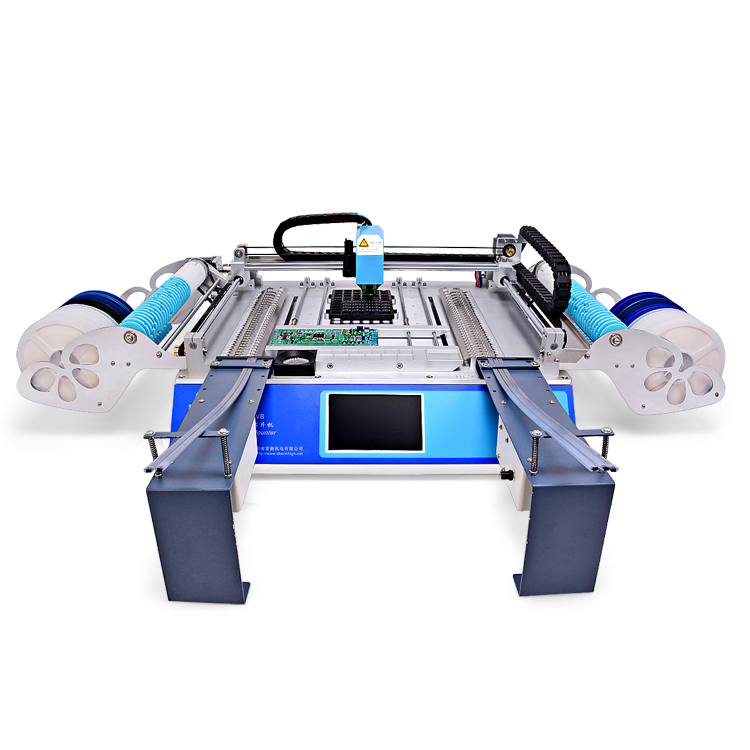

Desktop Pick and Place machine CHM-T48VBwith 1pcs Vibration feeders

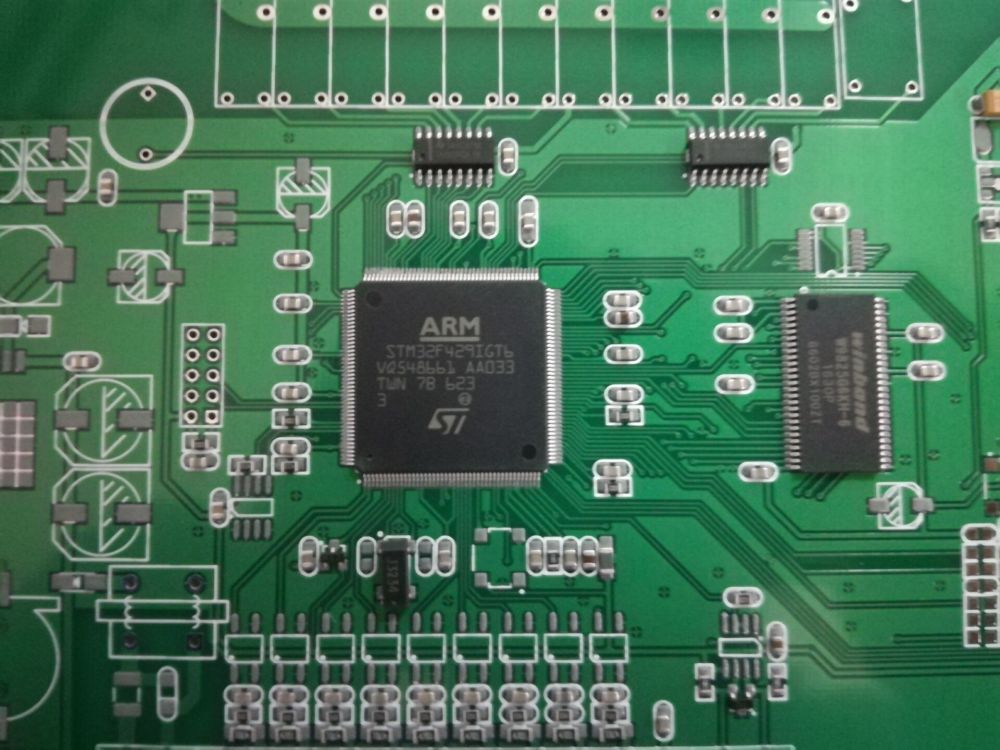

embeded computer with Linux system

with vision system

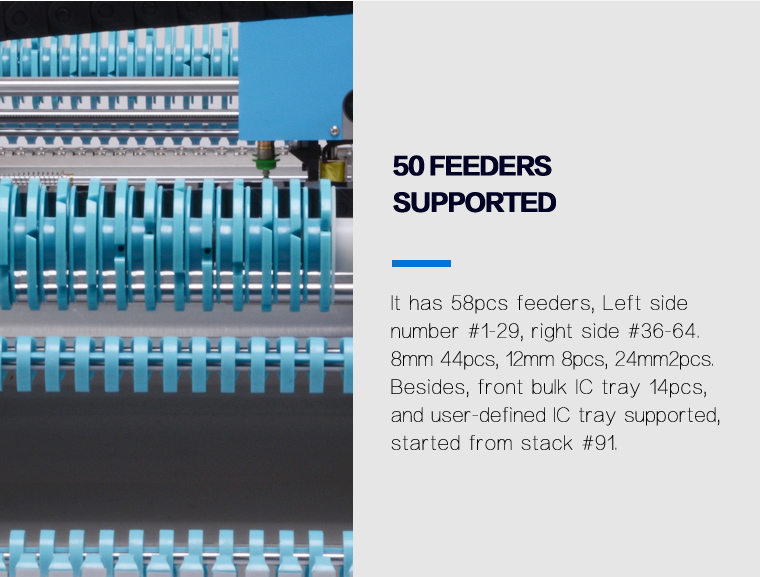

58pcs feeders more effective

This machine will be deliveried to you from china by fedex, DHL or TNT door to door shipping way! with tracking No. included.

Machine is ready for work, best quality machine and after sales service will be supplied, each machine will be 100% tested before shipping, QC passed.with CE certification.

