Good News:

New items have arrived our USA Warehouse,welcome you to purchase.

Two options are available for you to choose from:

Package Include:

- 1 × 4 Axis DDCSV4.1 CNC offline stand alone motion controller

- 1 × 4GB USB flash drive

- 1 × USB extension cable and other small accessories

- 1 × parallel port link cable

- 1 × Breakout Board

- Pdf. English User manual

4 Axis DDCSV4.1+MPG:- 1 × 4 Axis DDCSV4.1 CNC offline stand alone motion controller

- 1 x 4 Axis Handwheel MPG with E-Stop

- 1 × 4GB USB flash drive

- 1 × USB extension cable and other small accessories

- 1 × parallel port link cable

- 1 × Breakout Board

- Pdf. English User manual

4 Axis Offline controller DDCS V4.1+Handwheel MPG

- 1 × 4 Axis DDCSV4.1 CNC offline stand alone motion controller

- 1 x 4 Axis Handwheel MPG with E-Stop

- 1 × 4GB USB flash drive

- 1 × USB extension cable and other small accessories

- 1 × parallel port link cable

- 1 × Breakout Board

- Pdf. English User manual

4 Axis Offline controller DDCS V4.1+Handwheel MPG

4 Axis Offline controller DDCS V4.1+Handwheel MPG

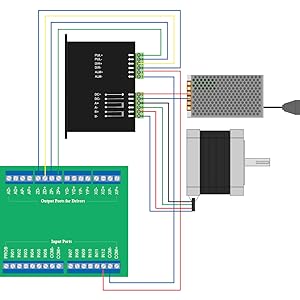

