Ship from USA Warehouse fast shipping service to US Customers

(USA)4 Axis CNC Offline Motor Motion Controller DDCS Expert+MPG+24V Power Supply

Parcel include:

- 1 x 4 Axis CNC Offline stand alone Controller Model: DDCS-EXPERT

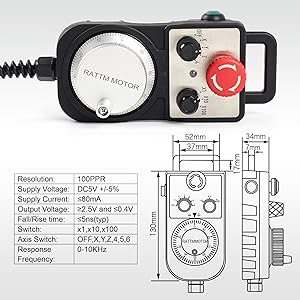

- 1 x 4 Axis Handwheel MPG with Estop with 15-pin connector (plug & play)

- 1 x Cable

- 1 x 4G USB Flash Drive

- 2 x 75W 24V DC Switching power supply

- User manual will send by email

DDCS EXPERT+MPG

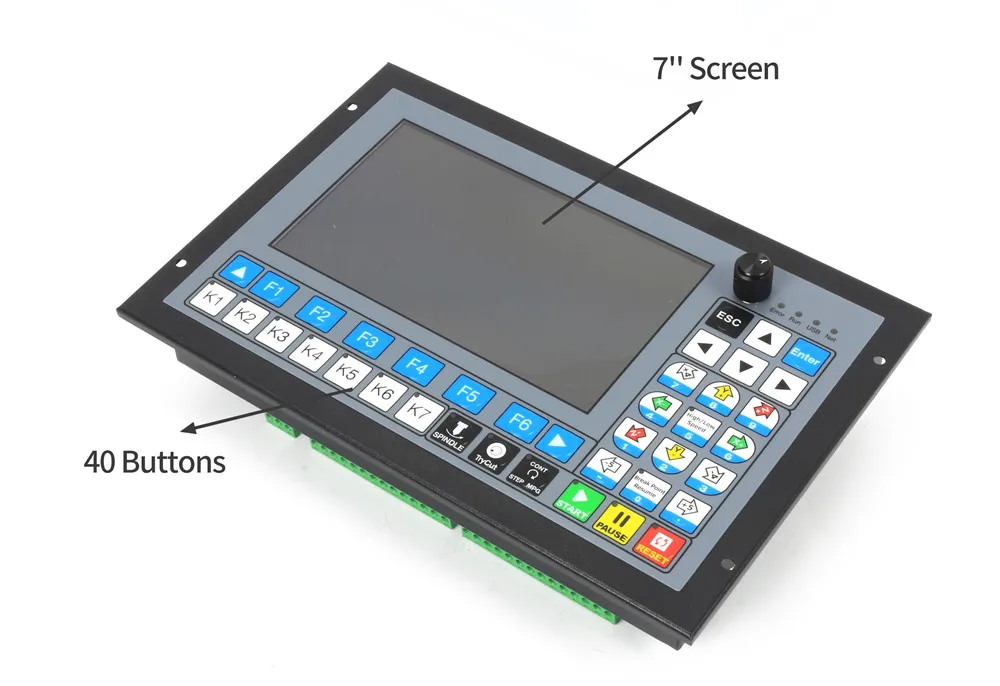

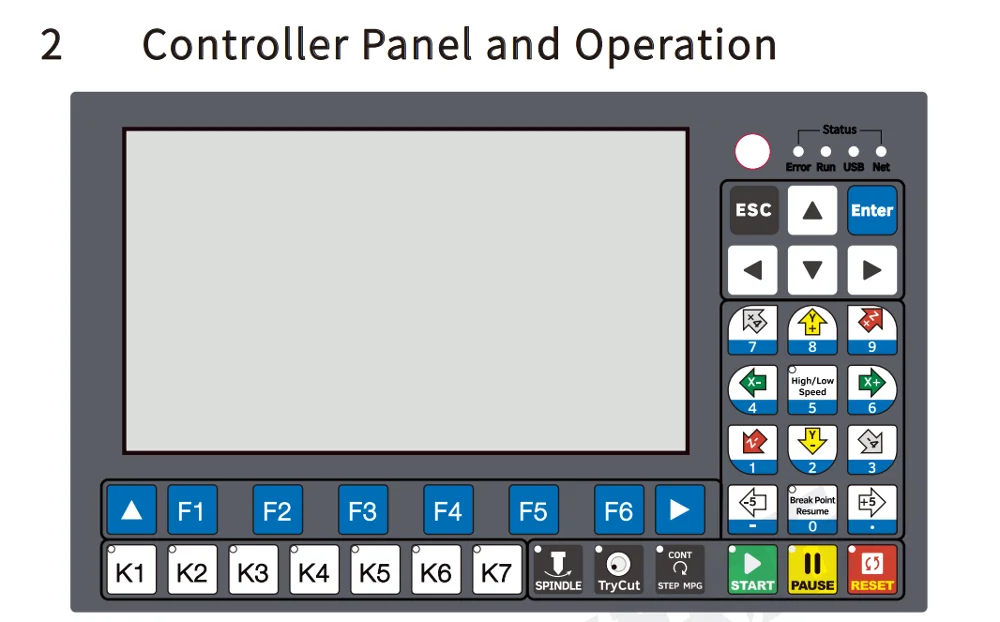

- ♞【Product】Model Number:DDCS EXPERT ; 1M Hz output frequency for each axis; 7 inch full color display screen; resolution ratio: 1024*600, 40 operation keys

