Good News:

Ship from Germany to below EU Countries. | ||||

fast shipping by DHL to EU Customers. | ||||

Austria | Belgium | Bulgaria | CzechRepublic | Denmark |

Estonia | Finland | France | Germany | Greece |

Hungary | Ireland | Italy | Latvia | Lithuania |

Luxembourg | Netherlands | Poland | Portugal | Romania |

Slovakia | Slovenia | Spain | Sweden | UnitedKingdom |

1-2 days to: Germany2-4 days to: Austria,France,Spain and Italy3-5 days to: UK4-5 days to: Other Europe Countries

Parcel included:

- 1 x 4 Axis DDCSV3.1 Offline standalone Motion Controller

- 1 x 4GB USB Flash Drive

- 1 x USB Extension Cable

- user manual

1.Digital Dream is a numerical control company specializing in the research, development and production of various CNC (Computer Numerical Control) systems since 2008. Digital Dream

2.aims to combine high quality and high reliability with affordability. The DDCS is a 3~4 axis motion controller for stepper and servo systems. DDCS V3.1 is updated from DDCS V2.1 on software and hardware.We are very proud of this product, it combines .great power with a tiny footprint and is easy to use. After a very short time you will be familiar with the functions and this manual will help you.

3.The highest output pulse per axis is 500KHz. This provides high control precision for stepper motors and servo motors.

4.The DDCS numerical control system adopts the ARM+FPGA design framework. ARM controls the human-computer interface and code analysis and the FPGA provides the underlying algorithms and creates the control pulse. This guarantees reliable control and easy operation.

5.The internal operating system is Linux based. The panel layout structure of the DDCS V3.1 is very rational to save space. All operations are controlled by only 17 keys and a comprehensive G code set is supported. The DDCS can be used for many styles and types of CNC machines. Lathes, Routers, Pick and Place and Mills are just a few examples. The DDCS operates as a Stand Alone system without the need of a computer. This guarantees high precision, accuracy and reliability. The interface, even very comprehensive, can be learned in a very short time.

6.Digital Dream Standalone Motion Controller DDCS V3.1 Page -4 DDCS V3.1 Users Manual 1.2 DDCS V3.1 Brief technical feature

1.1 Introduction

DDCSV3.1 is the 4 axis motion controller which has been researched and developed by Faster CNC for four years. The control period of each position is only 4 milliseconds, with a high control precision. The highest uniaxial output pulse is 500KHz and the pulse width can be adjusted. It supports the common stepper motor and servo motor.

DDCSV3.1 numerical control system adopts the ARM+FPGA design framework. The ARM can finish the part of human-computer interface and code analysis and the FPGA can finish the part of underlying algorithm and control pulse generate, with the reasonable design, reliable control and easy operation.

The panel layout structure of DDCSV3.1 is rational. The CNC MOTION SYSTEM Controller can be finished only by 17 keys and it supports the FANUC with high universality to be compatible with G code set.

This manual introduces the operation method of the DDCSV3.1,the machine tool and the operation procedure of the machine tool. By lots of graphical representation and examples, the uses can quickly learn to use the DDCSV3.1 CNC system.

DDCS V3.1 Brief technical feature:

1) 16 photoelectric isolated digital inputs,3 photoelectric isolated digital outputs;

2) 3.1 Version enhenced Algorithm,support soft interpolation,fixed arc interpolation bug of the old version;

3) Analog spindle control 0-10V spindle control (can be modified as PWM output);

4) 3-4 axis motor Control.Differential Pulse and direction output signal,Max.500Khz per axis;

5) ARM9 main control chip,FPGA core algorithm chip;

6) 5 inches TFT screen, resolution ratio: 480x272,17 operation keys;

7) The Power Supply for the controller is 24VDC, minimum Current is 0.5A;

8) The Power Supply for IO Port is 24VDC,minimum current is 0.5A;By the IO power supply,system already supply the power for IO ports.So no need the external power supply for IO port anymore;

9) USB flash disk support for G code file input,no size limited of the G-code file ;

10) Support standard MPG;

11) Jog function for each axis (continuous, step, defined distance);Customer can define the distance;

12) Support the operation of quickly specify the running position;

13) Support for “Power Cut” recovery. Data is automatically saved;

14) The controller only support NPN type limited switch.

1.3 Outward Appearance, Structure and Size

The DDCS V3.1 is a small box that can fit in a window of a small control box or control cabinet.

Four locking hooks fix this controller from the frame.

