4 Axis CNC Controller Offline Motion Control+MPG+M3K extended keyboard+24V Power

Parcel include:

- 1 x 4 Axis CNC Offline Standalone motion controller DDCS-EXPERT

- 1 x 4GB USB Flash drive

- 1 x M3K extended keyboard

- 1x matching cable

- 1 x USB extension cable

- 1x 4GB USB flash drive

- 1 x network cable

- 2 x 75W 24V DC power supply

- 1 x 4 Axis Pendant Handwheel MPG with E-Stop with plug

- English User manual

DDCS EXPERT+MPG+Keyboard+DC Power supply

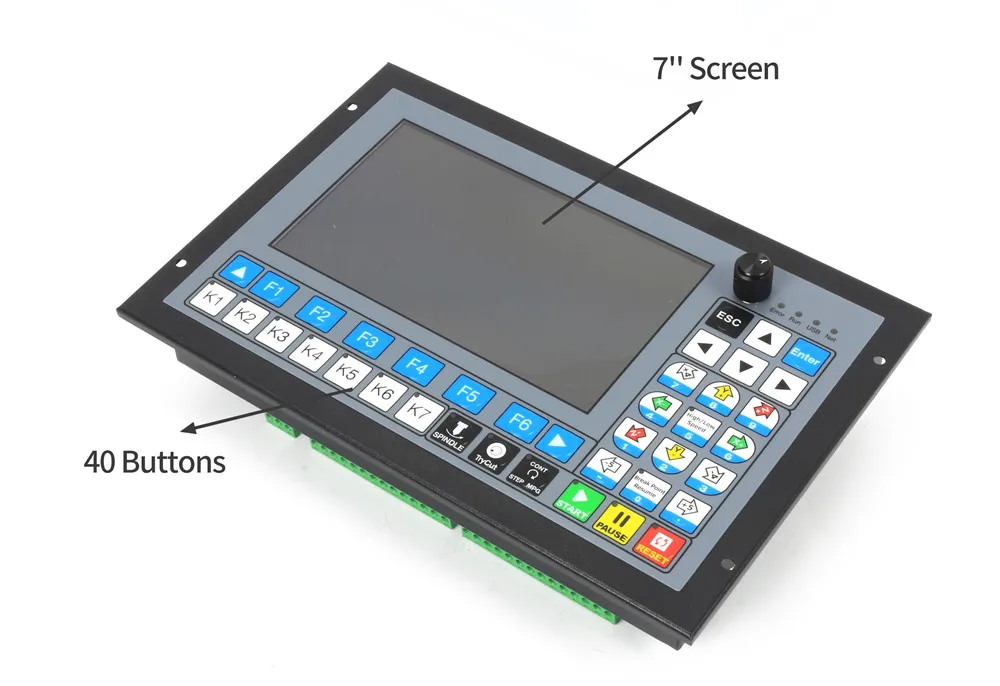

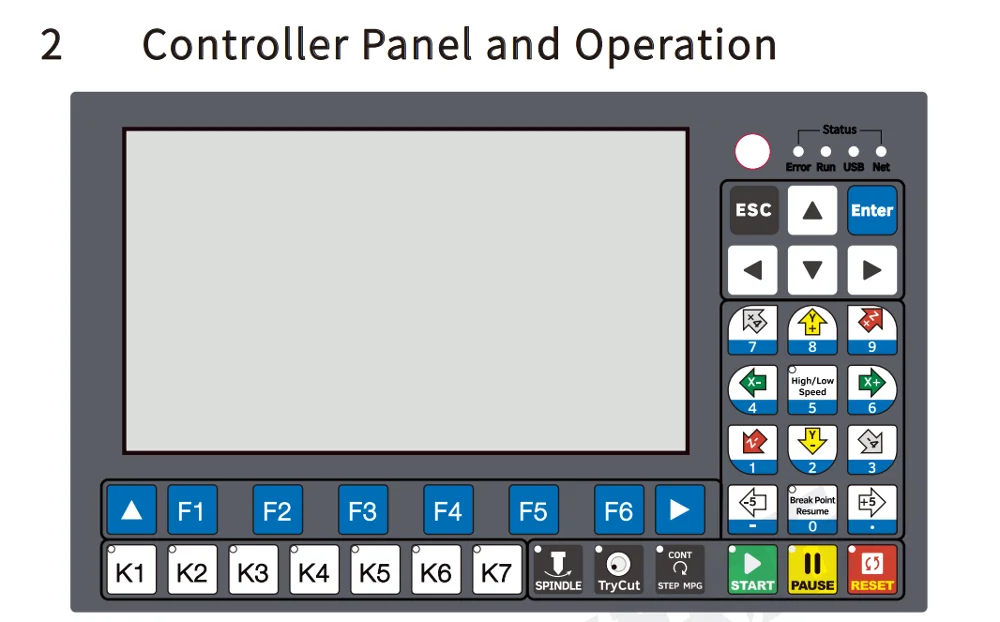

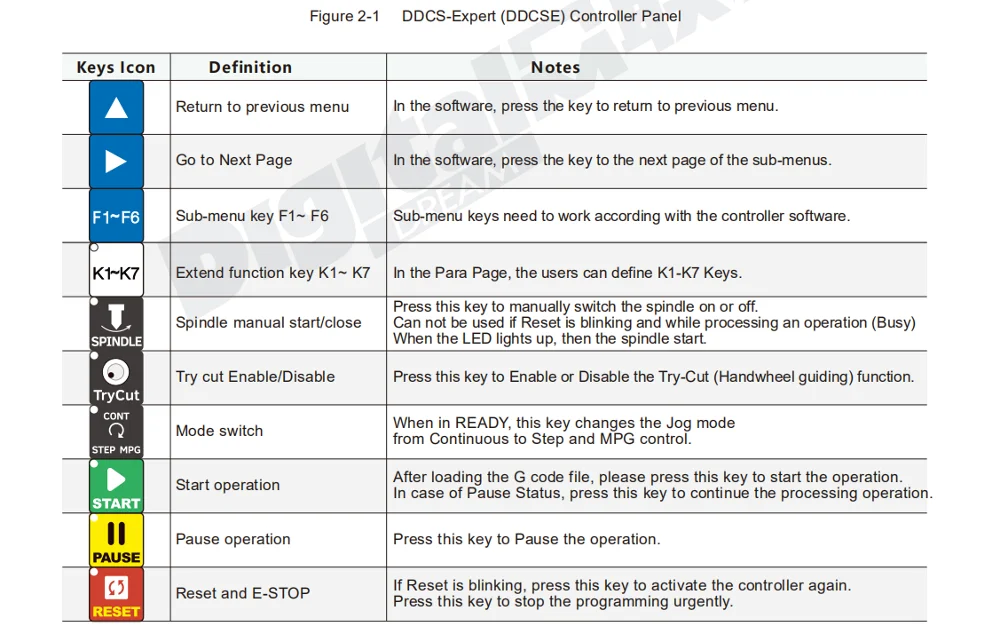

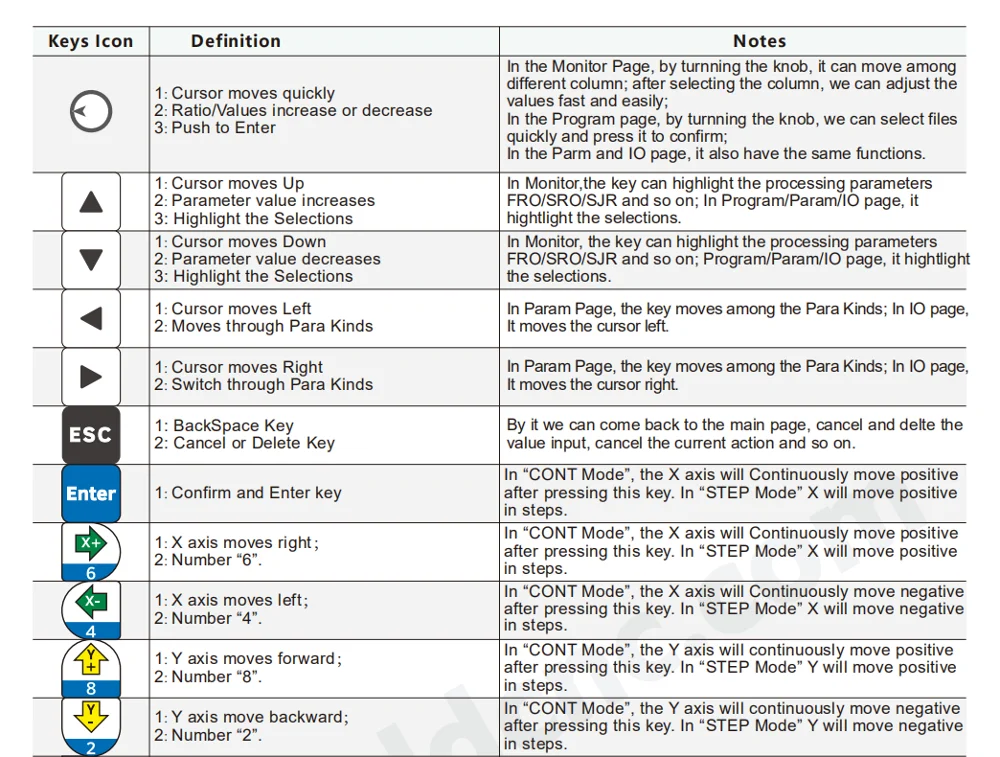

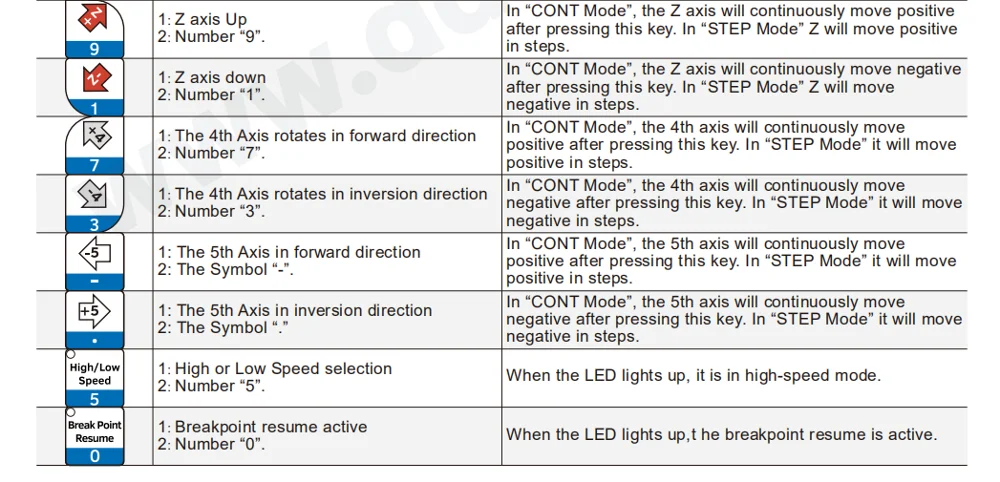

- ♞【Product】Model Number:DDCS EXPERT ; 1M Hz output frequency for each axis; 7 inch full color display screen; resolution ratio: 1024*600, 40 operation keys

