1PC LD-WS4810 DC Brushless Motor Driver Spindle Driver of CNC Engraving Machine

Main features:

1. Current loop design, high low-speed torque, smooth operation;

2. High torque, high speed output, maximum speed up to 20000rpm/min (depending on motor speed);

3. With pulse speed output, the motor speed can be observed at any time.

4. Speed regulation mode: 0-5V analog and 10 Hz-300 Hz PWM speed regulation, convenient for users to use;

5. Input of start-stop enabling control signal and direction signal;

6. Over-current, over-voltage, stop-up and phase-out protection functions.

Functional overview:

The default mode of standard factory is square-wave Hall-free open-loop mode, which can be written into

different programs according to the needs of different customers to realize the closed-loop control of square

-wave Hall-free speed, square-wave Hall-free control, square-wave Hall-free speed closed-loop control and

other control modes.

- Electrical properties (ambient temperature Tj = 25 C):

- Power supply: DC 18V-50V DC power supply, capacity according to motor power selection

- Output current: peak 5.0 A

- Rated power: maximum 240W

- Insulation resistance: 500 M at room temperature

- Insulation strength: 0.5KV, 1 minute at room temperature and pressure

Using environmental parameters:

Cooling mode: natural air cooling (forced air cooling is recommended)

Use environment: 0 ~+50, <80% RH, 5.9m/s 2 Max

Preservation temperature: - 20 ~65 ~

Shape size: 96 x 61.5 x 27.5 mm

Weight: about 0.15Kg

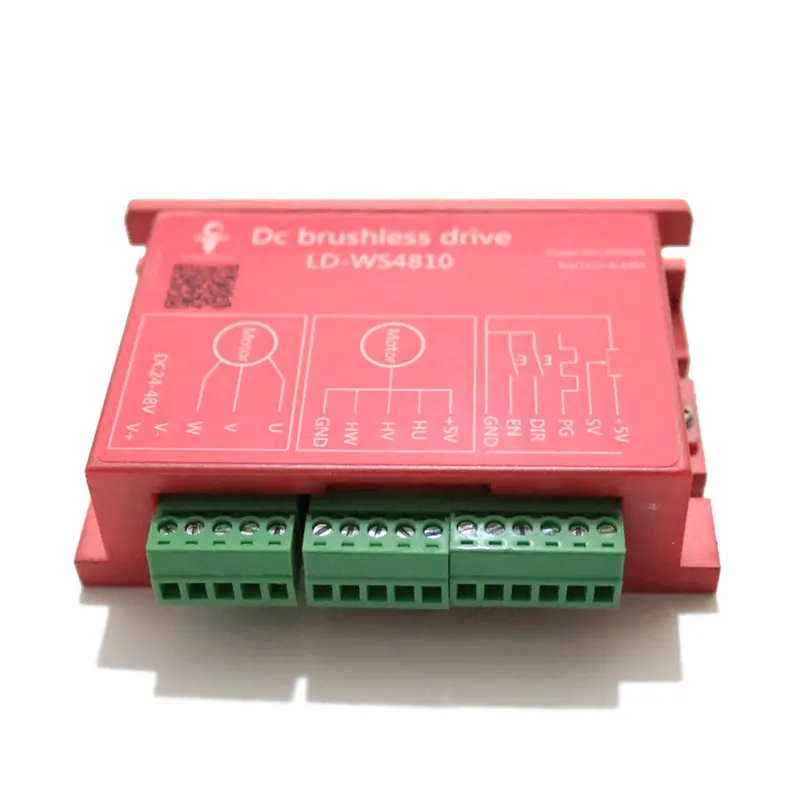

Port description:

POWER: Green power indicator, power on indicates normal power supply

ALARM: Red state indicator, slow flash waiting, flash operation, and with the motor speed change; often

illuminated for failure or offline

+5V1: Control signal power supply positive (built-in power output)

VSP: External speed control signal, through external potentiometer, etc. to achieve 0-100% motor speed

regulation

FG: Pulse output of motor speed, which can be converted into actual motor speed by measuring the

frequency of the signal.

DIR: High and low level control motor forward and reverse, connected to GND1 motor reverse, not

connected to GND1 or + 5V1 motor forward and reverse, in order to reduce the impact, it is better

to set EN high first, so that the motor stops working.

EN: Motor enabling control, EN connected to GND1, motor rotation (on-line state), EN not connected

or high level, motor non-rotation (off-line state, this state red light is always on)

GND1: Control signal power source

Hall signal terminal:

- +5V2: Hall power supply for motor

- HU: Hall sensor signal U phase input

- HV: Hall sensor signal V phase input

- HW: W phase input of Hall sensor signal

- GND2: Electric Hall Power Source

- Motor and power supply end:

- U, V, W: Three-phase output signal of motor connected with motor winding

- V-, V+: DC power supply input from 18V to 50V. (panel nominal DC24V~48V)

Functional description:

Speed control mode selection (VSP/PWM):

1. External input speed regulation: Two fixed ends of external potentiometer (5K~10K) are connected to

GND1 and+5V1 ends of driver respectively, and the regulating end is connected to VSP end. The external

potentiometer speed regulation can be realized by using external potentiometer, or by inputting analog

voltage to VSP end through other control units (such as PLC, MCU, etc.). The receiving range of VSP

port is DC 0V~+5V, corresponding to motor switching. Speed is 0~rated speed.

2. PWM speed regulation: connect the positive end of PWM to VSP, and the negative end to GND1.

The input frequency is 10Hz-300Hz, and the duty cycle is changed.

Speed measurement signal output (FG):

The driver provides the motor speed measurement pulse signal, which is proportional to the motor speed.

The output mode of the pulse is the open circuit output of the pull-up resistance 10K collector.

Speed calculation method: motor speed (RPM) = F_N *60

F = Frequency on FG foot measured by frequency meter

N = motor pole logarithm (2 pole motor N = 2; 4 pole motor N = 4)

For example, when the user chooses two pairs of pole motors, when the output FG signal is 600Hz,

the speed of the motor is 600_2*60=1800 rpm.

Direction/Inversion Signal (DIR): By controlling the high and low level conversion of DIR terminal,

the forward and reverse of motor can be controlled.

Note: In order to avoid sudden commutation and huge impact on motor and mechanical equipment

during high speed operation, when the DIR terminal receives the commutation signal, the driver first

slows down the motor until it stops. After stopping about 2S, the motor changes its direction and

increases its speed to the set speed.

Motor Start/Stop Signal (EN): By controlling the high and low level conversion of EN terminal,

the stop and operation of the motor can be controlled. When EN is high level, the motor works

normally; when EN is low level or short connection, the motor stops working and is in free state,

and the red light is always on. At this time, the power consumption of the driver is less than 20 mA.

The factory is set to EN and GND disconnection.

quantity: 1pc

warranty: 120 days

On Jan-04-22 at 05:02:59 PST, seller added the following information: