Aquarium Construction Resin

1.5 Gallon Kit

1 gallon of MAX ACR Resin Part A

½ gallon MAX ACR Curing Agent Part B

Bonds Glass, Steel, Aluminum, Soft Metals, Concrete, Ceramic, Fiberglass, Composite

Excellent Impact Resistance, Excellent Balance of Strength and Flexibility

Excellent Water/Salt Water Resistance

Excellent film barrier properties

Low Toxicity Formulation

DESCRIPTION

Use this specially formulated resin system to create a waterproof barrier when applied on concrete, wood and other materials used for fabricating wood aquariums tanks and artificial concrete ponds.

It is formulated to be an effective hermetic barrier or sealant to prevent any chemicals that can leach into the contained water that can cause dangerous pollutants to the marine animals.

MAX ACR works well as a fiberglass impregnating resin for plywood aquarium tank construction.

Color can also be added to the clear resin using our epoxy compatible color pigment paste.

Other Products Used For Aquarium Construction

https://www.ebay.com/itm/311946633043

FIBERGLASS FABRIC FOR CONSTRUCTION AND REINFORCEMENT

https://www.ebay.com/itm/223508087559

MAX ACR Aquarium Construction Resin. Axoloti Tank Construction. Aquarium Safe Epoxy Coating \u0026 Glue

Video will open in a new window

Using the eBay App? Paste link into a browser window:

The resin component or the PART A may crystallize due to cold temperature exposure.

Please inspect the resin component for any solidified crystals which will appear as waxy solid or cloudiness on the bottom of the PART A bottle.

An information postcard is included with each package.

View the following video for identification and processing.

DO NOT USE UNLESS PROCESSED TO REVERT ANY CRYSTALLIZED RESIN BACK TO A LIQUID STATE AND AVOID POOR CURED RESULTS.

Physical Properties

Mixed Color | Transparent Clear |

Viscosity Mixed | 2500 cps @ 25°C |

Density | 9.3 Pounds Per Gallon |

Mix Ratio | 2:1 By Volume or by Weight |

Working Time | 50 minutes at 200 grams |

Thin Film Dry Time | 8 hours @ 25°C |

Mechanical Properties

Cure time | 24 hours 80% cure 3 to 7 days 90% cure 7 to 12 days 100% cure |

Hardness | 75 to 81 Shore D @ 25°C |

Compressive Strength | 11,500 psi @ 25°C |

Tensile Elongation @ Break | 8.0 % @ 25°C |

Glass Transition Temp | 95°C |

Tensile Strength | 8400 psi @ 25°C |

Tensile Modulus | 320 kpsi @ 25°C |

Weight Gain | |

5% Ammonia Water Solution | <0.2 % |

5% Nitrate Water Solution | <0.2 % |

Sea Water | No change in pH & TDS |

Distilled Water | No change in pH & TDS |

Proper Mixing Technique For Epoxy Resins

MAX ACR will require complete and uniform blending of the resin and curing agent.

Poorly mixed batches will result in tacky spots, uneven surface, poor adhesion and other detrimental effects.

The mix ratio between the resin and curing agent is fixed and reducing or increasing the established ratio will not increase or decrease the cure rate.

Physical and mechanical results will differ as stated below if this ratio is altered.

To ensure trouble-free results follow this mixing procedure.

MAX ACR will require complete and uniform blending of the resin and curing agent. Poorly mixed batches will result in tacky spots, uneven surface, poor adhesion and other detrimental effects. The mix ratio between the resin and curing agent is fixed and reducing or increasing the established ratio will not increase or decrease the cure rate. Physical and mechanical results will differ as stated below if this ratio is altered. |

BASICS STEPS OF WOOD SEALING AND WATERPROOFING

- Ensure that the wood is as dry as possible; any excessive moisture will be sealed within the wood once it is impregnated with resin

- Use a fast evaporating solvent to dilute the epoxy such as acetone or MEK (ketone based solvents).

