High Strength Epoxy Adhesive

Non-Sag Thixotropic

(Will Not Flow At Rest But Easily Spread)

1 Pint Of Resin -PART A

And

1 Pint Of Curing Agent- PART B

1 Quart Combined Volume (32 Fluid Ounces)

High Strength Epoxy Adhesive For Wood, Metals, Concrete, Fiberglass, Plastics, Stone And Masonry

Non-Sag-Thixotropic

(Will Not Flow At Rest But Easily Spread)

DESCRIPTION

MAX BOND THIXOTROPIC A/B is a two-part modified epoxy/polyamide based adhesive system specially formulated to provide structural bond strength to a variety of substrates.

It is a thickened version of the MAX BOND System.

Its consistency allows for coating of the mixed adhesive to be applied onto a vertical or overhead application with minimal drips or runs.

MAX BOND THIXOTROPIC A/B exhibits structural bond strengths to numerous substrates commonly used in composites industry such as steel, aluminum, metals and alloys, resin impregnated composites, and most plastics. It performs well in wide range of service temperature and resists cracking and delamination due to cyclic vibration, thermal expansion and contraction.

Conforms To Hundreds of Aerospace/Military/Naval Materials Specifications

MIL-A-8623 T1

MS-511

MMM-134 Type1 and Type 2

OS-9923A

Boeing BMS-5-29

NASA Requirements For Low Outgassing Polymers

(<1% CVCM, collected volatile condensable material )

Tested For Aerospace Application Under NASA Low Outgassing Specifications of less than 1% CVCM, TMLV requirement

Conforms To Code Of Federal Regulations

FDA CFR Title 21 175.300 For Direct/indirect Food Contact Adhesive

MAX BOND THIXOTROPIC A/B

Utilized As A Structural Adhesive For Bonding Wood And Steel

Available Kit Sizes

MAX BOND THIXOTROPIC A/B 32 OUNCE KIT | |

MAX BOND THIXOTROPIC A/B 64 OUNCE KIT | |

MAX BOND THIXOTROPIC A/B 1 GALLON KIT | |

MAX BOND THIXOTROPIC A/B 2 GALLON KIT |

For food contact applications, MAX BOND THIXOTROPIC A/B must be fully cured to ensure no chemical leaching can occur when foodstuffs' come in contact with the cured resin system.

Any uncured chemical compounds from the improperly prepared MAX BOND THIXOTROPIC may be extracted and cause cross-contamination or leaching during food contact.

Please review the following use instructions to avoid any curing problems.

Check for resin crystallization. During the colder season, the MAX BOND THIXOTROPIC resin component or PART A may crystallize and must be heat-processed to fully polymerize the resin system.

Inspect the PART A bottle for any turbidity or a solid mass that typically forms on the bottom of the bottle.

- Weigh or measure the components accurately at a 1:1 mix ratio. Any off-ratio excess of either the resin or curing agent in the mixture can cause poor cure and can cause chemical leaching that can transfer to the food or beverage.

- Use a digital scale and weigh each component for best results.

For example, 200 grams of MAX BOND THIXOTROPIC PART A require

200 grams of MAX BOND THIXOTROPIC PART B.Mix the components thoroughly.

Any unmixed component from poor mixing will result in poor polymerization and can be extracted and cross-contaminated the foodstuffs.

Please view the following mixing demonstration below;

SEE MIXING DEMO BELOW

• Allow the applied resin to fully cure for a minimum of 48 hours at 75°F before exposing the coating to any food or beverage.

• Heat cure to 170°F for 4 hours for faster cure time.

• Rinse the cured coating with warm water and mild detergent before allowing any food contact.

POSSIBLE HEAT CURING TECHNIQUES

If an oven is not available to provide the needed thermal post cure, exposing the assembled part to solar heat (sun exposure) for a short period will provide enough heat cure for the part to be handled.

Other heat curing such as infrared heat lamps can be used if a heat chamber or oven is not available.

MAX BOND A/B SERIES VISCOSITY COMPARISON

AVAILABLE IN THREE VERSIONS

NON-SAG OR THIXOTROPIC VERSION FOR BONDING AND ADHESIVE APPLICATIONS

MAX BOND THIXOTROPIC A/B 32 OUNCE KIT | |

MAX BOND THIXOTROPIC A/B 64 OUNCE KIT | |

MAX BOND THIXOTROPIC A/B 1 GALLON KIT | |

MAX BOND THIXOTROPIC A/B 2 GALLON KIT |

Physical Properties

Mixed Density | 1.10 gm/cc |

Form and Color | Thixotropic Gel |

Part A – Resin | White Thixotropic Liquid |

Part B - Curing Agent | Amber Gel |

Viscosity Mixed | 135,624 cPs @ 77°F (25ºC) |

Mix Ratio | Equal parts by volume or weight |

Working Time (200-gram mass) | 85 Minutes @ 77°F (25ºC) |

Peak Exotherm (200-gram mass) | 160°F |

Cure Time | 24 Hrs. Minimum |

Accelerated Cure | 2 Hours Room Temperature Plus 1 hour 212oF |

Mechanical Properties

Hardness | 85 ± 5 Shore D |

Tee-Peel Strength | 4 Lbs. per inch Width |

Compressive Strength | 15,800 psi @ 77°F (25ºC) |

Tensile Shear Strength | 3,700 psi @ 77°F (25ºC) |

| 2,200 psi @ -112°F (-80ºC) |

| 1,450 psi @ 212°F (100ºC) |

Elongation Maximum Yield | 2.3% |

Tensile Strength | 8,800 psi |

Service Temperature | -67°F to 250°F |

Thin Film Set Time | 120 minutes |

CHEMICAL RESISTANCE TEST

10 Day Soak Test @ 77°F (25°C)

Test Solvent | % Change in weight |

Distilled Water | .23 |

Sulfuric Acid 30% | 1.9 |

Nitric Acid | 3.8 |

Toluene | 3.7 |

Sodium Hydroxide | 10.00 |

Anti-Freeze | No Effect |

Motor Oil soak | No Effect |

MATERIAL | VISCOSITY (centipoises) |

Water @ 70° F | 1-5 |

Blood or Kerosene | 10 |

Anti-Freeze or Ethylene Glycol | 15 |

Motor Oil SAE 10 or Corn Syrup | 50-100 |

Motor Oil SAE 30 or Maple Syrup | 150-200 |

Motor Oil SAE 40 or Castor Oil | 250-500 |

Motor Oil SAE 60 or Glycerin | 1,000-2,000 |

Corn Syrup or Honey | 2,000-3,000 |

Black-strap Molasses | 5,000-10,000 |

Hershey Chocolate Syrup | 10,000-25,000 |

Heinz Ketchup or French’s Mustard | 50,000-70,000 THIXOTROPIC |

Tomato Paste or Peanut Butter | 150,000-200,000 THIXOTROPIC |

Crisco Shortening or Lard | 1,000,000-2,000,000 |

Caulking Compound | 5,000,000-10,000,000 |

Window Putty | 100,000,000+ |

|

|

VOLUME AND WEIGHT FACTORS THAT RELATES TO ANY UNDILUTED EPOXY RESIN AS A GUIDE:

1 GALLON = 231 CUBIC INCHES |

1 GALLON OF RESIN CAN COVERS 1608 SQUARE FEET 1 MIL OR 0.001 INCH CURED COATING THICKNESS |

1 GALLON OF RESIN IS 128 OUNCES |

1 GALLON OF MIXED EPOXY RESIN IS 9.23 POUNDS |

1 GALLON OF RESIN IS 3.7854 LITERS |

Mixing Instructions

Dispense equal parts of Part A and Part B and mix thoroughly until a homogeneous consistency is achieved.

The mixture will turn translucent milky amber but will clarify when applied in a thin film during curing.

Transfer the mixed resin into another clean container and mix for another minute and use.

For mix metering application, ensure that an equal flow rate of Part A and Part B is achieved. A 24 element static mixer provides excellent mix results.

Attach the static mixer and dispense and discard approximately 1-ounce material before using the material.

Dispense the material in on the corner of the component casing and allow the material to completely flow throughout.

This technique will reduce voids and air entrapment.

The use of a weighing scale is highly recommended for proportioning the components.

The resin systems used for direct food contact must yield absolute cure to ensure no chemical leaching can occur when the cured coating comes in contact with the foodstuff.

Improper or poor mix ratio accuracy from using volumetric measurement may cause inaccuracy which may cause uncured components to leach from the applied coating.

Use a digital scale to precisely weigh the resin and curing agent and ensure full polymerization of the resin and curing agent and prevent leaching.

Step 1. Measure Resin And Curing Agent Mix Ratio 1:1

Step 2. Mix Gently But Thoroughly As Not Introduce Excessive Air Bubbles

Step 3. Mix For 3 To 5 Minutes Or Until Uniform

Step 4. Ready For Use, Apply With Brush Or Spread With Spatula

Usage And Applications Instructions

This item is a thickened version of the MAX BOND Medium Viscosity. It is specially formulated so that the adhesive will not flow allowing the user precise and clean adhesive placement.

MAX BOND THIXOTROPIC is paste-like in consistency but maintains the adhesion performance of MAX BOND Medium Viscosity.

MAX BOND THIXOTROPIC is a general purpose high strength adhesive is used in all types of bonding application where excellent water resistance and a wide service temperature exposure is expected.

This resin system is an industry "workhorse" standard and is the most versatile system available.

It can also be used as a reinforcing resin for Fiberglass, Aramid ( Kevlar Type) Fibers, Carbon Fiber or as crack filling resin and surface sealing for many different types of substrates.

Used In Hundreds Of Structural Bonding Applications

Marine and Aircraft repair

Fiberglass To Fiberglass Bonding

Filleting Compound

Rod Building

Golf Club Assembly

Concrete bonding, patching, sealing

Electronic Potting, Insulating, Encapsulating

Woodwork Bonding, Filleting For Corner Joints

Composite Adhesive, Laminating

Honeycomb Bonding and Edge Closeout

MAX BOND THIXOTROPIC does not contain nonreactive plasticizer that can leach out over time.

It is FDA compliant for direct and indirect food contact applications.

Just measure out equal amounts of Part A and Part B, mix and apply and allow to cure overnight.

It has a 90 minute working time and can be handled in 6 hours.

A strong bond will develop in 10 hours of room temperature curing and will fully cure within 24 to 36 hours.

Heat curing is also ideal for MAX BOND for a faster cure time and will maintain its non-flowing properties at elevated temperatures.

The mixed consistency is similar to peanut butter and is easily applied using a brush, spatula, trowel or injected into place using a syringe.

Why Epoxy Coatings Bead-up. Testing & Preparing Surface Before Applying Epoxy Coating Or Adhesive. - YouTube

Video will open in a new window

Using the eBay App? Paste link into a browser window:

Surface Treatment Prior To Bonding

This is particularly true of adhesive applications where stress will be applied to the cured bond line.

The following surface preparation procedures are recommended.

METALS Degrease – Wipe laying surfaces with Methyl Ethyl Ketone (MEK) or acetone to remove all oil, dirt, and grease.

Etch – For optimum results, metal parts should be immersed in a chromic acid bath solution consisting of: Sodium dichromate – 4 parts by weight Sulfuric acid – 10 parts by weight Water – 30 parts by weight The solution should be held at a temperature of 160°F (71°C), and the parts left immersed for 5 to 7 minutes.

Rinse – remove metal parts from etching bath and rinse in clean cold water (de-ionized water is recommended). If thoroughly clean, metal surfaces so treated will hold a thin film of water.

Dry – To accelerate drying, items to be bonded can be placed in an air-circulating oven.

ALTERNATE PROCEDURE Degrease, scour and dry – Often etching as outlined above is not practical. The metal surfaces may be cleaned by degreasing as noted above, scouring with an alkaline cleanser followed by rinsing and drying.

Degrease and dry – Degrease the surface as noted above, sand or sandblast the surface lightly but thoroughly. Rinse with acetone or Methyl Ethyl Ketone (MEK), and dry. | GLASS Degrease – With MEK as above, or with a strong boiling solution of a good grade household detergent.

Etch – For optimum results, degreasing can be followed by the chromic acid bath outlined above.

WOOD Sand – Bonding surfaces should be sanded lightly, but thoroughly to remove all external contamination.

Clean – Carefully remove all dust, or particles of wood from sanded areas. A stiff and clean brush or compressed air can be used.

PLASTIC (see Flame Treating below) Clean – Remove all dirt, oil, or other surfaces contaminated with detergent soap or degreasing solvent and water, followed by thorough rinsing and drying. A solvent that does not have a detrimental effect may also be used.

Sand – Surfaces to be bonded should be sanded lightly, but thoroughly to remove surface sheen.

Clean – Carefully remove all dust or particles of plastic from the sanded area. A clean brush, lint-free cloth, or compressed air may be used. |

The working time is greatly affected by the amount of resin that is being mixed per batch.

Other factors such as the ambient temperature of the environment and the temperature of the PART A and PART B respectively will also affect the rate of cure.

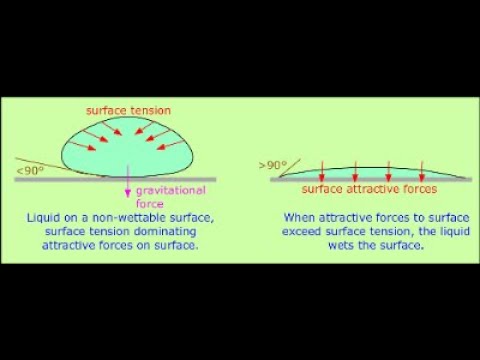

Obtaining adequate bond strength when bonding plastic-to-plastic substrates or plastic to dissimilar substrates is often a challenge for epoxy bonding In general plastic surfaces demonstrates poor ‘wettability’ or the ability of a liquid to form a continuous film.

These types of substrates or are called LSE or Low Surface Energy substrates and in general, most thermoplastic surfaces fall into this category.

Teflon or its generic name PTFE and other polyethylene derivatives such as HDPE, LDPE, UHMW and olefinic-based plastics demonstrate poor liquid wettability due to its low surface energy.

To create a viable bondable surface condition for these types of plastics, it must be surface treated by creating a superficial oxidized surface to increase its dynamic surface tension.

Various types of physical treatment can be used to increase the surface energy of plastics, mostly through oxidation of the superficial layer.

Flame treatment is the most widely used and cost-effective pre-treatment for polyethylene (HDPE, LDPE, UHMW) and polyolefin-based plastics prior to polymer bonding or printing.

The resulting change of the surface by creating an oxidized layer onto the substrate greatly improves the ability of liquids wet-out the surface thus creating a strong adhesive bond between the surface and the coating.

A Flame Treating process consists of exposing the surface to a suitable oxidizing flame for a period in the range 0.2 to 3.0 seconds.

This treatment brings about a change to the polymer surface that increases its surface energy allowing fluids to effectively wet-out the surface and permits a strong adhesive molecular and mechanical bond.

Flame Treating Using A Commercially Available Propane Torch

Flame Treated Surface Ideal For Bonding

Storage Secure the caps for both bottles after use and store above 65°F minimum temperature to prevent re-crystallization. The resin system will remain viable for at least 12 months or longer when stored properly. The PART A or resin component may 'crystallize' after prolonged storage. Please inspect the PART A bottle for any solid crystallization that will appear on the bottom of the bottle.

Please Check Out Other Available Resin Systems At Our eBay Store

For our complete listing, please Visit our eBay store!

PLEASE CHECK OUT OTHER AVAILABLE RESIN SYSTEMS AT OUR eBay STORE

IMPORTANT NOTICE Your purchase constitutes the acceptance of this disclaimer. Please review before purchasing this product. The user should thoroughly test any proposed use of this product and independently conclude satisfactory performance in the application. Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval. The information contained herein is based on data believed to be accurate at the time of publication. Data and parameters cited have been obtained through published information, Polymer Composites, Inc. laboratories using materials under controlled conditions. Data of this type should not be used for a specification for fabrication and design. It is the user's responsibility to determine this Composites fitness for use. There is no warranty of merchantability of fitness for use, nor any other express implied warranty. The user's exclusive remedy and the manufacturer's liability are limited to refund of the purchase price or replacement of the product within the agreed warranty period. Polymer Composites, Inc. and its direct representative will not be liable for incidental or consequential damages of any kind. Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether there is any infringement of patents is the sole liability of the user.

Your purchase constitutes the acceptance of this disclaimer. Please review before purchasing this product. The user should thoroughly test any proposed use of this product and independently conclude satisfactory performance in the application. Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval. The information contained herein is based on data believed to be accurate at the time of publication. Data and parameters cited have been obtained through published information, Polymer Composites, Inc. laboratories using materials under controlled conditions. Data of this type should not be used for a specification for fabrication and design. It is the user's responsibility to determine this Composites fitness for use. There is no warranty of merchantability of fitness for use, nor any other express implied warranty. The user's exclusive remedy and the manufacturer's liability are limited to refund of the purchase price or replacement of the product within the agreed warranty period. Polymer Composites, Inc. and its direct representative will not be liable for incidental or consequential damages of any kind. Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether there is any infringement of patents is the sole liability of the user.