Please purchase it with confidence.

This offer including:

1pcs pick and Place machine CHMT48VB

1pcs Vibration feeders

4pcs Juki Nozzles: 503, 504,505,506.

1pcs 8G USB flash

1pcs Power cord

1pcs Pull pins

1pcs coil for pull pin

1pcs camera positioning adjust black board

1pcs Hex wrench

1pcs Tweezers

1pcs Brush

1pcs machine english opperaiton manual

Machine features and advantages:

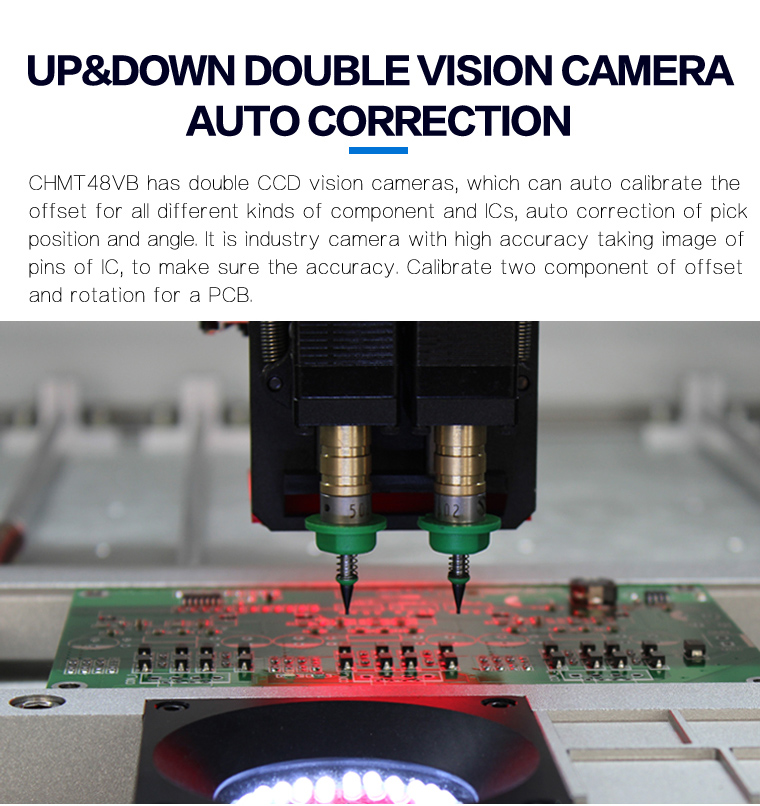

With Vision system , and embeded computer with linux system.