- ♞【Introduction】The DDCS Expert numerical control system adopts the ARM+FPGA design framework. ARM controls the human-computer interface and code analysis and the FPGA provides the underlying algorithms and creates the control pulse. This guarantees reliable control and easy operation.The internal operating system is Linux based.

- ♞【Compatible G Code】Compatible with standard G-code,support popular CAD/CAM software, such as ArtCam, MasterCam, ProE, JDSoft SurfMill, Aspire, Fusion 360 and so on;

- ♞【Power Supply】The Power Supply for the controller is 24VDC, minimum Current is 0.5A

- ♞【Applications】The DDCS Expert can be used for many styles and types of CNC machines. Lathes, CNC Routers,Pick&Place and Milling Machine, lathe and cutters are just a few examples.

|

|

|

|---|---|---|

Comes with 4 Axis MPG

| Features of the MPG

| Plug & PlayIn order to make the convenient for the users, we already solder the MPG cables to the PIN15 male interface plug,so that you can plug the MPG to the controller directly.

|

Shipping

Please open the package and check if there are some damages before sign,if there are some damages,please do not sign and contact us immediately.

Problem&Feedback

Please give us the opportunityto resolve any problem when you have,we concern your problem and we will try our best to resolve it.

Pls contact us before you want to leave any negative feedback.

Refund

Any reason required for all refund. Item must be in it's original condition and no physical damage,buyer responsible for all shipping cost.

When you have the parcel,and not satisfied the goods or it is other problem like as broken,pls tell us the detail reason and provide the photos.

Needs two power supplies

Needs two power supplies

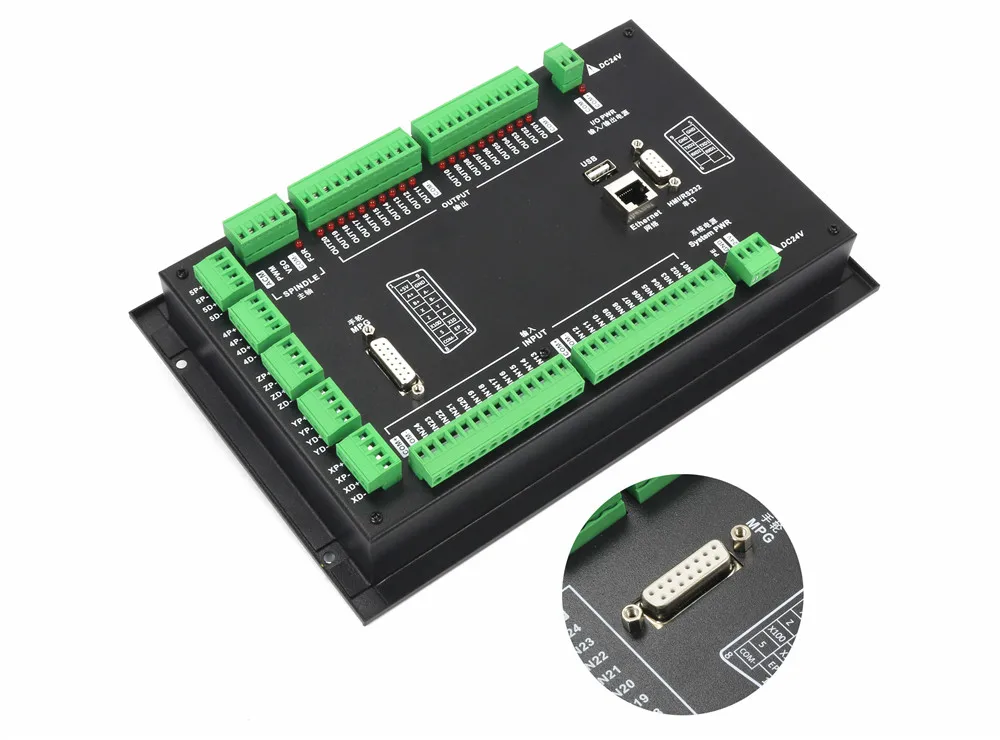

Wiring diagram

Wiring diagram