| |||||||||||||||||||||||||||||||||||||||

Package included: |

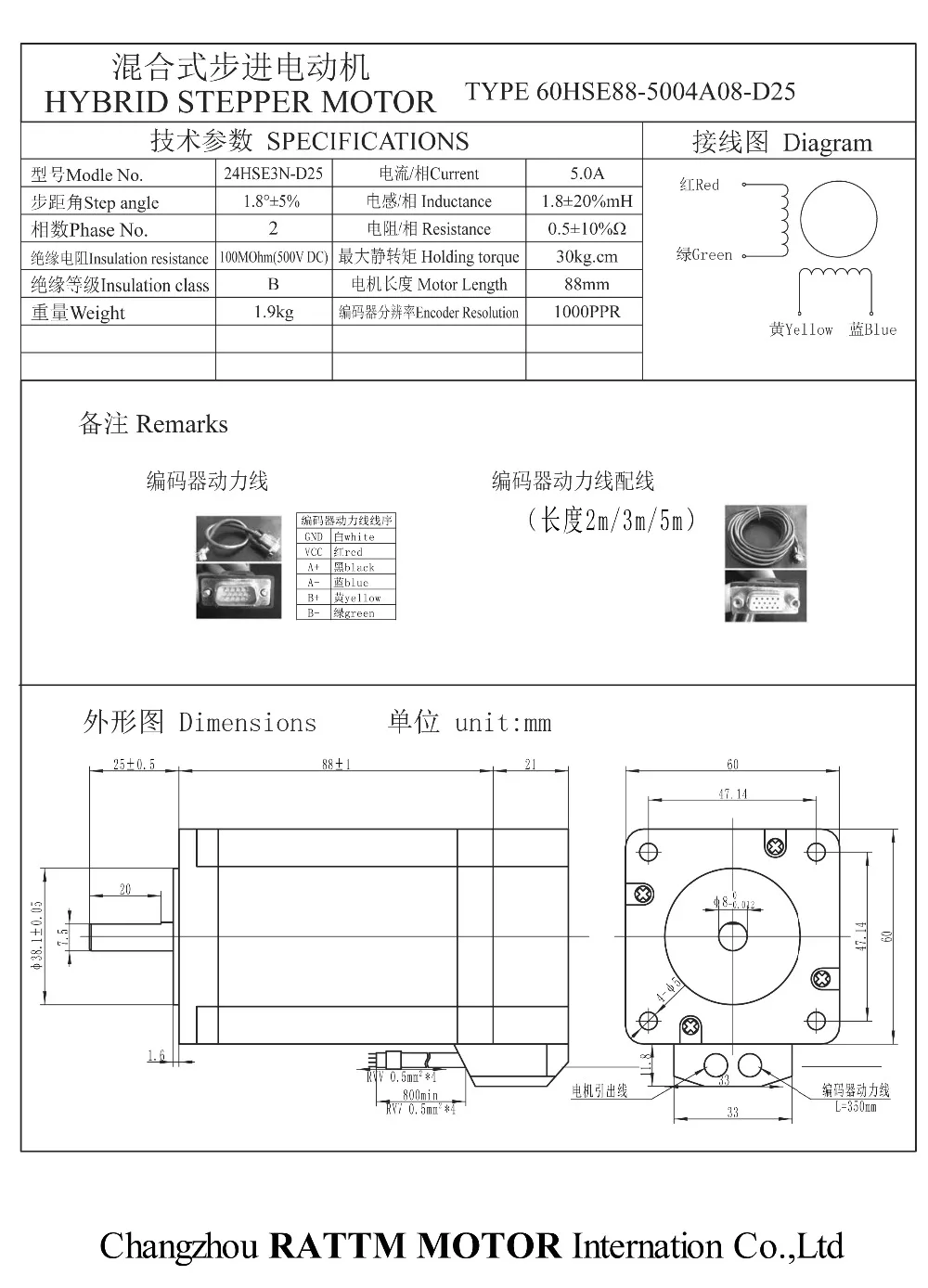

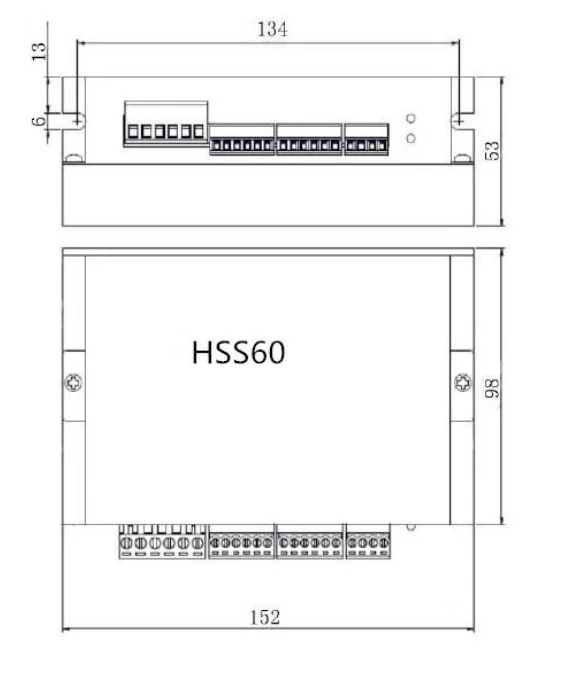

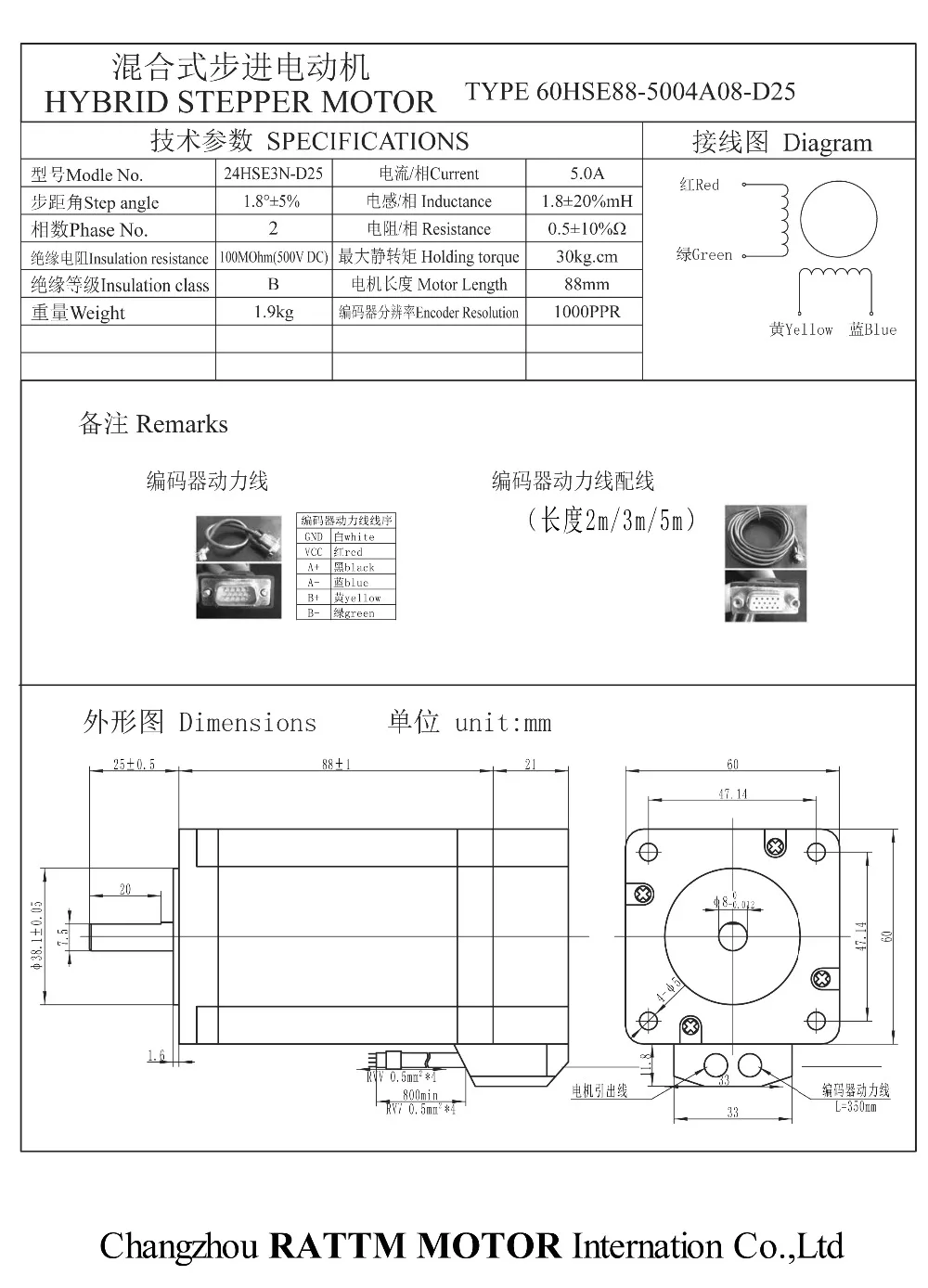

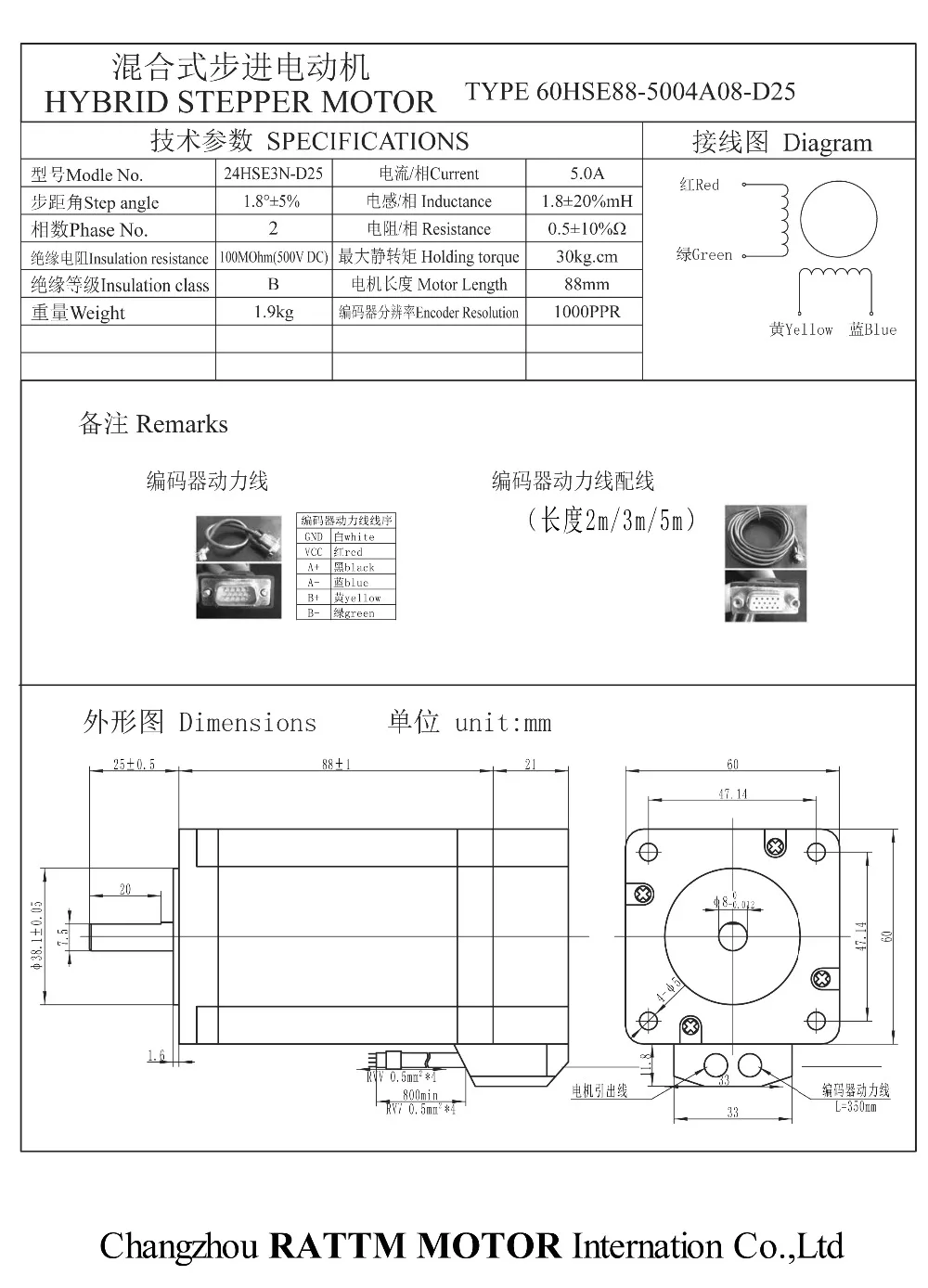

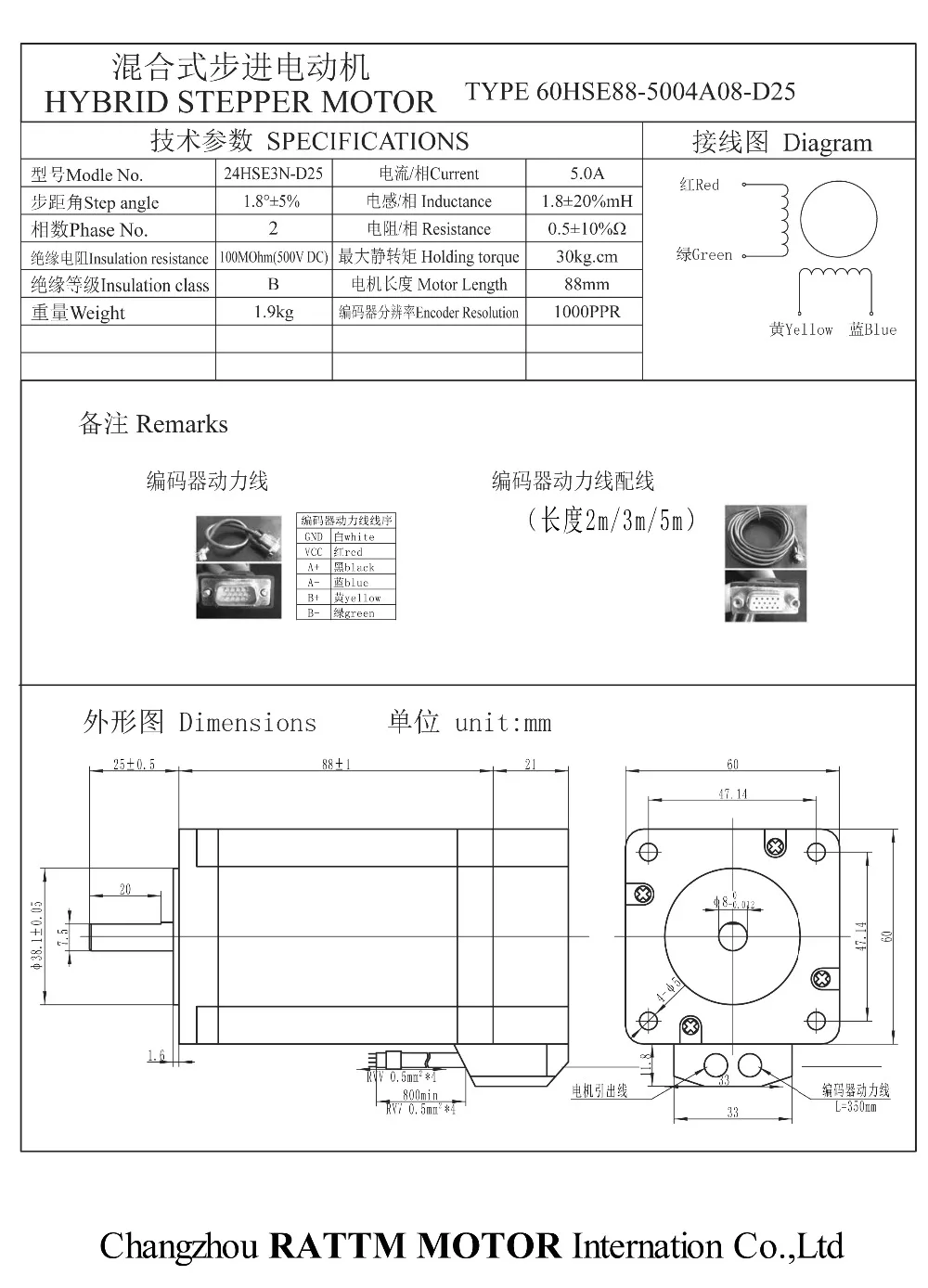

1. 3N.m Closed loop servo motor

1. 3N.m Closed loop servo motor

Wiring:

Red: A+

Green: A-

Yellow: B+

Blue: B-

2. HSS60 2-Phase Hybrid Stepper Servo Driver

2.1) Overview

HSS60

is 2 phase nema 24 series hybrid stepper servo driver. It adopts new

generation 32 bit DSP and vector control technology, which can avoid the