The front panel is 191mm*128mm*5mm;

The main body is 191mm*128mm*37mm;

To mount the unit in an equipment c abinet, cut the hole182.5mm*59mm

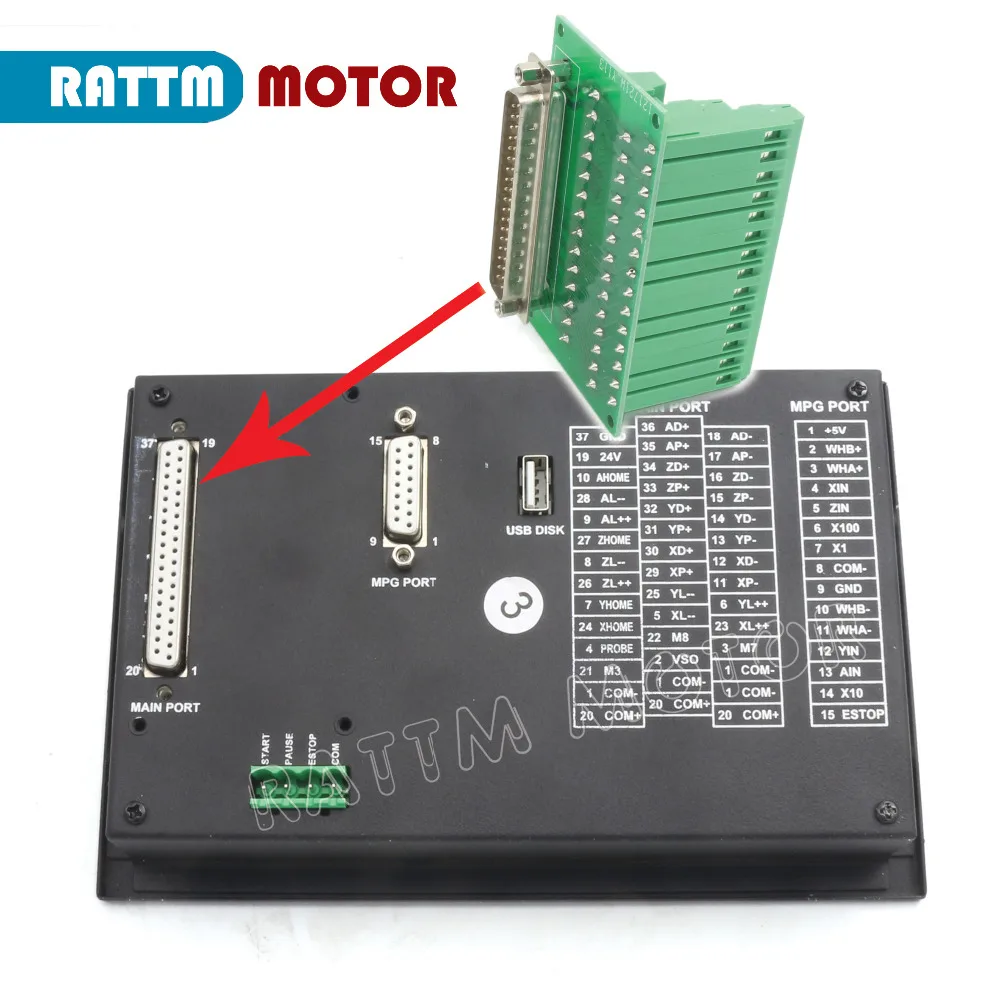

The front of the product is 17 user keys and 1 4.3’’and 480*272 LSD (Liquid Crystal Display), and the reverse side is input signal, spindle control, stepper/ servo control, MPG and other four sets of interfaces as well as USB interface and power interface. Please look at the reference picture 1-3 and picture 1-4 in detail.

This USB Interface is the standard USB socket of A-type, attached a 50cm USB extension cord with installation lugs.

1.4 Explanation of Abbreviations

When operating the DDCS, the users will come across some English abbreviations. Here a list with explanations

FRO: Feed Rate Override

SRO: Spindle Rate Override

SRJ: Jog Speed Setting

F: Feed rate, unit is mm/min

S: Spindle Speed, unit rev/min.

X: The coordinate code of the X axis.

Y: The coordinate code of the Y axis.

Z: The coordinate code of the Z axis.

A: The coordinate code of the A axis

BUSY: The system is busy. You still can adjust FRO and SRO

READY: READY mode, any operation can be done

RESET: Reset mode, controller is in“ OFF” mode, no operation can be performed

CONT: Continuous mode, each axis can be manually jogged with the arrow keys

Step :Manual Step Mode,each axis can be jogged in defined steps

MPG: MPG mode. Operate the machine with the MPG (Manual Pulse Gener ator)

AUTO: Run G code. Auto is showing when file is processing

Shipping

· Please open the package and check if there are some damages before sign, if there are some damages,please do not sign and contact us immediately

· We ship to worldwide but if your country’s custom is strict, please contact us before you bid to check detail and confirmed.

· Please check out your address carefully when processing order.We are not responsible for wrong or undeliverable address.

Payment

· We accept paypal payment only.

· Payment must be made within 48hours of the auction end time

Problem&Feedback

· Please give us the opportunityto resolve any problem when you have,we concern your problem and we will try our best to resolve it.

· If you are not satisfied, please contact us to resolve any issues. Please do NOT leave negative feedback without asking for help. We work hard to make sure EVERY CUSTOMER 100% satisfaction.

· For any inquiries,issues or assistanceplease contact us via eBay message

Refund

· When you have the parcel,and not satisfied the goods or it is other problem like as broken,pls tell us the detail reason and provide the photos to us.

· Any reason required for all refund. Item must be in it's original condition and no physical damage. Buyer responsible for all shipping cost

Contact us

· Please feel free for any questions, all the emails will be replied within 1-2 business days,if you didn’t receive any mail, maybe it’s in the junk mail fold.

· We are online from Monday to Saturday.