〖DDCS Expert〗CNC 4 Axis Offline Stand Alone PLC Motor Motion Controller 24V+MPG for CNC Router Milling Lathe Engraving Machine

【Ship from Germany Warehouse】

fast shipping time to the following EU Countries

Austria,Belgium,Bulgaria,CzechRepublic,Denmark,Estonia,Finland,France,Germany,Greece,

Hungary,Ireland,Italy,Latvia,Liechtenstein,Lithuania,Luxembourg,Monaco,Netherlands,Poland,

Portugal,Romania,Slovakia,Slovenia,Spain,Sweden.United Kingdom.

Austria,Belgium,Bulgaria,CzechRepublic,Denmark,Estonia,Finland,France,Germany,Greece,

Hungary,Ireland,Italy,Latvia,Liechtenstein,Lithuania,Luxembourg,Monaco,Netherlands,Poland,

Portugal,Romania,Slovakia,Slovenia,Spain,Sweden.United Kingdom.

We will ship this item from our Germany Warehouse by DHL to EU customers.

Estimated transportation time:

1-2 working days to: Germany

2-3 working days to: Austria,France,Spain and Italy

3-4 working days to: Other Europe Countries.

1-2 working days to: Germany

2-3 working days to: Austria,France,Spain and Italy

3-4 working days to: Other Europe Countries.

Parcel include:

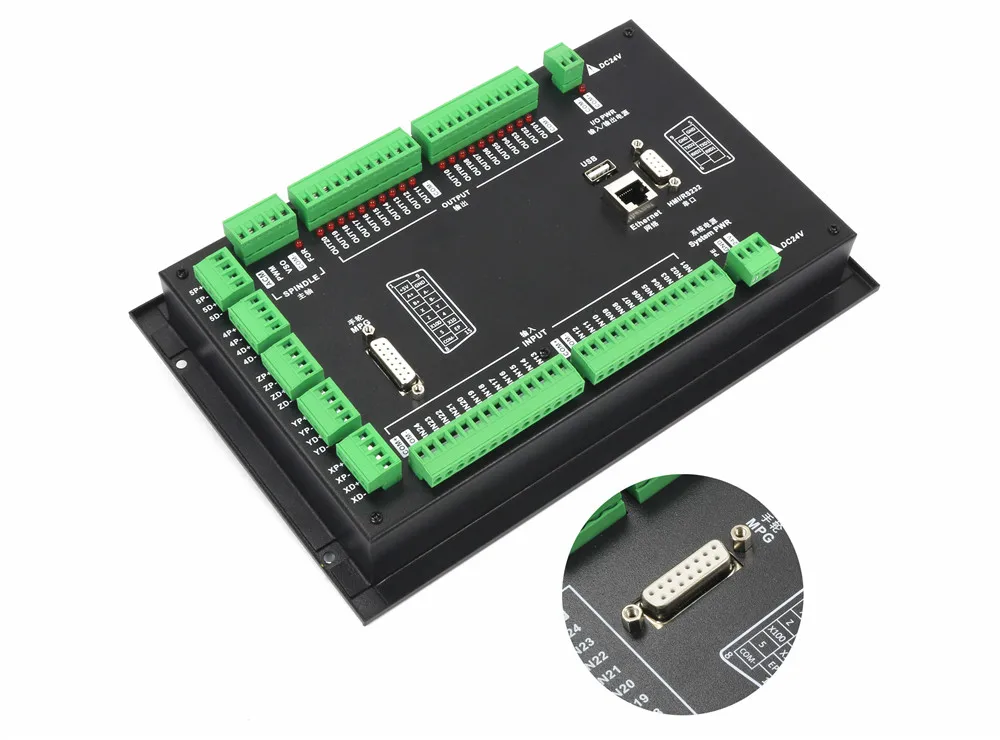

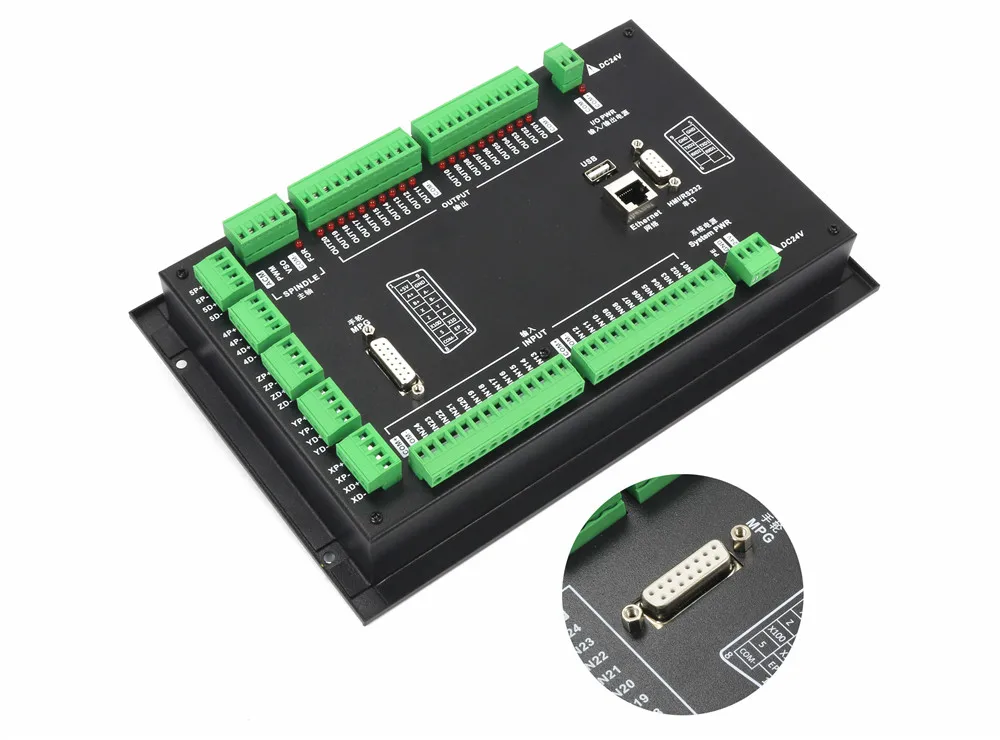

- 1 x 4 Axis 1000Khz CNC Offline Stand-alone Controller DDCS-EXPERT

- 1 x 4 Axis 100 Pulse MPG with Estop with 15-pin connector (plug & play)