Add no more than 5% solvent by weigh or by volume to the mixed resin.

- Insure that all wood surface is coated with the epoxy sealant.

For best results coat the entire exposed surface area with the prepared epoxy resin mixture.

- Apply multiple coats until all porosity of the wood is sealed; some grain raising can be expected upon coating.

- Allow the applied coats to cure for at least 24 to 36 hours before proceeding.

- For a smoother finish, sand the cure surface just enough to remove surface gloss and removed and surface blemishes caused by the grain raising.

Lightly sand the surface to remove any grain raising if desired using 280 to 300 grit sandpaper.

Fiberglassing over the seal wood for increase strength and stability

- Choose the proper fiberglass weight and weave for the job. Here are some good fiberglass style.

- Apply another coat of the epoxy, this time do not add any solvent to insure maximum strength development.

FIBERGLASS CLOTH HEXCEL 7781 was used for the structural reinforcement.

https://www.ebay.com/itm/223508087559

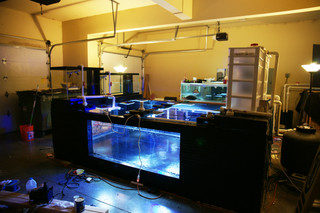

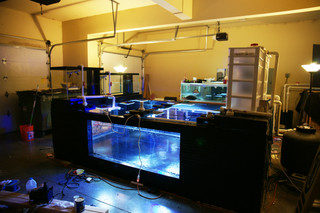

220 GALLON PLYWOOD AQUARIUM CONSTRUCTION

MATERIALS USED IN THE AQUARIUM CONSTRUCTION

MAX ACR A/B was used to seal the wood's porosity and create an aquarium-safe waterproof barrier.

MAX BOND A/B THIXOTROPIC was used for the general bonding adhesive.

FIBERGLASS CLOTH HEXCEL 7781 was used for the structural reinforcement.

https://www.ebay.com/itm/223508087559

MAX ACR A/B was used as the primary wood sealer and fiberglassing resin.

https://www.ebay.com/itm/222628038510

MAX EPOXY COLORANTS used to add color to the resin system

MAX EPOXY COLOR KIT

https://www.ebay.com/itm/311946633043

MAX ACR was used to coat all the surfaces that come in contact with the aquarium water

and impart non-toxic (upon full cure) hermetic barrier and waterproofing aquarium construction resin

300 Gallon Fresh Water Plywood Aquarium

OTHER MAX ACR A/B PROJECTS

Suggested Artificial Reef Fabrication

Determine the volume or size of the artificial reef and have a rough idea of the shape desired in mind.

In this procedure, a standard 3-inch thick, 2 pounds per cubic foot EPS Styrofoam sheets were bonded together to create a thick block 4 layers thick .

his type of foam can be purchased from any hardware centers in 4 x 8 sheets and are commonly used for insulation.

Click On Picture To View Video

- Pre- Cut the foam to the desired size and basic shape and remove the protective skin.

- Bond the sheets using MAX ACR to create workable block medium and Allow to cure for 24 hours.

- Fill a spray bottle (HDPE plastic bottle) with acetone and adjust output spray to a fine mist. Mist over the surface of the foam block to soften the surface

- Gouge out chunks from EPS foam block to create the desired shape and contour.

- Continue using the acetone mist to melt the EPS foam to achieve a rough texture. Note how the adhesive bond line used to bond the sheets begins to act like strata layers after the acetone has melted.

- Allow the acetone and EPS FOAM to outgas for 24- 36 hours. Placing the foam under direct sunlight will accelerate outgassing of any residual solvent.

- Mix 200 grams of MAX ACR PART A to 100 Grams of MAX ACR Part B in a clean container.

- Apply the coating onto the foam to create the primary barrier coating. Color can be added at this point to help determine complete coverage of the foam.

- Allow curing for 24 hours. Inspect the entire surface of the foam to ensure complete coverage.

- Repeat Step 8 thru Step 10 but omit the acetone addition and add a more colorant to distinguish first coat from the second application. This technique will give the foam further depth of field. Apply the coating onto the foam and allow to cure. The surface is now noticeable harder.

- Allow curing for 2 to 3 days to allow full outgassing and cure of the MAX ACR. Placing the foam under direct sunlight will accelerate the cure and any solvent outgassing.

- After the MAX ACR has fully cured, the foam surface has now developed a very rigid shell.

- Rinse the entire surface with warm water several times and allow it to completely dry.

- The artificial reef is now ready to be bonded to the aquarium to secure it in place. If a permanent bond is desired, use the MAX ACR as an adhesive and bond it directly to the aquarium floor and sides. If a temporary removable bond is desired use aquarium safe silicone adhesive and bond it directly to the aquarium floor or underground filtration plate.

Conditioning the MAX ACR artificial reef

After 36 hours of curing, fill the aquarium with warm water and lightly scrub the entire surface area.

Drain the aquarium and repeat this process for at least 3 times.

Do not use soaps or detergents, just warm water or aquarium safe cleaner.

Fill the aquarium with water and begin water conditioning process.

Allow the filled aquarium to stabilize in temperature.

If the water becomes cloudy, drain the aquarium once more and repeat cleaning process.

Place the live fish into the aquarium only when the water color and pH has stabilized for 24 hours.

The MAX COLOR CONCENTRATE can be blended into any epoxy resin system.

Color Addition With MAX COLOR PIGMENT PASTE KIT5 Colors In One Convenient KitBlack - White - Red - Yellow - Blue2 Ounces Per Color ConcentrateIncludes 5 Yorker Caps For Easy Dispensing

High Color Pigment Concentration

Precision Milled For Uniform Color Dispersion

Specially Formulated For Epoxy Resin Compatibility

Complies With FDA Mandates For Food Contact ApplicationsTo create special colors use the following procedure by adding the MAX COLOR PASTE to the PART A or resin component first. Each color can be used by itself or blended with other colors to create secondary, etc. color shades, tints, and hue.

- Warm the resin component or PART A and pigment concentrate to 100°F.

This will make dispersion more efficient. - Pour all of the resin in an appropriate size container.

Calculate the amount of resin needed by determining length x width x thickness = cubic volume - Add the MAX COLOR PASTE to the PART A or the resin component only.

- Add in small increments until the desired color is achieved.

- Mix until the MAX COLOR PASTE is uniformly mixed.

- Allow the mixture to rest for 24 hours to allow any air bubbles to degas.

Warming the mixture will accelerate degassing. - The resin needs to be cooled before adding the curing agent.

- View the epoxy mixing instructional video posted on this item page to ensure proper mixing.

Click On Picture To View Video Demonstration

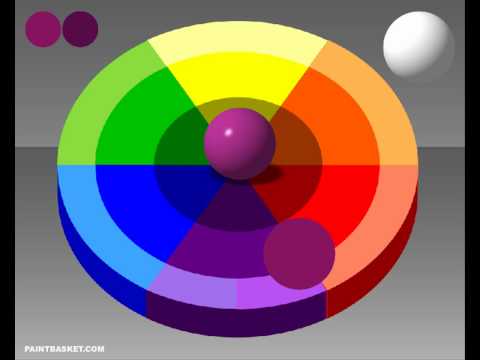

Each MAX COLOR CONCENTRATE color is used to mix with other colors in varying amounts to create secondary and tertiary colors.

The white and black MAX COLOR CONCENTRATE are used to adjust color tints and shade.

In color theory, a tint is a mixture of a color with white, which reduces darkness, while a shade is a mixture with black, which increases the darkness.

Review the ‘color theory’ on the web for more details.

The color wheel is one of the most basic color appearance systems.

The main purpose of this system is to identify the different sets of colors, different color schemes, and color relationships.

There are a number of levels of color within the color wheel. The levels have aptly named the primary, secondary, and tertiary colors.

The color schemes defined by the color wheel begin with the three levels mentioned.

Below is a diagram of a 12-part color wheel.

The primary colors in the traditional color wheel are red, blue, and yellow.

These are considered primary because, theoretically, every color can be made by mixing these three colors.

The secondary colors are the colors that are made by the primary colors: green, orange, and violet.

The next level, tertiary, is created by mixing an unequal amount of two primary colors and a secondary color, which is essentially the same as an unequal amount of two primary colors.

The tertiary colors are named with little creativity in mind: yellow-orange, red-orange, red-purple, blue-purple, blue-green, and yellow-green. THE USE OF A WEIGHING SCALE IS HIGHLY RECOMMENDED FOR COLOR SHADE AND BATCH REPRODUCIBILITY

USE A DIGITAL SCALE AND TAKE NOTE OF PROPORTIONS FOR COLOR REPEATABILITY

AND MAKING LARGE BATCHES

Purchase this scale with any of product offering and the shipping cost of the scale is free.

Please request a total before paying for combined shipping savings.

Sample Formula: Opaque Coating or Casting

MAX ACR Resin

100 grams

Calcium Carbonate Marble Epoxy Powder Epoxy Filler 325 Mesh

50 grams

MAX EPOXY COLORANT

3 grams

Premix the Color Paste first with the MAX ACR PART A until well dispersed and then add the calcium carbonate and mix until a uniform consistency is achieved. Allow the mixed resin to de-gas at room temperature or soak the container in a warm water bath and then allow to cool before adding the curing agent. Add the adjusted amount of Curing Agent and mix as described above.

Part B

MAX ACR Curing Agent

50 grams

AQUARIUM DECORATIONS PROTECTIVE COATING

USE THESE THEORETICAL FACTORS THAT RELATES TO ANY UNDILUTED EPOXY RESIN AS A GUIDE:

1 GALLON = 231 CUBIC INCHES

1 GALLON OF RESIN CAN COVERS 1608 SQUARE FEET

1 MIL OR 0.001 INCH CURED COATING THICKNESS

1 GALLON OF RESIN IS 128 OUNCES

1 GALLON OF MIXED EPOXY RESIN IS 9.23 POUNDS

1 GALLON OF RESIN IS 3.7854 LITERS

Storage

Secure the caps for both bottles after use and store above 65°F minimum temperature to prevent re-crystallization. The resin system will remain viable for at least 12 months or longer when stored properly. The PART A or resin component may 'crystallize' after prolonged storage. Please inspect the PART A bottle for any solid crystallization that will appear on the bottom of the bottle.

Please Check Out Other Available Resin Systems At Our eBay Store For our complete listing, please Visit our eBay store!

PLEASE CHECK OUT OTHER AVAILABLE RESIN SYSTEMS AT OUR eBay STORE

IMPORTANT NOTICE Your purchase constitutes the acceptance of this disclaimer. Please review before purchasing this product. The user should thoroughly test any proposed use of this product and independently conclude satisfactory performance in the application. Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval. The information contained herein is based on data believed to be accurate at the time of publication. Data and parameters cited have been obtained through published information, Polymer Composites, Inc. laboratories using materials under controlled conditions. Data of this type should not be used for a specification for fabrication and design. It is the user's responsibility to determine this Composites fitness for use. There is no warranty of merchantability of fitness for use, nor any other express implied warranty. The user's exclusive remedy and the manufacturer's liability are limited to refund of the purchase price or replacement of the product within the agreed warranty period. Polymer Composites, Inc. and its direct representative will not be liable for incidental or consequential damages of any kind. Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether there is any infringement of patents is the sole liability of the user.

BASICS STEPS OF WOOD SEALING AND WATERPROOFING

MATERIALS USED IN THE AQUARIUM CONSTRUCTION MAX ACR A/B was used to seal the wood's porosity and create an aquarium-safe waterproof barrier. MAX BOND A/B THIXOTROPIC was used for the general bonding adhesive. FIBERGLASS CLOTH HEXCEL 7781 was used for the structural reinforcement. https://www.ebay.com/itm/223508087559 MAX ACR A/B was used as the primary wood sealer and fiberglassing resin. https://www.ebay.com/itm/ MAX EPOXY COLORANTS used to add color to the resin system MAX EPOXY COLOR KIT https://www.ebay.com/itm/ MAX ACR was used to coat all the surfaces that come in contact with the aquarium water and impart non-toxic (upon full cure) hermetic barrier and waterproofing aquarium construction resin

After 36 hours of curing, fill the aquarium with warm water and lightly scrub the entire surface area. Drain the aquarium and repeat this process for at least 3 times. Do not use soaps or detergents, just warm water or aquarium safe cleaner. Fill the aquarium with water and begin water conditioning process. Allow the filled aquarium to stabilize in temperature. If the water becomes cloudy, drain the aquarium once more and repeat cleaning process. Place the live fish into the aquarium only when the water color and pH has stabilized for 24 hours. The MAX COLOR CONCENTRATE can be blended into any epoxy resin system.

Color Addition With MAX COLOR PIGMENT PASTE KIT 5 Colors In One Convenient Kit Black - White - Red - Yellow - Blue 2 Ounces Per Color Concentrate Includes 5 Yorker Caps For Easy Dispensing High Color Pigment Concentration Precision Milled For Uniform Color Dispersion Specially Formulated For Epoxy Resin Compatibility Complies With FDA Mandates For Food Contact Applications To create special colors use the following procedure by adding the MAX COLOR PASTE to the PART A or resin component first. Each color can be used by itself or blended with other colors to create secondary, etc. color shades, tints, and hue. Click On Picture To View Video Demonstration Each MAX COLOR CONCENTRATE color is used to mix with other colors in varying amounts to create secondary and tertiary colors. Review the ‘color theory’ on the web for more details. The color wheel is one of the most basic color appearance systems.  These are considered primary because, theoretically, every color can be made by mixing these three colors. The secondary colors are the colors that are made by the primary colors: green, orange, and violet. The next level, tertiary, is created by mixing an unequal amount of two primary colors and a secondary color, which is essentially the same as an unequal amount of two primary colors. The tertiary colors are named with little creativity in mind: yellow-orange, red-orange, red-purple, blue-purple, blue-green, and yellow-green. THE USE OF A WEIGHING SCALE IS HIGHLY RECOMMENDED FOR COLOR SHADE AND BATCH REPRODUCIBILITY USE A DIGITAL SCALE AND TAKE NOTE OF PROPORTIONS FOR COLOR REPEATABILITY Purchase this scale with any of product offering and the shipping cost of the scale is free. Please request a total before paying for combined shipping savings.

Storage

Your purchase constitutes the acceptance of this disclaimer. Please review before purchasing this product. The user should thoroughly test any proposed use of this product and independently conclude satisfactory performance in the application. Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval. The information contained herein is based on data believed to be accurate at the time of publication. Data and parameters cited have been obtained through published information, Polymer Composites, Inc. laboratories using materials under controlled conditions. Data of this type should not be used for a specification for fabrication and design. It is the user's responsibility to determine this Composites fitness for use. There is no warranty of merchantability of fitness for use, nor any other express implied warranty. The user's exclusive remedy and the manufacturer's liability are limited to refund of the purchase price or replacement of the product within the agreed warranty period. Polymer Composites, Inc. and its direct representative will not be liable for incidental or consequential damages of any kind. Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether there is any infringement of patents is the sole liability of the user. | ||||||||||||||||||||||||||||||||||||