Product Description

10'' 3-Jaw Self-Centering Lathe Chuck

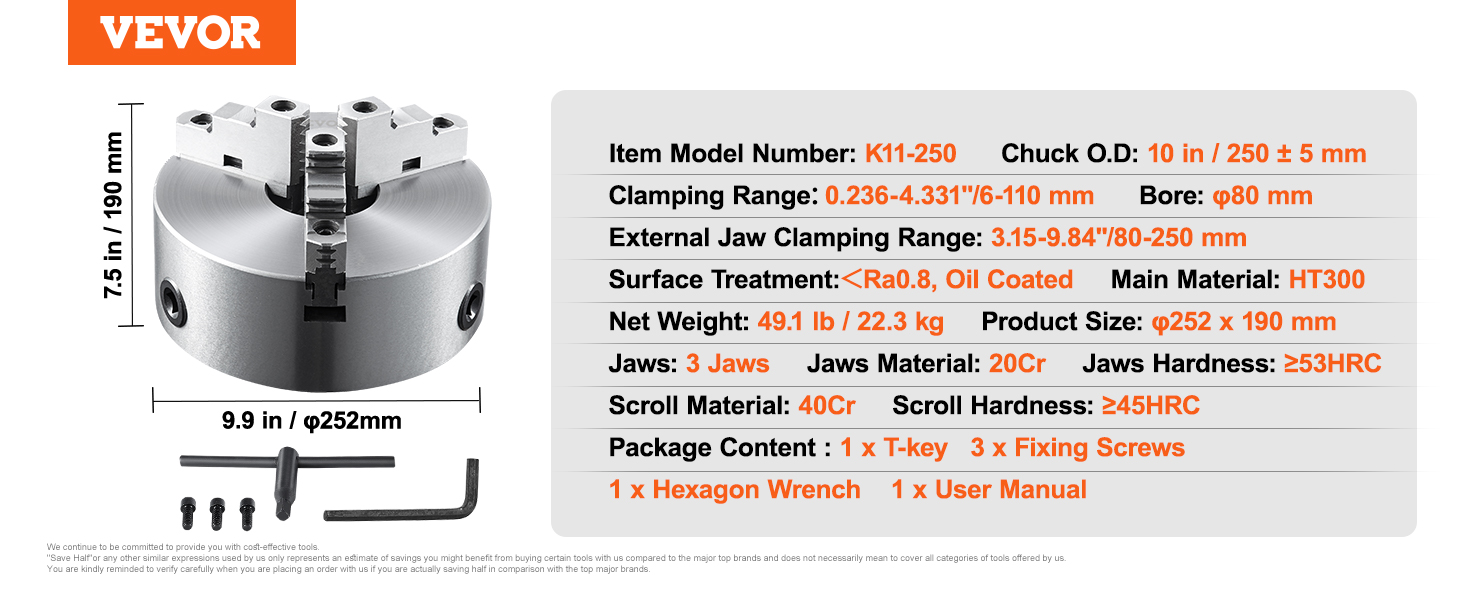

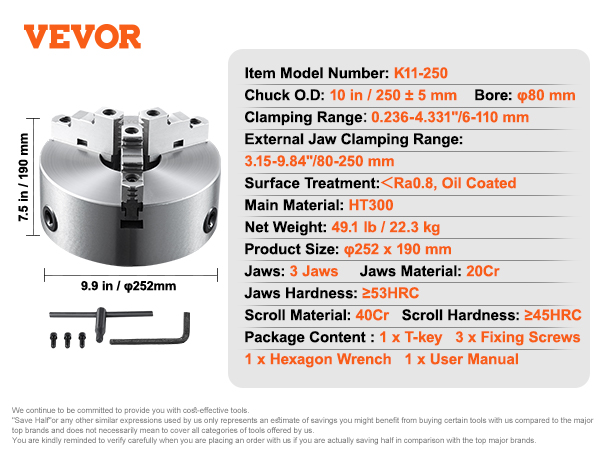

The 10'' 3-jaw lathe chuck is made of high-strength HT300 material with strong compression resistance and long service life. It can be used as internal and external jaws to clamp larger-sized industrial components and a self-centering function to avoid repeated calibration.

