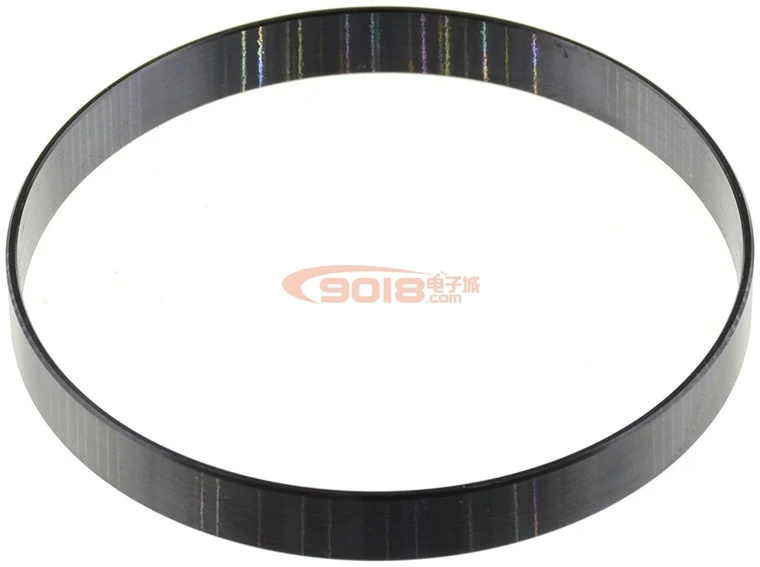

8110 81*10mm disc brushless outer rotor motor silicon steel sheet stator core

product name:8110 outer rotor motor stator core

product material:Imported silicon steel sheet

Slot structure:36N34P,36N38P,36N40P,36N42P,36N48PWait

Size specification: diameter81mm*the inside diameter of58.5mm*thick10mm

Surface treatment:Insulation coating + anti-rust coating

Product Weight:92g

Applicable scene:

Large thrust droneWired aircraft, aerial photography aircraft, pan-tilt motor, servo direct drive motor, DC brushless motor, disc generatorWait

This product adopts imported high-performance silicon steel sheet and high-speed CNC punching and stamping. It has the advantages of low eddy current loss and high saturation magnetic flux density. Multi-groove multi-pole structure and fractional slot concentrated winding make the motor light in weight. High performance, small torque ripple and large torque. This product is painted on the surface, waterproof, rust-proof and corrosion-resistant. It can significantly improve the life of the motor in a harsh and humid environment. It can be used to make a large-load aircraft anti-gravity system with high-performance magnetic steel + carbon fiber propeller (24 to 28 inches). The maximum pulling force can reach 10KG.

-------------------------------------------------- ----------------------

product name:8110 motor outer rotor yoke steel sleeve

product material:Low-carbon steel

Adapted stator: inner diameter81mm*height10mm

Adapted magnetic steel: long10mm*width5mm*thick3mm

Adaptation architecture:36N40P,36N42PWait

Size specification: inner diameter88.2mm*Outer diameter91.2mm*height13mm

Surface Technology:Black rust

Product Weight:50g

This product is specially designed for the 8110 disc stator core. It is the yoke of one of the three core components of the motor. It is recommended to use the high-performance magnetic steel of this station at the same time. It can be 36N40P or 36N42P.

Due to the difficulty in turning such thin-walled pipe fittings, there are turning lines on the inner and outer walls. In order to avoid deformation of the workpiece caused by repeated clamping, no further fine grinding and polishing is performed, but the use is not affected. If you do not mind, please do not buy.

This product is the core component of the motor. No other information is provided except the above product description. Please do not consult. Thank you!

-------------------------------------------------- ----------------------

product name:T-flange hollow shaft (with circlip)

Dimensions:Diameter 20mm* inner diameter 16mm* length 35mm, flange F40*4mm

Diameter tolerance:-0.02mm

Application scenario:Hollow motor shaft, rigid coupling, etc.