stepper motor losing steps and ensure the accuracy of the motor. The

torque reducing is much lower than open loop stepper motor when it is at

higher speed. The high speed performance and torque are enhanced in a

great extent. Meanwhile the current control is based on the load, that

can reduce the motor temperature rising effectively, then can extend the

using life of the motor. The build-in place in position and alarm

output signal can help the upper monitor to monitor and control. The

function of position ultra difference alarm can ensure the machine work

safely. The closed loop system is an ideal improvement and a good

replacement of open loop system, Besides that, it also have some

function of AC servo motors, but price is just half of AC servo.

2.2) Features

2.2.1 Stepper motor closed loop system, never lose step.

2.2.2 Improve motor output torque and working speed.

2.2.3 Automatic current adjustment based on load, lower temperature rising.

2.2.4

Suitable for all mechanical load conditions (include low rigidity belt

pulley and wheel), no need to adjust gain parameter.

2.2.5 Motor work smoothly and low vibration, high dynamic performance at acceleration and deceleration.

2.2.6 No vibration from high speed to zero speed.

2.2.7 Drive nema 24 series 3N.m closed loop stepper motor.

2.2.8 Pulses response frequency can reach 200KHZ.

2.2.9 16 kinds microsteps choice, highest 51200 microsteps/rev.

2.2.10 Voltage range: DC24V~50V.

2.2.11 Over-current, over-voltage and position ultra difference protection function.

2.3 Applications

Closed loop stepper system can be applied to all kinds small automatic equipment and

Instruments,

such as engraving machine, special industrial sewing machine, stripping

machine, marking machine, Dispensing machine, cutting machine, laser

phototypesetting, graph plotter, NC machine, automatic, assembly

equipment and so on.

