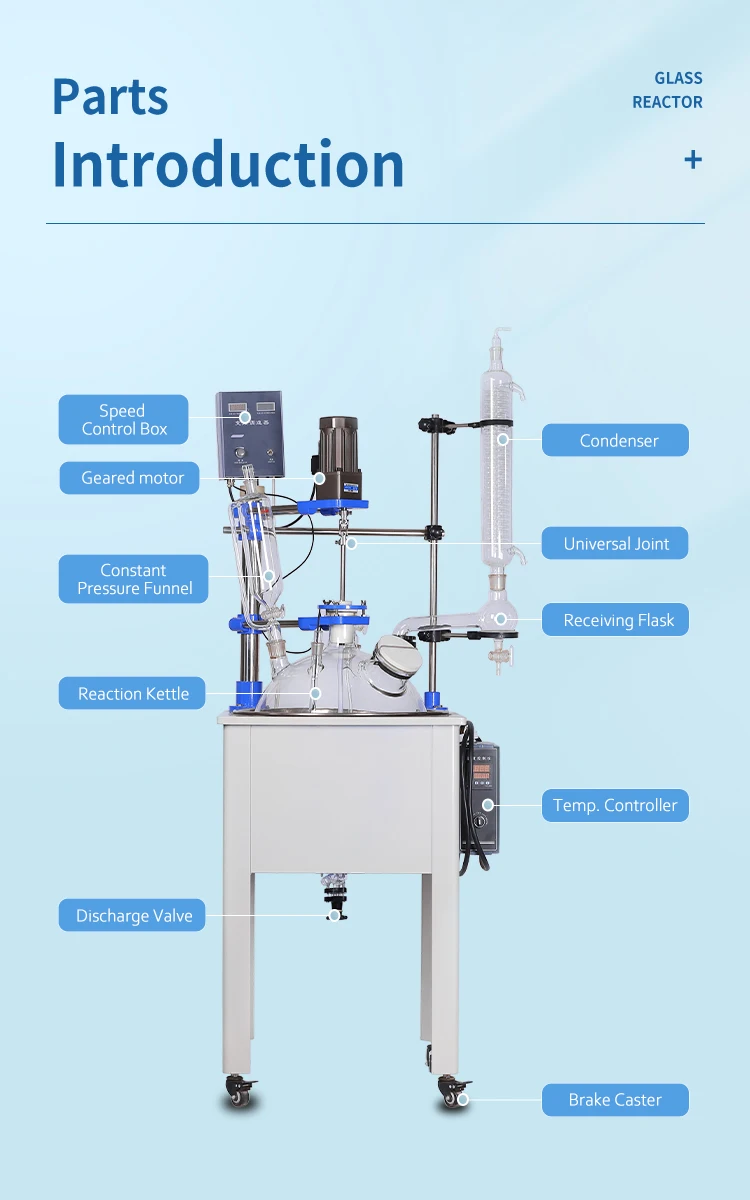

The working principle and application range of the Single Layer Glass Reactor: under the constant temperature condition, in the closed glass reactor, the stirring reaction can be carried out under normal pressure or negative pressure according to the use requirements, and the reaction solution can be refluxed. With distillation, the reaction is completed, the material can be discharged from the discharge port of the bottom of the kettle, and the operation is extremely convenient. It is an ideal pilot and production equipment for the synthesis of modern fine chemical plants, bio-pharmaceuticals, and new materials.

