Welcome to be the distributor of our machines in your country! for more details. please feel free to contact us!

SMT production Line

High precision 3040 Stencil printer + CHMT48VB 58 feeders + 2500w Reflow oven BRT-420(220v),

Free shipping TNT / Fedex/ DHL express door to door shippping.

or you can arrange pick up machine from our factory directly!

Stencil printer 3040 is the best quality in China with high feedback, 100% high feedback. CHMT48VB sells very well and it has 58pcs feeders, which can meed more customers demand, it is very popular now! And BRT-420 reflow oven is the best quality drawer type oven in China, it is better than other drawer type oven in China, we recommend!

Machine is completed, ready for work, each machine will be 100% tested well, QC passed.

Please purchase it with confidence.

Quality guarantee, quality is better than other brand machines.

Packing list:

1set CHMT48VB Desktop pick and place machine complete set

1set Vibration Feeder for CHMT48VB

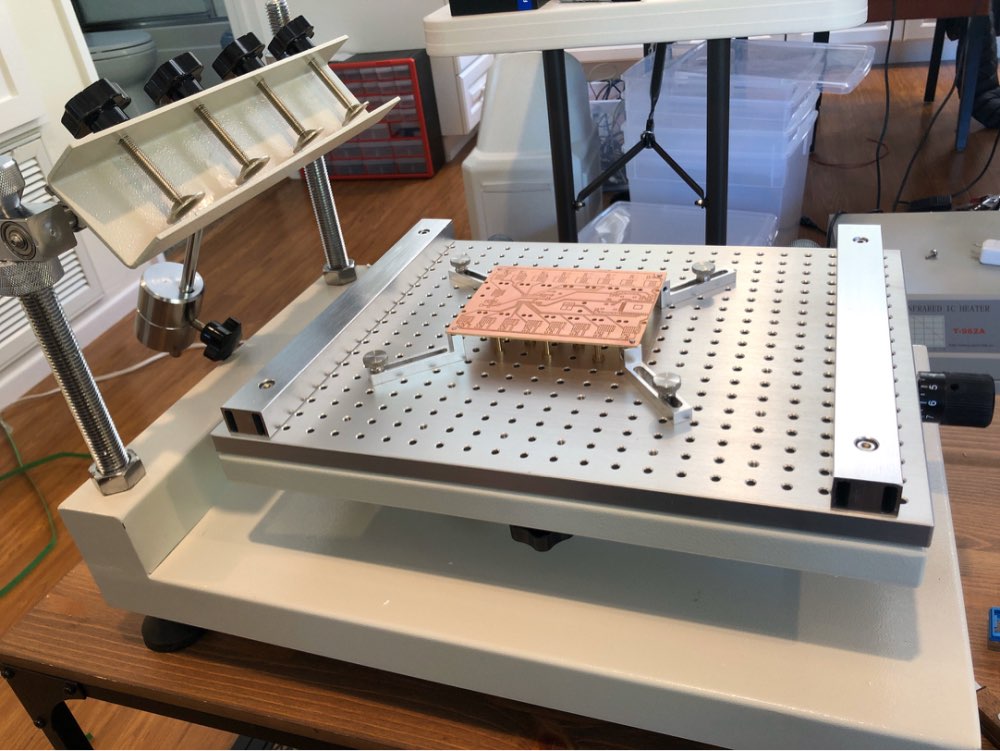

1set High precision stencill printer 3040 best quality

1set 2500W 300*300mm Infrarad + hot air reflow oven BRT-420 (220v)

Machine is ready for work, best quality machine and after sales service will be supplied, each machine will be 100% tested before shipping, QC passed.with CE certification.

Please purchase it with confidence.

This offer including:

1pcs pick and Place machine CHMT48VB

1pcs Vibration feeders

4pcs Juki Nozzles: 503, 504,505,506.

1pcs 8G USB flash

1pcs Power cord

1pcs Pull pins

1pcs coil for pull pin

1pcs camera positioning adjust black board

1pcs Hex wrench

1pcs Tweezers

1pcs Brush

1pcs machine english opperaiton manual

1pcs vibration feeder

1pcs 3040 stencial printer

1pcs Reflow Oven

Specifications for three items:

