Xboxexperts stands for quality, if you get FAKE kits and mess up your Xbox dont expect any sympathy!

(Look out for the Xboxexperts Logo, all our Official Resellers proudly use it)

xbox-experts.com presents:

Hybrid eXtreme Uniclamp™ X-Clamp Repair Kit

The OriginalThese Kits actually work, if you buy cheap chinese copies of this kit, don't complain to us if it kills your Xbox!

w/ eXtreme-Cool 360™ Thermal Compound

Fixes:

1RLOD 1RLOD | E74; E73; |

2RLOD 2RLOD | 0013; 0012; 0011; |

3RLOD 3RLOD | 0001; 0020; 0021; 0022; 0100; 0102; 0103; 0110; |

4RLOD 4RLOD | YES |

Other Common Errors:

Any kind of in game freezing, artifacts, no video/audio issues etc.

Includes the following:

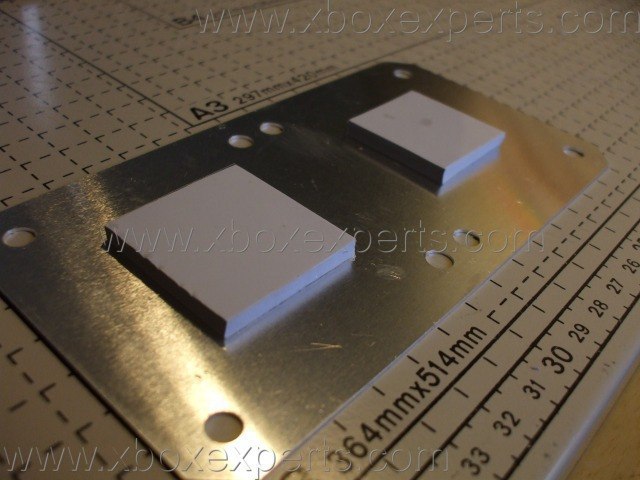

- 1 x Xbox 360 Hybrid eXtreme Uniclamp™ backplate with eXtreme-Cool 360™ Thermal Pads for the CPU/GPU.

- 8x M5 14mm perfect fit cheese-head metric screws and 40x M5 1mm steel washers

- 1 gram eXtreme-Cool 360™ Thermal Compound (outperformed AS5 in testing!) (nano-carbon technology)

- 2x eXtreme-Cool 360™ Thermal Pads for the RAM under the GPU heatsink (to fill small air gap)

- 1x set Hybrid eXtreme Foam Shims™ for GPU&CPU (upgraded for 2011) (protects chips during installation and helps proper heatsink alignment)

- We DONT use NYLON WASHERS, They DEFORM under the HEAT over time, this makes your console break again after a few months!!!

- No cheap quality chinese origin repair kits

like the replicas you find, ours are the original, made in the E.U with

suppliers from Germany and the U.K, we think with a product like this

quality is important, fractions of a millimeter can decide over fail or

success, so support our local companies and the high quality products

they make. :)

Hybrid eXtreme Uniclamp™

- Hybrid eXtreme Uniclamp™ xbox 360 backplate developed exclusively by xbox-experts.com for the "extreme" version of "Team HYBRID's Ultimate X-clamp Fix".

- World's best X-clamp hardware replacement available and ensures proper installation/support of the motherboard and heatsinks.

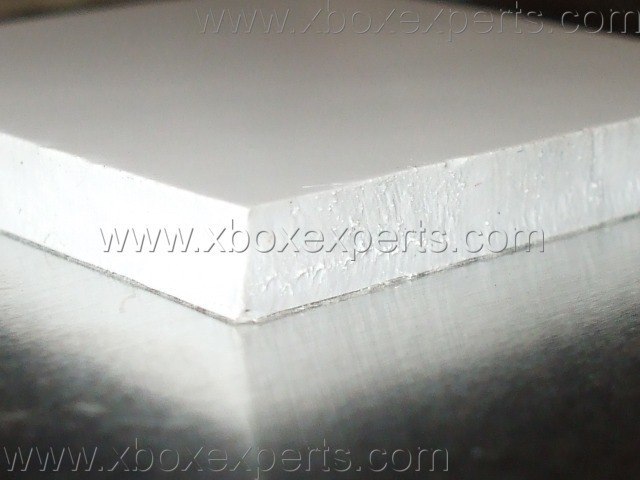

- Thermal Pads under the heat sources (cpu/gpu) transfer heat to the Uniclamp made from the most heat conductive alloy of aluminum available.

- The heat then is then radiated off into the metal chassis of the xbox 360, essentially turning the entire chassis into a passive heatsink!

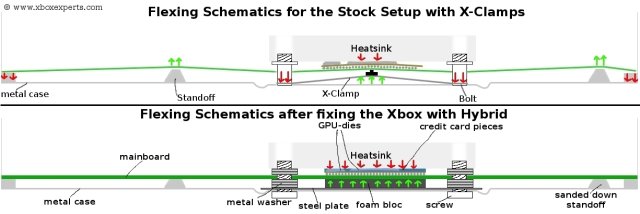

- The Uniclamp and thermal pads create a sandwich effect with the heatsink/shims from above, providing counter pressure and support from below which prevents board flexing.

- Designed to work in tandem with the metal chassis to secure the motherboard in a flat position and prevent further flexing.

- Easily secure most compromised solder joint connections without the need for reflowing to get you gaming again within an hour. (small percentage of units with extreme damage will require a reflow as well replacing the x-clamps)

- Made from thermally conductive non-toxic silicone based material which was was selected after months of testing materials from several manufacturers around the world.

- They provide the perfect density needed to counter the pressure from the heatsink.

- Pads on the uniclamp help cool the cpu/gpu chips and two smaller pads are used to fill the tiny air gap between the ram and gpu heatsink.

- High quality 3m thermal adhesive is used to ensure the pads stay in the correct position and don't fall off.

- No compromises on cost, simply the best quality thermal pad material available.

Hybrid eXtreme Foam Shims™ for the CPU/GPU

- Made from high

quality rubber infused/fiber reinforced closed-cell foam composite material that provides the correct

pressure and stability.

- Ensures proper parallel heatsink alignment with the chips.

- Protects the dies from cracking due to excess pressure.

- Extends pressure from the heatsink over the entire bga chip helping to hold the solder balls in place by preventing lifting/warping at the corners of the chips caused by uneven pressure and several heat/cooling cycles.

- High quality adhesive layer holds them in place.

eXtreme-Cool 360™ Thermal Compound (1gm)

- Nano-Carbon based thermal compound modeled after latest NASA technology (similar formula used in modern spacecraft)

- Over 1/3 gram of extreme thermal conductive pure Nano-Carbon compounds per syringe blended in a base of other nanometer sized metal oxide particles (silver/aluminum/boron/zinc) and small amount of organosiloxane compounds for ultimate stability and thermal conductance.

- Low bleed, non-flowing and low evaporation mean it will not run all over the place or dry out over time. Very easy to install and spread out over chips and cleans up easy compared to many other brands.

- Extreme operating temperature range....stable from -55~300°C without degradation in performance.

- Very high Dielectric constant, it will not short out components...can withstand above 10,000 volts without causing a short!

- Thermal impedance (<0.067-in2/W)

- Thermal conductivity (>4.5 W/Mk)

Support:

Xboxexperts is the biggest Xbox 360 Repair Website in the scene, we have got a forum, a free repair chat, the largest collection of tutorials, and our famous Errorcode Database which helps you analyse what is wrong with your console.

We have been in the business for over 4 years now and unlike people who just "resell" we actually know what we are talking about, we are the people who developed these fixes, test us against the other sellers if you want, we have always been giving free support and always will do no matter if you buy a kit from us or not :)

Shipping:

| E.U | Other Countries | Worldwide & Outside E.U |

|---|---|---|

3.00€  | Not Available | 2.50€  |

6.00€   | 6.00€   | 4.50€   |

| Due to problems, shipping to these countries a tracking number is enforced, thus why it costs more. For the Tracking number, check your emails! | Shipping to these countries is a bit cheaper because no taxes are charged. |

Invoice:

Invoices include VAT and are sent automatically to you by Email as a PDF document after payment, please check your spam folder if you didn't receive it.

Bulk purchases are also possible we provide many professional repair stores and resellers with our parts in the UK and all over Europe, special discounts will be granted for these sales of course :)

How it all works...

Has your Xbox 360 ever started flashing red lights around the power button and cease to work? Commonly referred to as the "three red rings of death" or 3rrod, rod, 3 red light, 3rlod, etc they can encompass a wide range of hardware failures each indicated by unique secondary error codes such as e74, 0013, 0012, 0011, 0001, 0020, 0021, 0022, 0100, 0102, 0103, 0110, and other less common errors. Sometimes the unit will suffer from no video, freezing video, showing artifacts, or other graphical errors. These are just red light errors that the unit has not yet detected. Many of the problems are originated by the GPU since it produces the most heat, but other components can be affected as well such as the CPU, RAM, HANA/ANA, Southbridge etc.

There are three main factors which contribute to the red rings, overheating, poor solder connections and flexing from the chassis design and x-clamp retention setup.

The Uniclamp kits were designed by xbox-experts.com to help with all of these symptoms. They provide better pressure to the chips, holding the connections in place while eliminating board flexing. Heat is drawn away from the underside of the board into the chassis.

Metric screws are only used to ensure proper threading since imperial size threads are slightly off which leads to stress on the heatsink and motherboard.

Only steel washers are used since nylon

washers are outdated and can absorb moisture/dry out over time leading

to them expanding/contracting and eventually cracking. Only quality

steel washers give the full needed support. The OEM mounting hardware

was all metal, so there is no worry of a short and no need for plastic

washers. People who say you need nylon washers don't know what they are talking about.

Most 3 red light errors can be easily repaired just by installing the kit, although a few bad ones will need to be reflowed as well (usually ones with failed fix-it attempts in the past). Keep on reading for an in depth analysis to the causes of the 3 red light errors and why it is essential to replace the x-clamps, even in working units...

What Causes Most Xbox 360 Red Light Errors ? (RROD)...

- Xbox 360 Flexing Zones Caused by Chassis Design and X-clamps

Zone 1:

The most frequent error codes are 0102 (0100;0101;0103 as well)and 0020. These are GPU and CPU related errors mainly. 0020 can also be caused by the RAM in rare cases. About 80% of the errors fall into this category, as the solder balls under the CPU and GPU experience the most flexing of all. This is caused by the x-clamps flexing upwards in the area directly under the cpu/gpu, all concentrated on small points extremely in addition to the natural flexing caused by the metal case layout. Zone 1 is the area right under the CPU and GPU.

Zone 2:

The next most frequently occurring error codes are E74, 0022 and 0110, which are usually either RAM or ANA/HANA chip related. Sometimes E74 and 0022 can also be GPU related depending on the trace. Since the RAM and ANA/HANA chips are close to the GPU they can be affected by the Zone 1 flexing, in addition flexing caused from the two standoffs. These may not occur as often as the Zone 1 errors, but still make up approximately 12.5% of the overall error codes.

Zone 3:

The Zone 3 area experiences the least amount of flexing versus the other 2, but can still make up about 7.5% of the error codes. The related error codes are E73, 0021, E79(if hardware related), E71(if hardware related). The components effected by Zone 3 flexing are the Southbridge, ethernet chip, NAND and the entire motherboard to some extent. Since the NAND and ethernet chips are not BGA (ball grid array) chips like the Southbridge, GPU, CPU, HANA, etc, they are a bit more resistant to the flexing.

- Xbox 360 Overheating / Thermal Runaway

Many of the 3 red light errors are blamed on overheating due to heat buildup caused by thermal runaway. Microsoft tried to combat this issue by installing better GPU heatsinks with added heatpipe attachment which didn't help much as the problems still persisted. Eventually MS got sick of the red rings and came out with the SLIM model which has an entirely new thermal design. The SLIM models seem to handle the heat a bit better, but still suffer from overheating and insufficient air flow.

In 2007 thermal design experts Naoki Asakawa and Mayuko Uno from Nikkei Electronics in Japan analyzed the 360's heat radiation system in early models to determine if overheating was a problem or not. Some of their findings...

- The

airflow cooling the heat sink is proportional to the cross-sectional

area of the flow path, and in this case the cross-sectional area for

the graphics IC heat sink was only about one-seventh that of the

microprocessor. "Almost all of the air pulled in by the fan is

used to cool the microprocessor, it looks like. They've made some

effort to increase the cross-sectional area by widening the heat sink,

but it doesn't look like it's very effective." "In PCs it is common practice to enclose the

heat sink in a duct. There might not have been enough space available

in the Xbox 360, but the duct stops just short of the heat sink. The

heat sink is instead enclosed on top by the DVD drive, the case, etc.

If the duct should happen to be dislodged in transport, for example,

the airflow cooling the heat sink would drop significantly."

- There was a temperature gap of 22C between the exhaust and room air, "When designing consumer products, it is common to seek a temperature gap of around 10C between exhaust and room temperatures," the thermal design expert said.

- The maximum wind speed of the exhaust air is only 1.1 meters per second, only 1/2 to 1/3 compared to normal desktop PCs produce. The expert noted, "The amount of switched air is slightly in short considering the chassis' size (309 x 258 x 83 mm3)."

- It takes only 5 minutes of gaming for the GPU heatsink to reach 70C, a thermal gradient of about 10C/min and after 15 minutes of play, the GPU heatsink can reach temps near 100C.

- The heat sink temperature for the microprocessor was stable at 59*C, but the heat sink on the graphics IC reached 70*C within only five minutes of starting the game. The incline was about 10*C/min, and by 15 minutes it reached 80*C, representing a difference of 57*C from room temperature. Assuming a summer room temperature of 35*C, estimates indicate that heat sink temperature would exceed 90*C, and IC temperature might well exceed 100*C.

