|

20 ebooks on CD

THE Complete Course In WOOD TURNING

- An Ideal Resource For Learning the Art of WOOD TURNING - Ideal as a Teaching Resource for a Skilled Instructor!

COURSE 1 BEGINNER

A COURSE IN WOOD TURNING (52 pages)

"'with illustrations in seperate folder for easy printing'"

"Wood turning has had a definite place in the commercial world for a great many years. It is used in various forms in making furniture and furniture parts, building trim, tool parts, toys, and many other useful and beautiful articles."

When properly taught in the schools it is one of the most valuable types of instruction.

This text shows the proper use and care of tools including the care of the lathe, the grinding of chisels, the polishing of projects, and the specific directions and cautions for working out the various exercises and projects with the drawings. (1919)

CONTENTS:

CHAPTER I

Introductory

-- Commercial and Educational Values of Wood Turning

-- Elements of Success

CHAPTER II

The Lathe

-- Care of the Lathe

-- Speed of the Lathe

-- Method of Figuring the Diameter of Pulleys

-- Rules for Finding the Speeds and Sizes of Pulleys

-- Points on Setting Up the Lathe and Shafting

CHAPTER III

Wood Turning Tools

-- Grinding and Whetting Turning Tools

-- The Gouge

-- The Parting Tool

-- Scraping Tools

CHAPTER IV

Spindle Turning

-- Centering Stock

-- Clamping Stock in the Lathe

-- Adjusting the Tool Rest

-- Position of the Operator at the Lathe

-- Holding the Tools

-- Use of the Tools in Spindle Turning

CHAPTER V

Tool Processes in Spindle Turning

-- The Roughing Cut

-- The Sizing Cut

-- The Smoothing Cut

-- Testing for Smoothness

-- Measuring for Length

-- Squaring Ends

-- Cutting Off

-- Shoulder Cuts

-- Taper Cuts

-- V Cuts-Concave Cuts

-- Convex Cuts

-- Combination Cuts

-- Chisel Handles

-- Mallets and Handles

-- Vise Handles

CHAPTER VI

Oval Turning

-- Tool Operations

CHAPTER VII

Duplicate Turning

-- Use of Measuring Stick

-- Use of Templets

CHAPTER VIII

Finishing and Polishing

-- Ordinary Cabinet Finishing

-- French Polishing

-- Method of Applying French Polish

CHAPTER IX

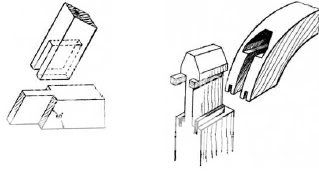

Face-Plate and Chuck Turning

-- Methods of Fastening Stock

-- Small Single Screw Face-Plate

-- Large Surface Screw Face-Plate

-- Gluing to Waste Stock>

-- Lathe Adjustments

-- Position of Tool Rest

CHAPTER X

Tool Processes in Face-Plate and Chuck Turning

-- Straight Cuts

-- Roughing Off Corners

-- Calipering for Diameter

-- Smoothing Cut

-- Roughing Cut on the Face

-- Smoothing the Face

-- Laying Off Measurements

-- External Shoulders

-- Internal Shoulders

-- Taper Cuts

-- V Cuts

-- Concave Cuts

-- Convex Cuts

-- Combination Cuts

-- Use of Scraping Tools

-- Internal Boring

-- Turning a Sphere

CHAPTER XI

Spiral Turning

-- Single Spiral, Straight Shaft

-- Tapered Shaft

-- Double Spiral, Tapered Shaft

-- Double Spiral, Straight Shaft

-- Double Groove Spiral, Straight Shaft

"Course in Wood Turning" is truly timeless and is not only a valuable reference, but also ideal as a class text to be studied in connection with the making of the projects. The drawings show exact dimensions."

COURSE 2

Course 2 "The Examination"

PREPARED FOR THE USE OF STUDENTS IN MANUAL TRAINING

HIGH SCHOOLS, TECHNICAL SCHOOLS,

AND COLLEGES (1909) 90 pages

The object of these pages is to place before pupils such information as will be

of practical help to them in their work in wood .turning.

It has been the writer's experience that pupils lose confidence and become

nervous because of the mishaps that are sure to occur, especially in attempting

certain forms often presented early in courses of this character ; and for this reason

these exercises have been arranged in such a way that the turning of beads and

similar work is left until such time as the confidence of the pupil is fully established ;

in fact, until he has had considerable experience on the lathe in handling the principal

tools in connection with the simpler forms.

COURSE 3

Course 3 "The Laboratory Course" 80 pages

THE practice of wood-turning is an art relative to which

there is little published, and there is, in consequence, little

chance for arriving at conclusions as to the best method

for performing any given operation; so there is a wide

diversity in the methods by which different operators arrive

at the same results. Some use one tool almost exclusively,

while others use a large variety of tools.

The following exercises are designed to give the operator

command of the more commonly used tools, using each

for the operations for which it is especially fitted.

The first four exercises are of special importance, and

the operator is urged to continue the practice of them until

he can perform them easily and safely ; the operations involved

in the third exercise, when mastered, will be found

to give special confidence.

As the exercises have been arranged to give in the

most direct manner, and without repetition, the typical

operations of the wood-turner, some learners may desire to

add further practice in some or all of them, and, for the

benefit of such, further exercises, involving similar operations,

have been added in the form of an appendix. These

have drawings, and, where necessary, additional instructions.

The operator is urged, however, to perform the

regular exercise before attempting the added one.