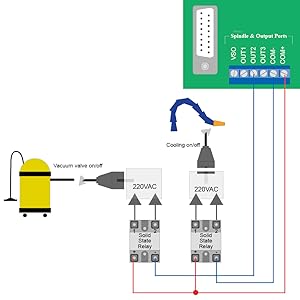

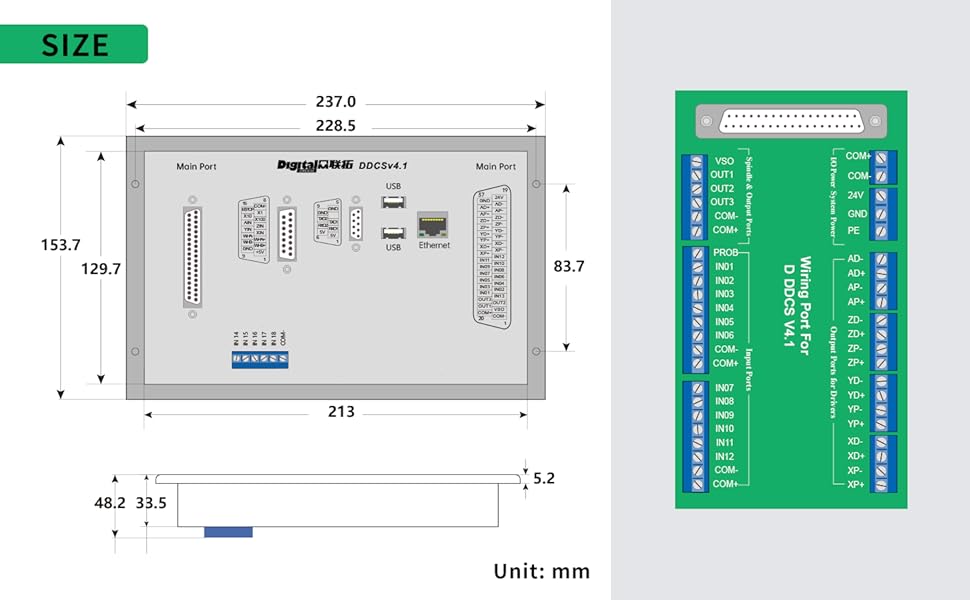

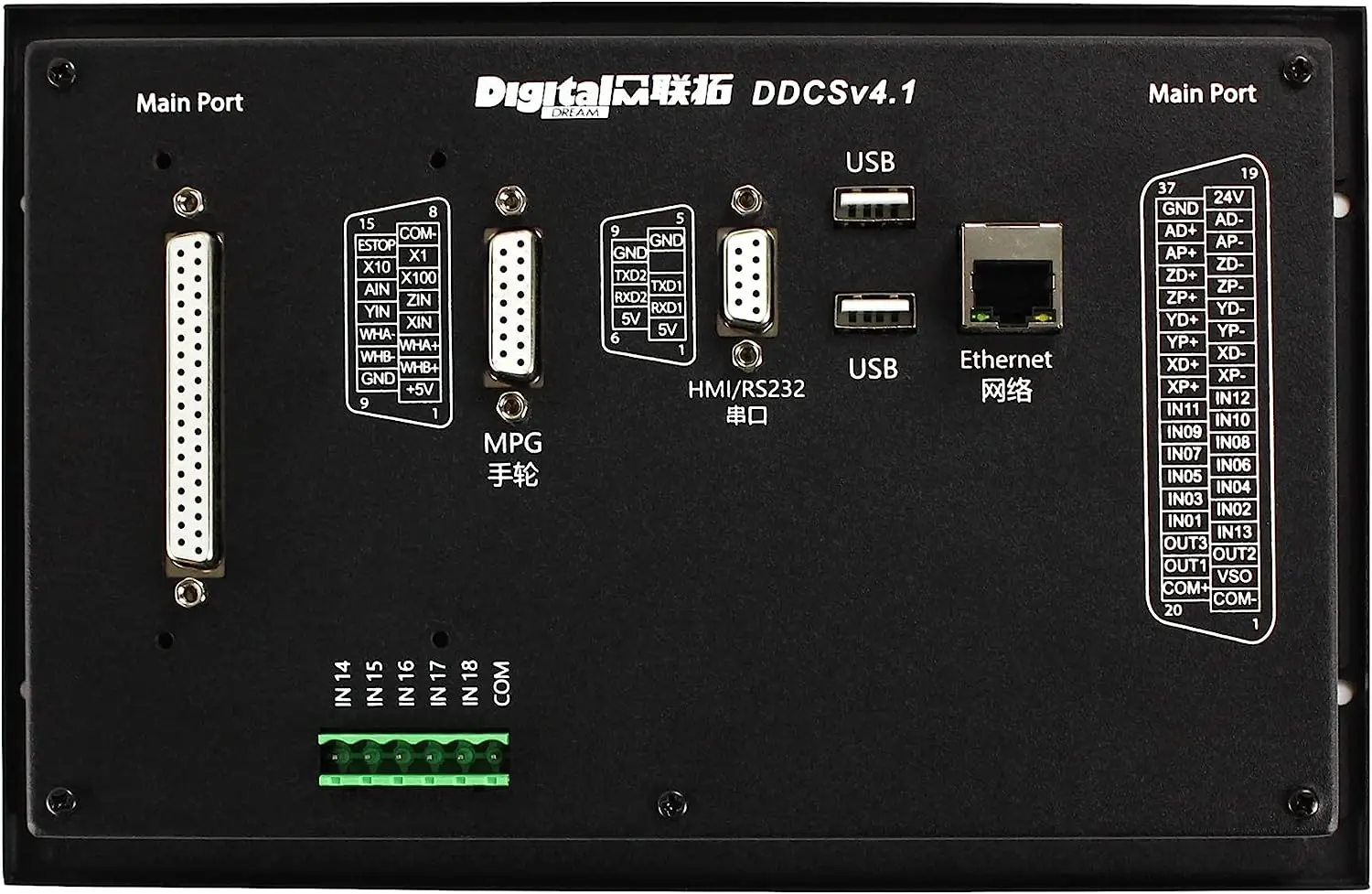

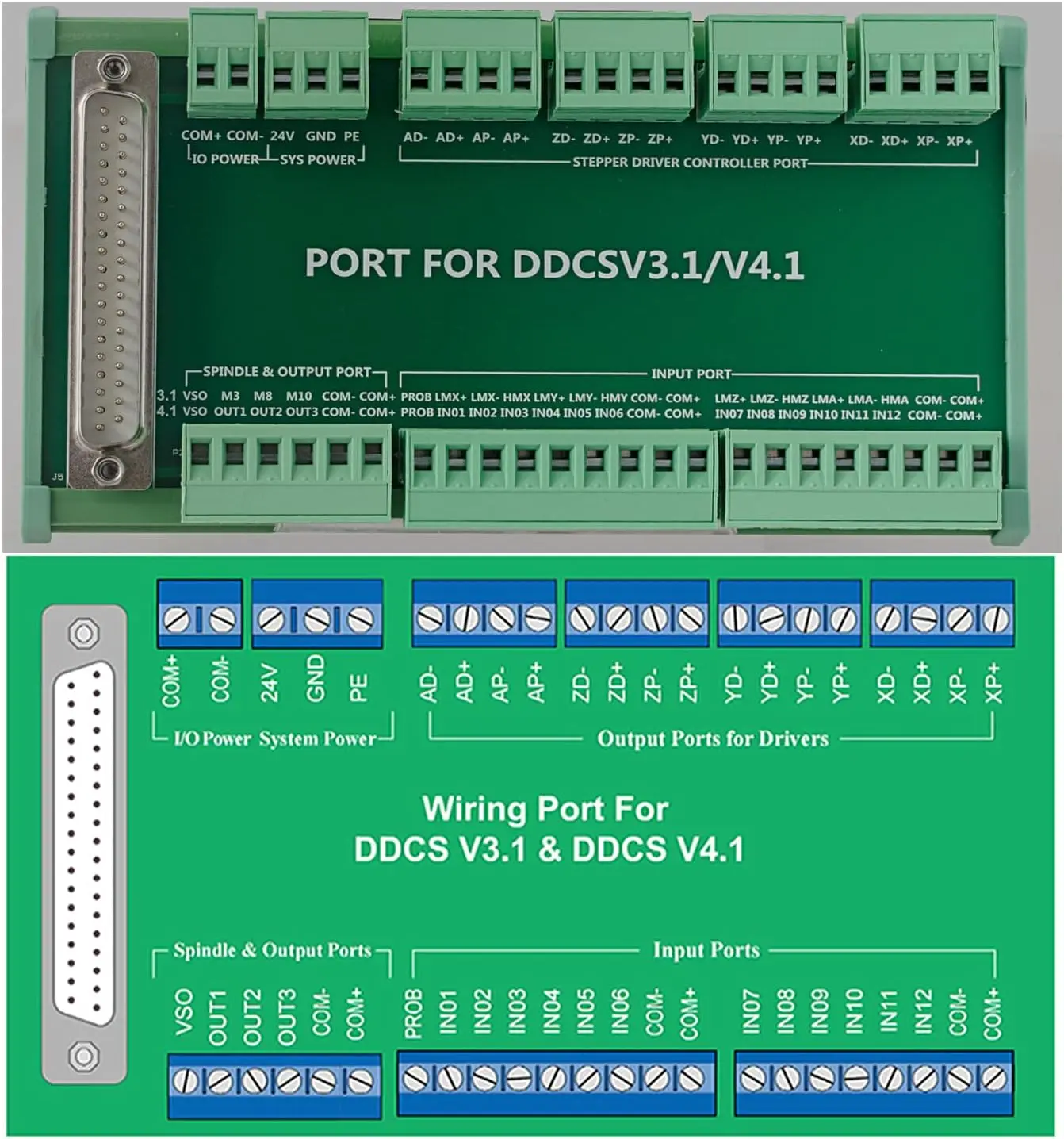

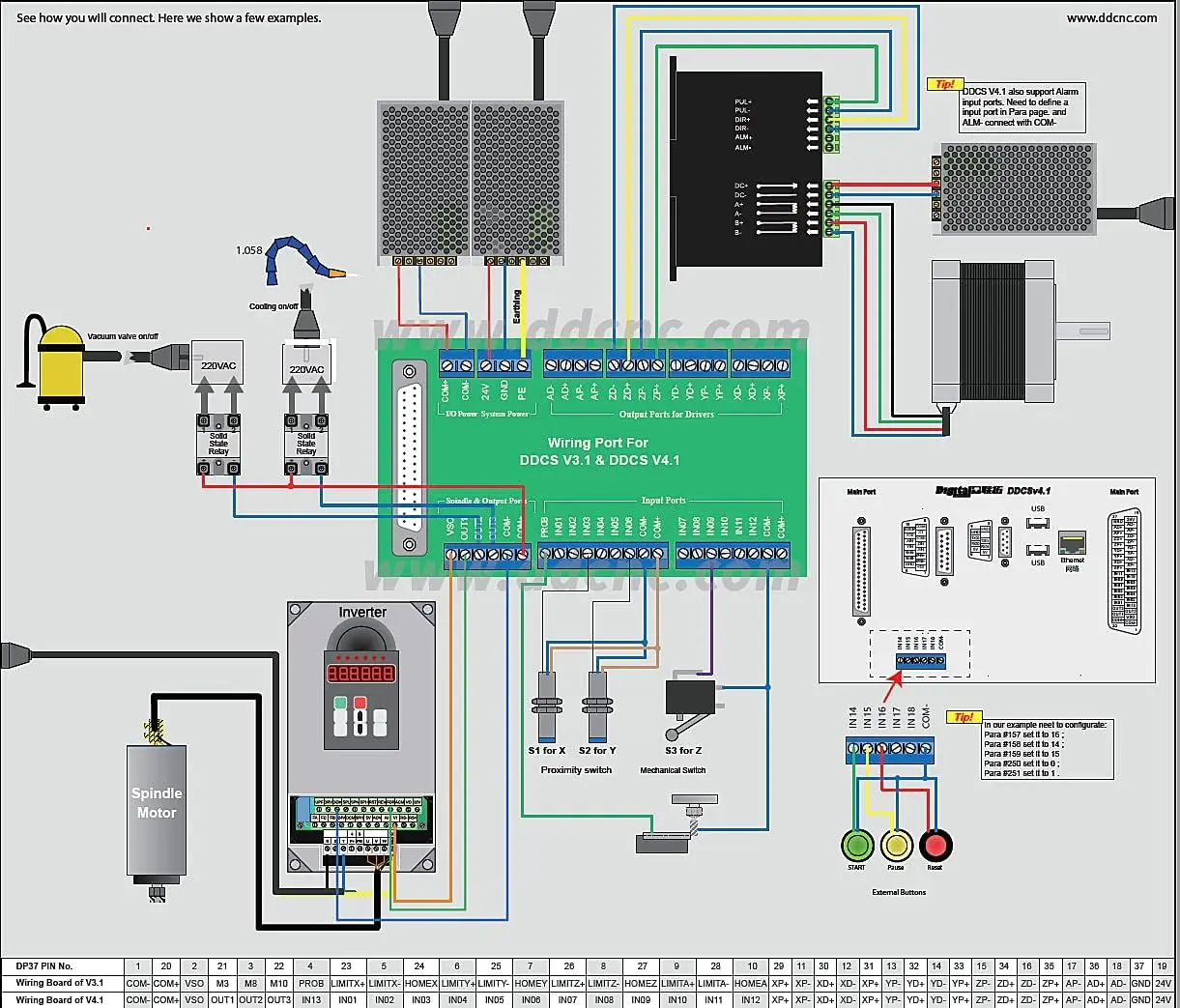

DDCS V4.1: 7 inches TFT screen, resolution ratio: 1024x600,17 operation keys;Difffferential Mode and Double Pulse Mode output signal for optional, Maximum interpolation pulse output frequency is 500Khz/Axis, 2-4 Axis linear interpolation, any 2 axis circular interpolation;ARM9 main control chip,FPGA core algorithm chip;18 photoelectric isolated digital inputs,3 photoelectric isolated digital outputs. The spindle can be confifigurated as Analog spindle(0~10V) and also Servo spindle;Slave X, Slave Y Or Slave Z, for Gantry machine with two independent motors on main axes;The Power Supply for IO Port is 24VDC,minimum current is 0.5A, the Power Supply for Control ler system is also 24VDC,minimum current is 0.5A. Controller needs both power to work properly;USB flash disk support for G code file input; Can transfer the files by Ethernet communication between the computer and DDCS V4.1 controller; No size limited of the G-code file.