- ♞【Introduction】The DDCS Expert numerical control system adopts the ARM+FPGA design framework. ARM controls the human-computer interface and code analysis and the FPGA provides the underlying algorithms and creates the control pulse. This guarantees reliable control and easy operation.The internal operating system is Linux based.

- ♞【Compatible G Code】Compatible with standard G-code,support popular CAD/CAM software, such as ArtCam, MasterCam, ProE, JDSoft SurfMill, Aspire, Fusion 360 and so on;

- ♞【Power Supply】The Power Supply for the controller is 24VDC, minimum Current is 0.5A

- ♞【Applications】The DDCS Expert can be used for many styles and types of CNC machines. Lathes, CNC Routers,Pick&Place and Milling Machine, lathe and cutters are just a few examples.

Description:

Description:

1) CNC system and position control of various mechanical devices, mainly for CNC machine tools and various mechanical zero correction and signal division.

2) 100 times per revolution slightly

cracking point,100 pulses per revolution output, holding the handle of the panel and all-metal high-grade design.

3) Metal code disc, high precision, good texture

4) Easy installation, shaped thin, ultra-light.

5) DC 5V power system

6) Voltage, single-ended, differential in three output options provide 100PPR pulse output options.

7) Driver output type, anti-interference ability, long-distance transmission.

8) Oil, water, dust-proof design (grade IP65) spiral stretch 20 million guaranteed.

Features:

1) Novelty, easy to move, interference, load capacity.

2) Full plastic shell, insulation, high strength, anti-oil seal design.

3) With × 1, × 10, × 100 third gear ratio, enabling 4-12 axis magnification switch

