|

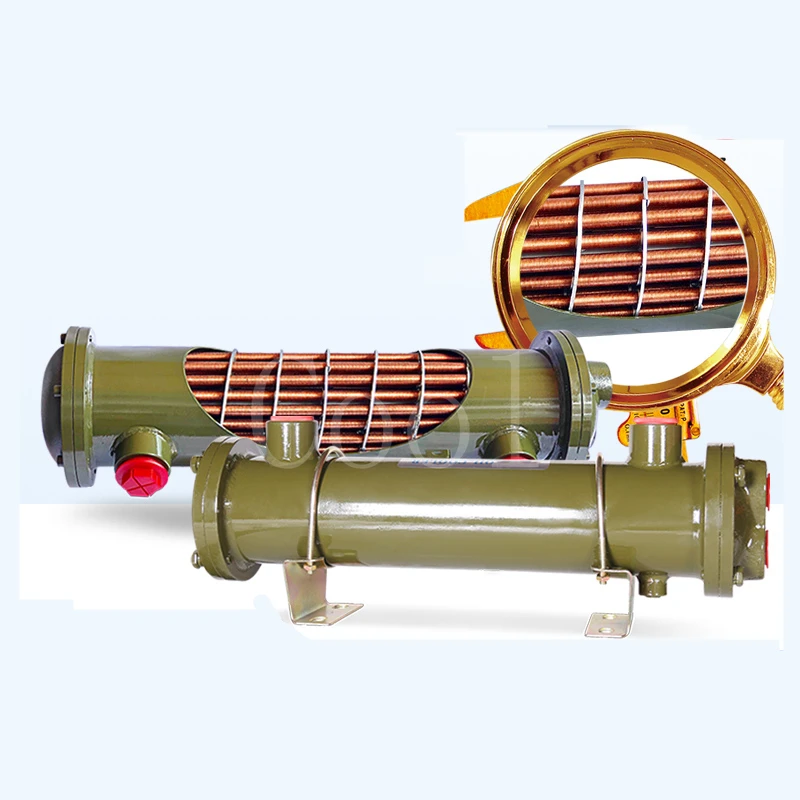

DC-303 Hydraulic Oil Water Cooler Tubular Oil Radiator Injection Molding Machine

Product name: DC series water cooler Product material: A3 material processing and forming, internal finned spiral tube design Product Features: Bare tube design has a wide heat transfer area; pure copper design is a good heat transfer tube; the plate tube and the main body are designed in an integrated manner, which is not easy to leak oil; easy to assemble, the bracket can rotate freely Product overview: The tubular water cooler is composed of shell/front cover/rear cover/cooling core, etc. The cooling core is composed of heat exchange tubes, fixed tube sheets, floating tube sheets, dismantling plates, support rods, and heat exchange tubes. The finned spiral tube is adopted; the foot seat can be rotated 360 degrees freely, and the foot seat can be directly welded to any position of the mother machine or oil tank, which is convenient and simple Water cooler use and operation: 1. The foundation of the cooler must be enough to prevent the equipment from sinking. Sufficient space should be reserved at the end of the fixed hole pan head so that the tube bundle can be pulled out from the shell. When the equipment is in place, it should be carried out according to the lifting specifications. Tighten the anchor screws to connect the inlet and outlet pipes of the hot and cold medium. 2. The air in the cavity should be exhausted before the cooler is started to improve the heat transfer efficiency. The steps are as follows: ① Loosen the vent plugs on the hot and cold medium ends, and close the medium discharge valve; ② Slowly open the water inlet valve of the hot and cold medium until the hot and cold medium overflows from the air vent, then tighten the air vent plug and close the water inlet valve. 3. When the water temperature rises by 5-10°C, open the water inlet valve of the cooling medium (Note: Do not open the water inlet valve quickly, because a large amount of cooling water flows through the cooler, it will cause a long-term formation of a surface of the heat exchanger. The "supercooled layer" with poor thermal conductivity of the layer), and then open the inlet and outlet valve of the heat medium to make it in a flowing state, and then pay attention to adjusting the flow rate of the cooling medium to keep the heat medium at the optimum temperature for use. 4. If galvanic corrosion occurs on the cooling water side, a zinc rod can be installed at the designated position. 5. Before the dirty medium passes through the cooler, a filter device should be provided. 6. The pressure of the cooling medium should be greater than the pressure of the cooling medium. Water cooler notes: 1. Before the dirty medium passes through the cooler, there should be a filter 2. It is best to install it in a separate circulating loop, because the pressure (tail end) is small. 3. When working, both circulation loops need to be exhausted to achieve high efficiency and avoid loop corrosion. 4. The cold medium is connected first, and then the hot medium is connected to achieve high efficiency and avoid corrosion of the circuit. 5. The pressure of the cooled medium should be greater than that of the cooling medium. 6. The cooling water is usually fresh water (special order is required when cooling with sea water). 7. Regularly exhaust and clean at intervals. 8. In the cold season and the cooler is not working, the water must be drained to avoid freezing. |