DDCS V4.1: 7 inches TFT screen, resolution ratio: 1024x600,17 operation keys;Difffferential Mode and Double Pulse Mode output signal for optional, Maximum interpolation pulse output frequency is 500Khz/Axis, 2-4 Axis linear interpolation, any 2 axis circular interpolation;ARM9 main control chip,FPGA core algorithm chip;18 photoelectric isolated digital inputs,3 photoelectric isolated digital outputs. The spindle can be confifigurated as Analog spindle(0~10V) and also Servo spindle;Slave X, Slave Y Or Slave Z, for Gantry machine with two independent motors on main axes;The Power Supply for IO Port is 24VDC,minimum current is 0.5A, the Power Supply for Control ler system is also 24VDC,minimum current is 0.5A. Controller needs both power to work properly;USB flash disk support for G code file input; Can transfer the files by Ethernet communication between the computer and DDCS V4.1 controller; No size limited of the G-code file.

DDCS V4.1 Brief technical feature:

2) The spindle can be confifigurated as Analog spindle(0~10V) and also Servo spindle.

3) 3-4 axes motor Control. Difffferential Mode and Double Pulse Mode output signal for optional, Maximum interpolation pulse output frequency is 500Khz/Axis, 2-4 Axis linear interpolation, any 2 axis circular interpolation;

4) ARM9 main control chip,FPGA core algorithm chip.

5) 7 inches TFT screen, Size: 1024x600 Pixels, Resolution:72 Pixels/Inch; 17 operation keys.

6) The Power Supply for IO Port is 24VDC,minimum current is 0.5A, the Power Supply for Control ler system is also 24VDC,minimum current is 0.5A. Controller needs both power to work properly.

7) USB flflash disk support for G code fifile input; Can transfer the fifiles by Ethernet communication between the computer and DDCS V4.1 controller; No size limited of the G-code fifile.

8) Compatible with standard G-code, support popular CAD/CAM software, such as ArtCam, MasterCam, ProE, JDSoft SurfMill, Aspire, Fusion 360 and so on;

9) Support standard MPG.

10) Support function of“ Try cutting” (handwheel guiding) function. the distance.

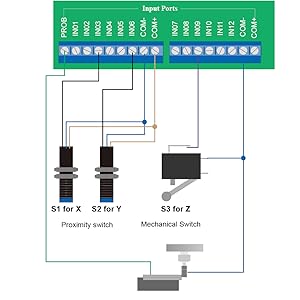

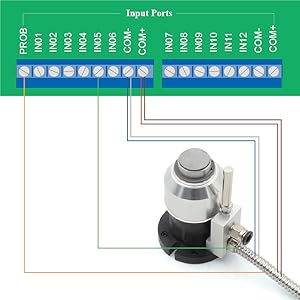

12)Support Float Probe, Fix Probe, Vertex Probe and Tool Length Measurement.

13) Support the operation of quickly go to specify line and closest position. cal machining.

15) Support Bias for XYZA axis, and can defifind the Bias distance.

16) Support Pause breakpoint, Power-Cut Recovery Beakpoint and loaded breakpoint; And Support Start from the specifific line and closest line.

17) Support Multiple origin points operation, the users can create an origin point and load it.

18) Support Find Middle for X and Y axis.

19) Improved the simulation function. During the simulation, you can adjust the FRO and observe whether the programming path meets the expectations and check the soft limits. During the simulation, it can be paused, and when press the Start key again, the system will continue to simulate from the pause breakpoint.

20) Slave X, Slave Y Or Slave Z, for Gantry machine with two independent motors on main axes.

22) DDCS V4.1 Only Supports NPN Type Limited Switch.

23) Support 4 kinds operation rights: visitor, operator, admin, super admin.