The 3-jaw chuck has a self-centering function and a bevel gear to precisely control the accuracy of the clamped workpiece for precise machining. Bearing tolerance ≤ 0.05 mm / 0.002" ensures the lathe chuck's structural stability and high accuracy.

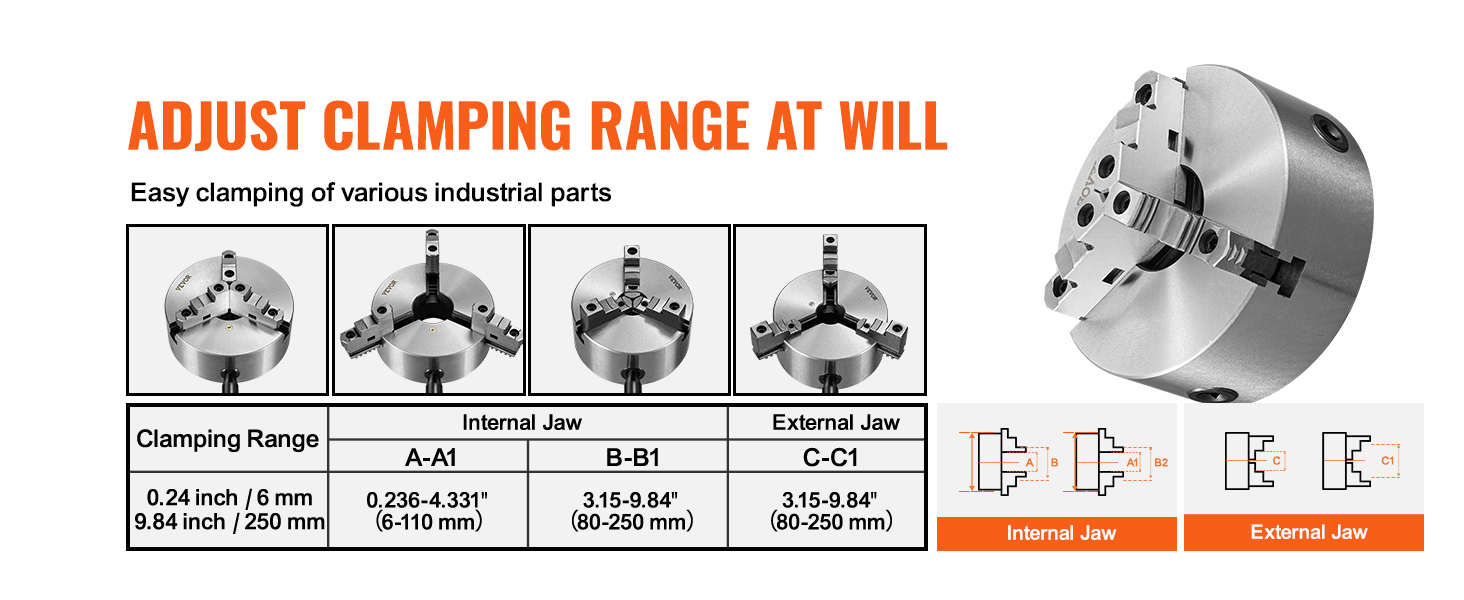

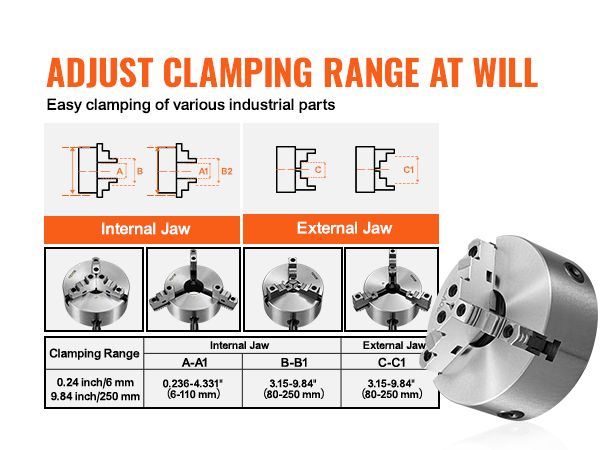

The chuck jaws can be used as both internal and external jaws, capable of clamping larger-sized industrial components. You can precisely clamp and secure various industrial components.

This chuck consists of a chuck body, movable chuck, and jaw drive with a simple structure. When clamping a work part, the chuck is able to find and hold the center of the part automatically. All you need to do is install them in the correct order.

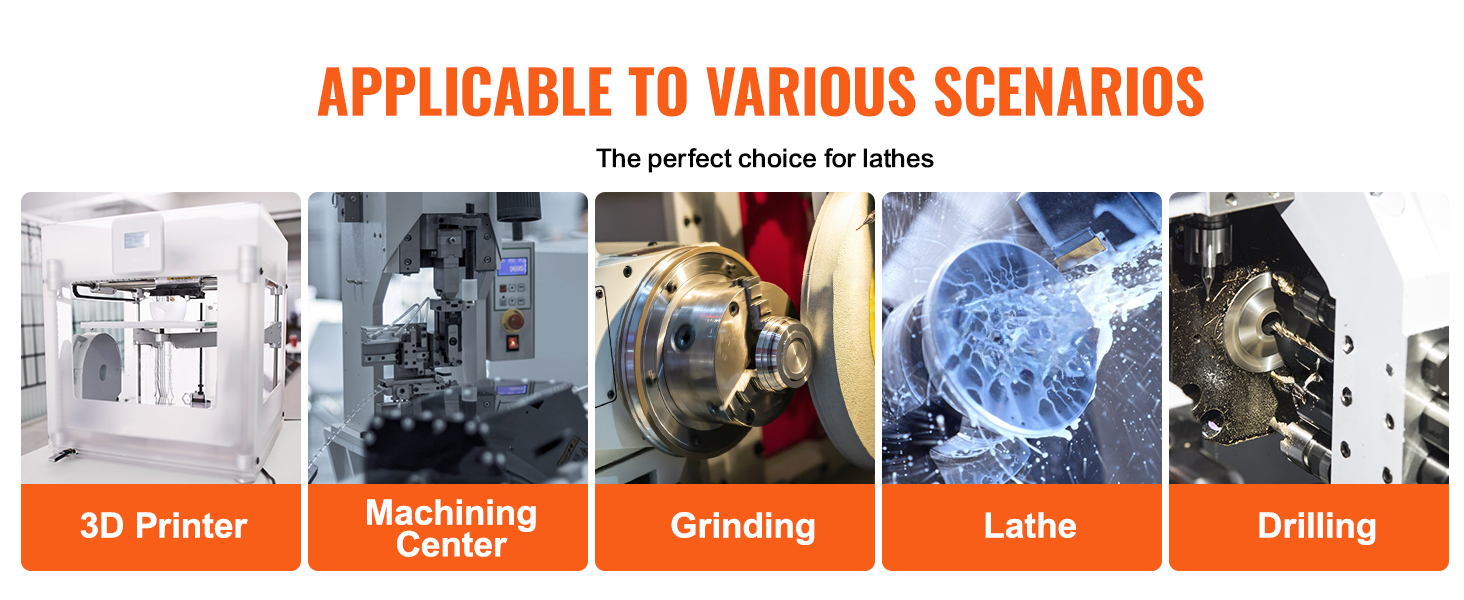

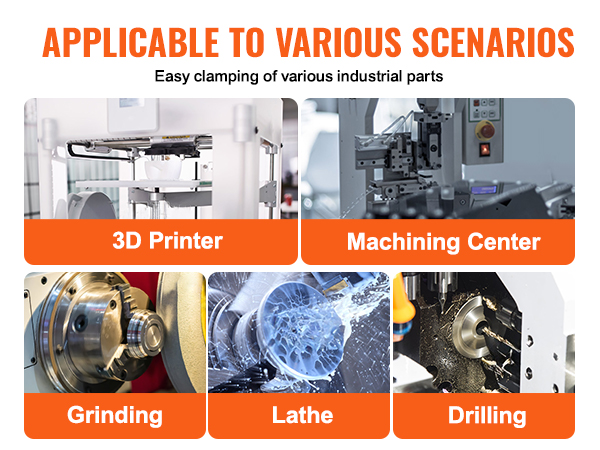

Whether you're working in woodworking, metalworking, drilling, or milling, our 3-jaw self-centering lathe chuck can meet your requirements for improved machining efficiencies and increased job flexibility and precision.

