| ❤️+ Save This Seller to Enjoy a Menber Exclusive Coupon! |

The Bulk Man 3D Work-Bee Newest Version is based on the original WorkBee design by Ryan Lock of Ooznest. Our kit has some differences to the original design by Ryan including additional wheels and an Upgraded Tension System, which allows for stronger and more reliable tension to be placed on the X and Y Axis lead screws, and helps to solve the " Whip" problem for long lead screws or faster Speed.

It is reliable based on C-Beam, V-Slot, Xtreme Solid V-Wheels and TR8x8(P2) Leadscrews. It has been carefully designed and can accurately cut foams, woods, plastics and aluminum to 0.1-0.2 mm accuracy or better.

The Work-Bee CNC Machine is a 4 axis (3 + 1) machine, this means there are 3 physical axis (X,Y,Z) and a slave axis of Y which is called the A Axis. The Work-Bee CNC Machine uses specific lengths of Extrusions and Leadscrews.

With a Work-Bee CNC Kit you can manufacture functional engineering parts, toys, signs, or whatever you can imagine without leaving the workshop.

- GRBL Software based controllers: xPRO V5, High Torque GRBL, MakerShield GRBL

- Mach3/Drufel CNC Software based controllers: UC300, NVUM, STB5100

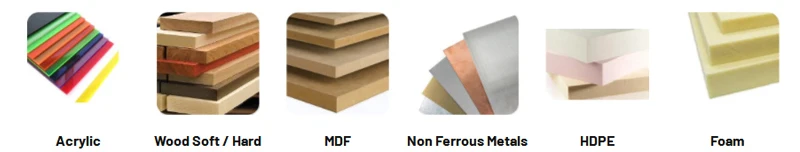

- Compatible Material for Cutting/Milling/Engraving:

- Aluminium / Hard Wood / Soft Wood / Oak / Plexi Glass / Delrin / HDPE / Foam

- Work-Bee CNC Mechanical Kit

- 4 x Nema23( 2.45N.m) Stepper Motors

- Cable Drag Chain Bundle

- Z-Axis Touch Plate Probe

- XYZ Touch Probe

- Spindle Dust Cover Collector

- Controller Bundle ( Choose 1 of 6 )

- Spindle Bundle ( Optional for 1.5kW Air or 1.5kW Water or 2.2kW Water Cooled. Voltage range from 110V~250V. We will send 110V by default.For 220V please leave us message! )

- All Extrusions are M5 Tapped as where it is necessary.

- For any customized request please feel free to contact us!

----------------------------------------------------------------------------------------------------------------------------------------------------------

- NEMA 23

- Shaft Size: 1/4″

- Step Angle: 1.8

- Holding Torque: 2.45N.m

- Rated voltage: 3.6V

- Rated current: 3A

- 1.5kW Air Cooled Spindle Net weight: 2.6kg

- 1.5kW Air Cooled Spindle Spec: φ 65 x 205 mm

- 1.5kW Water Cooled Spindle Net weight: 4.2kg

- 1.5kW Water Cooled Spindle Spec: φ 80 x 205 mm

- Power: 1.5 kW

- Voltage: 220 ~250 V or 110 V

- Frequency: 400 Hz

- Speed: 8000-24000 R/min

- Air/Water Cooling

- Run-out off: less than 0.005 mm

- Grease Lubrication

- VFD Inverter 1.5 kW 220 V or 110 V

- Collet: ER11 (15pcs/set, size from 1 mm to 7 mm)

Specs of 2.2 kW Water Cooled Spindle:

- Net weight: 5.3kg

- Spindle Spec: φ 80 x 215 mm

- Power: 2.2 kW

- Voltage: 220 ~250 V or 110 V

- Frequency: 400 Hz

- Speed: 0-24000 R/min

- Water Cooling

- Run-out off: less than 0.005 mm

- Grease Lubrication

- VFD Inverter 1.5 kW 220 V or 110 V

- Collet: ER20 (28pcs/set, size from 1 mm to 13 mm)

Please note:

- MDF Working Table and Drill Bits are NOT included with this kit.

- We do not provide technical support for software debugging.

- Mach3 License is not included with this kit. This License can be purchased directly from the official website.

- Any Mains power connections must be installed by a Licensed electrician or suitability qualified person

- Instruction Manual is available via Bulk Man 3D Resource Page (Message Us)

- Look how The Work-Bee CNC Full Kit is Cutting our Bulk Man 3D Logo!

Z Height

54mm Or 94mm Travel, 27mm Or 47mm Workable depth, with a 12mm spoilerboard. The spoilerboard supports have two height configurations, these are the maximums for each configuration.

Motion

Drive System- ACME Lead Screws Or GT3 Timing Belts

Linear Guides- Polycarbonate wheels on anodised C-Beam V-Slot Extrusion.

Motors- NEMA23 175oz Stepper Motors (X, Y & Z)

Accuracy- 0.05 - 0.10mm (Screw Driven) Or 0.10 - 0.20mm (Belt Driven)

Note

Maximum recommended speed for Lead Screws 1000mm or greater is 400RPM.

Attribution-ShareAlike".