Single Layer Glass Reactor

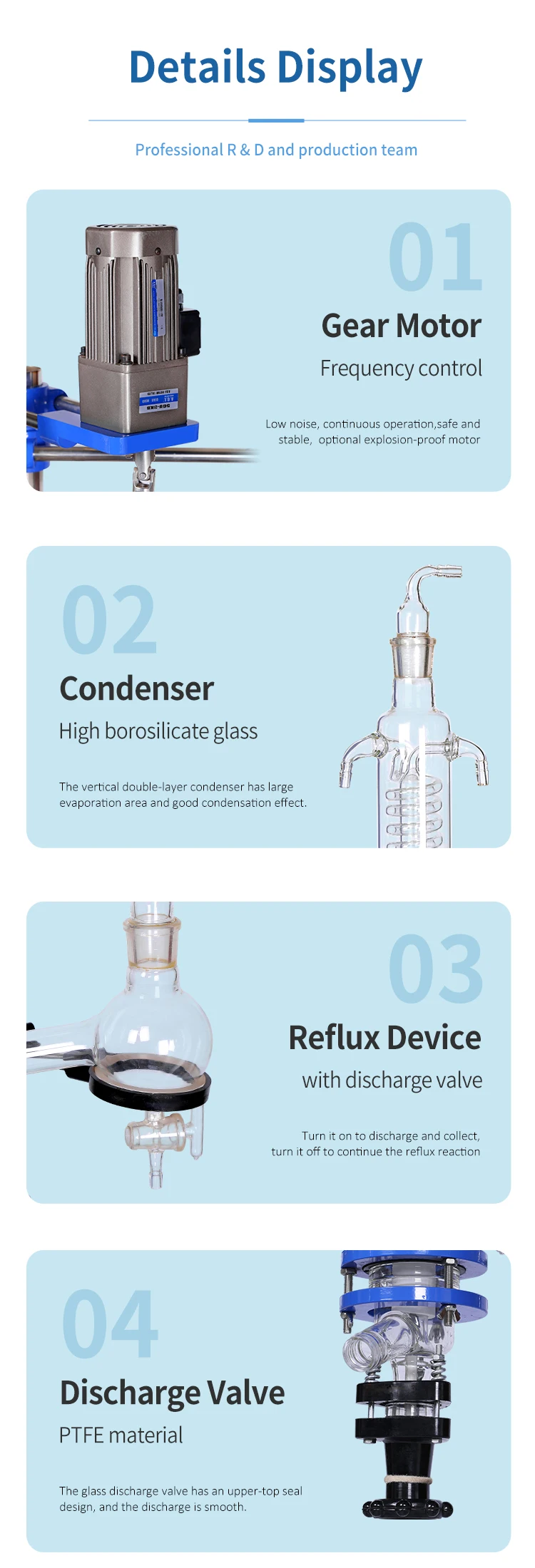

All glassware is from First-class high-borosilicate glass that is heat/cold/corrosion-resistant, owns excellent chemical and physical performance.

Overall Stainless steel (304)frame and screw with strong support and hardness.

Its temperature using range is RT-250°C,Temperature can be customized to 350℃.

Imported high torque reinforcement electrical machine, frequency conversion constant temperature stirring system, stable working state.

Corrosion resistant discharge valve is without dead space design. solids / liquid material can be easily released from below.

- Payment should be completed within 4 (Four) days of auction closing. Or unpaid dispute will be filed for closing auction.

- We will leave a positive feedback immediately after payment is received. We appreciate a positive feedback as much as you do. If for some reason there is any issue with the purchase, please contact us prior to leaving feedback, we will be glad to work together and provide a satisfying solution.

- We only ship the item to the eBay Verified address that is sent to us at the time of checkout, most shipment will be shipped within 1-5 business day. Please verify the correct shipping address in your eBay account before making your payment. Shipping time during holidays may take longer than normal.

- Any brokerage, customs, and duty fees associated with international shipments are the customer's responsibility and are not included in our shipping charges.

- If you are located outside of the continental 48 United States, please email us in advance to see if the specific item ships to your location. These orders are generally shipped within 1-5 days after payment is received.

- Please be patient as they are often subject to additional inspection upon delivery.

- All of our items are backed with a 30-day return policy. We ensure all our items are new and in excellent condition prior to shipping. In case you receive the item that is not to the standards above, please contact us via e-Bay messages. All returns must be in new original condition as received and should be shipped with delivery confirmation

- Please note that all returns must be pre-approved by us. Unauthorized returns will not be accepted. If you need to return, please check twice to confirm the item not work and contact our customer service representative, let us know the detailed problem and send us some pictures for confirmation.

- We ONLY accept returns with original package. Please make sure that item has NO man-made sabotage. Used items will not be accepted for return.

- We are a comprehensive company specializing in the research and development, production and sales of lab related equipment. Company tenet: Respect reputation and contract, provide high-quality and low-cost equipment for serve scientific research.

- We believe that it is our vision and mission to provide innovative products with best service and competitive price to satisfy you. Our goal is to make sure that you can find exactly what you are looking for and make it easy for you to place your orders.

- Email Customer Support:

- 9:00am-2:00am PST Sunday-Friday

- All emails will be responded to within 12-24 hours