSIONAL STABILITY PROPERTIES.

FOR HIGHER THERMAL CONDUCTIVITY PROPERTIES AND HEAT DISSIPATION, THE ADDITION OF A DENSE FILLER SUCH AS

DIMENSIONAL STABILITY OF

MAX MCR A/B

MAX MCR A/B IS AN UNFILLED RESIN SYSTEM THAT MAY REQUIRE ADDITION OF A THERMAL CONDUCTIVE FILLER TO IMPROVE ITS THERMAL CONDUCTIVITY AND DIMENSIONAL STABILITY PROPERTIES.

FOR HIGHER THERMAL CONDUCTIVITY PROPERTIES AND HEAT DISSIPATION, THE ADDITION OF A DENSE FILLER SUCH AS

CALCIUM CARBONATE IS TYPICALLY INCORPORATED INTO THE MIXTURE.

CALCIUM CARBONATE IS TYPICALLY INCORPORATED INTO THE MIXTURE.

PLEASE CLICK ON THE LINK FOR MORE INFORMATION AND MIXING TECHNIQUE.

CALCIUM CARBONATE ITEM PAGE

Click the link to visit item page

CALCIUM CARBONATE EPOXY FILLER

THE USE OF A WEIGHING SCALE IS HIGHLY RECOMMENDED TO ENSURE PROPER CURE

AVAILABLE AT eBay - Search for 'Digital Scale'

NOTE THE DIMENSIONAL STABILITY AND LOWERED DIMENSIONAL SHRINKAGE BY THE ADDITION OF THE CALCIUM CARBONATE. BOTH SYRINGES WERE FILLED WITH MAX MCR A/B.

THE BOTTOM SYRINGE WAS FILLED WITH 25% CALCIUM CARBONATE AND MIXED MAX MCR A/B RESIN SYSTEM AND VACUUM DEGASSED TO REMOVE ANY MIX BUBBLES OR MICRO AIR ENTRAPMENT PRIOR TO FILLING. THE TOP SYRINGE WAS LEFT UNMODIFIED MAX MCR A/B.

PLEASE CLICK ON THE LINK FOR MORE INFORMATION AND MIXING TECHNIQUE.

CALCIUM CARBONATE ITEM PAGE

Click the link to visit item page

CALCIUM CARBONATE EPOXY FILLER

THE USE OF A WEIGHING SCALE IS HIGHLY RECOMMENDED TO ENSURE PROPER CURE

AVAILABLE AT eBay - Search for 'Digital Scale'

NOTE THE DIMENSIONAL STABILITY AND LOWERED DIMENSIONAL SHRINKAGE BY THE ADDITION OF THE CALCIUM CARBONATE. BOTH SYRINGES WERE FILLED WITH MAX MCR A/B.

THE BOTTOM SYRINGE WAS FILLED WITH 25% CALCIUM CARBONATE AND MIXED MAX MCR A/B RESIN SYSTEM AND VACUUM DEGASSED TO REMOVE ANY MIX BUBBLES OR MICRO AIR ENTRAPMENT PRIOR TO FILLING. THE TOP SYRINGE WAS LEFT UNMODIFIED MAX MCR A/B.

THE BOTTOM SYRINGE DEMONSTRATED LESS SHRINKAGE AS ILLUSTRATED BY THE PHOTOGRAPH, NOTE HOW THE UNMODIFIED FORMULATION (TOP) DEMOLDED FROM THE SYRINGE.

THE BOTTOM SYRINGE DEMONSTRATED LESS SHRINKAGE AS ILLUSTRATED BY THE PHOTOGRAPH, NOTE HOW THE UNMODIFIED FORMULATION (TOP) DEMOLDED FROM THE SYRINGE.

THE BOTTOM SYRINGE INDICATES LOWER VOLUMETRIC SHRINKAGE DURING POLYMERIZATION.

THE MODIFICATION ALSO IMPROVED HARDNESS OF THE RESIN BY 5 POINTS SHORE D HARDNESS SCALE.

