Advertising Cloth Heat Sealing Inkjet Cloth Splicing Machine Grid Cloth Welding Machine Lamp Cloth Pvc Material Splicing

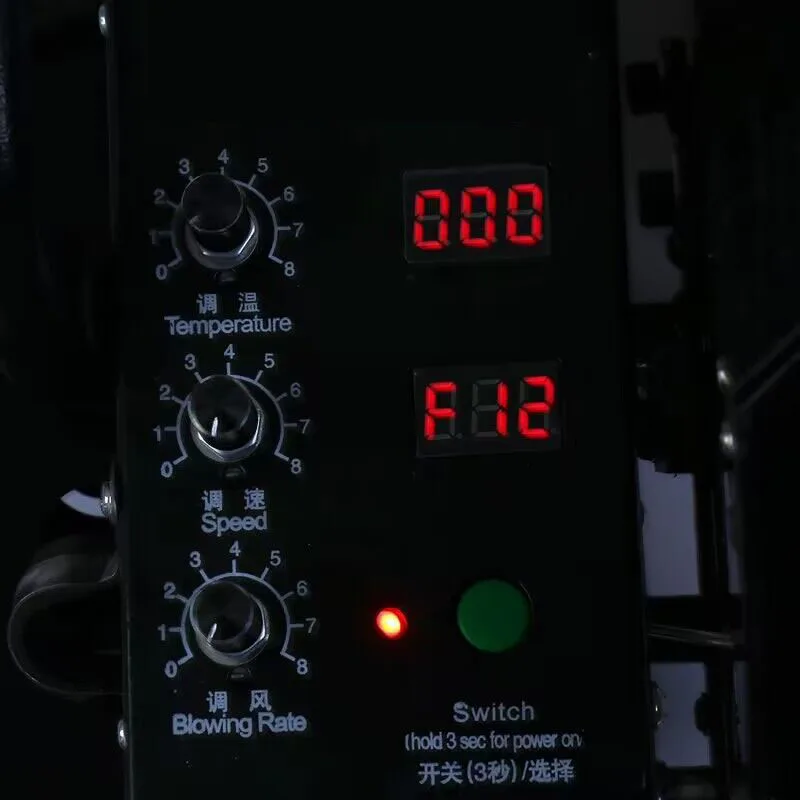

AC voltage:220V/50Hz

Power consumption:2000W, average 1500W

Heating temperature: high 750 degrees

Adjustable working temperature: 0-600 degrees

Heating output temperature: 50-480

Air flow: 40-100

Fan voltage display value: 12-28

Automatic sleep timing: no operation within 15 minutes

Adjustable self-propelled splicing speed: 0.8-15 m/min

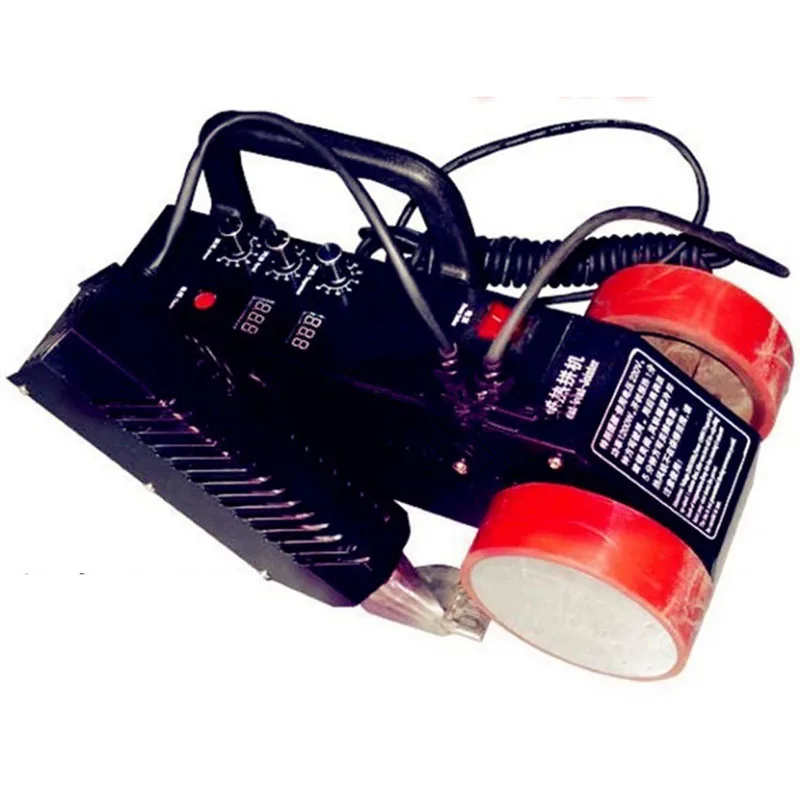

Full weight: 12 kg

Package size: 52*52*22cm

Ink-painted cloth, light box cloth, PVC tarpaulin, flail net canvas, awning and other coated film structures (polyethylene, polypropylene, polyvinyl chloride and other heat-meltable materials) plane splicing.

●2. Operation method:

Lay the edges of the two pieces of the spray painting picture to be spliced up and down according to the lap width of 30-40CM, and use adhesive tape or clips to fix them at the two ends at a distance of 40CM from the seam;

●Turn on the power button of the hot stamping machine, turn on the temperature and speed knobs respectively, set the speed and temperature according to the cloth thickness, material and ground conditions, and start preheating for about 2 minutes;

●Put the machine on the overlapping lamination of the ends of the two inkjet splices, and align the rollers with the edge of the seam;

●Turn the end handle to the left, insert the hot air nozzle into the upper and lower seam layers of the inkjet splice, and start splicing;

After the hot air nozzle is inserted into the gap between the upper and lower splicing screens, the machine will start to move by itself. During the crimping process, you can lightly hold the left handle to control the direction to adjust the running deviation, and make the edge of the upper splice contact with the inner side of the nozzle ;

●When splicing reaches the end of the screen, pull the handle at the end to the right to lift the hot air nozzle away from the gap between the upper and lower splices, and then stop the machine, and you're done.

●Special reminder: After finishing the work, in order to protect the electric heating core from premature aging, it is necessary to do cooling treatment: turn on the hot air head, reset the temperature adjustment knob to zero, and then turn off the power button of the machine after 5 minutes to stop the fan rotation . In the event of special circumstances during work, such as a sudden power failure, you must first turn on the hot air head, then return the temperature control knob to zero, and then consider the problem of power on.

●3. Automatic sleep: If the machine has no operation within 15 minutes, it will automatically enter the sleep state to save energy. (Automatically stop heating at the 12th minute, and automatically turn off the power at the 15th minute), press ( Select) key will restart.

Reasons to choose us!

1. High-power splicing uses a 3-second switch. When not working, start the switch and automatically sleep for 50 seconds to protect the heating core and save power

2. The air gun adopts an isolation net cover, and the air gun part is safe for long-term high-temperature work, and the operation is stable without being hot

3. It adopts high-torque motor, precision reducer, super heat-resistant rubber rolling wheel, fine-processed aluminum alloy material, high-performance hot air blower, and the key parts are reinforced twice, so it is durable and simple in structure. The structure adopts modules components for easy maintenance.