MAX 5MIN A/B

2 GALLON KIT

(2 Gallon Combine Volume)

1 Gallon of Resin

And

1 Gallon of Curing Agent

BUY IN BULK AND SAVE

AVERAGE COST PER OUNCE $0.86 FOR THIS KIT

VERSUS

$1.55 PER OUNCE, SMALL PACK KITS

GUARANTEED LOWEST PRICE

DESCRIPTION

MAX 5MIN A/B is a two part toughened epoxy/polymercaptan resin system that provides fast set up time suitable for bonding, general assembly, and construction.

It is an improved performance equivalent to the common 5-minute epoxy resins that are typically supplied in dual-syringe packaging but formulated to provide higher tensile shear and peel strength.

This offering is presented at a much lower bulk pricing than the common pre-packaged kits typically offered in commercial hardware stores.

MAX 5MIN A/B offers higher peel strength than the conventional 5- minute systems which makes it suitable for a wider selection of bondable substrates.

THIS KIT INCLUDES A SET OF YORKER CAPS FOR CONTROLLED DISPENSING.

Use these Yorker caps to dispense the material with ease and minimize over pouring and reduce spills.

We do not recommend using dispensing pumps.

The curing agent or PART B of any epoxy resin system is sensitive to moisture and carbon dioxide.

It will react with the curing agent and form carbamate crystals (salt-like crystals that form on the tip of the pump) and reduce reactivity.

CARBAMATE CRYSTALS THAT FORM ON THE PUMP WHEN THE CURING AGENT IS EXPOSED AMBIENT MOISTURE AND CARBON DIOXIDE.

THESE CRYSTALS ARE INSOLUBLE IN EPOXY RESIN RESULTING IN CONTAMINATION AND CAUSES POOR CURE AND AMINE-BLUSHING.

RESIN CRYSTALLIZATION FROM PROLONGED STORAGE OR COLD WEATHER EXPOSURE

The resin component or the PART A may crystallize due to cold temperature exposure.

Please inspect the resin component for any solidified crystals which will appear as waxy solid or cloudiness on the bottom of the PART A bottle.

An information postcard is included with each package. View the following video for identification and processing.

DO NOT USE UNLESS PROCESSED TO REVERT ANY CRYSTALLIZED RESIN BACK TO A LIQUID STATE AND AVOID POOR CURED RESULTS.

MAX 5MIN A/B CAN SUPPORT THIS 1000 GRAM LOAD ACROSS 3 POINT OVERLAP BONDED PANELS

MAX 5MIN A/B can be used for bonding composites, metals, concrete, glass, wood and almost all types of substrates.

It offers ease of use, fast set-up time and adequate bond strength for light to medium duty adhesive applications.

It can also be used as a fast setting impregnating resin for fiberglass, Kevlar and carbon fiber reinforcing and field repairs or as fast casting resin of small to medium parts for rapid prototyping.

MAX 5MIN A/B can also be used for waterproofing of porous or absorbent substrates such as wood, textiles masonry and stone substrates.

MAX 5MIN A/B can be used as an adhesive to bond to plastic substrates such as ABS, Polypropylene (PP), High and Low-Density Polyethylene (HDPE and LDPE) and Polyethylene Terephthalate(PET) with proper surface pre-treatment before any significant adhesion develops due to the inherent low surface tension or substrates that demonstrate poor wettability.

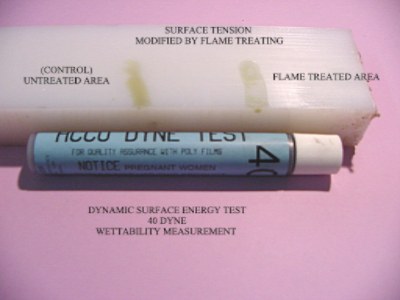

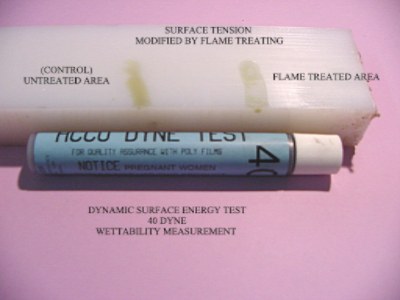

Corona treating or Flame Treating the plastic as demonstrated below enables MAX 5MIN A/B adequate surface bonding of plastic substrates.