3. Electrical, mechanical, environment Parameter

3.1 ) Electrical Parameter

Voltage range

DC24~50V

Peak current

Peak 6.0A (current change according to load)

Logic input current

7~20mA

Frequency

0~200KHz

Suitable motor

60HSE3N

Encoder lines

1000

Insulation resistance

>=500MΩ

3.2 Environment Parameter

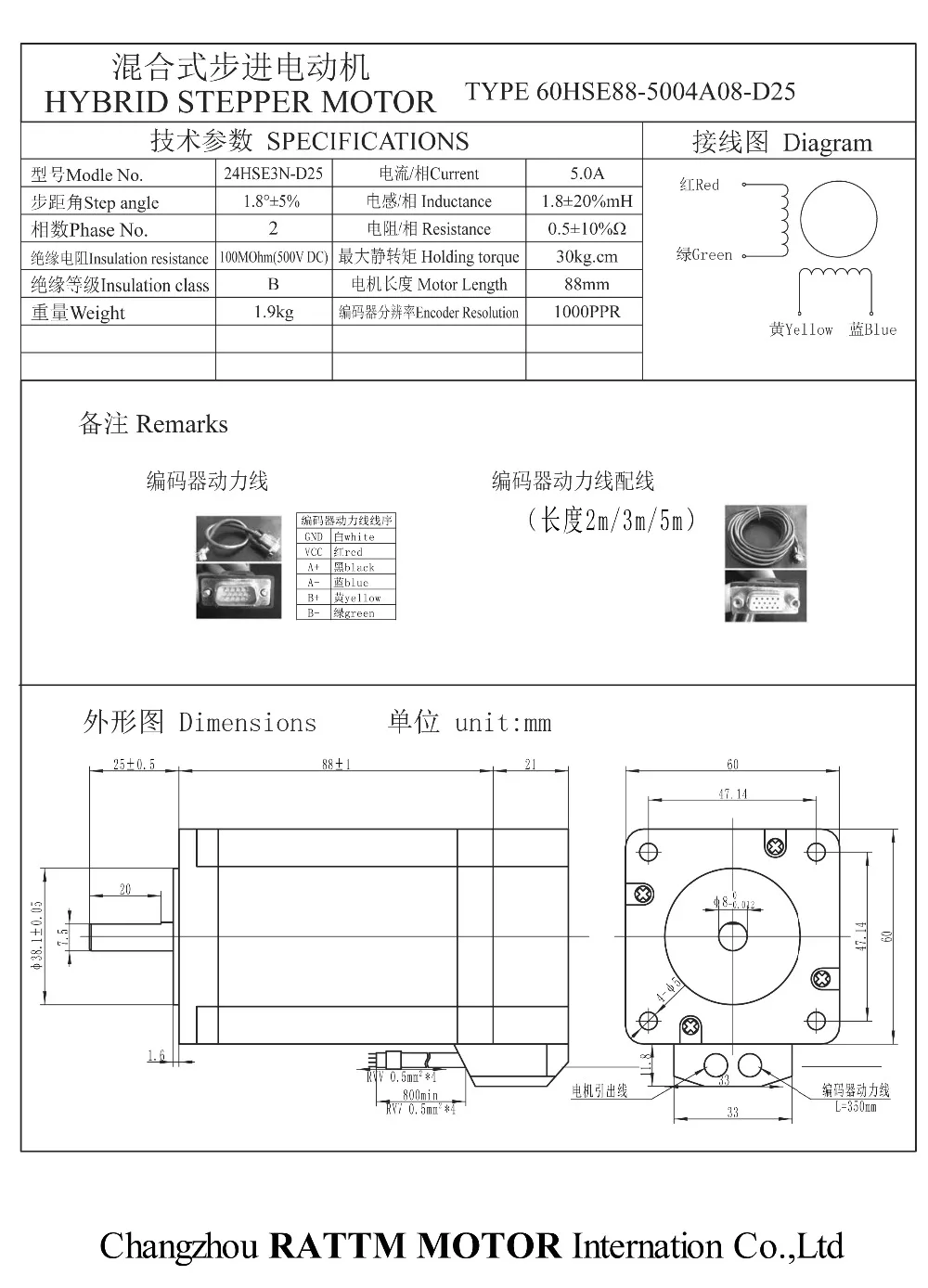

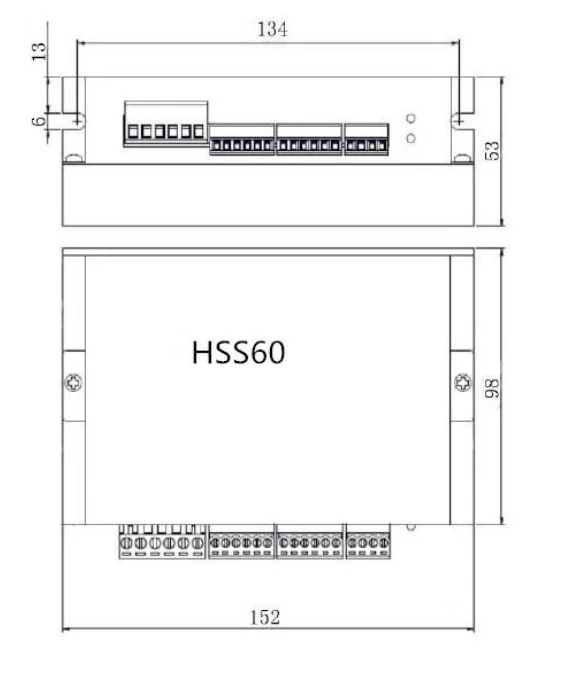

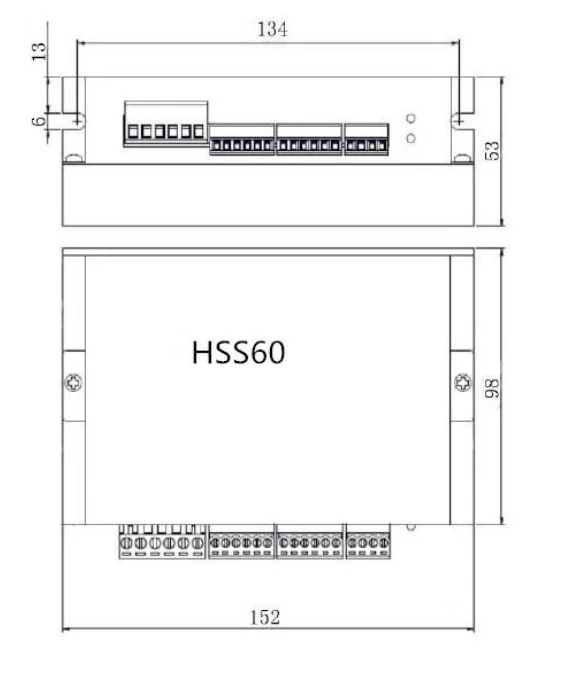

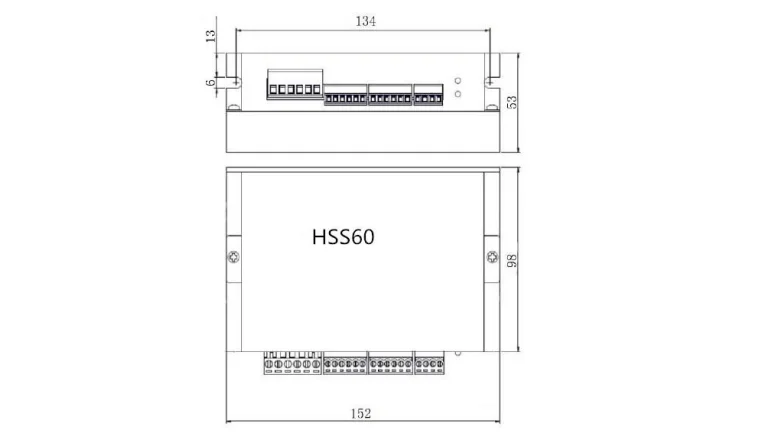

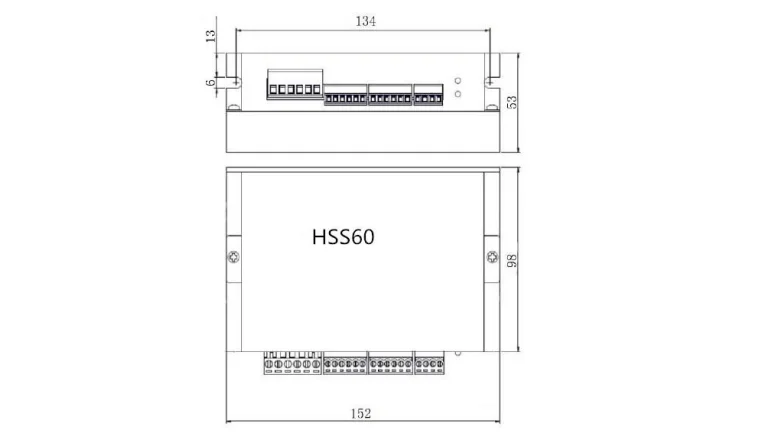

3.3) Installation Dimension

2HSS60 Servo Driver

Wiring diagram

1. 3N.m Closed loop servo motor

Wiring:

Red: A+

Green: A-

Yellow: B+

Blue: B-

Wiring:

Red: A+

Green: A-

Yellow: B+

Blue: B-

2. HSS60 2-Phase Hybrid Stepper Servo Driver

2. HSS60 2-Phase Hybrid Stepper Servo Driver

2.1) Overview

HSS60

is 2 phase nema 24 series hybrid stepper servo driver. It adopts new

generation 32 bit DSP and vector control technology, which can avoid the

stepper motor losing steps and ensure the accuracy of the motor. The

torque reducing is much lower than open loop stepper motor when it is at

higher speed. The high speed performance and torque are enhanced in a

great extent. Meanwhile the current control is based on the load, that

can reduce the motor temperature rising effectively, then can extend the

using life of the motor. The build-in place in position and alarm

output signal can help the upper monitor to monitor and control. The

function of position ultra difference alarm can ensure the machine work

safely. The closed loop system is an ideal improvement and a good

replacement of open loop system, Besides that, it also have some

function of AC servo motors, but price is just half of AC servo.