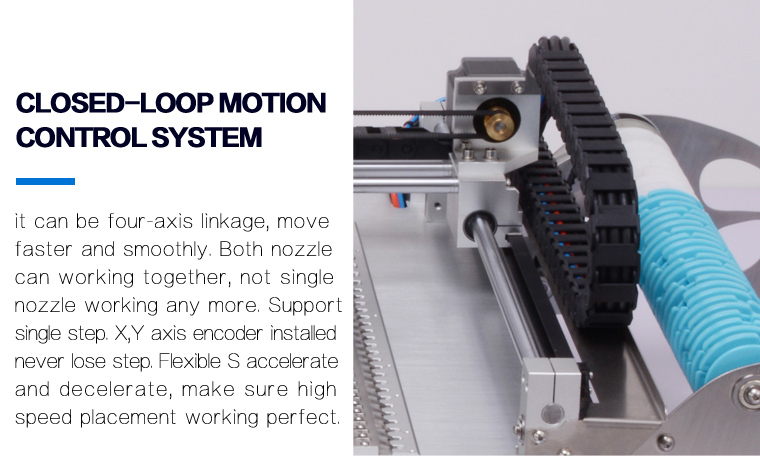

With closed loop control. can move more faster and smoothly

with 58pcs feeders, more effective. can work with more kinds of components.

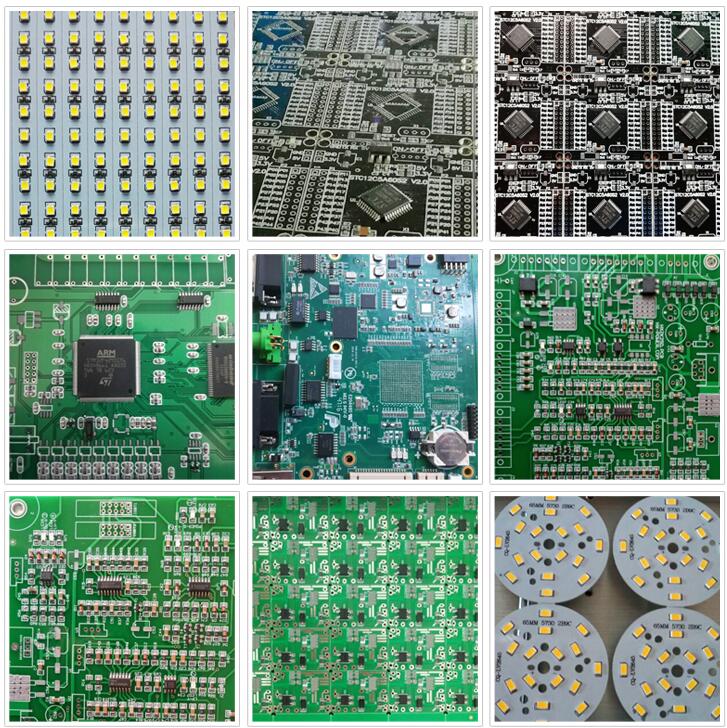

with 9 kinds of different nozzles, can place with0201, 0402. 0603, 0805-505etc, and QFN, SOP, LQFP. all kinds of IC. and diode, triode.

with Z axis detection can self-checking the height and angle during placement. can make sure this machine work well with various kinds of components.

We can supply english machine opperation manual and technical support. Please be confident to make the purchase.

