Generator Features:

1.low start-up torque, wind energy utilization high;

2.small size, beautiful appearance, low vibration;

3.human friendly design, easy installation, maintenance and repair;

4.permanent magnet generator rotor using patented alternator, together with the special stator design, effectively reduce the generation of resistance torque, while allowing more wind turbines and hydroelectric generator has good matching characteristics, the unit runs reliability

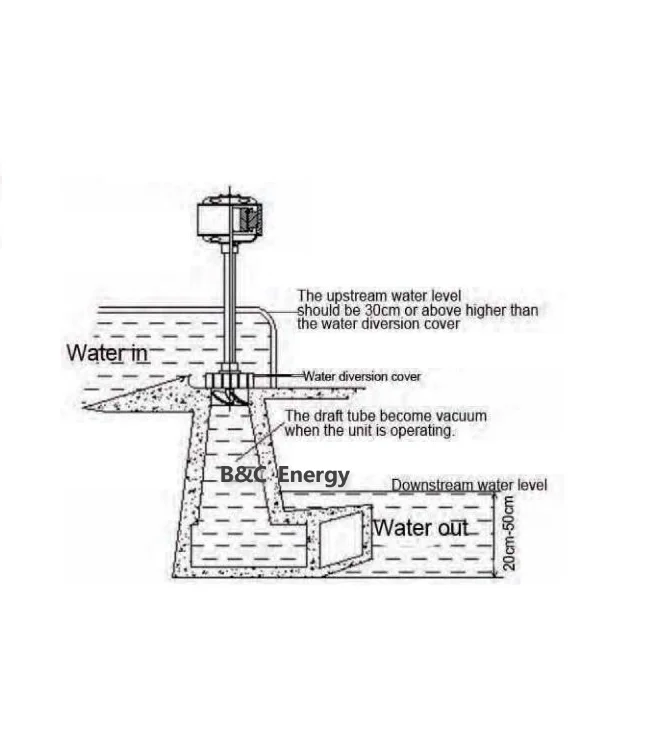

Flow rate: 0.24m³/s

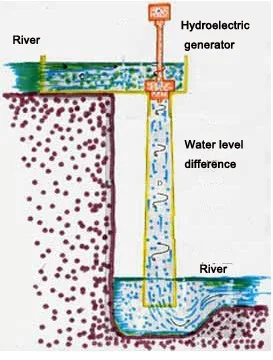

Water level difference : 6-12m

Speed: 1500 rpm

Voltage : single phase 220v

Current : 40-55A

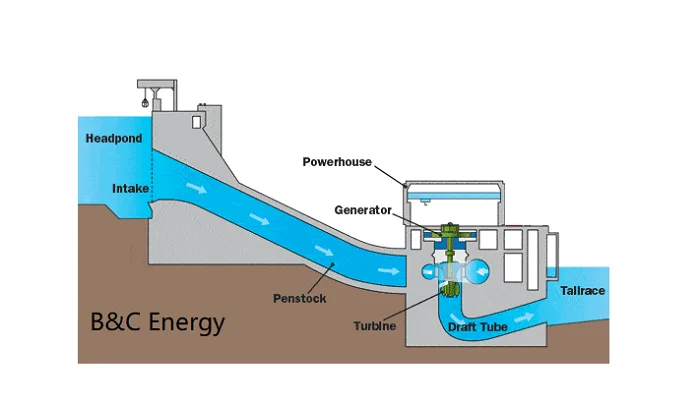

The axial flow hydroelectric generator is composed of a water turbine and a generator coaxial. The water turbine is mainly composed of water blades, guide covers, bearings, water seals, main shafts, etc. The axial flow hydroelectric generator mainly uses the corresponding height of the draft tube to form a vacuum suction pipe, which pulls the incoming water from the upstream through the vortex chamber to form a vortex. The jet water blades rotate at high speed and drive the generator to work through the main shaft.

The three stator windings of generators below 0.6kw are connected in a triangular manner, and the rotor is made of permanent magnet material.

The stator winding of generators above 0.6kw (including 0.6) adopts the method of measuring shape connection, and the rotor is made of permanent magnet material.

Product Structure of Axial Flow Hydrogenerators

|

9.oil seal |

| 2.Upper cover |

10.casing pipe |

| 3. bearing |

11. water coning |

| 4.rotor |

12. water guide cover |

| 5.Stator coil |

13. runner |

| 6.Motor barrel |

14. Spring pad |

| 7.base |

15.nut |

| 8.bearing |

16.cotter pin |

Product Description: