Honeywell PTM 7950 Thermal Phase Change Pad

- Honeywell PTM7950 is an industrial standard thermal interface material with phase changing properties. (becomes liquid at 45°C.)

- One of the best applications for this material is as heat dissipation contact for CPU's and GPU's with a thermal conductivity of 8.5W/m·K.

- It boasts a high reliability under thermal cycling, with no degradation in performance over time.

Key benefits

PTM7950 has several practical and performance related benefits over its competitors:

- Long Term stability - Pads will not leak or dry out over time.

- Not electrically conductive - Unlike liquid metal this product doesnt run the risk of shorting your build.

- Performance par with market leading thermal pastes and liquid metals - Refer to the multitude of performance tests over the internet, as well as LTT videos and the fact that many manufacturers are now using PTM7950 in laptops and phones.

- Performance does not degrade over time - Pads do not have to be reapplied to maintain maximum perfomance - long term usage without degradation over time.

- Cost effectiveness - While the initial outlay may be higher than regular paste, the longevity of the pads means a greater cost effectiveness especially against higher end brands.

- No over-application - Pads come in a standard 0.2mm thickness and can be cut to size, so no leaking out the sides of the application area.

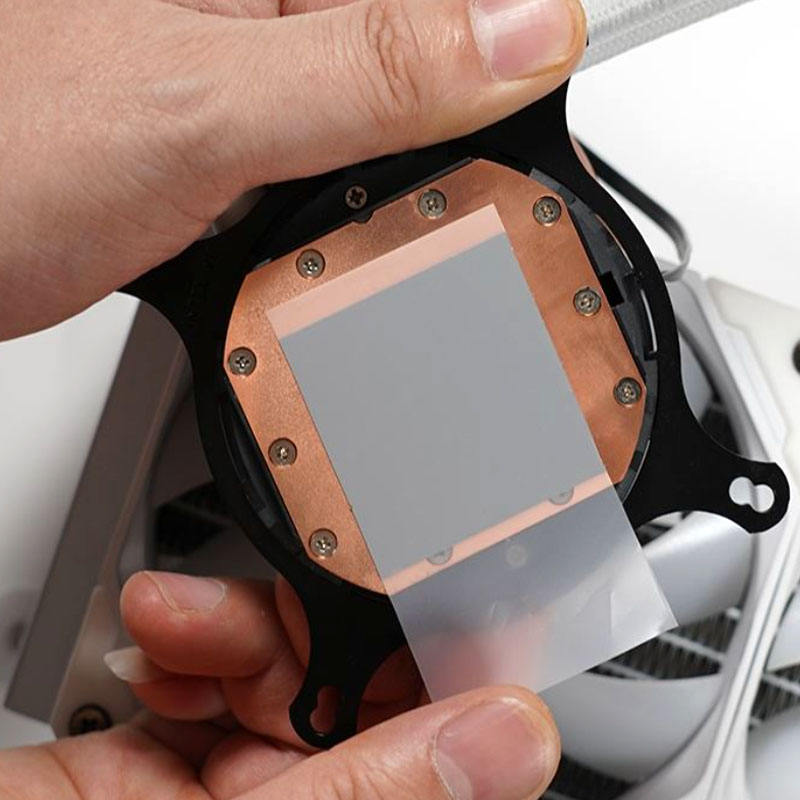

- Can be applied at various contact points - (See images)

Contact

If you have any questions about wether this product is right for you, I can be contacted at any time through eBay. I aim to respond within 24 hours and do my best to help where I can.

| Payment | Immediate payment required. |

|---|---|

| Shipping | Shipping is Royal Mail 2nd Class letter by default, but faster services are available for an additional fee. Product is sent next or same day depending on time of purchase - excluding weekends and postal non-service days. Multiple items can be shipped under one postage fee, any additional paid will be refunded. |

| Disclaimer | I cannot be responsible for missaplication of this product. While it is easy to apply when following the guide, accidents do happen. I can only refund your return if the pad is in the same condition it was sent (plastic front/back not removed, no bends or folds) |

STORAGE

Recommended storage temperature prior to application is 19°C-25°C.

Best Known Application Method for PTM7950 Pad Materials

- Clean surface of heat sink with IPA.

- Using a heat gun or an oven, heat the surface of the heat sink where the PTM7950 is to be applied. The temperature should be between 90 and 150˚F.

- Remove the roll liner side of the liner from the PTM. Cooling the material in a refrigerator for 10 minutes will make it easier to remove the liner.

- Place the PTM on the heated heat sink surface. Then using your thumb, apply even pressure across the entire surface of the PTM pad. It would be the same as applying a sticker.

- Let the heat sink cool to room temperature.

- After the heat sink has cooled the tab liner can then be removed (a fastmotion may be used). Starting to peel from a corner edge may also be helpful.

NOTES:

- Chilling the material will make the liner easier to remove.

- Slightly heating the substrate before applying the material assists adhesion.

- Remember to apply even pressure across entire surface of pad.

- Let substrate cool before removing tab liner.

Recommended Application Clamping pressure and temperature are suggested to achieve a minimum bond line thickness, typically less than 1.5 mil (0.038mm) for best thermal performance.

Storage & Use

Shelf Life: 12 months

Availability

PTM pad is available in both sheet and roll formats. Thickness Range: 0.2mm-1.0mm Stencil printable (SP) material is available in 300cc syringes or 1kg jars.

TYPICAL PROPERTIES | ||||||

PROPERTY | LTM | PCM45F | PTM5000 | PTM6000 | PTM7000 | TEST |

DESCRIPTION | SERIES | SERIES | SERIES | SERIES* | SERIES | METHOD |

Physical Properties

Specific Gravity | 1.8 | 2.2 | 2.3 | 2.3 | 2.7 | ASTM D374 |

Thickness Range (mm) NA 0.20-1.00 0.20-1.00 0.20-1.00 0.20-1.00 NA

Thermal | Properties | |||||

Thermal Conductivity (W/m·K) | 1.8-2.4 | 2.0-2.5 | 3.5-4.5 | 3.5-4.5 | 6.0-8.5 | ASTM D5470 |

Electrical | Properties | |||||

Volume Resistivity (ohm·cm) | 3.0×1015 | 8.2×1014 | 2.1×1014 | 2.1×1014 | 2.1×1014 | ASTM D257 |