SURFACE PREPARATION OF SUBSTRATES FOR BONDING OR COATING

In virtually every application the quality of the bond between the resin system and the surface to which it is applied is improved if the surface is clean and dry.

This is particularly true of adhesive applications where stress will be applied to the cured bond line.

It is also true where protective coatings are used. The following surface preparation procedures are recommended.

METALS

1. Degrease – Wipe faying surfaces with Methyl Ethyl Ketone (MEK) to remove all oil, dirt, and grease.

2. Etch – For optimum results, metal parts should be immersed in a chromic acid bath solution consisting of:

Sodium dichromate – 4 parts by weight

Sulfuric acid – 10 parts by weight

Water – 30 parts by weight

The solution should be held at a temperature of 160°F (71°C), and the parts left immersed for 5 to 7 minutes.

3. Rinse – remove metal parts from etching bath and rinse in clean cold water (de-ionized water is recommended). If thoroughly clean, metal surfaces so treated will hold a thin film of water.

4. Dry – To accelerate drying, items to be bonded can be placed in an air-circulating oven.

ALTERNATE PROCEDURE

1. Degrease, scour and dry – Often etching as outlined above is not practical. The metal surfaces may be cleaned by degreasing as noted above, scouring with an alkaline cleanser followed by rinsing and drying.

2. Degrease and dry – Degrease the surface as noted above, sand or sandblast the surface lightly but thoroughly. Rinse with acetone or Methyl Ethyl Ketone (MEK), and dry

GLASS

1. Degrease – With MEK as above, or with a strong boiling solution of a good grade household detergent.

2. Etch – For optimum results, degreasing can be followed by the chromic acid bath outlined above.

WOOD

1. Sand – Bonding surfaces should be sanded lightly, but thoroughly to remove all external contamination.

2. Clean – Carefully remove all dust, or particles of wood from sanded areas. A stiff and clean brush or compressed air can be used.

PLASTIC

1. Clean – Remove all dirt, oil, or other surface contaminants with soap and water, followed by thorough rinsing and allow to dry. A solvent that does not have a detrimental effect may also be used.

2. Sand – Surfaces to be bonded should be sanded lightly, but thoroughly to remove surface sheen.

3. Clean – Carefully remove all dust or particles of plastic from the sanded area. A clean brush, lint-free cloth, or compressed air may be used.

Flame Treatment of Plastic Substrates for Adhesive Bonding

Obtaining an adequate bond strength when bonding plastic-to-plastic substrates or plastic to dissimilar substrates is often a challenge for resin system.

In general, plastic surfaces demonstrate poor ‘wettability’ or the ability of a liquid to form a continuous film. These types of substrates or are called LSE or Low Surface Energy substrates and typically thermoplastic surfaces fall within this category. Teflon or its generic name PTFE and other polyethylene derivatives such as HDPE, LDPE, UHMW and olefinic-based plastics demonstrate poor liquid wettability due to its low surface energy.

To create a viable bondable surface condition with these types of plastics, it must be surface treated by creating a superficial oxidized surface to increase its dynamic surface tension.

Various types of physical treatment can be used to increase the surface energy of plastics, mostly through oxidation of the superficial layer. Flame treatment is the most widely used and cost-effective pre-treatment for polyethylene (HDPE, LDPE, UHMW) and polyolefin-based plastics prior to polymer bonding or printing.

It consists of exposing the surface to be coated to a suitable oxidizing flame during a short period of time (0.2 to 3 sec.). The resulting change of the surface by creating an oxidized surface greatly improves the liquids ability to wet-out the surface thus creating a strong adhesive bond between the surface and the coating. A Flame Treating process consists of exposing the surface to a suitable oxidizing flame for a period in the range of 0.2 to 3.0 seconds.

This treatment brings about a change to the polymer surface that increases its surface energy allowing fluids to effectively wet-out the surface.

Commercially Available Propane Torch

Adjust the propane torch so that a low oxygen burning flame is achieved and pass over the area to be treated several times until a slight haze is noticed on the surface of the substrate.

Note the fluid behavior on the flame treated area demonstrating improved substrate wetting thus making adhesion possible for polymers such as adhesives and inks.