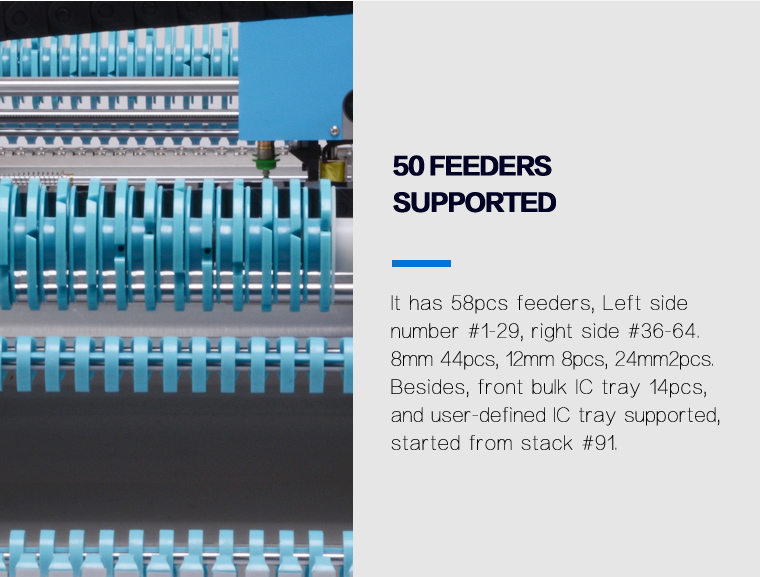

Competitive Advantages: (CHMT48VB)