Pick and Place Machine Parameters:

Main parameters:

Machine structures:

Machine structures:

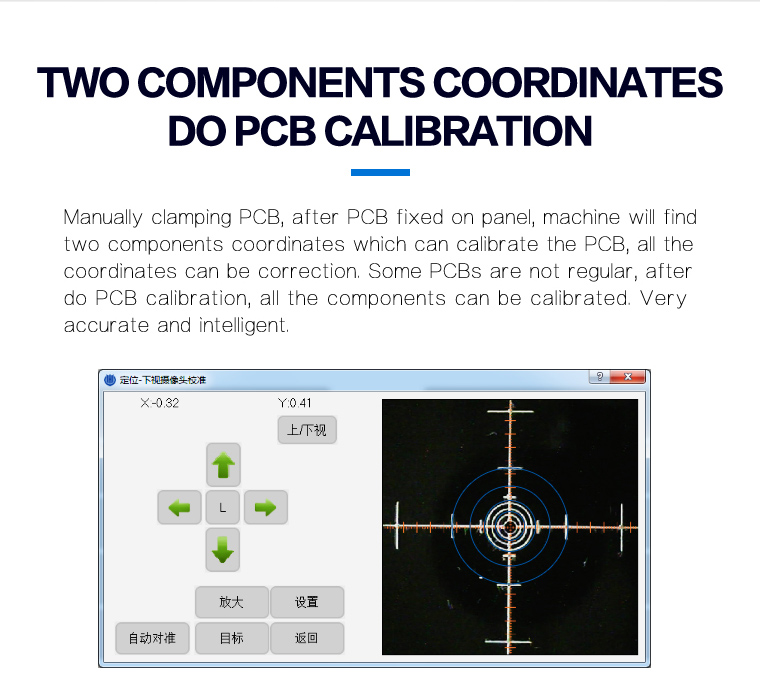

(1) Up camera: Used for calibrating the components position, angle, so as to improve placement accuracy.

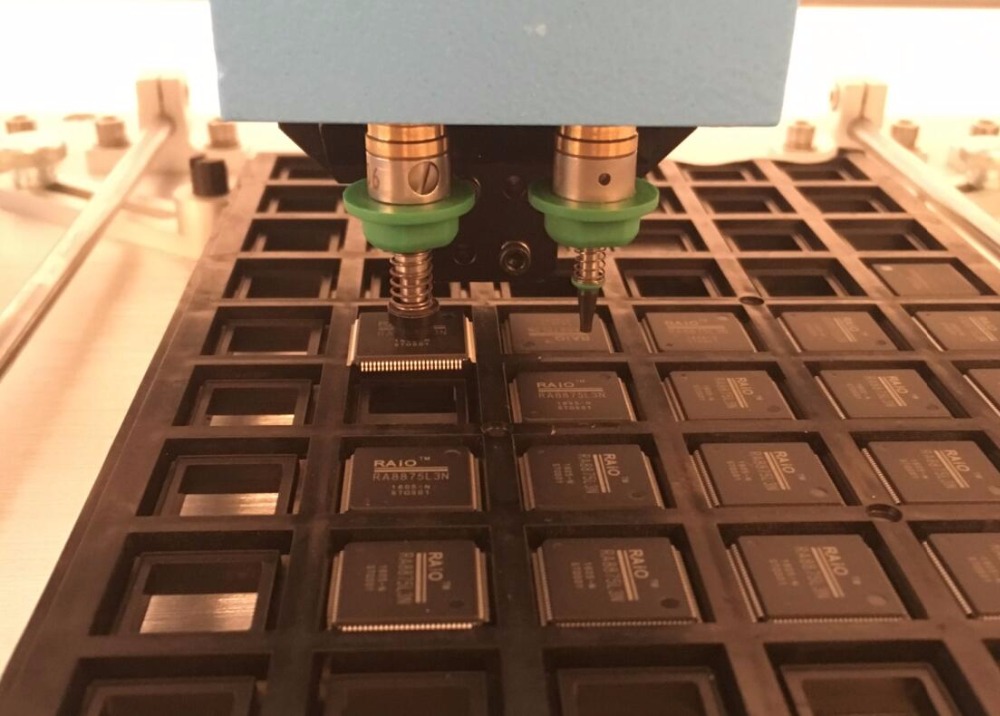

(2) IC material stack: used for place the big IC.