Note the improved wettability of the flame treated side allowing the tension modified liquid to effectively wet-out the surface.

By modifying the surface condition of the plastic, polymer bonding is now possible. 1 CC Of Distilled Water Low Surface Energy Substrate. The Extreme Angle Of Droplet Is Due To Low Surface Energy Of The Substrate Yielding Poor Surface Wettability. In Order To Achieve An Adequate Bond To This Substrate, The Substrate Most Be Treated By Either Mechanical Sanding Or Chemical Etching To Increase The Surface Energy Which Will Allow A Lower 'truncated Sphere' Or Meniscus Height Profile. 1 CC Of Distilled Applied On This Glass Surface That Is Measured With A High Surface Energy Characteristic And Note Low Angle Of The Meniscus Or Truncated Sphere Of The Droplet Un Comparison To The Brass Plate. An Application Of A Reactive Polymer Will Yield Structural Adhesion Which Means The Bond Strength Will Be As Strong Or Stronger Than The Glass Substrate POLISHED BRASS PLATE

GLASS PLATE

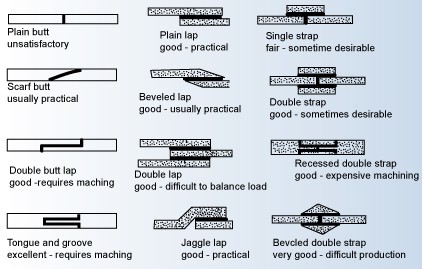

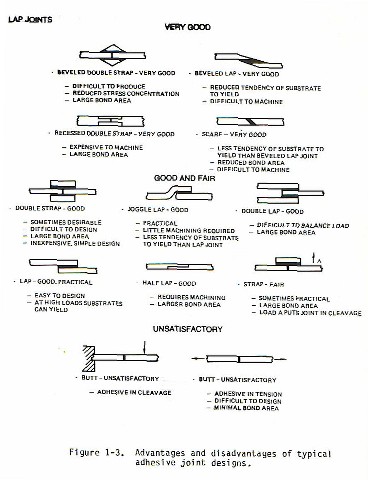

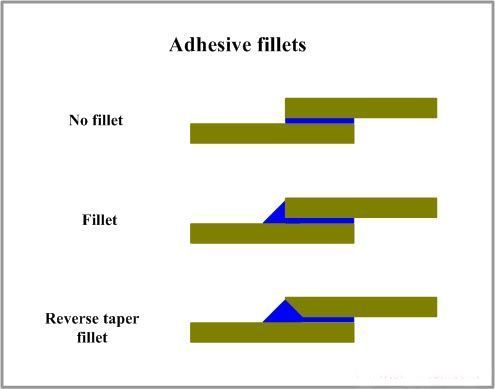

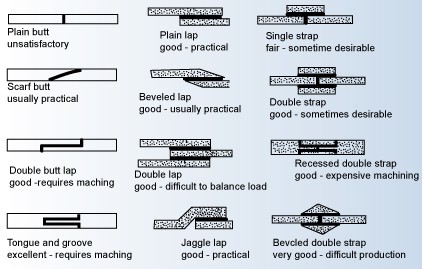

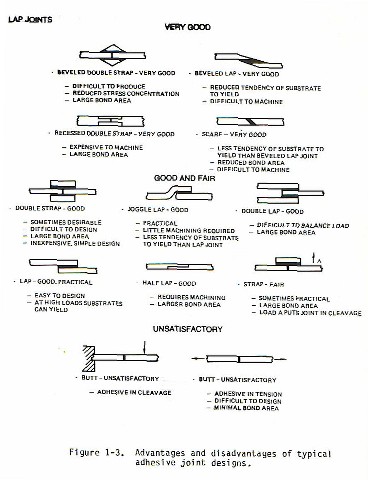

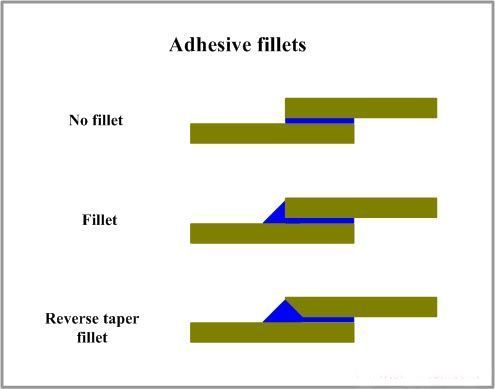

EFFECTIVE BONDING DESIGN AND DYNAMICS

This is particularly true of adhesive applications where stress will be applied to the cured bond line.