COURSE 4

Course 4 "Art and Education in Wood Turning"

By WILLIAM W. KLENKE

INSTRUCTOR IN WOODWORKING AND ARCHITECTURAL DRAWING,

CENTRAL COMMERCIAL AND MANUAL TRAINING

HIGH SCHOOL, NEWARK, NEW JERSEY (1921) 120 pages

THIS book is intended primarily for the use of students in

normal schools, high schools, colleges or similar institutions

and for lovers of all things useful and beautiful in wood-turning.

It aims by means of text and illustrations to give such facts about

the art of wood-turning as are needed by students and teachers in

the schools. In giving these facts, whenever there is a question

between two methods of procedure, the one being the method of the

factor}' expert in wood-turning, and the other the method of the

art craftsman in the school. As a

result it is sometimes true that a less direct method is recommended

than is employed by the commercial turner, but this is justified on

the ground of the purpose of the book, which is fundamentally

educational.

Besides being a book of instruction on the process of woodturning,

it is a book of problems, in the designing of which the

author has constantly aimed to recognize beauty of form. As indicated

by the title of the book, the author's chief purpose has been

to make a contribution to the teaching of art and to education,

through the fine old craft of wood-turning.

5. Problems in Wood-turning 64 pages (1909)

Author: Fred Duane Crawshaw

WOOD-TURNING doubtless is an art. However, if the statements which follow in this text

are facts, the subject comprises some of the elements of a science. The art of wood-turning

is the ability of the operator to skilfully handle the tools in making the several wood-turning

cuts. The science in wood-turning is found in the mathematical principles discovered when these cuts

are analyzed.

______________________________

6. Patternmaking 360 pages (1920)

A treatise on the construction and application of patterns,

including the use of woodworking tools, the art of joinery,

wood turning, and various methods of building patterns and

core-boxes of different types (1920)

Author: Shelly, Joseph Atkinson, 1877-

Subject: Pattern-making

________________________________

7. Lathe work for beginners 288 pages (1922)

A practical treatise on lathe work with complete instructions for

properly using the various tools, including complete directions

for wood and metal turning, screw cutting, measuring tools,

wood turning, metal spinning, etc., and instructions for building

home-made lathes with their attachments, etc. (1922)

Author: Yates, Raymond F. (Raymond Francis), 1895-

Subject: Lathes; Turning (Lathe work)

----------------------------------------------------

8. Amendment to code of fair competition for wood turning, shaping industries as approved on October 19 (1934) 9. Artistic Wood Turning Works catalogue 1917- 1918 (1917) 10. Code of fair competition for the wood turning, shaping industries as approved on April 4, (1934) 11. Finishing for woodturners 12. Inside Out Turning Instructions 13. Supplementary code of fair competition as approved on August 20, 1934 (1934) 14. The Lathe & Its Uses Or, Instruction in the Art of Turning Wood and Metal (1868) 15. The young mechanic, including the art of turning in wood and metal (1902) 16. Training in wood-work, designed for use in manual training and technical school (1902) 17. Wood Working Wood Turning, Patternmaking, Green-sand Molding, Core Making (1903) 18. Wood-turning (1921) -------------------------------------------------------------------------------------------------

Buy The Complete Course In WOOD TURNING

This is probably the most detailed course in Wood Turning to give you the utmost knowledge of every aspect of Wood Turning you can imagine.

Also Included at No Extra Cost are the Following

FREE Bonus!

"WOODWORK JOINTS"

HOW THEY ARE SET OUT, HOW MADE AND WHERE USED; WITH FOUR HUNDRED ILLUSTRATIONS.

CONTENTS:

The Glued Joint

The Halved Joint

The Bridle Joint

The Tongued and Grooved Joint

The Mortise and Tenon Joint

The Dowelling Joint

The Scarf Joint

The Hinged Joint

Shutting Joints

The Dovetail Joint

Dovetail Grooving

The Mitred Joint

Joints for Curved Work

Miscellaneous Joints

Puzzle Joints

Plus as a Special Bonus you will Recieve

THE COMPLETE GUIDE TO WOOD FINISHING

A 141 PAGE EBOOK COVERING ALL ASPECTS TO FINISHING YOUR PRIZED WOOD WORK

Table of Contents

I. WOOD FINISHING IN GENERAL. ........... 4

II. PREPARATION OF NEW AND OLD SURFACES. . 8

III. STAINS IN GENERAL .................... 15

IV. FACTORY PREPARED STAINS. ............. 16

V. WATER STAINS ........................ 18

VI. STAIN BRUSHING AND PROCEDURE ....23

VII. PREPARING WOOD TO TAKE STAIN EVENLY.....25

VIII. THE MIXING AND USE OF WOOD FILLERS. . 31

IX. VARNISH AND SHELLAC ................. 39

X. VARNISHING, RUBBING, POLISHING ........46

XI. VARNISH DEFECTS AND THEIR CAUSES ..... 64

XII. LACQUERS ....... 79

XIII. WAX FINISHES AND OIL-RUBBED FINISHES...84

XIV. SCHEDULES OF WORKING OPERATIONS. .... 88

XV. WOOD & DESCRIPTIONS OF CHARACTERISTICS .......100

XVI. BRUSH GRAINING ......................131

XVII. DECORATIVE WOOD FINISHES BY GLAZING AND

HIGHLIGHTING ...................133

XXVIII. REPAIRING DAMAGED FINISHES ..........137

____________________________________________________________

Take Note!

THIS ITEM WILL BE PROVIDED FOR YOU ON CD ROM AND POSTED ONCE YOU HAVE MADE A PAYMENT

All items in this listing are ebooks. No physical book will be shipped.

All International Buyers MUST use PayPal

Please include your eBay name as reference to any payments made - Thank you

|

_______________________________________________________________________

Notice to eBay

This auction abides by eBay’s listing rules and polices.

No trademarks and or copyrights have been violated.

We are either the publisher or an authorized distributor. | |