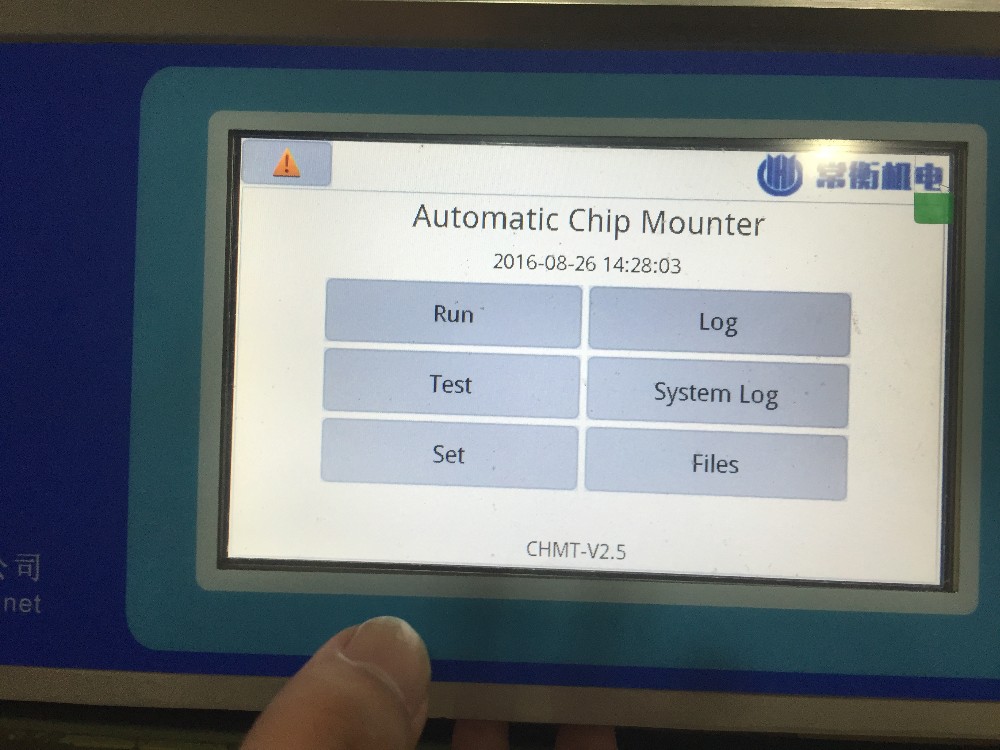

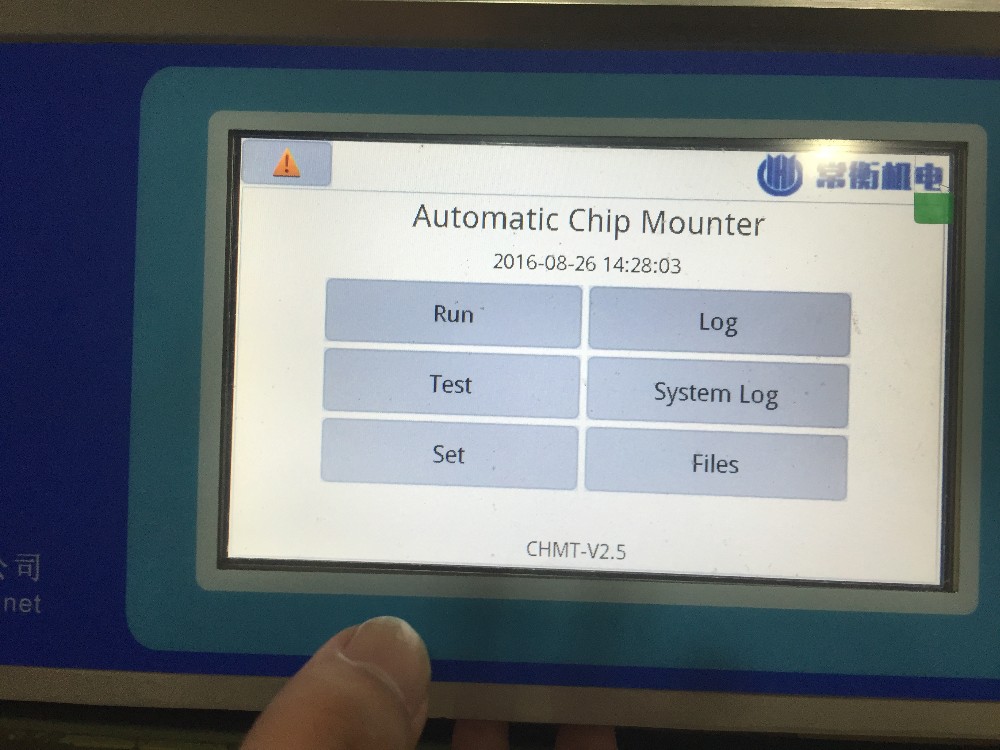

(3) LCD touch screen: Used for operating the machine.