It is also true where protective coatings are used. The following surface preparation procedures are recommended.

METALS 1. Degrease – Wipe faying surfaces with Methyl Ethyl Ketone (MEK) to remove all oil, dirt, and grease. 2. Etch – For optimum results, metal parts should be immersed in a chromic acid bath solution consisting of: Sodium dichromate – 4 parts by weight Sulfuric acid – 10 parts by weight Water – 30 parts by weight The solution should be held at a temperature of 160°F (71°C), and the parts left immersed for 5 to 7 minutes. 3. Rinse – remove metal parts from etching bath and rinse in clean cold water (de-ionized water is recommended). If thoroughly clean, metal surfaces so treated will hold a thin film of water. 4. Dry – To accelerate drying, items to be bonded can be placed in an air-circulating oven. ALTERNATE PROCEDURE 1. Degrease, scour and dry – Often etching as outlined above is not practical. The metal surfaces may be cleaned by degreasing as noted above, scouring with an alkaline cleanser followed by rinsing and drying. 2. Degrease and dry – Degrease the surface as noted above, sand or sandblast the surface lightly but thoroughly. Rinse with acetone or Methyl Ethyl Ketone (MEK), and dry | GLASS 1. Degrease – With MEK as above, or with a strong boiling solution of a good grade household detergent. 2. Etch – For optimum results, degreasing can be followed by the chromic acid bath outlined above. WOOD 1. Sand – Bonding surfaces should be sanded lightly, but thoroughly to remove all external contamination. 2. Clean – Carefully remove all dust, or particles of wood from sanded areas. A stiff and clean brush or compressed air can be used. PLASTIC 1. Clean – Remove all dirt, oil, or other surface contaminants with soap and water, followed by thorough rinsing and allow to dry. A solvent that does not have a detrimental effect may also be used. 2. Sand – Surfaces to be bonded should be sanded lightly, but thoroughly to remove surface sheen. 3. Clean – Carefully remove all dust or particles of plastic from the sanded area. A clean brush, lint-free cloth, or compressed air may be used. |

Flame Treatment of Plastic Substrates for Adhesive Bonding

In general, plastic surfaces demonstrate poor ‘wettability’ or the ability of a liquid to form a continuous film.

To create a viable bondable surface condition with these types of plastics, it must be surface treated by creating a superficial oxidized surface to increase its dynamic surface tension.

Various types of physical treatment can be used to increase the surface energy of plastics, mostly through oxidation of the superficial layer.

It consists of exposing the surface to be coated to a suitable oxidizing flame during a short period of time (0.2 to 3 sec.).

This treatment brings about a change to the polymer surface that increases its surface energy allowing fluids to effectively wet-out the surface.

Note the fluid behavior on the flame treated area demonstrating improved substrate wetting thus making adhesion possible for polymers such as adhesives and inks.

By modifying the surface condition of the plastic, polymer bonding is now possible.

| 1 CC Of Distilled Water Low Surface Energy Substrate. The Extreme Angle Of Droplet Is Due To Low Surface Energy Of The Substrate Yielding Poor Surface Wettability. In Order To Achieve An Adequate Bond To This Substrate, The Substrate Most Be Treated By Either Mechanical Sanding Or Chemical Etching To Increase The Surface Energy Which Will Allow A Lower 'truncated Sphere' Or Meniscus Height Profile. | 1 CC Of Distilled Applied On This Glass Surface That Is Measured With A High Surface Energy Characteristic And Note Low Angle Of The Meniscus Or Truncated Sphere Of The Droplet Un Comparison To The Brass Plate. An Application Of A Reactive Polymer Will Yield Structural Adhesion Which Means The Bond Strength Will Be As Strong Or Stronger Than The Glass Substrate |

POLISHED BRASS PLATE | GLASS PLATE |

EFFECTIVE BONDING DESIGN AND DYNAMICS

Storage

Secure the caps for both bottles after use and store above 65°F minimum temperature to prevent re-crystallization. The resin system will remain viable for at least 12 months or longer when stored properly. The PART A or resin component may 'crystallize' after prolonged storage. Please inspect the PART A bottle for any solid crystallization that will appear on the bottom of the bottle.

