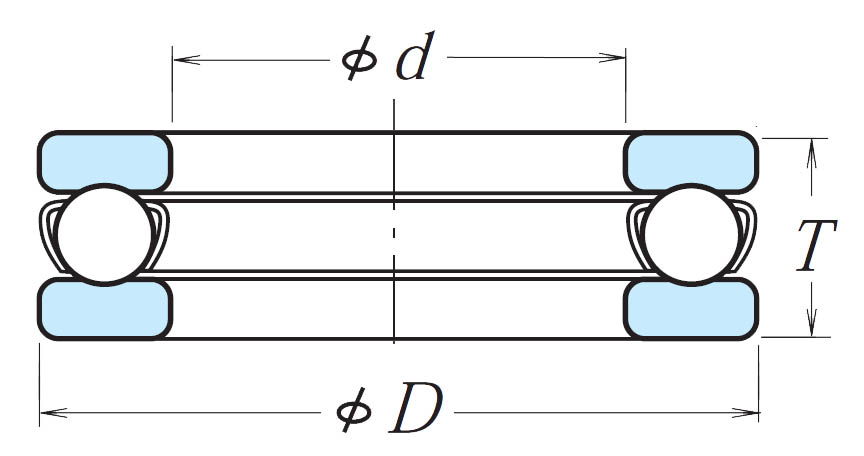

- Type: Full Ceramic Ball Bearing

- Cage: PTFE

- Balls: ZrO2 Ceramic

- Inner/outer races: ZrO2 Ceramic

- Package: 1set Ceramic plane thrust Bearing

1. high speed: with cold resistance, stress resistance to pressure, small elastic, thermal conductivity, light weight, the advantages of small friction coefficient, can be applied to 12000 rpm to 75000 rpm for high speed spindle and other high precision equipment;

2. high temperature resistant: use the temperature at 100 degrees to 600 degrees between the generated due to the range of temperature expansion. Can be used in furnaces, plastic, steel and other high temperature equipment;

3.corrosion resistance: the material itself has corrosion resistance characteristics, can be used in strong acid, strong alkali, inorganic, organic salt, water and other fields, such as: plating equipment, electronic equipment, chemical machinery, shipbuilding, and other medical equipment.

4. because of no magnetic, magnetic dust absorption, can reduce premature bearing flaking, big noise. Available in the demagnetization device. Precision instruments and other fields.

5. due to electrical resistance, electrical insulation, can avoid arc damage bearings, can be used in a variety of insulation of power equipment.

6. because of the unique ceramic materials, vacuum oil-free self-lubricating property, in ultra-high vacuum environment, zirconia ceramic bearings can overcome the plain bearing can not realize the problems of lubrication.

Main uses: Medical equipment, optical instruments, printing machinery, machine tools, high-speed motor, low temperature engineering, food processing machinery

| Bearing number | Bore Diameter (d) | Outside Diameter (D) | Width (T) |

| 51100 | 10 | 24 | 9 |

| 51101 | 12 | 26 | 9 |

| 51102 | 15 | 28 | 9 |

| 51103 | 17 | 30 | 9 |

| 51104 | 20 | 35 | 10 |

| 51105 | 25 | 42 | 11 |

| 51106 | 30 | 47 | 11 |

| 51107 | 35 | 52 | 12 |

| 51108 | 40 | 60 | 13 |

| 51109 | 45 | 65 | 14 |

| 51110 | 50 | 70 | 14 |

| 51111 | 55 | 78 | 16 |

| 51112 | 60 | 85 | 17 |

| 51113 | 65 | 90 | 18 |

| 51114 | 70 | 95 | 18 |

| 51115 | 75 | 100 | 19 |

| 51116 | 80 | 105 | 19 |

| 51117 | 85 | 110 | 19 |

| 51118 | 90 | 120 | 22 |

| 51120 | 100 | 135 | 25 |