2.2) Features

2.2.1 Stepper motor closed loop system, never lose step.

2.2.2 Improve motor output torque and working speed.

2.2.3 Automatic current adjustment based on load, lower temperature rising.

2.2.4

Suitable for all mechanical load conditions (include low rigidity belt

pulley and wheel), no need to adjust gain parameter.

2.2.5 Motor work smoothly and low vibration, high dynamic performance at acceleration and deceleration.

2.2.6 No vibration from high speed to zero speed.

2.2.7 Drive nema 24 series 3N.m closed loop stepper motor.

2.2.8 Pulses response frequency can reach 200KHZ.

2.2.9 16 kinds microsteps choice, highest 51200 microsteps/rev.

2.2.10 Voltage range: DC24V~50V.

2.2.11 Over-current, over-voltage and position ultra difference protection function.

2.3 Applications

Closed loop stepper system can be applied to all kinds small automatic equipment and

Instruments,

such as engraving machine, special industrial sewing machine, stripping

machine, marking machine, Dispensing machine, cutting machine, laser

phototypesetting, graph plotter, NC machine, automatic, assembly

equipment and so on.

3. Electrical, mechanical, environment Parameter

3.1 ) Electrical Parameter

Voltage range

DC24~50V

Peak current

Peak 6.0A (current change according to load)

Logic input current

7~20mA

Frequency

0~200KHz

Suitable motor

60HSE3N

Encoder lines

1000

Insulation resistance

>=500MΩ

3.2 Environment Parameter

3.3) Installation Dimension

2.1) Overview

HSS60 is 2 phase nema 24 series hybrid stepper servo driver. It adopts new generation 32 bit DSP and vector control technology, which can avoid the stepper motor losing steps and ensure the accuracy of the motor. The torque reducing is much lower than open loop stepper motor when it is at higher speed. The high speed performance and torque are enhanced in a great extent. Meanwhile the current control is based on the load, that can reduce the motor temperature rising effectively, then can extend the using life of the motor. The build-in place in position and alarm output signal can help the upper monitor to monitor and control. The function of position ultra difference alarm can ensure the machine work safely. The closed loop system is an ideal improvement and a good replacement of open loop system, Besides that, it also have some function of AC servo motors, but price is just half of AC servo.

2.2) Features

2.2.1 Stepper motor closed loop system, never lose step.

2.2.2 Improve motor output torque and working speed.

2.2.3 Automatic current adjustment based on load, lower temperature rising.

2.2.4 Suitable for all mechanical load conditions (include low rigidity belt pulley and wheel), no need to adjust gain parameter.

2.2.5 Motor work smoothly and low vibration, high dynamic performance at acceleration and deceleration.

2.2.6 No vibration from high speed to zero speed.

2.2.7 Drive nema 24 series 3N.m closed loop stepper motor.

2.2.8 Pulses response frequency can reach 200KHZ.

2.2.9 16 kinds microsteps choice, highest 51200 microsteps/rev.

2.2.10 Voltage range: DC24V~50V.

2.2.11 Over-current, over-voltage and position ultra difference protection function.

2.3 Applications

Closed loop stepper system can be applied to all kinds small automatic equipment and

Instruments, such as engraving machine, special industrial sewing machine, stripping machine, marking machine, Dispensing machine, cutting machine, laser phototypesetting, graph plotter, NC machine, automatic, assembly equipment and so on.

3. Electrical, mechanical, environment Parameter

3.1 ) Electrical Parameter

Voltage range | DC24~50V |

Peak current | Peak 6.0A (current change according to load) |

Logic input current | 7~20mA |

Frequency | 0~200KHz |

Suitable motor | 60HSE3N |

Encoder lines | 1000 |

Insulation resistance | >=500MΩ |

3.2 Environment Parameter

3.3) Installation Dimension

2HSS60 Servo Driver

Wiring diagram

2.1) Overview

HSS60

is 2 phase nema 24 series hybrid stepper servo driver. It adopts new

generation 32 bit DSP and vector control technology, which can avoid the

stepper motor losing steps and ensure the accuracy of the motor. The

torque reducing is much lower than open loop stepper motor when it is at

higher speed. The high speed performance and torque are enhanced in a

great extent. Meanwhile the current control is based on the load, that

can reduce the motor temperature rising effectively, then can extend the

using life of the motor. The build-in place in position and alarm

output signal can help the upper monitor to monitor and control. The

function of position ultra difference alarm can ensure the machine work

safely. The closed loop system is an ideal improvement and a good

replacement of open loop system, Besides that, it also have some

function of AC servo motors, but price is just half of AC servo.