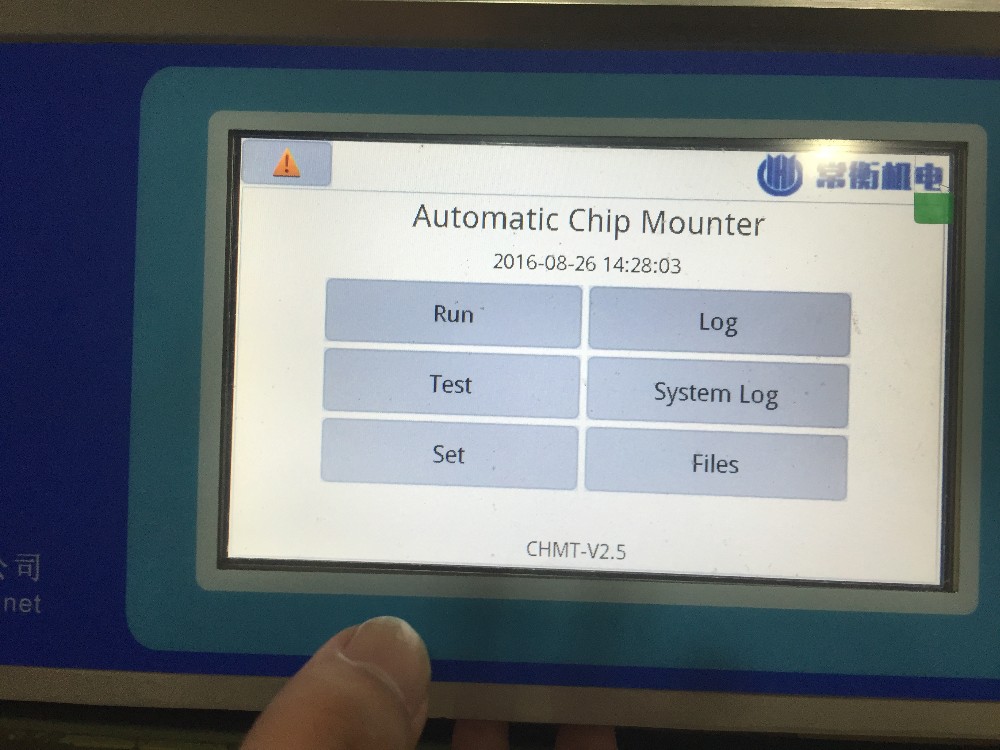

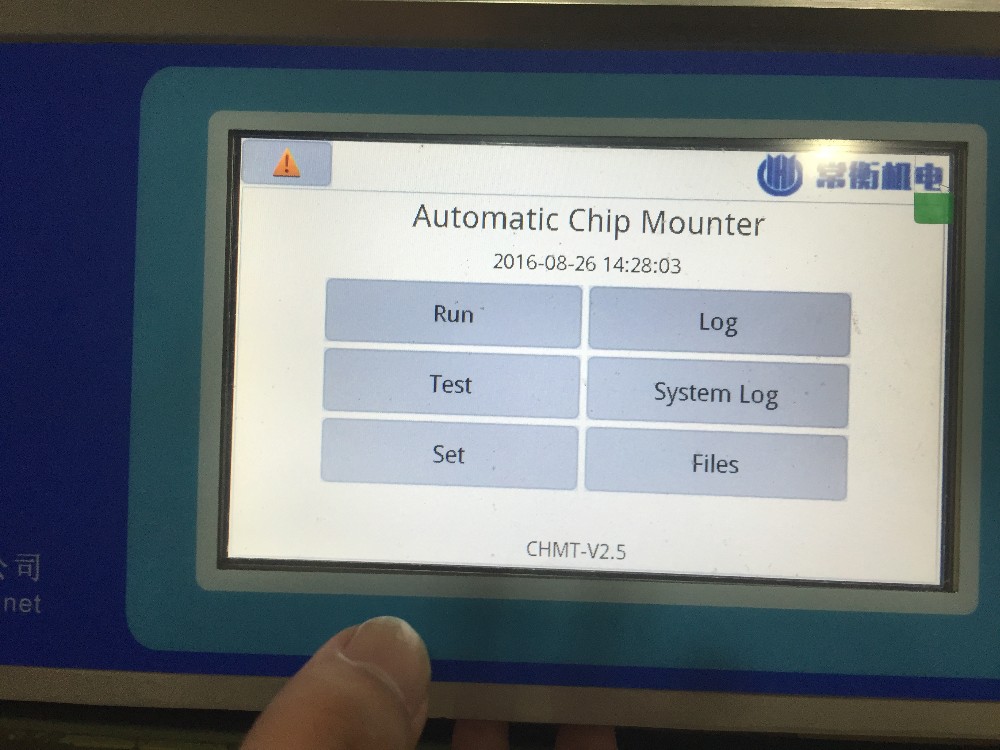

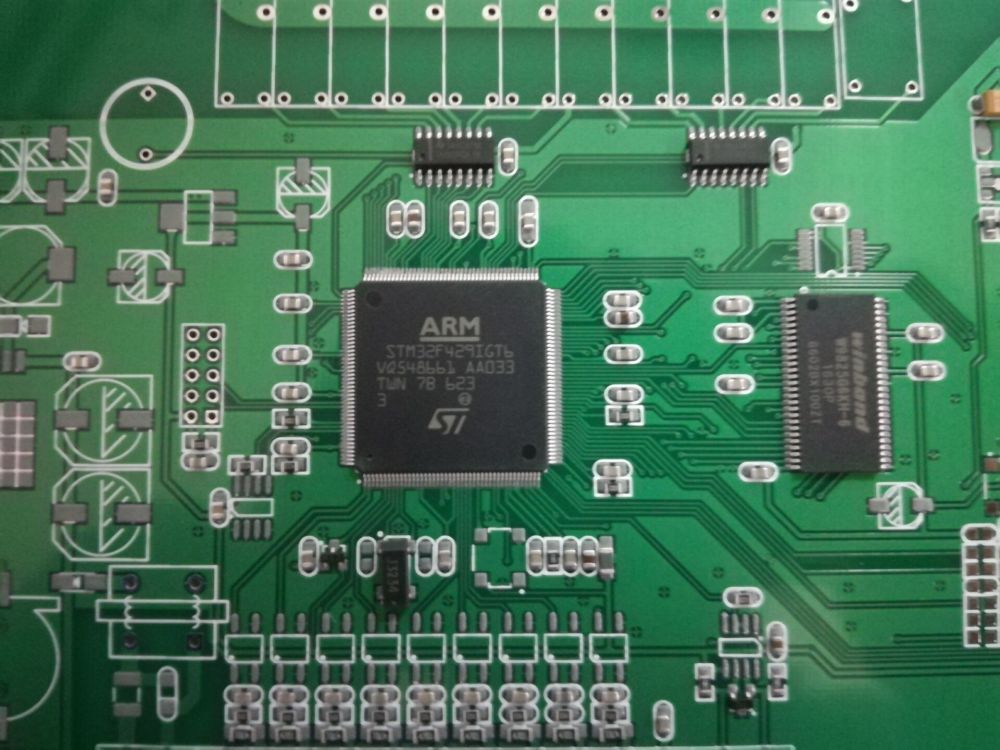

1. Convenient software, Embedded Linux System of the machine, stable industry main board, independent operation, no need external computer, operation easier and more convenient, learn fast.