4) With the control switch, emergency stop switch optional, easy to operate

5) For CNC machine tools, printing machinery, numerical control equipment

Specification:

| Resolution | 100PPR |

| Supply Voltage | DC5V +/-5% |

| Supply Current | ≤80mA |

| Output Voltage | ≥2.5V |

| ≤0.4V | |

| Output Current | <40mA |

| Fall/Rise time | ≤5ns(typ) |

| Switch | X1,X10,X100 |

| Axis Switch | OFF,X,Y,Z,4 |

| Response Frequency | 0-10KHz |

| Weight | 560g |

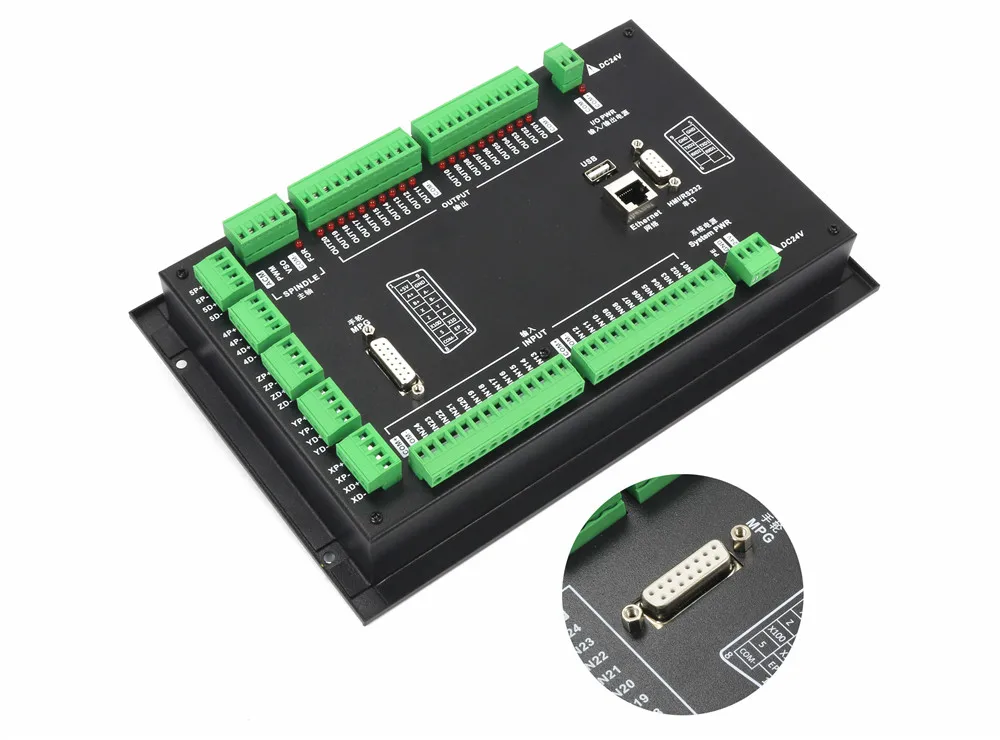

DDCS-EXPERT requires two power supplies, the main power supply is used for the controller system, and the IO port power supply is Used for input and output and MPG port. Both power sources are 24VDC and the current is 3A. Power input port, marked with 24V and GND is the main power input port; in the IO power input Ports, COM+ and COM- are input/output ports and power input ports of MPG. Please keep Please remember that the controller can work normally only if the two power sources are connected correctly Appropriately. Many new users only supply power to the system, and then there are limited switches, relays, MPG and The spindle does not work at all, then please check if it is still supplying power to the IO port. The IO power supply supplies power to all IO ports, including restricted switches, relays, MPG, Etop and All other input and output ports, without it, the spindle, MPG, input and output ports will not work. In order to avoid electrical noise, it is strongly recommended to use two separate 24V power supplies Supplies. In order to avoid high frequency electrical noise from the power cable, it is strongly recommended to install a noise filter at the power input end of the switching power supply

Introduction to inverter wiring:

In the analog spindle, the speed control output terminal can output 0-10V. It can be adjusted By sending a voltage between 0 to 10V to the VFD, the speed of the spindle motor Spindle speed setting. Use VFD (Variable Frequency Drive) to control the speed of the spindle, only need to start /Stop signal and 0-10V signal to control the frequency. The wiring method of the FOR port is the same as that of the normal output port. FOR is used for spindle forward output or start/stop output; The analog circuit is isolated from the power output, do not short-circuit ACM and COM- (DCM); If you only need the start and stop commands of the spindle, you only need to connect the FOR output port The structure of the controller with the start input port of the inverter

Shipping

Please open the package and check if there are some damages before sign,if there are some damages,please do not sign and contact us immediately.

Payment

Only accept paypal payment method.

Payment must be made within 3 days.

Problem&Feedback

Please give us the opportunityto resolve any problem when you have,we concern your problem and we will try our best to resolve it.

Pls contact us before you want to leave any negative feedback.

Refund

Any reason required for all refund. Item must be in it's original condition and no physical damage,buyer responsible for all shipping cost.

When you have the parcel,and not satisfied the goods or it is other problem like as broken,pls tell us the detail reason and provide the photos.