Please Check Out Other Available Resin Systems At Our eBay Store For our complete listing, please Visit our eBay store! DON'T FORGET OUR EPOXY MIXING KIT

Everything You Need To Measure, Mix, Dispense & Apply The Epoxy Resin

Click The Link To Add To Order

https://www.ebay.com/itm/222623932456

Proportioning the correct amount is equally as important to attain the intended cured properties of the resin system.

The container in which the epoxy and curing agent is mixed is an important consideration when mixing an epoxy resin system.

The container must withstand the tenacity of the chemical and must be free of contamination.

Most epoxy curing agent has a degree of corrosivity, as a general practice, protective gloves should be worn when handling chemicals of the same nature.

MIXING KIT CONTENTS 1 Each Digital Scale -Durable, Accurate Up To 2000.0 Grams

4 Each 32-ounce (1 Quart) Clear HDPE Plastic Mix Cups

4 Each 16-ounce (1 Pint) Clear HDPE Plastic Mix Cups

5 Pairs One Size Fits All Powder-Free Latex Gloves

2 Each Graduated Syringes

8 Wooden Stir Sticks

Assorted Size Foam Brush

DON'T FORGET OUR EPOXY MIXING KIT

Everything You Need To Measure, Mix, Dispense & Apply The Epoxy Resin

Click The Link To Add To Order

https://www.ebay.com/itm/222623932456

Proportioning the correct amount is equally as important to attain the intended cured properties of the resin system.

The container in which the epoxy and curing agent is mixed is an important consideration when mixing an epoxy resin system.

The container must withstand the tenacity of the chemical and must be free of contamination.

Most epoxy curing agent has a degree of corrosivity, as a general practice, protective gloves should be worn when handling chemicals of the same nature.

1 Each Digital Scale -Durable, Accurate Up To 2000.0 Grams

4 Each 32-ounce (1 Quart) Clear HDPE Plastic Mix Cups

4 Each 16-ounce (1 Pint) Clear HDPE Plastic Mix Cups

5 Pairs One Size Fits All Powder-Free Latex Gloves

2 Each Graduated Syringes

8 Wooden Stir Sticks

Assorted Size Foam Brush

PLEASE CHECK OUT OTHER AVAILABLE RESIN SYSTEMS AT OUR eBay STORE

IMPORTANT NOTICE Your purchase constitutes the acceptance of this disclaimer. Please review before purchasing this product. The user should thoroughly test any proposed use of this product and independently conclude satisfactory performance in the application. Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval. The information contained herein is based on data believed to be accurate at the time of publication. Data and parameters cited have been obtained through published information, Polymer Composites, Inc. laboratories using materials under controlled conditions. Data of this type should not be used for a specification for fabrication and design. It is the user's responsibility to determine this Composites fitness for use. There is no warranty of merchantability of fitness for use, nor any other express implied warranty. The user's exclusive remedy and the manufacturer's liability are limited to refund of the purchase price or replacement of the product within the agreed warranty period. Polymer Composites, Inc. and its direct representative will not be liable for incidental or consequential damages of any kind. Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether there is any infringement of patents is the sole liability of the user.

Your purchase constitutes the acceptance of this disclaimer. Please review before purchasing this product. The user should thoroughly test any proposed use of this product and independently conclude satisfactory performance in the application. Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval. The information contained herein is based on data believed to be accurate at the time of publication. Data and parameters cited have been obtained through published information, Polymer Composites, Inc. laboratories using materials under controlled conditions. Data of this type should not be used for a specification for fabrication and design. It is the user's responsibility to determine this Composites fitness for use. There is no warranty of merchantability of fitness for use, nor any other express implied warranty. The user's exclusive remedy and the manufacturer's liability are limited to refund of the purchase price or replacement of the product within the agreed warranty period. Polymer Composites, Inc. and its direct representative will not be liable for incidental or consequential damages of any kind. Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether there is any infringement of patents is the sole liability of the user.