2. In-build touch screen, no need external monitor, room saved, more convenient operation, USB mouse supported as well.

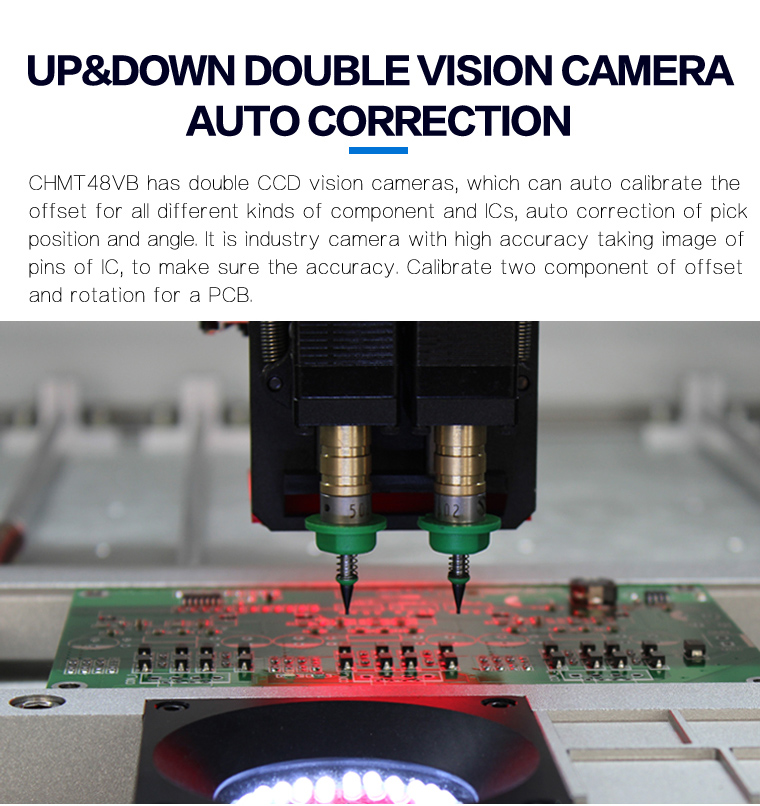

3. Top and bottom two vision cameras, correct the position of each components, you can view the vision image from screen for every components.(max component size 22*22mm)

4. It has flexible PCB clamping fixture, suitable for different size of PCB.

5. It supported custom IC tray, IC tray can be fixed on machine table.

6. Two mounting heads with 2pcs Juki Nozzles, Juki nozzle inside magnet, so it can be removed by finger, no need to disassemble with wrench, nozzles rotation angle -180 degree to +180 degree.

7. All-in-one machine, 29pcs feeders included in machine, no need to buy other parts, machine is ready to work.

8. Z axis detection, machine's pull needle automatically return to origin to avoid nozzles broken.

9. Max height component support 5mm.

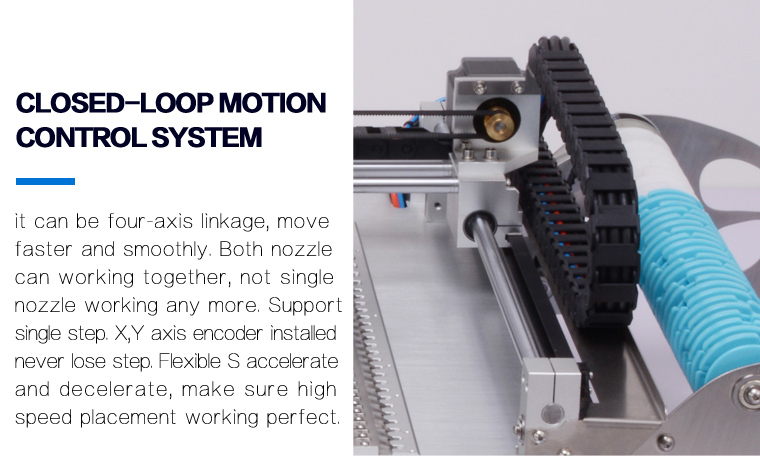

10. Closed-loop control, X,Y Axis with encoder, not out of step.

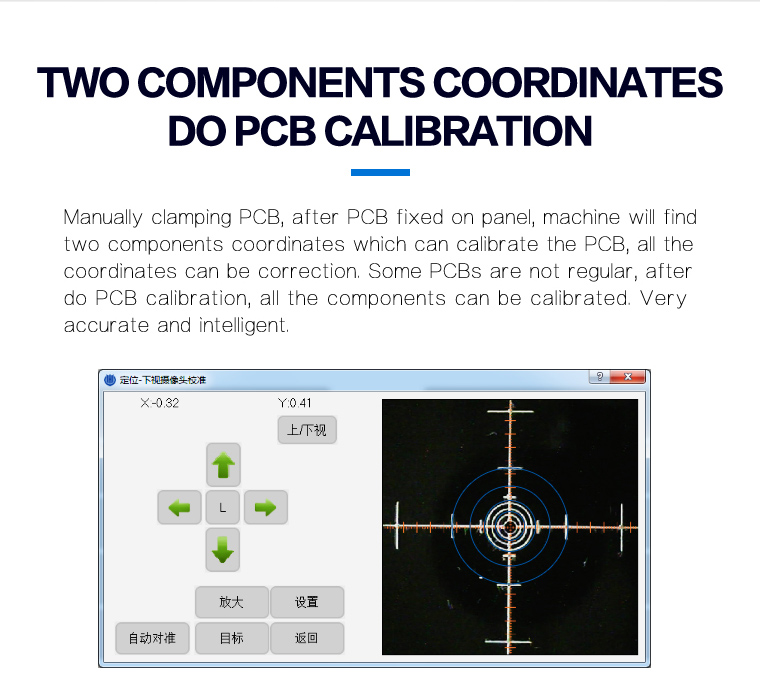

11. PCB calibrated by two components position, then rest components will be calibrated automatically.

12. With vacuum detection, with automatic feeding, if one component suck crooked, it will automatically throw it to deposit area, then pick a new one to mount again.