2.2) Features

2.2.1 Stepper motor closed loop system, never lose step.

2.2.2 Improve motor output torque and working speed.

2.2.3 Automatic current adjustment based on load, lower temperature rising.

2.2.4

Suitable for all mechanical load conditions (include low rigidity belt

pulley and wheel), no need to adjust gain parameter.

2.2.5 Motor work smoothly and low vibration, high dynamic performance at acceleration and deceleration.

2.2.6 No vibration from high speed to zero speed.

2.2.7 Drive nema 24 series 3N.m closed loop stepper motor.

2.2.8 Pulses response frequency can reach 200KHZ.

2.2.9 16 kinds microsteps choice, highest 51200 microsteps/rev.

2.2.10 Voltage range: DC24V~50V.

2.2.11 Over-current, over-voltage and position ultra difference protection function.

2.3 Applications

Closed loop stepper system can be applied to all kinds small automatic equipment and

Instruments,

such as engraving machine, special industrial sewing machine, stripping

machine, marking machine, Dispensing machine, cutting machine, laser

phototypesetting, graph plotter, NC machine, automatic, assembly

equipment and so on.

3. Electrical, mechanical, environment Parameter

3.1 ) Electrical Parameter

Voltage range

DC24~50V

Peak current

Peak 6.0A (current change according to load)

Logic input current

7~20mA

Frequency

0~200KHz

Suitable motor

60HSE3N

Encoder lines

1000

Insulation resistance

>=500MΩ

3.2 Environment Parameter

3.3) Installation Dimension

2.1) Overview

HSS60 is 2 phase nema 24 series hybrid stepper servo driver. It adopts new generation 32 bit DSP and vector control technology, which can avoid the stepper motor losing steps and ensure the accuracy of the motor. The torque reducing is much lower than open loop stepper motor when it is at higher speed. The high speed performance and torque are enhanced in a great extent. Meanwhile the current control is based on the load, that can reduce the motor temperature rising effectively, then can extend the using life of the motor. The build-in place in position and alarm output signal can help the upper monitor to monitor and control. The function of position ultra difference alarm can ensure the machine work safely. The closed loop system is an ideal improvement and a good replacement of open loop system, Besides that, it also have some function of AC servo motors, but price is just half of AC servo.

2.2) Features

2.2.1 Stepper motor closed loop system, never lose step.

2.2.2 Improve motor output torque and working speed.

2.2.3 Automatic current adjustment based on load, lower temperature rising.

2.2.4 Suitable for all mechanical load conditions (include low rigidity belt pulley and wheel), no need to adjust gain parameter.

2.2.5 Motor work smoothly and low vibration, high dynamic performance at acceleration and deceleration.

2.2.6 No vibration from high speed to zero speed.

2.2.7 Drive nema 24 series 3N.m closed loop stepper motor.

2.2.8 Pulses response frequency can reach 200KHZ.

2.2.9 16 kinds microsteps choice, highest 51200 microsteps/rev.

2.2.10 Voltage range: DC24V~50V.

2.2.11 Over-current, over-voltage and position ultra difference protection function.

2.3 Applications

Closed loop stepper system can be applied to all kinds small automatic equipment and

Instruments, such as engraving machine, special industrial sewing machine, stripping machine, marking machine, Dispensing machine, cutting machine, laser phototypesetting, graph plotter, NC machine, automatic, assembly equipment and so on.

3. Electrical, mechanical, environment Parameter

3.1 ) Electrical Parameter

Voltage range | DC24~50V |

Peak current | Peak 6.0A (current change according to load) |

Logic input current | 7~20mA |

Frequency | 0~200KHz |

Suitable motor | 60HSE3N |

Encoder lines | 1000 |

Insulation resistance | >=500MΩ |

3.2 Environment Parameter

3.3) Installation Dimension

Shipping

· Please open the package and check if there are some damages before sign, if there are some damages,please do not sign and contact us immediately

· We ship to worldwide but if your country’s custom is strict, please contact us before you bid to check detail and confirmed.

· Please check out your address carefully when processing order.We are not responsible for wrong or undeliverable address.

Problem&Feedback

· Please give us the opportunityto resolve any problem when you have,we concern your problem and we will try our best to resolve it.

· If you are not satisfied, please contact us to resolve any issues. Please do NOT leave negative feedback without asking for help. We work hard to make sure EVERY CUSTOMER 100% satisfaction.

· For any inquiries,issues or assistanceplease contact us via eBay message

Refund

· When you have the parcel,and not satisfied the goods or it is other problem like as broken,pls tell us the detail reason and provide the photos to us.

· Any reason required for all refund. Item must be in it's original condition and no physical damage. Buyer responsible for all shipping cost

Contact us

· Please feel free for any questions, all the emails will be replied within 1-2 business days,if you didn’t receive any mail, maybe it’s in the junk mail fold.

· We are online from Monday to Saturday.