Thank you very much for purchasing high quality accessories manufactured.Although our accessories are more expensive,we do not sell low-quality cheap products to our customers.Every customer is our good friend.We will treat every friend who trusts us sincerely.

The DDB utilizes an internal gearing ratio of 3:1 together with precision cnc-machined hardened steel drive gears to give you a compact powerhouse for all your applications.Whether you require high resolution prints with small nozzles or high-flow prints with big nozzles the optimized gearing ratio combined with our industry leading drive gears provides unparalleled pushing power and lightning fast retractions in a lightweight and compact package.

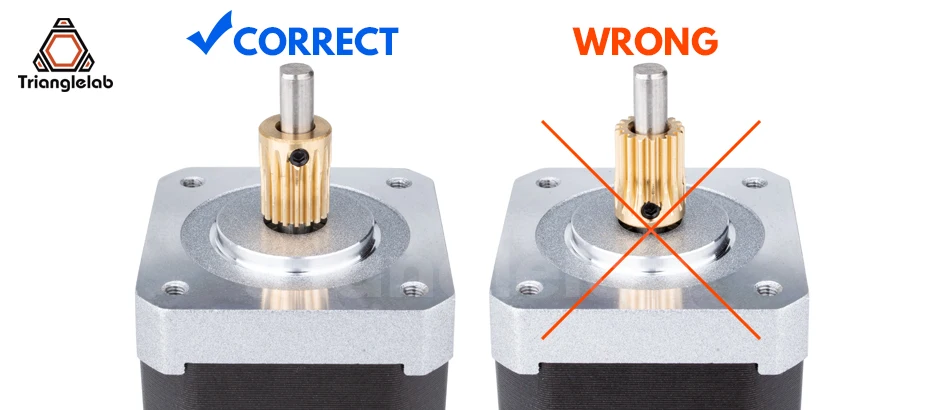

Very important notice!

Version upgrade notice:All DDB right-handed orders after September 19, 2020 will be upgraded to V2.0. The left-hand DDB still maintains the old model (no upgrade plan for the time being).

Orders made before September 19, 2020 will receive the old version of DDB. Please check the relevant upgrade analysis for specific upgrade content.

The old DDB only needs to purchase the new version of the shell to complete the upgrade.

▉Analysis of the highlights of the upgrade:

1: The position of the gear and the accuracy of all screw holes are calibrated.

2: Modified the new buckle, both sides of the V2.0 version of the DDB extruder support filament in and out (that is, it has no specified directionality, and you use either side of it as a material port)

3: The filament has an independent motion cabin inside the extruder. The white filament guide is made of a mixed material with lubricating properties. Its interior is very smooth, and it can withstand your crazy parameter settings.

4: A gap is reserved on the top to correspond to the threaded screw rod of the ender3 printer.

5: Brand new mixed materials, the shell is more rigid and tough.

DDB V2.1 upgrade guide:

Replaced with gears with stronger grip, under a strong bite, it will not damage the outer wall structure of the filament like inferior gears. We are trying to find the perfect bite strength. Gears have a longer life. You can almost always use your printer until it is scrapped.

DDB Direct Drive & Bowden Extruder

DDB V2.1 upgrade

Nylon Gears

Long-lasting and wear-resistant One-piece injection moulding

Large nylon gear Longer lasting and wear resistant.