(4) PCB clamping area: fixing the PCB, let PCB close to left, top spring should be compacted.

(5) USB port: Used for connect the USB storage device.

(6) Emergency stop switch: Emergency stop after press down, machine normal work when clockwise rotation and bounce.

(7) Power button: Used for opening or off the machine.

(8) Nozzle & Pull needle: Nozzle used for absorbing materials and mount on PCB, pull needle used for pull the material go ahead.

(9) Tape placing area A/B : Used for placing tape.

(10)Belt receiving wheel A/B : Used for collecting film.

(11)Ordinary material stack : Place tape packaging materials.

(12)IC tray area: Used for fixing IC tray.

(13)Down camera: Used for observing and location, and PCB MARK auto adjust.

Machine images:

User-defined IC Tray:

Touch screen , or you can connect USB mouse to control the screen!

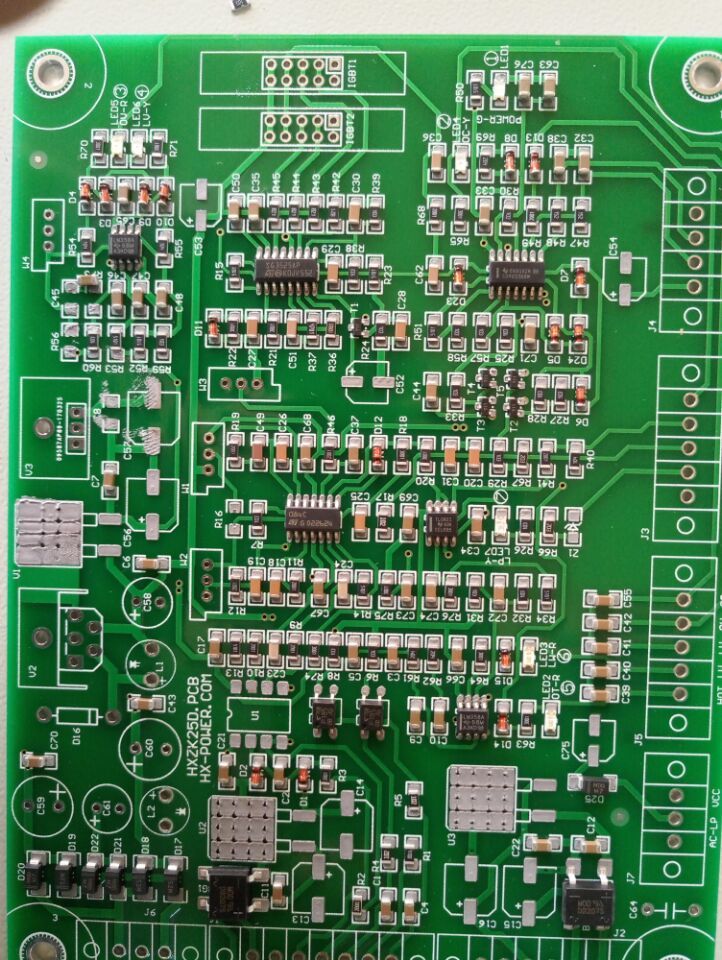

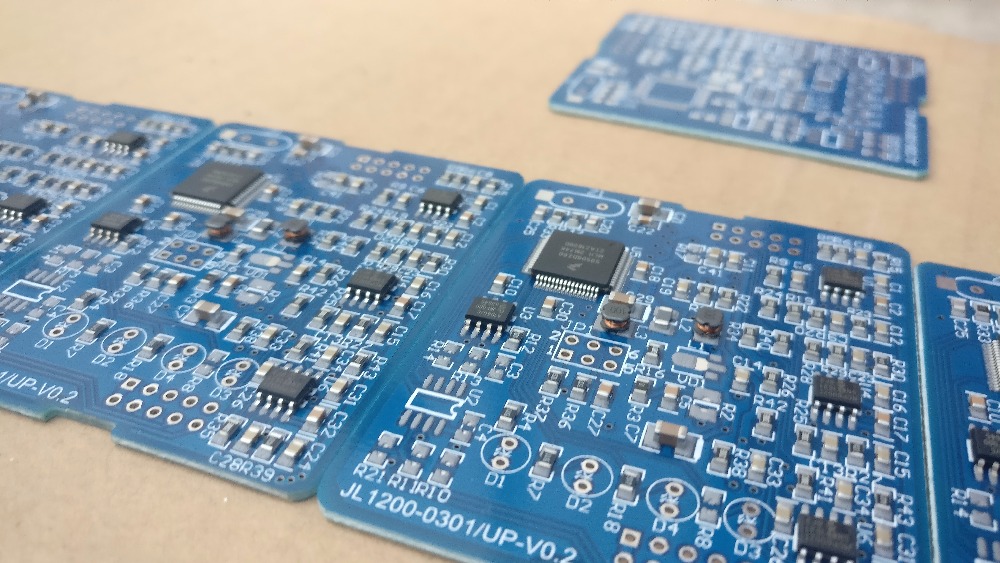

Samples:

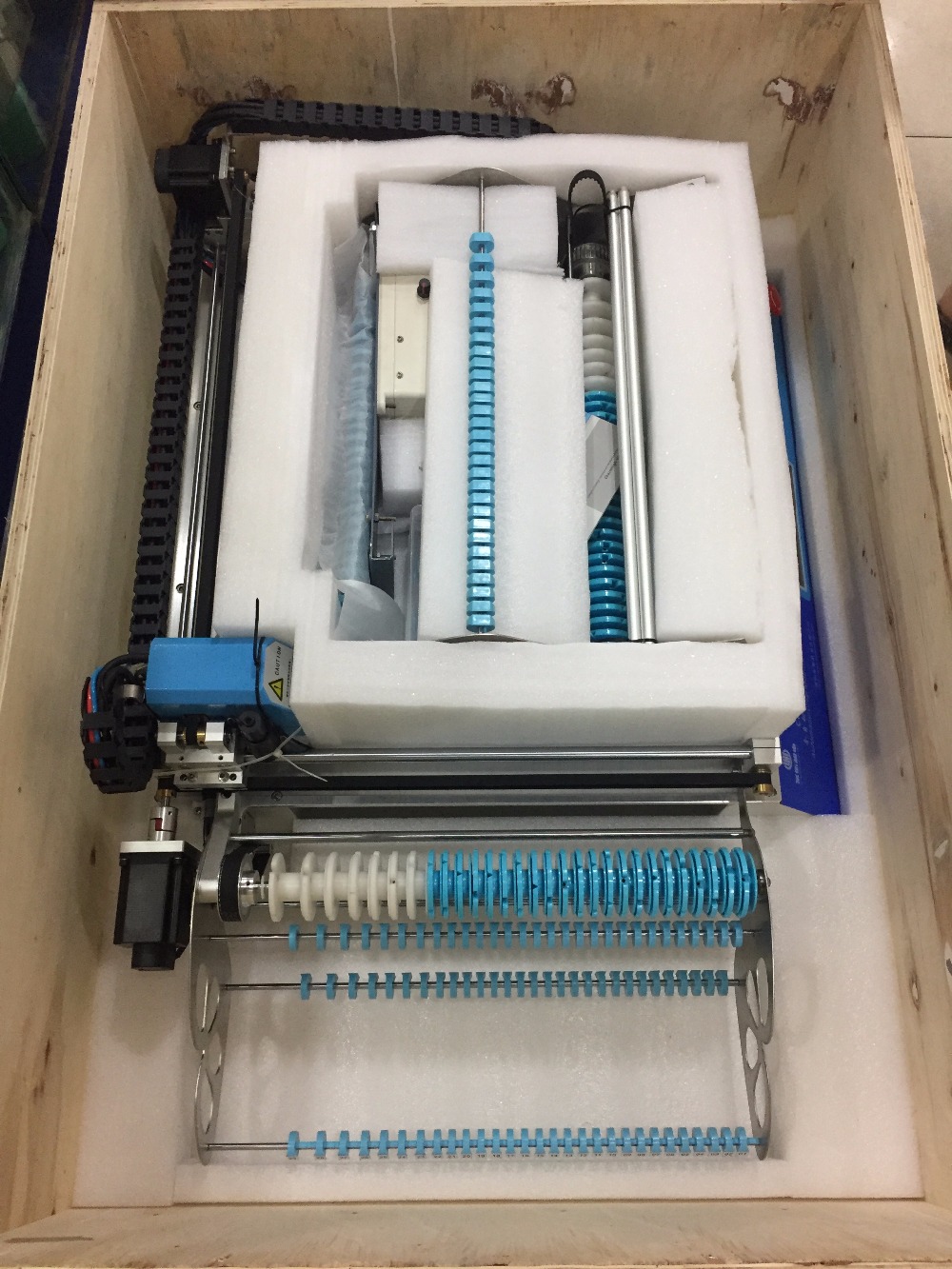

Packing:

、

Accerrory list

We also have models by below:

Maintenance:

Clearing machine after using, close software before switch off power;

According to condition of using, smear some grease to bearings regularly to make sure it work smoothly.

Cover machine if unused for a long time to avoid the dust.

Warranty:

Warranty range: SMT machine itself.

Warranty period: 12 months.

If there are problems in using, please contact us promptly, and do not repair by yourself to avoid damage to machine, or will lose your warranty.