Dimensional parameters (units mm, 20mm-0.02, other possible tolerances of 0.1mm):

This product is specially designed for large-diameter disc motors such as stators 8110 and 10010. It is made of stainless steel rods. It is waterproof, corrosion-resistant and rust-free. The diameter tolerance is -0.02mm. It is suitable for various deep groove ball balls with inner diameter of 20mm. Bearings, angular contact bearings. The T-axis flange end faces are evenly distributed with 4 M4 wire holes, which can be used to fix various types of loads. The other four diameter 4mm through holes have countersunk head slots and are fitted with ISO7380 standard hexagon socket screws. The end of the shaft is provided with a circlip retaining groove, which can meet the requirements of rapid assembly and positioning under the condition of low axial load. When the circlip does not meet the axial load requirements or the reliability of the circlip is not high (such as the 10010 disc motor axial tension can reach 14KG level, such a large dynamic axial load may cause the retaining ring to loose the rotor. ), the end of the inner hole of the shaft is designed with a narrow rib. It can be fixed by two to three screws from the inside of the hole to the outer ends of the hole by using two limit clips, so that the reliability is greatly improved. The double protection of the circlip and the limit piece prevents the accident of the loose shaft.

Due to the turning process, bearing inner diameter tolerance, etc., the shaft may not be easily inserted into the inner ring of the bearing. Please finely grind and polish the surface with fine sandpaper to ensure a good clearance fit or interference fit with the bearing. This product is made of stainless steel, so the surface is not treated by any electroplating or other special coating. Due to repeated clamping during the processing of the workpiece, transportation friction, mutual collision, etc., the surface has slight scratches, such as the appearance is not good, It is very beautiful to polish and polish itself.Hand polishing instructions for amateur conditions:Install the shaft on the hand drill (or self-prepare motor), rotate at a low speed of 300-1000, then half-pack the sandpaper on the outer wall surface of the shaft, slowly move it back and forth along the axis and gently sand it to obtain the ideal polishing. effect. During operation, be sure to pay attention to safety. Wear thick cotton gloves. If you grind once, you can try to insert the bearing. If you wear too much, the poor matching effect will affect the balance of the motor rotor. It is too difficult to assemble and grasp the amount of grinding. In order to achieve the desired results.

This product is the core component of the motor. No other information is provided except the above product description. Please do not consult. Thank you!

-------------------------------------------------- ----------------------

Product Name:Square NdFeB motor strong magnetic steel

Performance: N42H, motor dedicated

Magnetization direction:RadialThickness direction

size:10.5*5*3Mm

Surface Technology:Electroplating rust

The magnetic field strength of this magnetic steel is much larger than the common black ferromagnetic, and it is stronger than the N35 common in the Taobao market, and the height resistance is not easy to demagnetize. It can be used to make various high-performance permanent magnet motors.

This product is the core component of the motor. No other information is provided except the above product description. Please do not consult. Thank you!

-------------------------------------------------- ----------------------

Slot architecture analysis and recommendations:

- 36N34PThe number of magnetic steel is smaller than the number of slots, the gap between magnetic steel is large, the processing precision of outer casing and magnetic steel is general, the structure is firm, the cost is low, but the power density is small, the magnetic leakage is large, the torque is small, the rotation speed is high, and it is suitable for low vibration. Aircraft.

- 36N38P/40P: The number of magnetic steel is larger than the number of slots, the magnetic steel gap is moderate, the outer casing and magnetic steel have high processing precision, low cost, moderate power density, small vibration, and small torque ripple. Compared with 34P torque, low speed, suitable for aircraft .

- 36N42PThe number of magnetic steel is larger than the number of slots, the gap between magnetic steels is small, the processing precision of outer casing and magnetic steel is high, the cost is high, and the power density is large. Compared with the first three combinations, the magnetic reluctance is large, the torque is large, and the rotation speed is low, which is suitable for aircraft.

- 36N48PThe number of magnets is much more than the number of slots, the gap between magnets is extremely small, the machining accuracy of the outer casing and magnetic steel is extremely high, the cost is high, and the low-speed torque ripple is large, which is the highest power density and the strongest torque in all slot combinations. The lowest, the magnetic resistance card is very strong. Generally suitable for occasions requiring high power and high torque, not sensitive to vibration. In theory, the magnetic pole combination is the upper limit and should not exceed 48P.

Product Image: