Comparison chart of standard and upgraded punching machines

Ultrasonic drilling machines can be used for drilling and engraving of some high hardness materials such as crystal, gemstone, agate, jade, glassware, ceramics and enamel, silicon, etc. The machine uses high-efficiency transducers, which have the advantages of low noise, high efficiency and power saving.

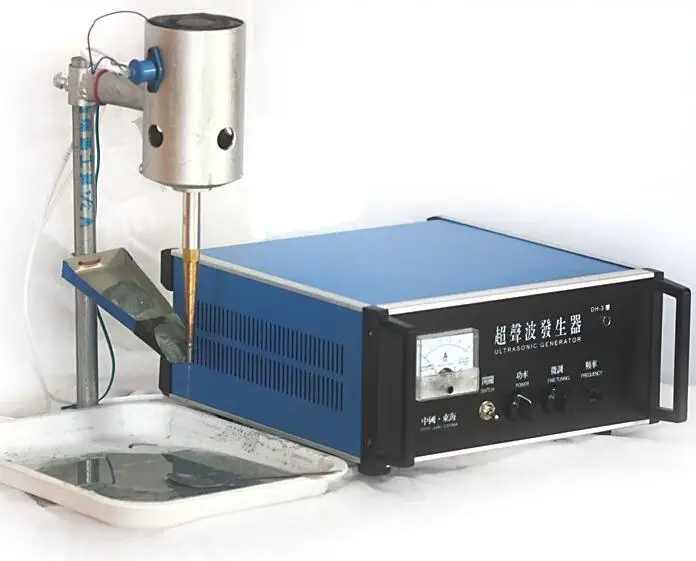

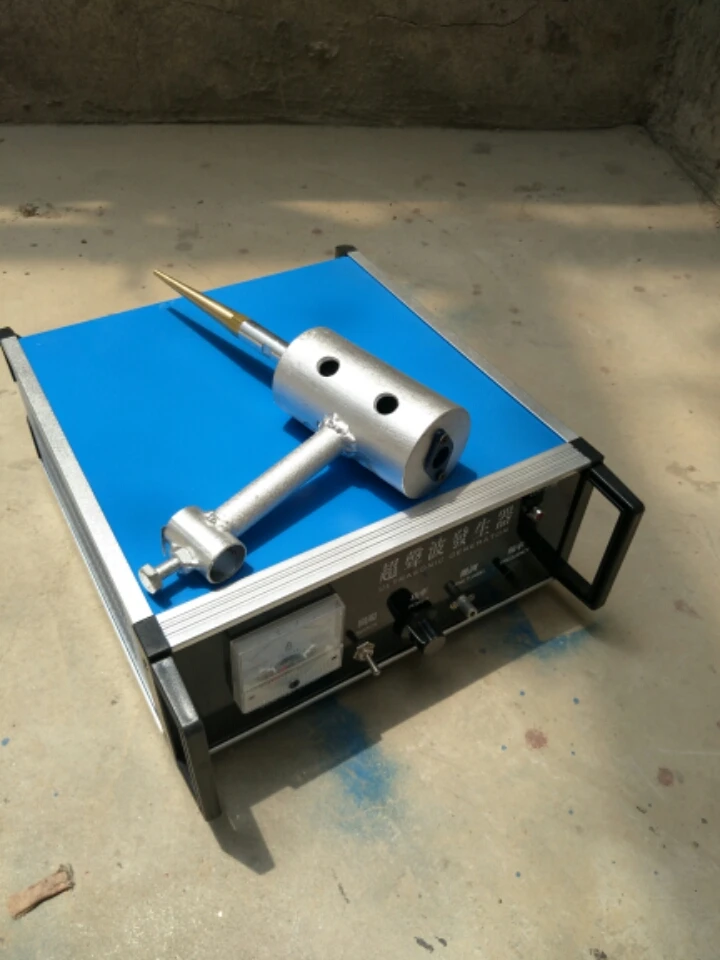

The machine is divided into two parts: the ultrasonic generator and the processing head.

First, the ultrasonic generator:

The ultrasonic generator consists of three stages of oscillation, push and power amplifier, which can generate ultrasonic signals with a variable frequency of 17--25KH, providing vibration energy for processing.

Second, the processing machine head:

It converts the ultrasonic energy of the generator into mechanical vibration energy through the transducer, and the vibrating head causes the grinding powder and water to repeatedly move to grind the workpiece to be processed. It can process high quality holes of any shape on hard materials.

Instructions

1. First confirm that the power switch is off, then insert the multi-pin plug into the rear of the generator and the corresponding socket, and insert it tightly. The power input must have a ground wire.

2. Turn on the 220V AC power supply, turn on the power switch, the power indicator light is on, observe the ammeter, and the indication should be zero. Adjust the zoom knob clockwise so that the ammeter is about 0~2A, and the current should not be too large, otherwise the component will be damaged.

3, the frequency is coarse. Pay attention to the water flow on the needle when the water flow becomes foggy.

4, the frequency is fine-tuned. Look at the water flow on the needle, and it is best to make a hazy sound.

5, the speed of the hole and the amount of water flow and abrasive, the thickness of the abrasive, the size of the working current, the quality of the needle welding, the contact between the copper rod and the transducer is tight, the cleaning rate and other factors are related. After practice, you can gain experience and increase speed. In the process of using the user, if there is no wave, weak wave or unstable, it is usually caused by the above reasons, and the user can check and solve it by himself.

6, welding needle:

(1) One end of the steel needle (10MM) is ground with a sand cloth, and the solder is placed on it.

(2) Use a 100W soldering iron plane to heat the solder on the side of the tip of the copper rod, melt the solder, pull out the old needle, insert a new needle, and evenly wrap the solder on the root of the needle. The tip of the copper rod is stabilized upward (needle up) It can be used after it has been cooled.

(3) The user must also weld a thin solder on the front end of the copper rod (the part where the flowing sand flows) to protect the copper rod and extend the service life of the copper rod.

Specifications:

Voltage: 220v/50Hz

Power: 100W

Motor cooling method: blower(built-in)

Transducer cooling method: blower

Working frequency: 17--23K(adjustable)

Hole diameter: 0.8mm, 1.0mm, 1.2mm, 1.5mm

Application range: crystal, glass, agate, jade, emerald, ceramics, etc.