If accessories are breakdown, we will send a new one to you after receiving the break one.

During warranty period, freight of send back to us is paid by user, freight of send to user is paid by us

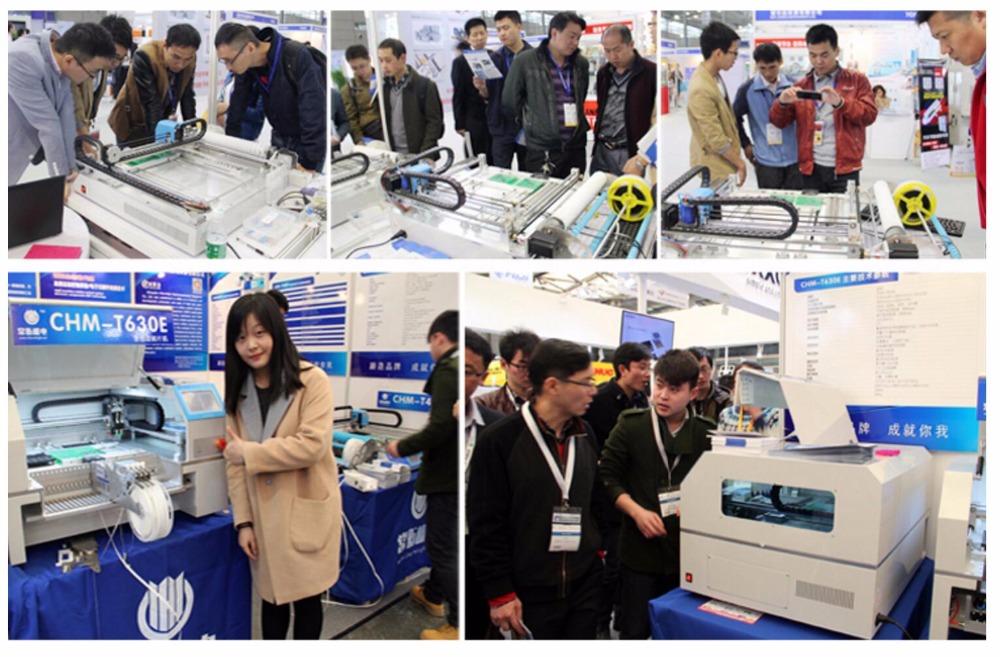

Factory and exhibition

CE CERTIFIATIONS:

Thanks!

Am 20.03.2023 hat der Verkäufer die folgenden Angaben hinzugefügt:

Am 24.04.2023 hat der Verkäufer die folgenden Angaben hinzugefügt:

Am 23.05.2023 hat der Verkäufer die folgenden Angaben hinzugefügt: