Package List:

only steel :steel +two abrasive Papers

with magnetic sheet:steel +two abrasive Papers+sticker

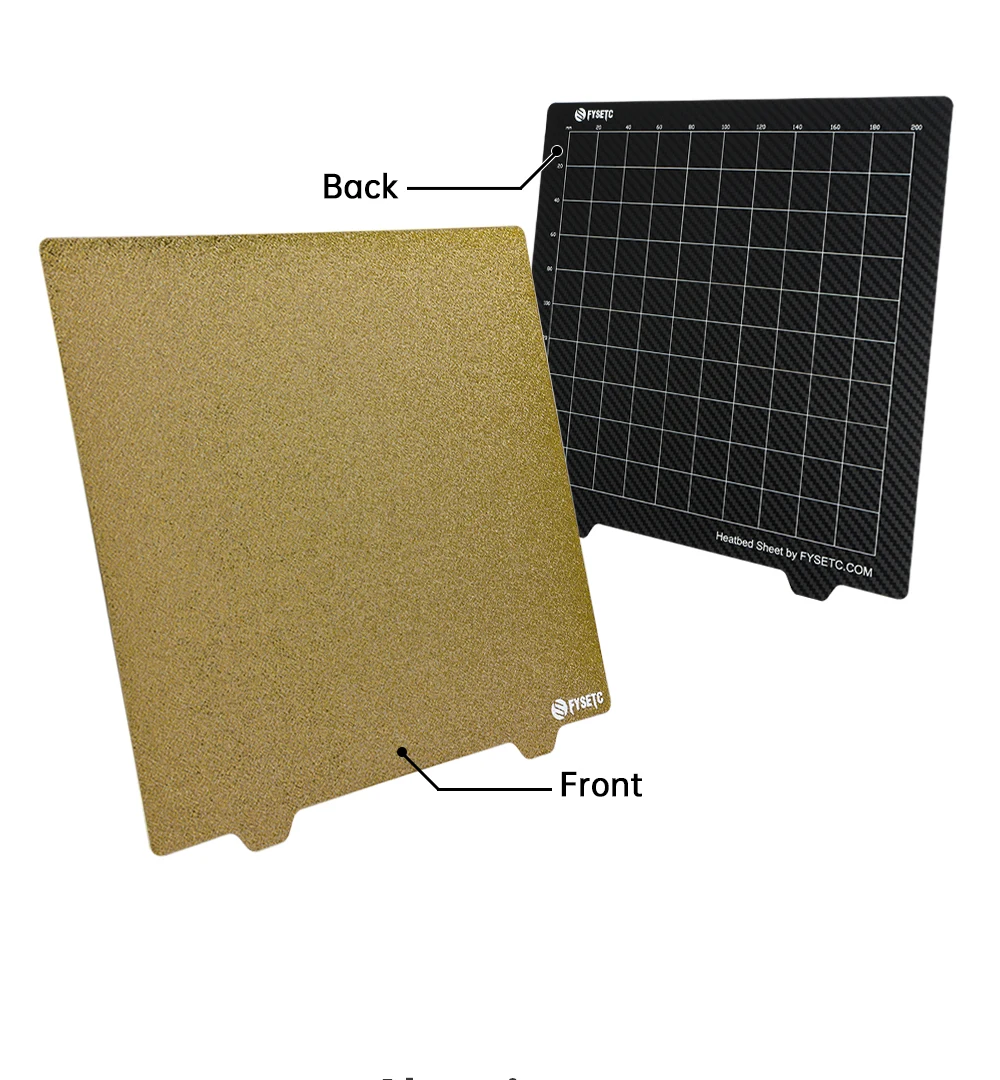

1. Name: Dual Carbon Fiber & Textured PEI Coated Spring Steel Sheet

2. Material: one side of PEI powder coating, one side of PET material carbon fiber texture film

3. Temperature resistance: PEI powder coating (maximum temperature 190℃), PET carbon fiber texture film (maximum temperature 100℃)

Advantages of 4.

1) There are many types of consumables compatible with printing, supporting PLA, PETG, ABS, TPU, TPE, HIPS, PA-CF, WOOD and other consumables

2) Easy to take the mold. After printing and cooling, remove the steel plate and gently bend the model to detach

3) The use of high elastic folding stainless steel plate, bending resistance

4) High temperature resistance, large adhesion, frosted surface, do not apply glue printing ABS and other materials easy to warp edge

5) PET carbon fiber texture screen printing has size grid, easy to observe and locate

5. Precautions:

1. If the adhesion is not enough, use sandpaper to gently polish the surface to increase its adhesion.

2.PET carbon fiber texture surface temperature resistance 100℃, powder PEI surface temperature resistance 190℃, nozzle can not directly touch the panel, to prevent hot panel surface.

3. The distance between the leveling nozzle and the platform of the first layer is within 0.05-0.2mm to ensure the adhesion of consumables on the printing platform. The speed of the first layer is recommended to be 10-25mm/s, and the cooling fan needs to be turned off for printing of the first 1-3 layers.

4. Reference temperature of different consumables; PLA: 50-65℃, PETG: 70-80℃, TPU: 60-70℃, ABS: 90-100℃ (carbon fiber texture surface is not suitable for ABS)

5. The leveling nozzle should not be too low, if the nozzle scratches the platform, permanent damage will be caused, or the first layer is too low, which will cause too tight adhesion, leading to tearing the surface layer.

6. It is recommended to take the mold after cooling. The uncooled mold has strong adhesion and is easy to cause the surface to fall off.

7. Steel plate is a consumable with a service cycle. The correct way of use can prolong the service cycle. Please use according to the above requirements!