13. With vision detection, camera will auto correction component angle and place on PCB board right place. If heads not picking up components, camera will detect it and go back to pick again, 3 times not picking, machine will alarm and stop, after supply material, then continue working, no need to start over again.

14. Comes with convert tool (PC version), edit work file in computer and load work file into machine by USB port, quick and convenient.

15. Support panelized boards.

16. If you don't have PCB file, you can create a new work file to program in machine directly.

17. Support single step.

18. Support cut tapes/ bulk material/ tube material.

1) Pick and Place Machine CHMT48VB + vibration feeder: 1 2) Juki nozzle: Totally 4pcs (503, 504, 505, 506 size) 3) 8G USB flash 1 4) Power Cord: 1 5) Pull pin: 2 6) Coil for pull pin:1 7) Camera positioning adjust black board: 1 8) Hex wrench: 6 9) Tweezers: 1 10) Brush: 1 11) English user manual: 1

BTR-420 Reflow oven:

SMD Machine features and advantages:

With Vision system , and embeded computer with linux system.

With closed loop control. can move more faster and smoothly

with 58pcs feeders, more effective. can work with more kinds of components.

with 9 kinds of different nozzles, can place with 0201, 0402. 0603, 0805-505etc, and QFN, SOP, LQFP. all kinds of IC. and diode, triode.

with Z axis detection can self-checking the height and angle during placement. can make sure this machine work well with various kinds of components.

We can supply english machine opperation manual and technical support. Please be confident to make the purchase.

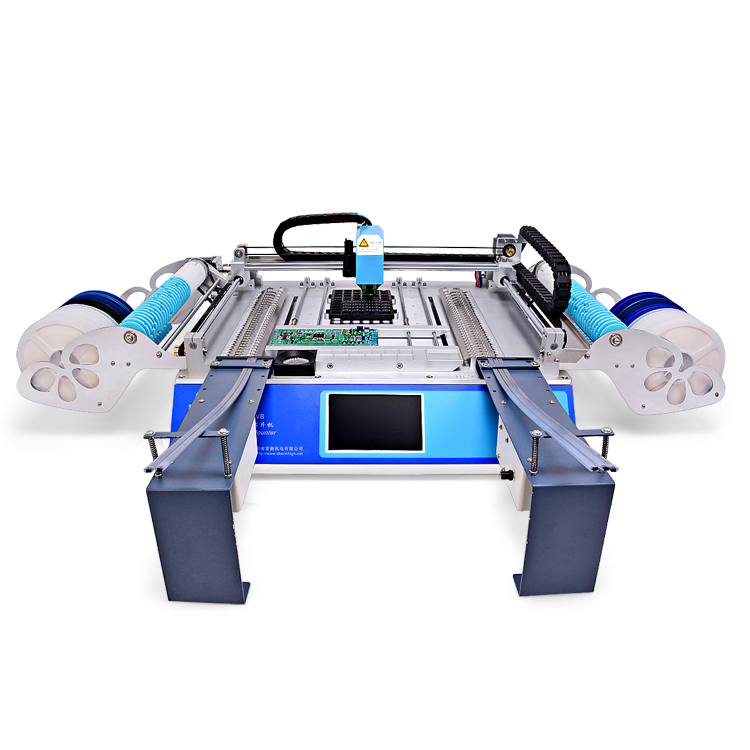

Machine Structions:

(1) Up camera: Used for calibrating the components position, angle, so as to improve placement accuracy.

(2) IC material stack: used for place the big IC.

(3) LCD touch screen: Used for operating the machine.

(4) PCB clamping area: fixing the PCB, let PCB close to left, top spring should be compacted.

(5) USB port: Used for connect the USB storage device.

(6) Emergency stop switch: Emergency stop after press down, machine normal work when clockwise rotation and bounce.

(7) Power button: Used for opening or off the machine.

(8) Nozzle & Pull needle: Nozzle used for absorbing materials and mount on PCB, pull needle used for pull the material go ahead.

(9) Tape placing area A/B : Used for placing tape.

(10)Belt receiving wheel A/B : Used for collecting film.

(11)Ordinary material stack : Place tape packaging materials.

(12)IC tray area: Used for fixing IC tray.

(13)Down camera: Used for observing and location, and PCB MARK auto adjust.

adjust.