IMPROVE THERMAL CONDUCTIVITY AND HEAT DISSIPATION FACTOR

- HIGHER VOLUME RESISTIVITY FOR ELECTRICAL INSULATIVE PROPERTIES

- IMPROVE DIMENSIONAL STABILITY AND LESS SHRINKAGE

- INCREASE IMPACT RESISTANCE

- HIGHER SURFACE HARDNESS

- IMPROVED COMPRESSIVE STRENGTH

- IMPROVE ADHESION BY REDUCING INTERNAL STRESS VIA DIMENSIONAL SHRINKAGE

- HIGHER CHEMICAL RESISTANCE

- LOWER COST BY VOLUME

THE BOTTOM SYRINGE INDICATES LOWER VOLUMETRIC SHRINKAGE DURING POLYMERIZATION.

THE MODIFICATION ALSO IMPROVED HARDNESS OF THE RESIN BY 5 POINTS SHORE D HARDNESS SCALE.

IMPROVE THERMAL CONDUCTIVITY AND HEAT DISSIPATION FACTOR

- HIGHER VOLUME RESISTIVITY FOR ELECTRICAL INSULATIVE PROPERTIES

- IMPROVE DIMENSIONAL STABILITY AND LESS SHRINKAGE

- INCREASE IMPACT RESISTANCE

- HIGHER SURFACE HARDNESS

- IMPROVED COMPRESSIVE STRENGTH

- IMPROVE ADHESION BY REDUCING INTERNAL STRESS VIA DIMENSIONAL SHRINKAGE

- HIGHER CHEMICAL RESISTANCE

- LOWER COST BY VOLUME

DON'T FORGET OUR EPOXY MIXING KIT!

DON'T FORGET OUR EPOXY MIXING KIT!

Our Epoxy Mixing Kit comes with all the necessary utensils and protective gloves needed for mixing, dispensing or applying any of our

MAX EPOXY SYSTEM in one convenient kit.

- Avoid Cross Contamination

- Save Time

- Measure Mix Ratio Accurately By Volume

- Reusable

- Safely Handle Chemicals

Use the included measuring cups to accurately measure the proper amount of Resin and Curing Agent.

The plastic mixing tubs are made from High-Density Polyethylene which can withstand the tenacity of the epoxy resin and curing agent. The paper cups are wax-free and the plastic tub comes with air-tight lids that make it an excellent temporary storage container.

Upon cure, any residue demolds easily from the plastic tubs and can be reused.

As a general practice, protective gloves should be worn at all times when handling chemicals.

Our MAX EPOXY MIXING KIT comes with 5 pairs of Powder Free Latex Gloves to protect the user from direct contact with the epoxy resin system that will reduce sensitization or contact dermatitis

MIXING KIT CONTENTS

4 each 32-ounce (1 Quart) clear HDPE plastic tubs

4 each 16-ounce (1 pint) clear HDPE plastic tubs

4 each clear HDPE Plastic Lids for the plastic tubs

4 each 8-ounce (1/2-Pint) Wax Free Paper Cups

5 pairs one size fits all Powder Free Latex Gloves (Large)

6 Piece HDPE Plastic Measuring Spoon Kit

(1 tablespoon - 1/8 teaspoon)

10 Piece HDPE Plastic Measuring Cup

(1 Cup to 1/8 Teaspoon)

2 each None Sterile Graduated 10 cc Syringes

1 pack of Wooden Stir Sticks

1 pack Assorted Size Bristle Brush (5 per pack)

For Technical Support

Please Call

TOLL FREE

877 403 8008

Mon-Fri

10:00 AM to 4:00 PM

Pacific Standard Time

NEED MORE INFORMATION?

Please visit our YouTube Channel to view our video demonstrations

IMPORTANT NOTICE

Your purchase constitutes the acceptance of this disclaimer . Please review before purchasing this product.

The user should thoroughly test any proposed use of this product and independently conclude satisfactory performance in the application. Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval. The information contained herein is based on data believed to be accurate at the time of publication. Data and parameters cited have been obtain through publish information, PolymerProducts and Polymer Composites Inc. laboratory analysis using materials under controlled conditions. Data of this type should not be used for specification for fabrication and design. It is the user's responsibility to determine this Composites fitness for use. There is no warranty of merchantability of fitness of use, nor any other express implied warranty. The user's exclusive remedy and the manufacturer's liability are limited to refund of the purchase price or replacement of the product within the agreed warranty period. PolymerProducts and its direct representative will not be liable for incidental or consequential damages of any kind. Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether er there is any infringement of patents is the sole liability of the use.