Pierburg CWA100.2 Brushless Water Pump 20mm OD - 12v CWA100-2

The Pierburg Electrical CWA coolant pumps make a significant contribution to emission control on modern engine designs. A delivery rate that is not dependent on the speed of another drive enables demand-based cooling. This reduces the power requirements whilst also cutting down on frictional loss, fuel consumption and pollutant emissions.

Electrical CWA coolant pumps offer top performance. They can be used for the main cooling of the combustion engine, as well as for cooling the fuel cell stacks of fuel cell drives.

Pierburg has made the electrical water pump ready for series production and was the world’s first series-production supplier for a leading premium vehicle manufacturer.

- Compact radial auxiliary coolant pump.

- Efficiency close to 40% at the nominal operating point.

- Demand-based cooling.

- High flow rate at a low pressure.

- Homogeneous heat dissipation.

- Improved resistance to influences that impair EMC.

| Specification | Metric | Imperial & Other |

| Liquid Temp Range | -40 to 110 °C | -40 to 230 °F |

| Ambient Temp Range | -40 to 120 °C | -40 to 248 °F |

| Hose Size | Ø 20 mm | Ø 0.787" |

| Nominal Diff. Pressure | 0.75 Bar | 10.87 Psi |

| Weight | 1 kg | 2.20 lbs |

| Voltage | 12v | |

| Maximum Current Draw | 8.5a | |

| Maximum Electrical Consumption | 102w | |

| Protection | IP67 & IP69K Rated | |

| Motor Type | Brushless Motor | |

| Manufacturer Part Number | Pierburg: 7.06754.05.0 / Mercedes: A0005000486 | |

| Pin | Use | |

| 1 | Ground | |

| 2 | LIN Signal | |

| 3 | PWM Signal | |

| 4 | +12v |

Connector Part Numbers

| Part | Description | Part Number | Quantity |

| Plug (Male) | Tyco 4 Way | 1-1718645-1 | 1 |

| Terminal | Kostal MLK 1.2 ELA | 32140734130 | 4 |

| Seal | Tyco MLK 1.2 ELA Seal | 967056-1 | 4 |

Plug, terminals and seals sold separately

Please ensure your supply is fused appropriately.

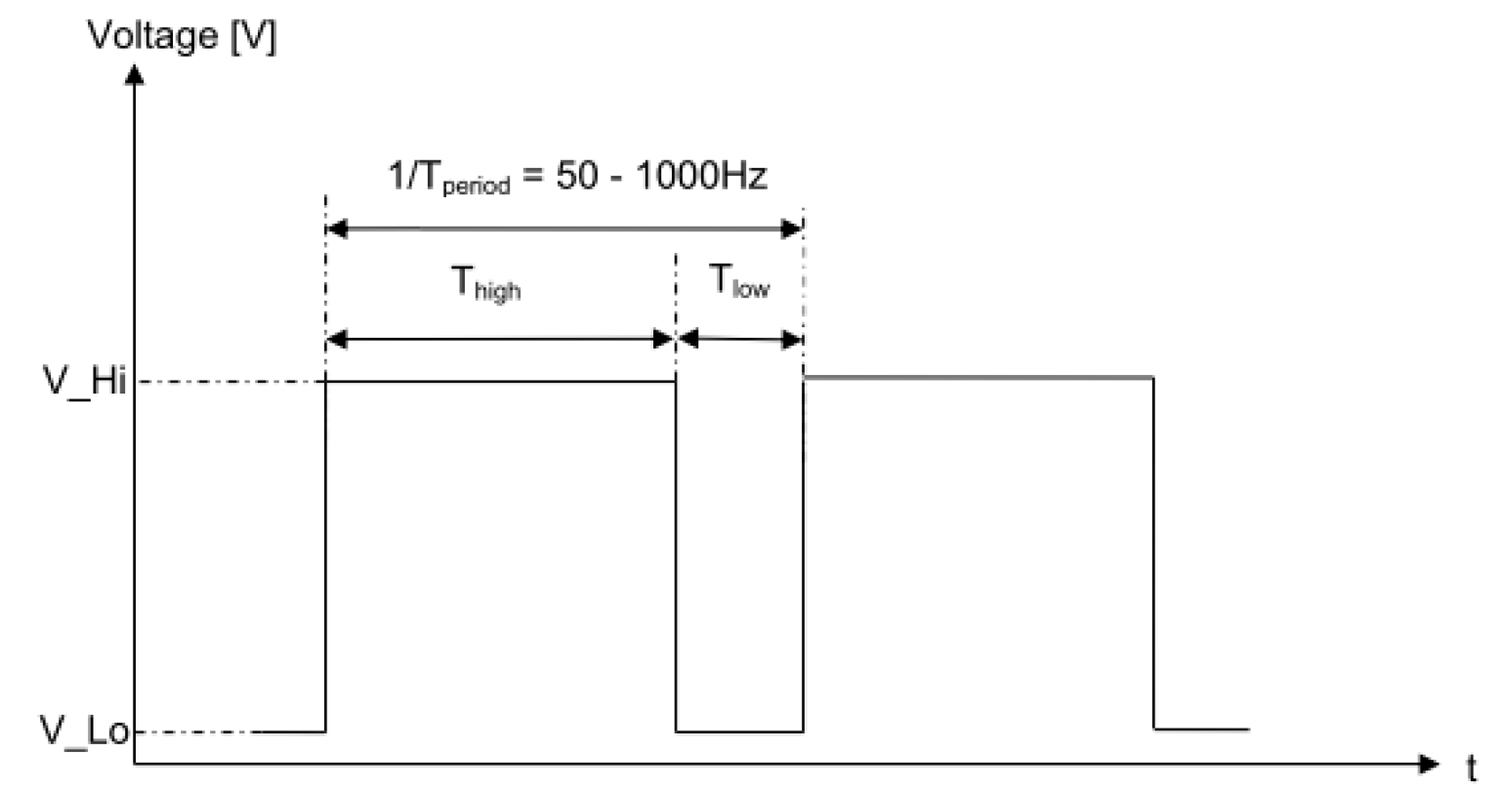

PWM Input Frequency

The PWM interface has the capability to handle frequencies between 50 to 1000 Hz.

Note: To assure that the pump awakes under PWM control, an uninterrupted high pulse of at least 3ms must be applied to the PWM input.

For Example: This is automatically achieved at a PWM frequency of 150 Hz and a duty cycle of 50% or above.

PWM Input Level

| Signal Description | Max | Min |

| V_Hi | UB + 3V* (Max 28v - 60s) | 0.6 UB |

| V_Low | 0.4 UB | Ground -3V* |

Duty Cycle vs Speed

| Mode | Duty Cycle | Speed | Description |

| 0 | 0% - 1% | 0 rpm | Stop |

| 1 | 1% - 7% | Default 6776 rpm | Emergency Run |

| 2 | 8% - 12% | 0 rpm | Stop and Error Reset |

| 3 | 13% - 85% | Min - Max | Controlled Operation |

| 4 | 86% - 97% | Max | Maximum Operation |

| 5 | 98% - 100% | Default 6776 rpm | Emergency Run |

The tolerance of the pump's interpretation of the PWM signal can vary +/-2% of the duty cycle.

Duty Cycle

The percentage duty cycle is represented by the relationship of Thigh to TPeriod.

Duty cycle is PWM.

Duty Cycle %=Thigh / (Tlow + Thigh).

- The pump can be installed in either a horizontal or vertical position. To avoid air-locks when mounted horizontally, the outlet should be turned in such a way that it is directed upwards or is placed on the upper side of the pump body.