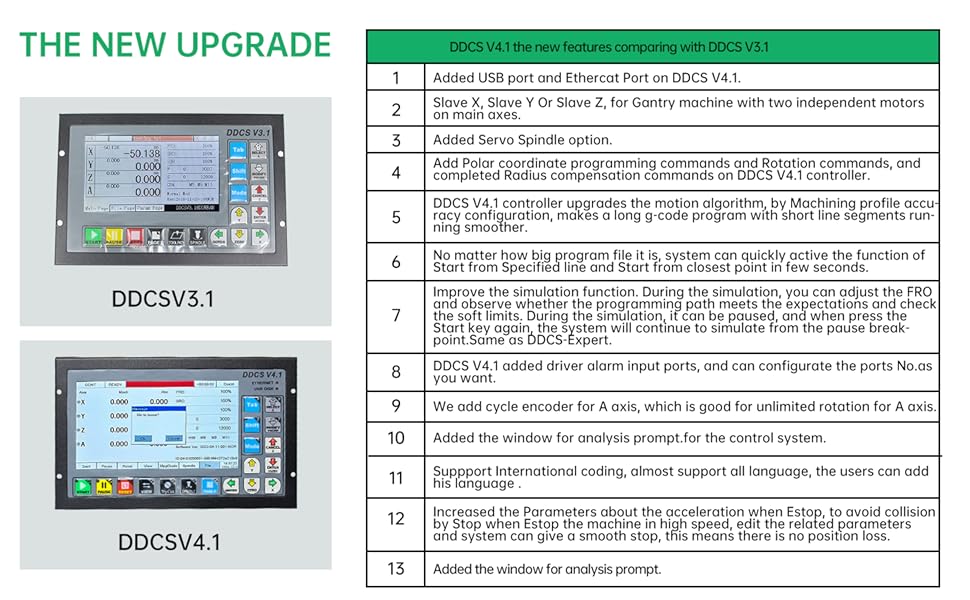

DDCS V4.1 the new features comparing with DDCS V3.1

1.Can transfer the files by Ethernet communication between the computer and DDCS V4.1 controller.

2.Slave X, Slave Y Or Slave Z, for Gantry machine with two independent motors on the main axes.

3.Servo Spindle can be connected to PUL/DIR output when selected;

4.We add Polar coordinate programming commands and Rotation commands, and completed Radius compensation commands on DDCS V4.1 controller.

5.DDCS V4.1 controller upgrades the motion algorithm, by Machining profile accuracy configuration, makes a long g-code program with short line segments running smoother.

6.No matter how big program file it is, system can quickly active the function of Start from Specified line and Start from closest point in few seconds.

7.Improve the simulation function. During the simulation, you can adjust the FRO and observe whether the programming path meets the expectations and check the soft limits. During the simulation, it can be paused, and when press the Start key again, the system will continue to simulate from the pause breakpoint.

8.DDCS V4.1 added driver alarm input ports, and can configurate the ports No.as you want.Same as DDCS-Expert.

9.We add cycle encoder for A axis, which is good for unlimited rotation for A axis.

10.Added the window for analysis prompt.

11.Suppport International coding, almost support all language, the users can add his language for the control system.

12.Increased the Parameters about the acceleration when Estop, to avoid collision by Stop when Estop the machine in high speed, edit the related parameters and system can give a smooth stop, this means there is no position loss.

13.System FPGE cited 32 -bit speed generator, with higher resolution for the speed / acceleration, it means higher positioning accuracy.

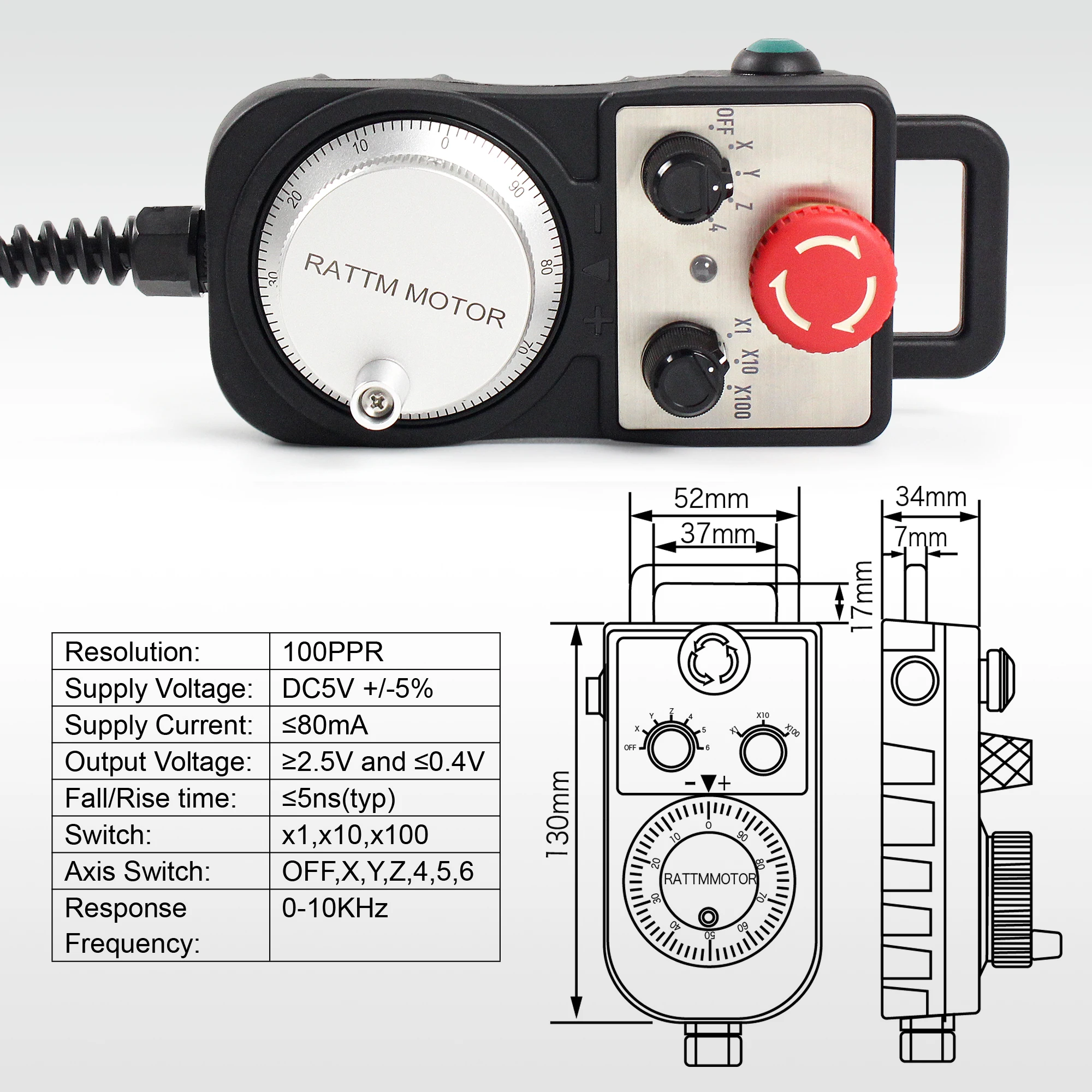

CNC MPG Pendant Handwheel with Emergency stop with 15-pin plug

Description:

Plug and play, this MPG comes with a 15-pin plug, which can be directly connected to the 15-pin socket of the controller MPG

Resolution: 100PPR

Power:5V

Current:≤80mA

Output Voltage:≥2.5V and ≤0.4v

Axis:X,Y,Z,ARatio:x1,x10,x100

Max response frequency:10Khz

Return&Refund

1.Any reason required for all refund.Item must be in it's original condition and no physical damage,buyer responsible for all shipping cost.

2.When you have the parcel,and not satisfied the goods or it is other problem like as broken,pls tell us the detail reason and provide the photos,we will help you to solve any problems.

Contact

1.If you are not satisfied, please contact us to resolve any issues. Please do NOT leave negative feedback without asking for help. We work hard to make sure EVERY CUSTOMER 100% satisfaction.

2.For any inquiries,issues or assistanceplease contact us via eBay or leave your mail address.

3.All emails will be answered within 1-2 working days.If you do not receive our reply,please kindly re-send your email and we will reply to you as soon as possible.