10000W 220V / 400V Kaplan Turbine Hydropower Generator Hydroelectric Water Wheel Power

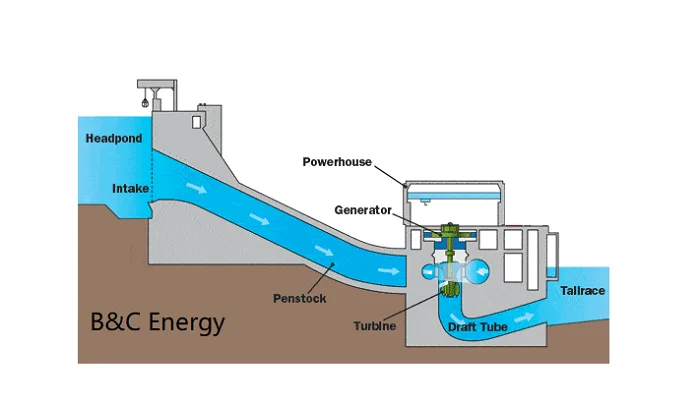

The axial flow hydroelectric generator is composed of a water turbine and a generator coaxial. The water turbine is mainly composed of water blades, guide covers, bearings, water seals, main shafts, etc. Axial flow turbine generator mainly uses the Draft tube of corresponding height to form a vacuum suction pipe. The incoming water from the upstream is pulled to form a swirl through the vortex chamber, and the jet water blades rotate at high speed, driving the generator to work through the main shaft.

- Rated Power: 10000W

- Voltage: Single phase 220V 50HZ

- Water Flow:0.2m3/s

- Water Head: 4m-9m

- Speed: 1500 r/min

- Current: 43A

- Rated Power: 10000W

- Voltage: 3 phase 400V

- Water Flow:0.24m3/s

- Water Head: 5m-10m

- Speed: 1500 r/min

- Current: 25A

Product structure of axial flow hydro generator:

(1) Bearing cover

(2) Upper cover

(3) Bearings

(4) Rotor

(5) Stator coil

(6) Motor barrel

(7) Lower seat

(8) Bearings

(9) Oil seal

(10) Casing

(11) Water cone

(12) Water guide cover

(13) Runner

(14) Spring pad

(15) Nut

(16) Split pin

(1) Bearing cover

(2) Upper cover

(3) Bearings

(4) Rotor

(5) Stator coil

(6) Motor barrel

(7) Lower seat

(8) Bearings

(9) Oil seal

(10) Casing

(11) Water cone

(12) Water guide cover

(13) Runner

(14) Spring pad

(15) Nut

(16) Split pin

When selecting the type, the corresponding unit should be selected based on the head and flow of local water resources. The rated operating head of this series of units is 1.2-5 meters, and the flow rate is 0.02-0.2 m³ /s .

The generating capacity of the unit can be calculated by the formula N=n₁n₂gHQ. In the formula: N - generating power (KW);

N1 - unit efficiency (estimated to be 0.4~0.5)

n2, - diversion efficiency (estimated to be 0.80~0.95)

g - Gravitational acceleration (9.8m²/s)

H - Power generation head (M)

Q - Flow rate (m³/s)

The generating capacity of the unit can be calculated by the formula N=n₁n₂gHQ. In the formula: N - generating power (KW);

N1 - unit efficiency (estimated to be 0.4~0.5)

n2, - diversion efficiency (estimated to be 0.80~0.95)

g - Gravitational acceleration (9.8m²/s)

H - Power generation head (M)

Q - Flow rate (m³/s)

Product Description:

Way of working

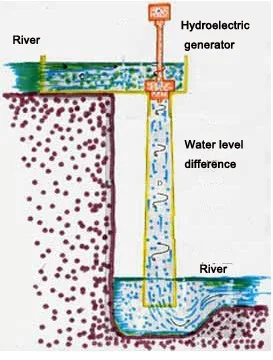

Axial flow small hydro-generators are mainly used in places where water flow drop is relatively low, such as small rivers and small creek.

The axial flow small hydro generator is mainly composed of a generator and an impeller coaxial.

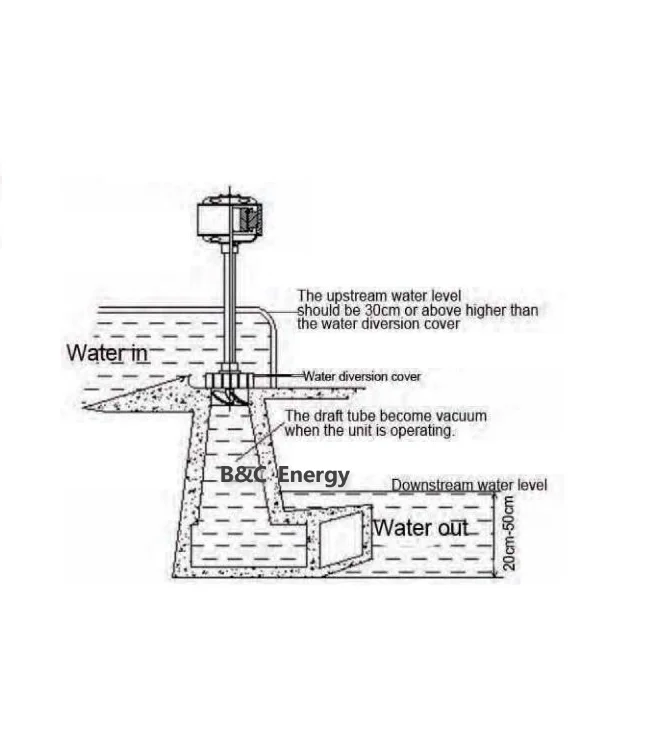

Working principle and installation method:

First, plan the installation site, generally next to it, or where there are rocks underneath. Use concrete and stone to build the inlet channel; use a wooden board to make a switch sluice; use a wire mesh to make a garbage baffle to form the water inlet system.

Use a concrete and stone to build a spiral flat channel according to the model, so that the water forms a vortex and drives the impeller to rotate.

Under the spiral plane, a small, large, horn-shaped draft tube is built, which is mainly used to make the water form a suction force inside, and attract the impeller downward, thereby generating strong power to drive the generator.

Therefore, the power of the generator is mainly from the draft tube, and the length of the draft tube is the drop of the water flow, called the water head. Small axial flow hydro generators generally work between 1 and 6 meters of water head.