- 1 x Connection Cable

- 1 x 4G U disk

- English user manual will send by email

DDCS EXPERT+MPG

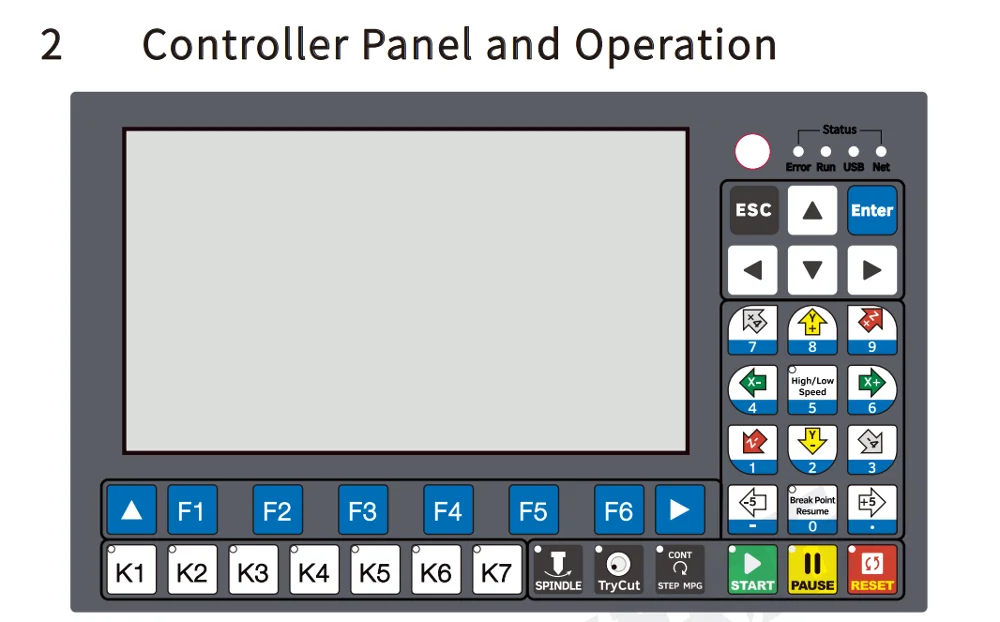

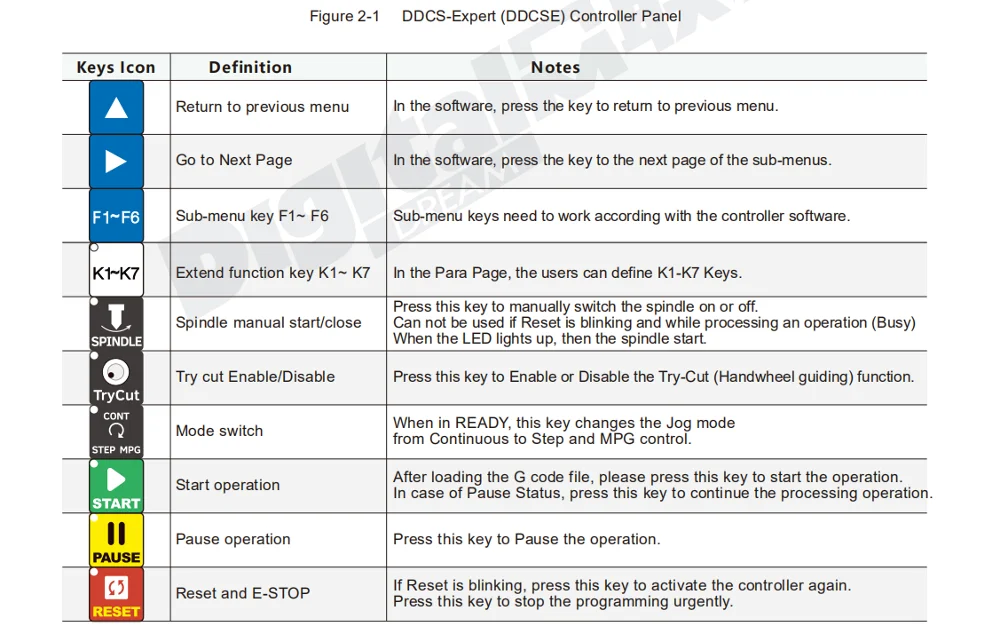

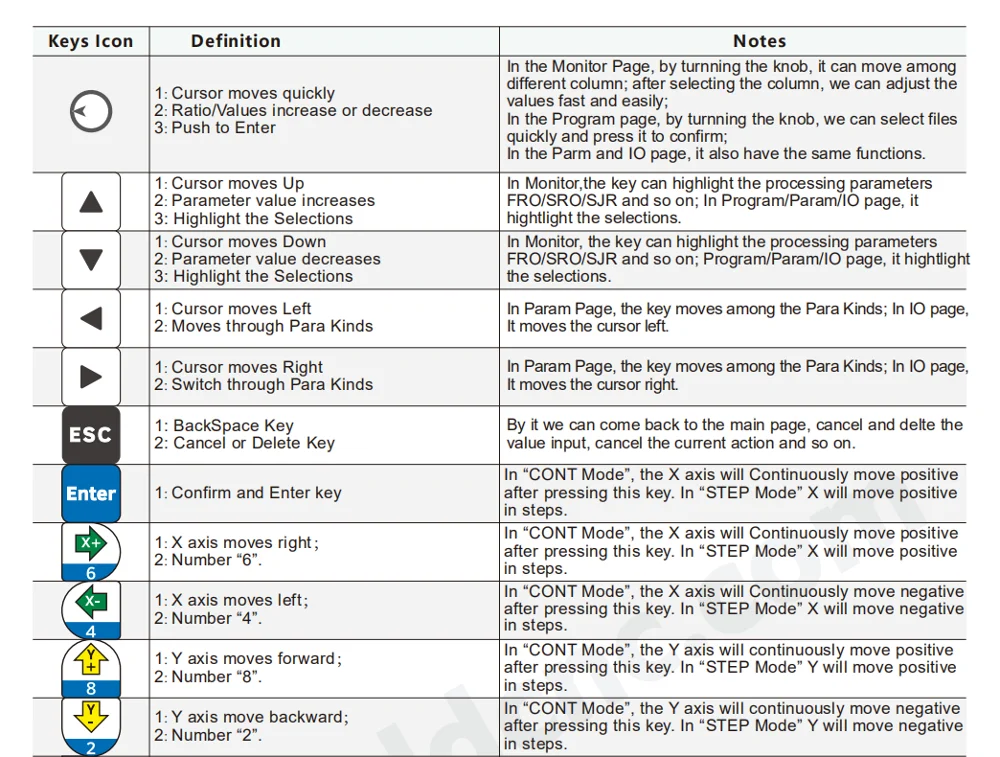

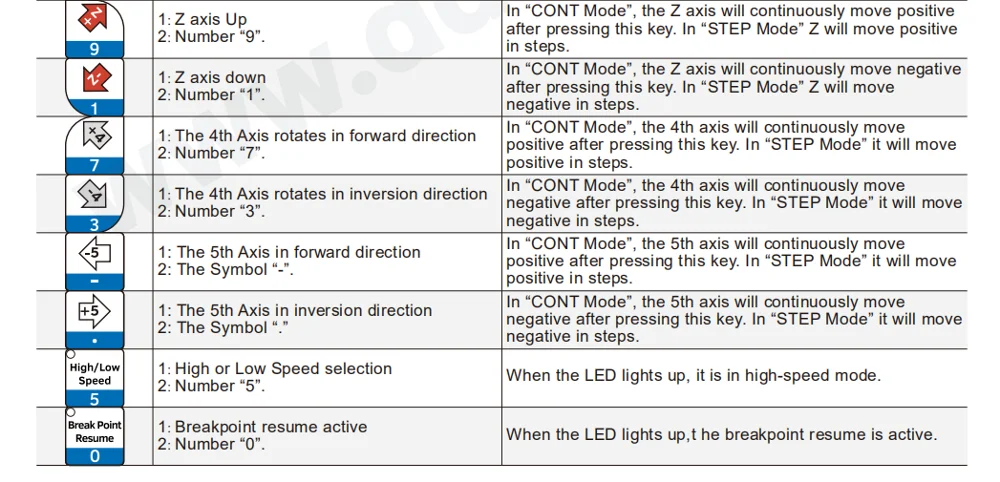

