Instruction:

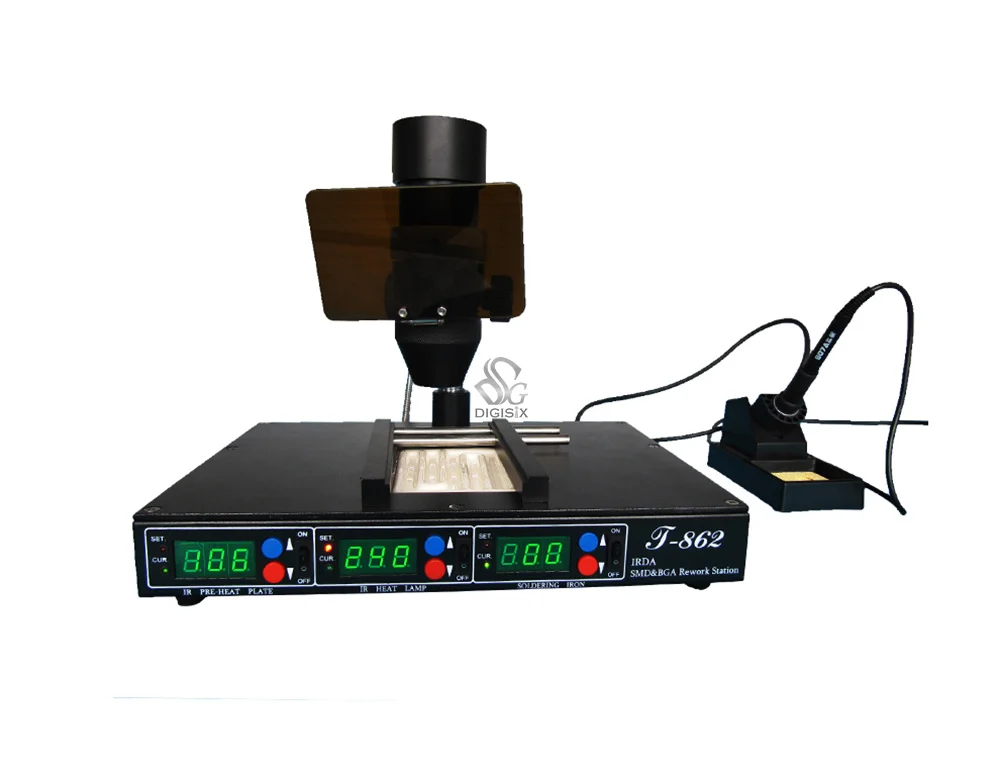

Unlike Air Re-Work systems, The T-862 uses an Infrared source and optics to target heat to individual components without dislodging other SMT parts by the way of eddies air currents.

Infrared soldering technology with independent exploration capabilities via the focus lenses which is included in the package.

Technician focused infrared heat is easy to target most component removal/replacement and rework.

The Workstation has a 80X120mm a 600W controlled Pre-heating system.

Infrared heat source bulbs are long-lived, in-expensive and easily replaced.

Processor controlled set-point regulated temperatures with thermocouple feed-back.

Integrated and adjustable Infrared (IR) eye protection.

Can suitable for the entire component, especially Micro BGA component.

The T-862 system also contains a temperature controlled touch-up iron and stand.

Extra soldering tools are not necessary to solder/unsolder and re-work Surface Mount Technology (SMT) components18X18cm in size.

Technical Parameters:

Working Voltage: AC220V/50Hz and AC110V/60Hz (we stock the item specail for the country all over the world)

Output power: 600W

Infrared lamp body power:120W

Preheating plate power: 450W

Working bench size: 350X260mm

Infrared lamp body heating size: 25X25mm

Preheating plate size:120X80mm

Preheating plate temperature range: 60-200 degrees

Infrared lamp body temperature range: 100-350 degrees

Features:

1. Infrared welding technology which was developed independenty.

2. Infrared heating is easy to pierce and distribute evenly, can avoid the IC damage due to the fast or uninterrupted heating up.

3. Easy operate; user can operate skillfully after one-day traning.

4. No need welding tools, it can weld any chips under 25mm( T-862)/35mm (T-862++)

With hot melt system, preheating range 120X80mm (T-862)/120X120mm(T-862++)

5. It doesn\'t impact the smart parts without hot air, and suits to weld all kinds of chips, especially Micro BGA components.