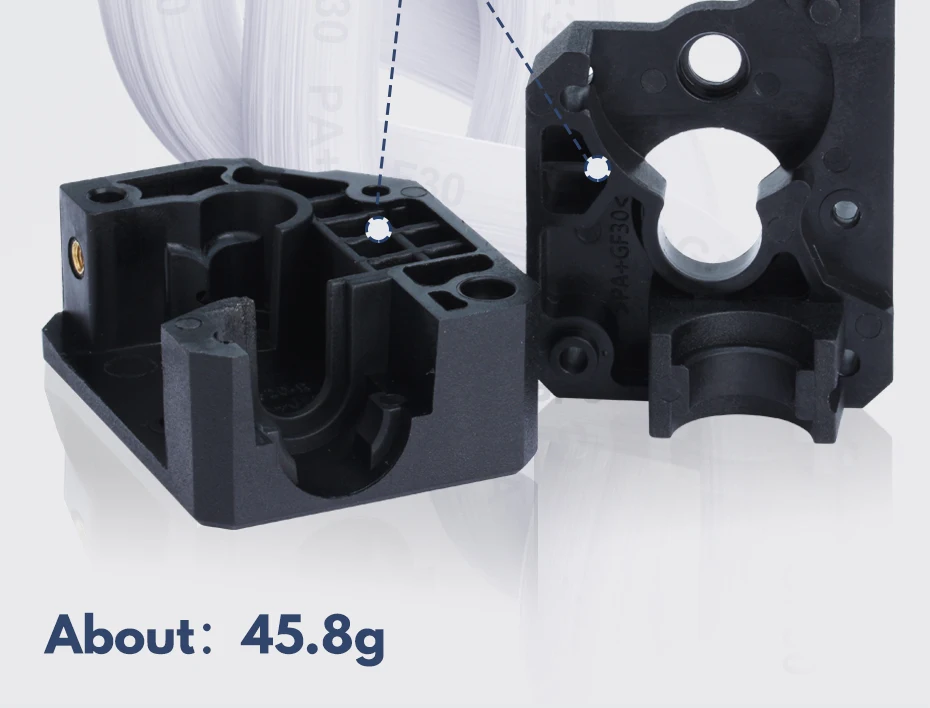

Rigid Shell-Shell made of PA+GF30

Weight saving design

Nylon and glass fibre,The shell is sturdy and has a hollowed out interior which greatly reduces the weight of the case.

Driving force 15KG

Hardened steel RNC nano coating gears

Dual drive gear-Hardened steel RNC nano coating gears,Stronger drive, more resistant to wear and tear。

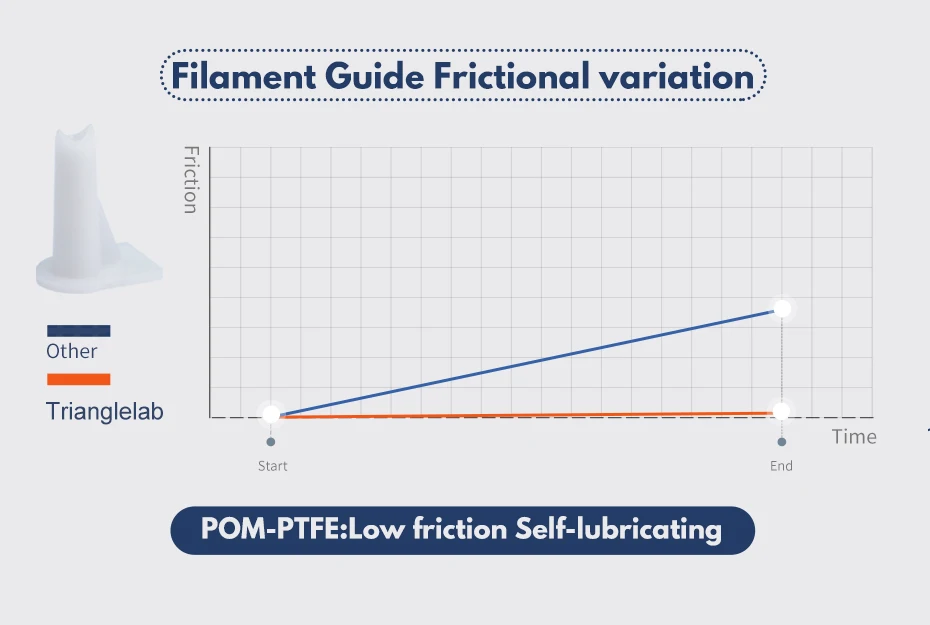

Filament Guide-POM-PTFE

Filament Guide-POM-PTFE:Low friction Self-lubricating

Friction comparison chart:

Other filament guides, after long hours of work, generate a lot of friction and the temperature rises causing them to wear out.

Trianglelab, Filament Guide, uses POM-PTFE as a raw material. Smooth surface, reduced friction and no wear after long working hours.

Ultra-high hardness HV3300

HRC 60+

Hardened steel with RNC Nano Coating

High hardness for greater resistance to wear and tear

Exploded view of the DDB extruder

If you would like to purchase a part individually, you can simply click on the image and make your purchase.

▉What's in the box:

DDB Extruder X 1

screws A package

*Simple tool A package(Gift)

◆ Please read here carefully!

In a long period of use. There may be a drop in color. But this does not affect the sharpness of the gear.