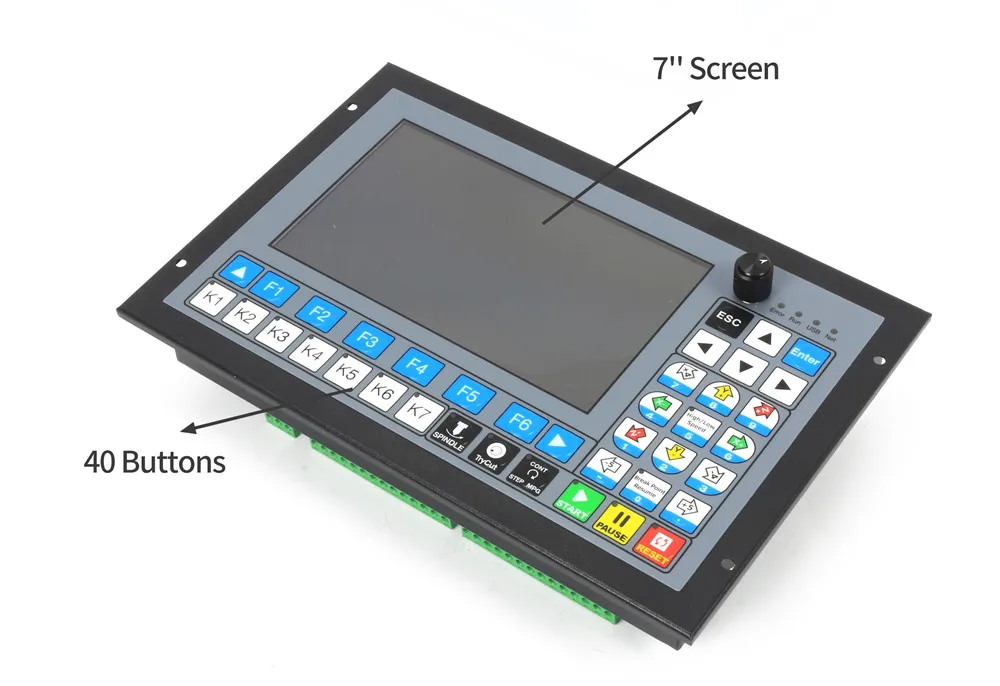

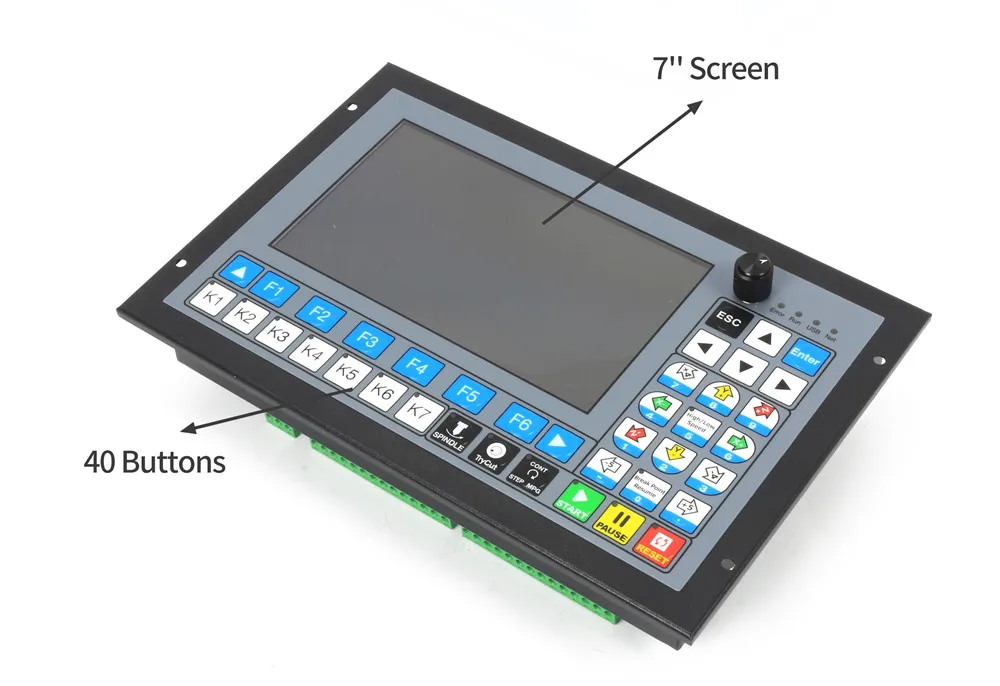

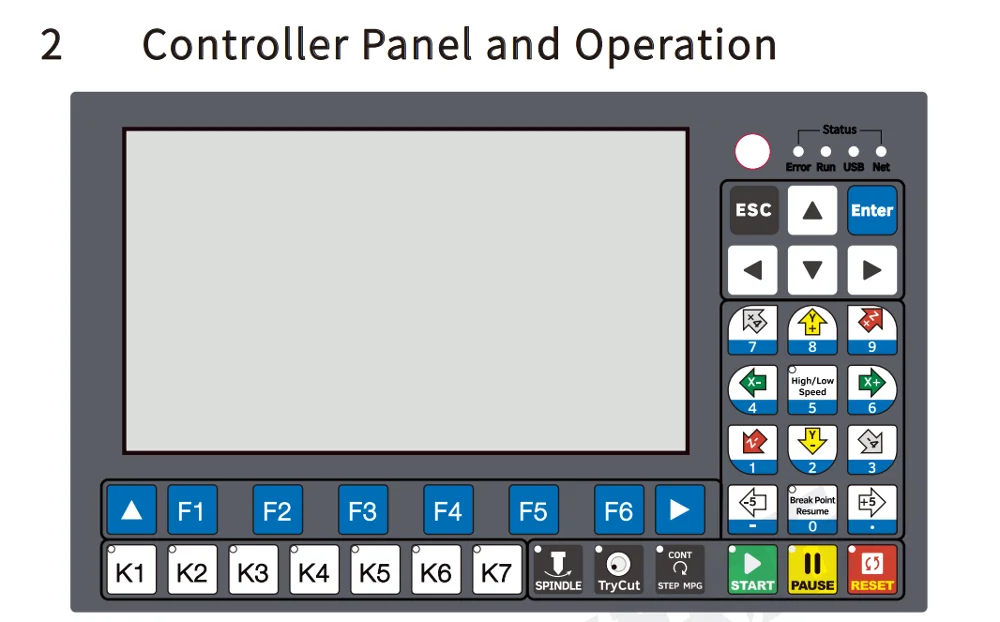

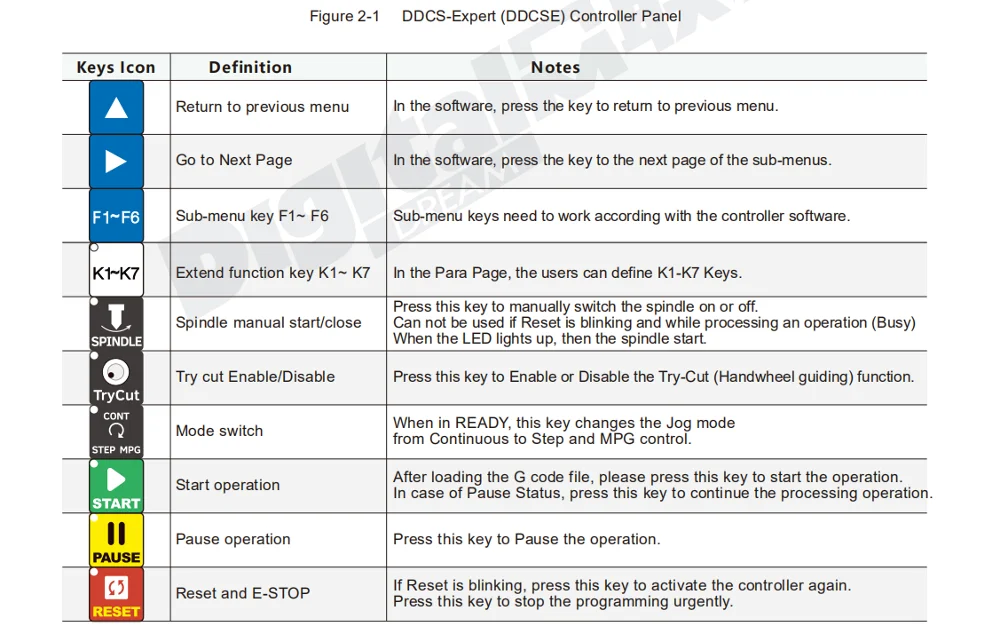

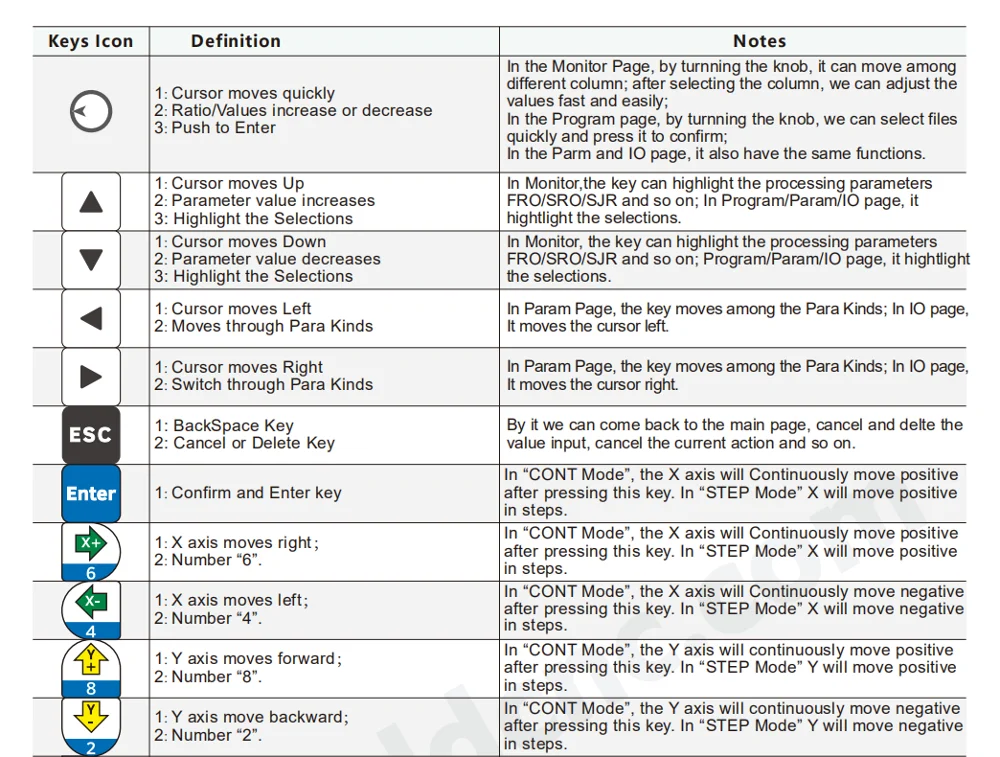

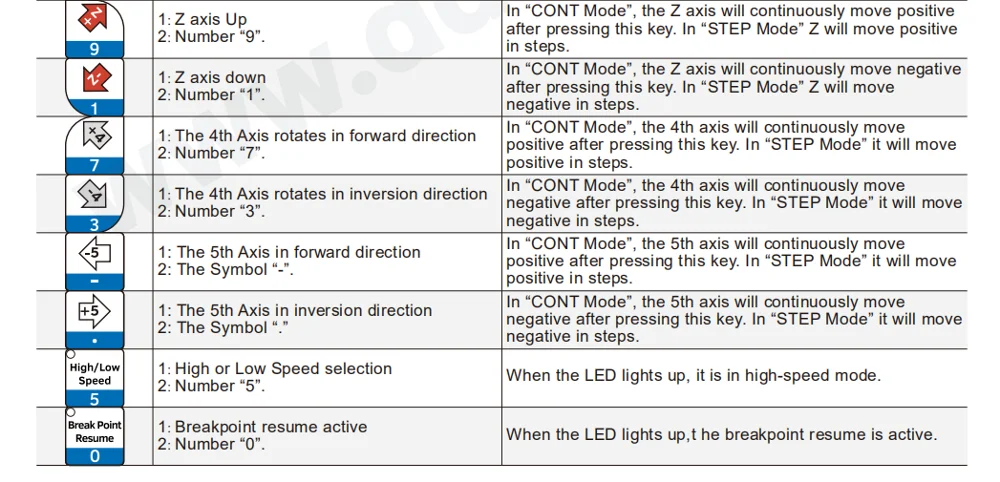

- ♞【Product】Model Number:DDCS EXPERT ; 1MHz output frequency for each axis; 7 inch full color display screen;

resolution ratio: 1024*600, 40 operation keys

-

♞【Introduction】The DDCS Expert numerical control system adopts the

ARM+FPGA design framework. ARM controls the human-computer interface and

code analysis and the FPGA provides the underlying algorithms and

creates the control pulse. This guarantees reliable control and easy

operation.The internal operating system is Linux based.

-

♞【Compatible G Code】Compatible with standard G-code,support popular

CAD/CAM software, such as ArtCam, MasterCam, ProE, JDSoft SurfMill,

Aspire, Fusion 360 and so on;

- ♞【Power Supply】The Power Supply for the controller is 24VDC, minimum Current is 0.5A