Features & Details

- Superior HT300 Material: Our 3-jaw lathe chuck is constructed from HT300 material, 20Cr steel chuck jaw with 53HRC hardness, and 40Cr steel scroll with 45HRC hardness. The lathe chuck is quenching hardened for superior hardness and rust resistance, providing outstanding working performance and reliability for both small and large workpieces.

- High Precision: A high-precision machining process is adopted to ensure the structural stability and machining accuracy of the 3-jaw chuck. The self-centering lathe part contains a delicate bevel gear and three pinion gears, which help to achieve precise machining progress. Bearing tolerance is ≤0.05 mm / 0.002 in.

- Dual-Use Jaw: The chuck jaws can be used as both internal jaw and external jaw. The external jaws are capable of clamping larger-sized industrial parts. 0.16-8 in/4-200 mm clamping range provides precise clamping and securing of various industrial components.

- Simple & Easy Operation: The 3-jaw lathe chuck features a simple and compact structure, pursuing the best balance of function and reliability. The built-in self-centering function allows you to use it without repeated calibration. All you need to do is install it in the right order and use it with peace of mind.

- Applicable to Various Lathes: Our self-centering lathe chuck is highly adaptable to meet your usage requirements, whether you are working in metal machining, drilling, or milling. By using our lathe chuck, you can improve machining efficiency and operational flexibility, achieving accurate and consistent results.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR's products are sold in more than 200 countries and regions with 10 million plus members worldwide.

10'' 3-Jaw Self-Centering Lathe Chuck

The 10'' 3-jaw lathe chuck is made of high-strength HT300 material with strong compression resistance and long service life. It can be used as internal and external jaws to clamp larger-sized industrial components and a self-centering function to avoid repeated calibration.

The 3-jaw chuck has a self-centering function and a bevel gear to precisely control the accuracy of the clamped workpiece for precise machining. Bearing tolerance ≤ 0.05 mm / 0.002" ensures the lathe chuck's structural stability and high accuracy.

The chuck jaws can be used as both internal and external jaws, capable of clamping larger-sized industrial components. You can precisely clamp and secure various industrial components.

This chuck consists of a chuck body, movable chuck, and jaw drive with a simple structure. When clamping a work part, the chuck is able to find and hold the center of the part automatically. All you need to do is install them in the correct order.

Whether you're working in woodworking, metalworking, drilling, or milling, our 3-jaw self-centering lathe chuck can meet your requirements for improved machining efficiencies and increased job flexibility and precision.

Features & Details

- Superior HT300 Material: Our 3-jaw lathe chuck is constructed from HT300 material, 20Cr steel chuck jaw with 53HRC hardness, and 40Cr steel scroll with 45HRC hardness. The lathe chuck is quenching hardened for superior hardness and rust resistance, providing outstanding working performance and reliability for both small and large workpieces.

- High Precision: A high-precision machining process is adopted to ensure the structural stability and machining accuracy of the 3-jaw chuck. The self-centering lathe part contains a delicate bevel gear and three pinion gears, which help to achieve precise machining progress. Bearing tolerance is ≤0.05 mm / 0.002 in.

- Dual-Use Jaw: The chuck jaws can be used as both internal jaw and external jaw. The external jaws are capable of clamping larger-sized industrial parts. 0.16-8 in/4-200 mm clamping range provides precise clamping and securing of various industrial components.

- Simple & Easy Operation: The 3-jaw lathe chuck features a simple and compact structure, pursuing the best balance of function and reliability. The built-in self-centering function allows you to use it without repeated calibration. All you need to do is install it in the right order and use it with peace of mind.

- Applicable to Various Lathes: Our self-centering lathe chuck is highly adaptable to meet your usage requirements, whether you are working in metal machining, drilling, or milling. By using our lathe chuck, you can improve machining efficiency and operational flexibility, achieving accurate and consistent results.