- The airflow cooling the heat sink is proportional to the cross-sectional area of the flow path, and in this case the cross-sectional area for the graphics IC heat sink was only about one-seventh that of the microprocessor. "Almost all of the air pulled in by the fan is used to cool the microprocessor, it looks like. They've made some effort to increase the cross-sectional area by widening the heat sink, but it doesn't look like it's very effective."

- When the IC, board, etc, reach excessive temperatures, the difference in the coefficients of thermal expansion cause board warpage, which in turn applies severe stress to the periphery of the ball grid array (BGA) connecting the two. Repeated exposure to elevated temperatures would cause cracks in the solder balls from heat fatigue, leading to failure.

- Lead-Free Solder and Improperly Reflowed Solder During Manufacture

Seattle PI's "Digital Joystick" interviewed an inside source who has worked on the Xbox 360 project for many years who stated that the...

"RROD is caused by anything that fails in the “digital backbone” on the mother board. Also known as a core digital error. CPU, GPU, memory, etc. Bad parts, incompatible parts (timing problems) bad manufacturing process (like solder joints), misapplied heat sinks or thermal interface material, missing parts, broken parts, parts of the wrong value, missed test coverage. Any one or more, on any chip, or many other discrete components, would cause this. And many of the failures were obviously infant mortality, where they work when they leave the factory and fail early in use. The main design flaw was the excessive heat on the GPU warping the mother board around it. This would stress the solder joints on the GPU and any bad joints would then fail in early life."

"Some defective parts, like BGAs where the solder balls are not of sufficient and uniform size, so they don’t solder down evenly, or the substrate is warped, causing some joints to have insufficient solder. Bad chips from marginal or under tested wafers. Others are deficient processes, like misaligning the solder paste to the circuit board, or same on the parts, or not having the thermal profile right in the reflow oven during soldering."

"Manufacturers new to PB free tend to err on the low temp side thinking they are saving the parts reliability wise from a large thermal load. What they are really doing is not reflowing the PB free solder enough to make a good joint. PB free solder is non eutectic, which means the different metals in the solder alloy melt at different temperatures, unlike leaded solder where everything melts at the same temperature. If you under heat it, it won’t bond well to the board or parts, won’t form a good joint, leaving voids and other defects in the joints that lead to early failure under normal circumstances. But when you add the extraordinary heat and mother board warpage that goes with it, well you get a catastrophic failure rate like we’ve all seen on 360."

Reflow experts from Manncorp did an extensive investigation into the quality of the lead free solder joints in the 360 and found that with an x-ray they could actually see solder balls that did not look like they had been re-flowed properly in the first place. On a pair of x-rays from the GPU, different sized solder balls are clearly visible, which is an indication some spheres were not completely reflowed during manufacture....

Manncorp also noted, "While a "cold" solder joint may provide an adequate electrical connection, long-term reliability is jeopardized, especially in application where the solder bonds are subject to wide temperature fluctuations. In such an environment, continuous expansion and contraction of materials with varying thermal coefficients will quickly destroy the integrity of a "cold" solder joint, creating intermittent problems or even complete failure. This is precisely the environment of the Xbox 360 motherboard, due to the high amounts of heat generated by the CPU, GPU and memory components when running graphics-intensive gaming applications."

The guys at bunniestudios decided to send in a 360 for failure analysis to MEFAS for solder joint inspection on the GPU through a process called “dye and pry”. In this process, the motherboard is flooded with red ink, and then the GPU is mechanically pried off the board. The red ink flows into any of the tiny cracks in the solder balls, and at least in theory, when you pry the GPU off the cracked regions will shear first so you will be left with visible red spots at the points of failure.

Normal Solder Joint:

- Bad Heatsink Mounting due to X-clamp Setup

The x-clamps essentially act like a little prying device that stresses the connections more and more with each thermal cycle until the already poor solder connections are broken. The pics below were from a "no video" unit....

- Sloppy Thermal Compound Application....

Detailed x-clamp replacement install guide

Interactive Xbox 360 Repair Guide by xbox-experts.com

*requires drilling 5mm holes through the metal chassis

**NOT compatible with newer "xbox 360 slim" models

**Beware of cheap imitations made using inferior materials and incorrect installation techniques (no-drill method is not feasible). xbox-experts.com is the original developer of the Hybrid eXtreme Uniclamp kits, any others are ripoff copycats trying to capitalize off others hard work!

*** Xbox-experts offers a 14-day money back satisfaction Guarantee from the time of purchase. If you are not happy with your purchase, return it for a full refund minus shipping. Item must be in unused condition for full refund, otherwise a partial refund is still available for used units.