Machine images:

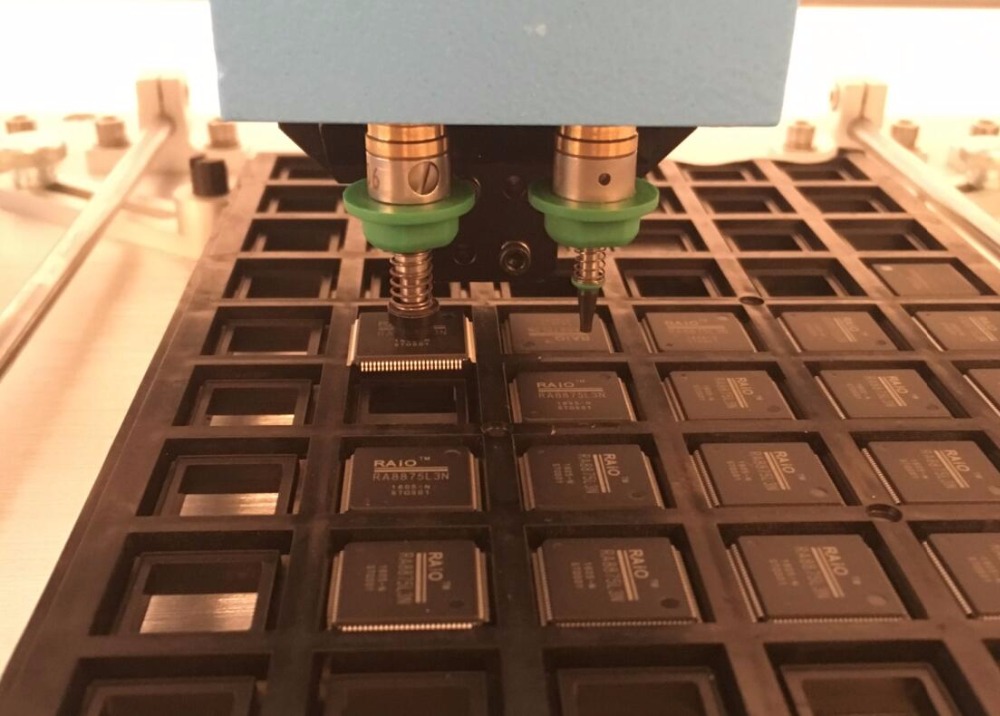

User-defined IC Tray:

Touch screen , or you can connect USB mouse to control the screen!

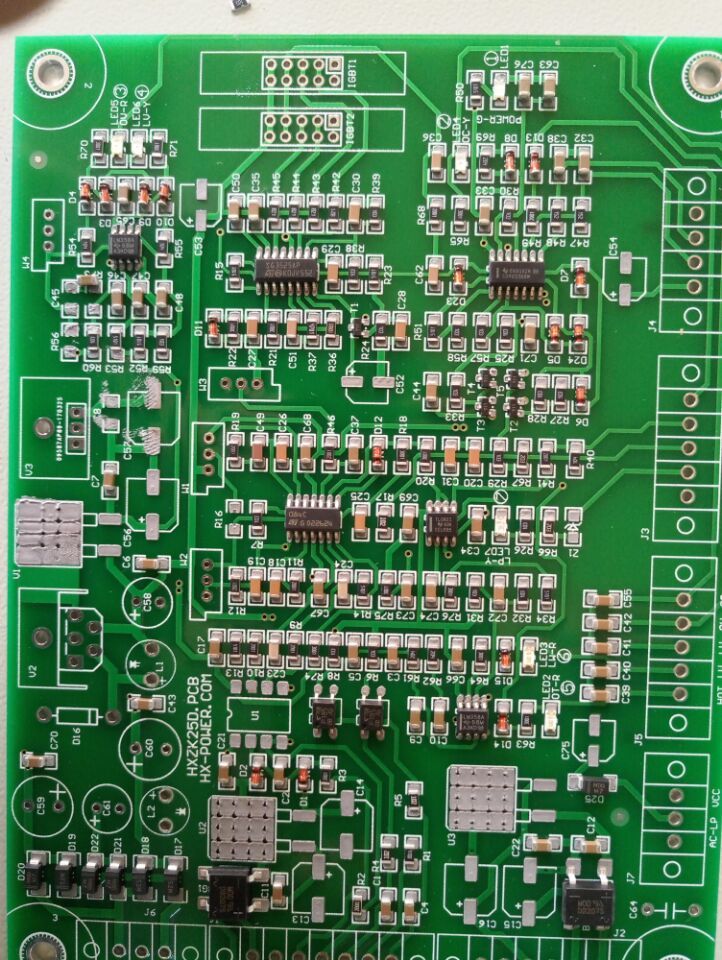

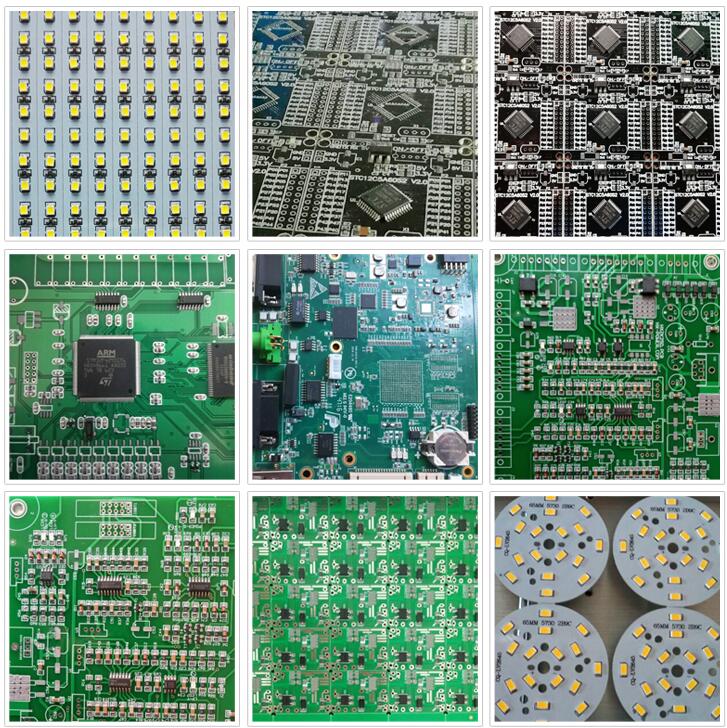

Samples:

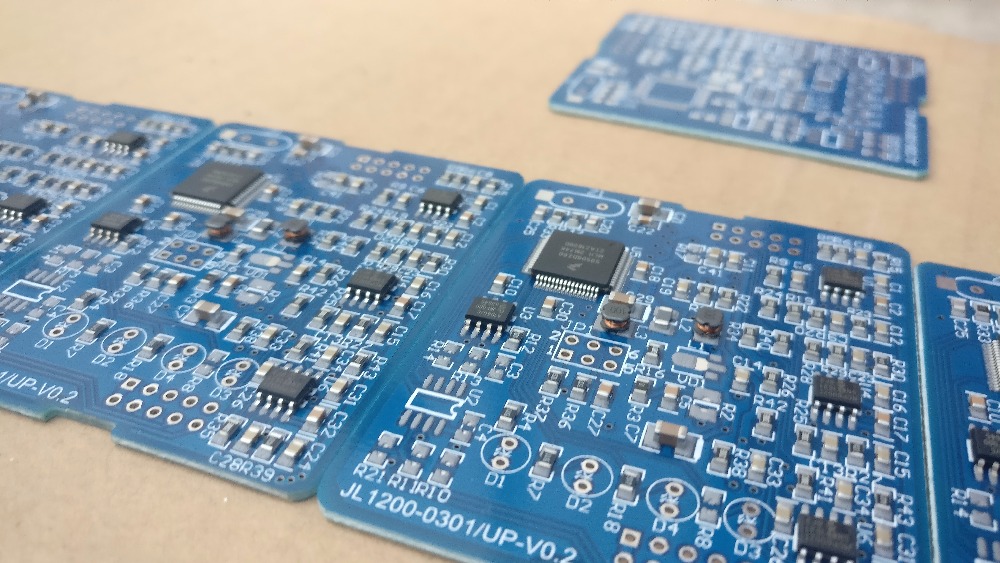

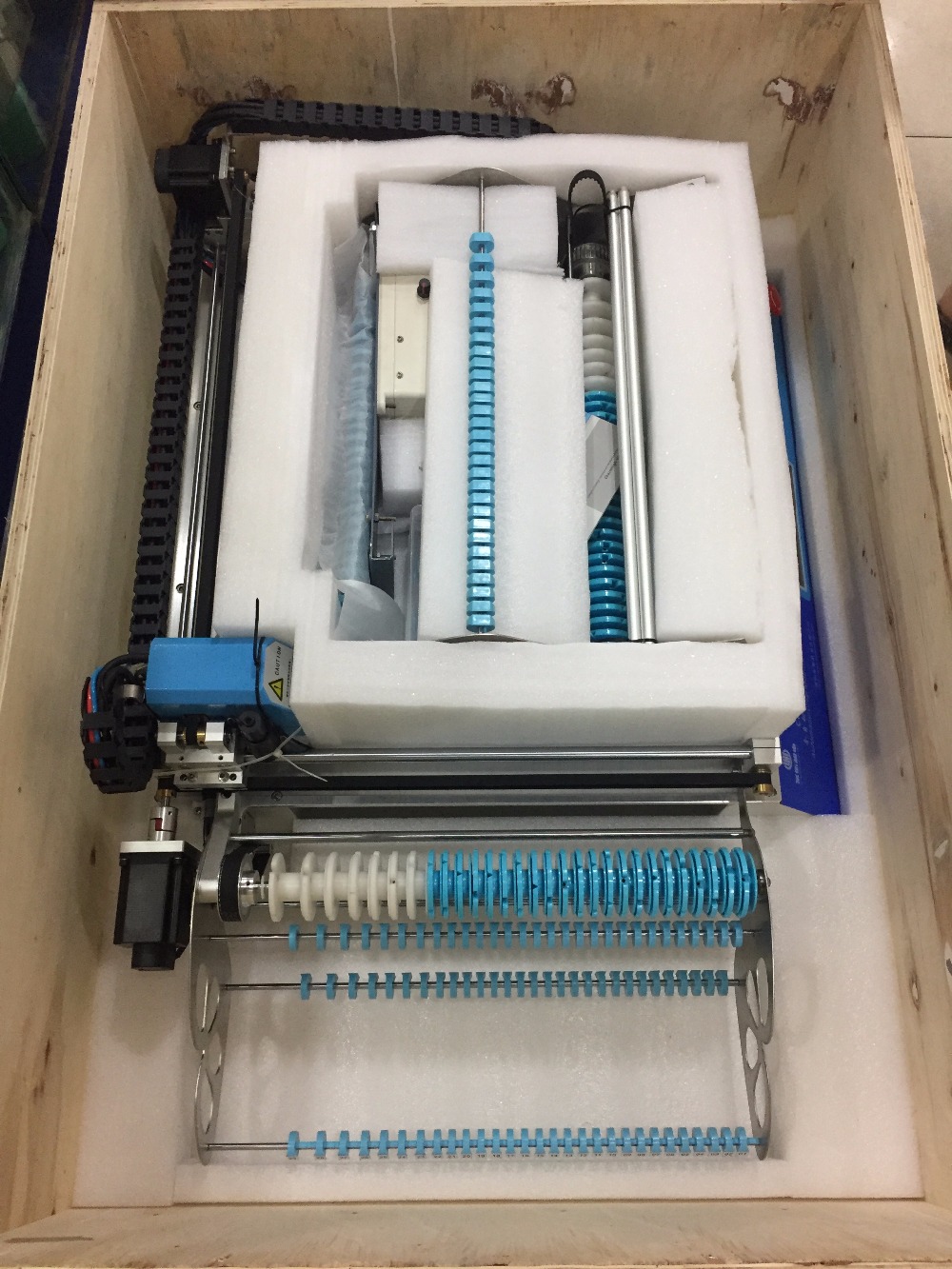

Packing:

、

Accerrory list

We also have models by below:

Maintenance:

Clearing machine after using, close software before switch off power;

According to condition of using, smear some grease to bearings regularly to make sure it work smoothly.

Cover machine if unused for a long time to avoid the dust.

Warranty:

Warranty range: SMT machine itself.

Warranty period: 12 months.

If there are problems in using, please contact us promptly, and do not repair by yourself to avoid damage to machine, or will lose your warranty.

If accessories are breakdown, we will send a new one to you after receiving the break one.

During warranty period, freight of send back to us is paid by user, freight of send to user is paid by us

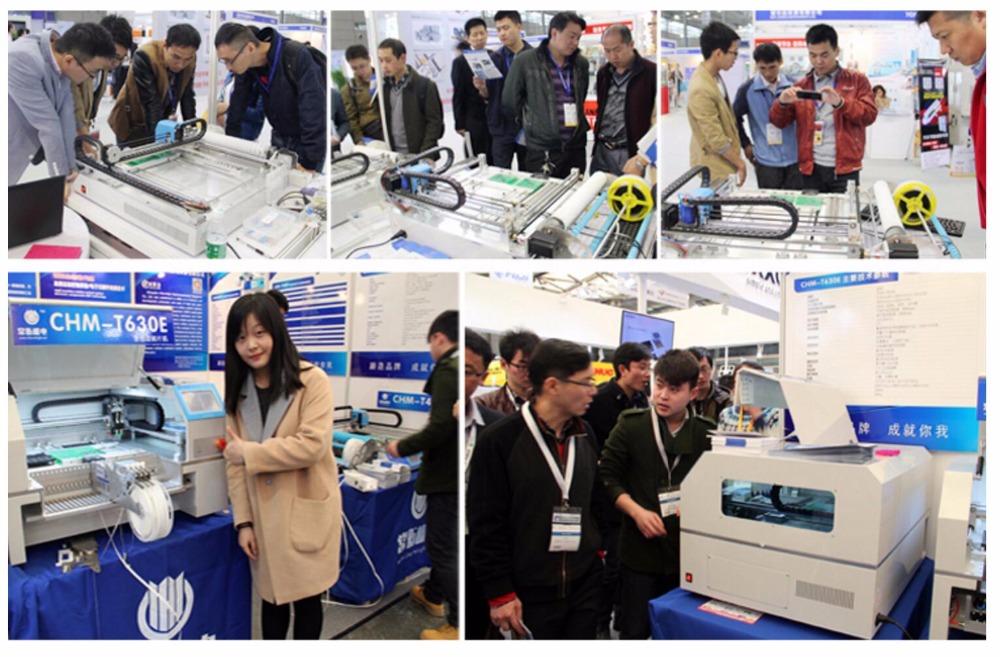

Factory and exhibition

CE CERTIFIATIONS:

Thanks!