-

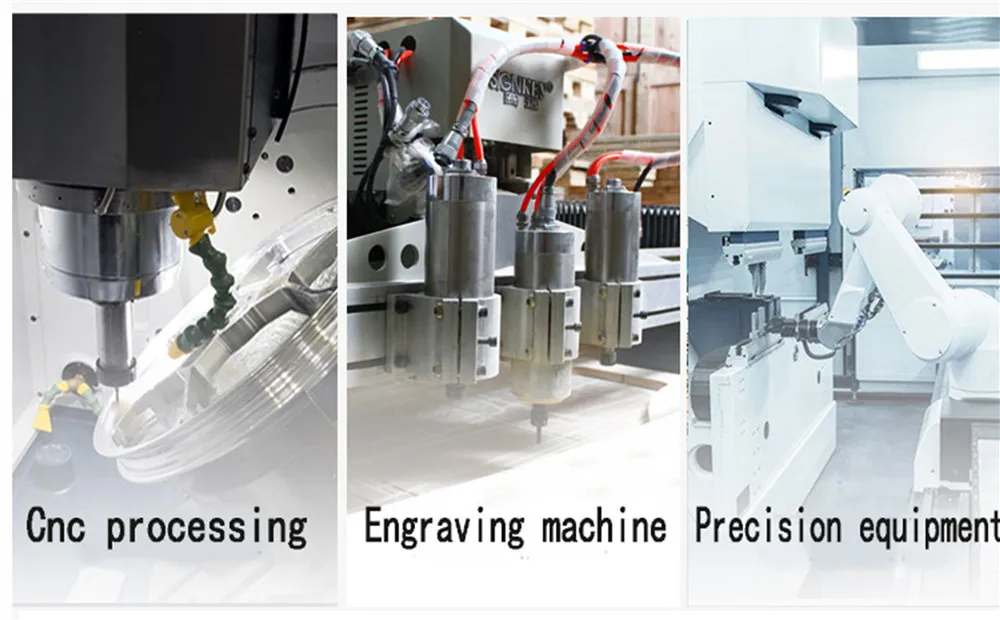

♞【Applications】The DDCS Expert can be used for many styles and types of

CNC machines. Lathes, CNC Routers,Pick&Place and Milling Machine,

lathe and cutters are just a few examples.

-

♞【Product】Model Number:DDCS EXPERT ; 1M Hz output frequency for each

axis; 7 inch full color display screen; resolution ratio: 1024*600, 40

operation keys

-

♞【Introduction】The DDCS Expert numerical control system adopts the

ARM+FPGA design framework. ARM controls the human-computer interface and

code analysis and the FPGA provides the underlying algorithms and

creates the control pulse. This guarantees reliable control and easy

operation.The internal operating system is Linux based.

-

♞【Compatible G Code】Compatible with standard G-code,support popular

CAD/CAM software, such as ArtCam, MasterCam, ProE, JDSoft SurfMill,

Aspire, Fusion 360 and so on;

-

♞【Power Supply】The Power Supply for the controller is 24VDC, minimum Current is 0.5A

-

♞【Applications】The DDCS Expert can be used for many styles and types of

CNC machines. Lathes, CNC Routers,Pick&Place and Milling Machine,

lathe and cutters are just a few examples.

Parcel include:

- 1 x 4 Axis 1000Khz CNC Offline Stand-alone Controller DDCS-EXPERT

- 1 x 4 Axis 100 Pulse MPG with Estop with 15-pin connector (plug & play)

- 1 x Connection Cable

- 1 x 4G U disk

- English user manual will send by email

DDCS EXPERT+MPG

- ♞【Product】Model Number:DDCS EXPERT ; 1MHz output frequency for each axis; 7 inch full color display screen; resolution ratio: 1024*600, 40 operation keys

- ♞【Introduction】The DDCS Expert numerical control system adopts the ARM+FPGA design framework. ARM controls the human-computer interface and code analysis and the FPGA provides the underlying algorithms and creates the control pulse. This guarantees reliable control and easy operation.The internal operating system is Linux based.

- ♞【Compatible G Code】Compatible with standard G-code,support popular CAD/CAM software, such as ArtCam, MasterCam, ProE, JDSoft SurfMill, Aspire, Fusion 360 and so on;

- ♞【Power Supply】The Power Supply for the controller is 24VDC, minimum Current is 0.5A

- ♞【Applications】The DDCS Expert can be used for many styles and types of CNC machines. Lathes, CNC Routers,Pick&Place and Milling Machine, lathe and cutters are just a few examples.

- ♞【Product】Model Number:DDCS EXPERT ; 1M Hz output frequency for each axis; 7 inch full color display screen; resolution ratio: 1024*600, 40 operation keys

- ♞【Introduction】The DDCS Expert numerical control system adopts the ARM+FPGA design framework. ARM controls the human-computer interface and code analysis and the FPGA provides the underlying algorithms and creates the control pulse. This guarantees reliable control and easy operation.The internal operating system is Linux based.

- ♞【Compatible G Code】Compatible with standard G-code,support popular CAD/CAM software, such as ArtCam, MasterCam, ProE, JDSoft SurfMill, Aspire, Fusion 360 and so on;

- ♞【Power Supply】The Power Supply for the controller is 24VDC, minimum Current is 0.5A

- ♞【Applications】The DDCS Expert can be used for many styles and types of CNC machines. Lathes, CNC Routers,Pick&Place and Milling Machine, lathe and cutters are just a few examples.

2. Pendant Handwheel MPG with Emergency stop