Komatsu Excavator

PC12R-8 PC15R-8

Service Manual &

Maintenance Manual

Computer PDF CD !!

Komatsu mini excavator

Komatsu mini excavator

2 in one service and owners

FACTORY MANUAL !!

Searchable oem crystal clear not a scan

Searchable oem crystal clear not a scan

please scroll down for pics !!

Note: not printed material !!

500 !! PLUS PAGES PDF FORMAT mailed cd

Thanks for looking !!

searches:

komatsu pc12 000 komatsu pc12 xt komatsu pc12/15r komatsu pc12 value komatsu pc 12 specs komatsu pc12uu-2 komatsu pc12 30 komatsu pc12 40 komatsu pc12 60 komatsu pc12 ng komatsu pc12 700 komatsu pc12 kit komatsu pc12-8 komatsu bc komatsu pc 12 mini excavator komatsu pc12 90 komatsu pc12 canada komatsu pc12 battery komatsu pc12 yamaha komatsu pc12 weight komatsu pc12r komatsu pc 12 technische daten komatsu pc12 pdf komatsu pc12 oil capacity komatsu pc12 loader komatsu pc12 instructions komatsu pc12 quebec komatsu pc12uu-1 komatsu pc 12 r8 usato komatsu pc12r-8 komatsu pc12 instruction manual komatsu pc12 900 komatsu pc12 70 komatsu pc12 00 komatsu pc12 mistral komatsu pc12 cells komatsu pc12 quattro komatsu pc12 600 komatsu pc 12 r8 ersatzteile komatsu pc12 owners manual komatsu pc12 youtube komatsu ontario komatsu pc12uu komatsu pc12 brochure komatsu pc 12 specifications komatsu pc12 wiring diagram komatsu pc 12 r technische daten komatsu pc 12 for sale komatsu pc12 wheels komatsu pc 12 mini excavadora komatsu pc12r-8 parts komatsu pc 12 usato komatsu pc12 interior komatsu pc 12 scheda tecnica komatsu pc12 yellow komatsu pc12uu parts komatsu pc12/15r8 komatsu pc12 water pump komatsu minibagger pc 12 komatsu pc12r track komatsu pc12r-8 hydraulic pump komatsu pc12r hs komatsu pc12r-8 manual komatsu pc12r-8 ersatzteile komatsu pc12r-6 elektro komatsu pc12r-8 technische daten

komatsu pc15 zero komatsu pc15-1 komatsu pc15 youtube komatsu pc15 xp komatsu pc15 weight komatsu pc 15 specs komatsu pc15 usato komatsu pc15-8 komatsu pc15 90 komatsu pc15 alternator komatsu pc15 specs cingoli komatsu pc15 komatsu pc15 excavator komatsu pc 15 hs komatsu pc15 iron komatsu pc15 jet komatsu pc15 kit komatsu pc15 mini excavator komatsu pc15 review komatsu pc 15 opinie komatsu pc15 parts komatsu pc15 bike komatsu pc15 00 komatsu pc15 75 komatsu pc15-2 specs komatsu pc15 nc komatsu pc15 45 komatsu pc15 50 komatsu pc 15 scheda tecnica komatsu pc15 for sale komatsu pc15 nt komatsu pc 15 forum komatsu pc15 000 komatsu pc15 70 komatsu pc 15 pdf komatsu pc15-2 komatsu pc15 r8 komatsu excavators canada komatsu pc 15 engine komatsu pc15 r-8 komatsu pc15 jacket komatsu pc15 r8 hs komatsu pc15 40 komatsu pc15 yamaha komatsu pc15-3 komatsu pc15 manual komatsu pc15 55 miniescavatore komatsu pc 15 usato komatsu pc15 kaufen komatsu pc15-2 weight komatsu pc 15 2 technische daten komatsu pc15 3 specs komatsu pc 15 dane techniczne komatsu pc 15 prezzo 1998 komatsu pc15 komatsu pc15 mr komatsu pc15 komatsu komatsu pc15r komatsu pc15 jobs komatsu pc 15 r hs komatsu pc15 mini excavator specs komatsu pc-20 komatsu pc15 4x4 komatsu pc 15 mr-1 komatsu pc 15 technische daten komatsu 1500 komatsu pc15 karcher komatsu pc 10 specs komatsu pc 15 r-8 technische daten komatsu pc 15 r8 scheda tecnica komatsu pc 15 mrx komatsu pc 15 r technische daten 1998 komatsu pc15 mini excavator komatsu pc 15 r-8 manual komatsu pc 15 r scheda tecnica komatsu pc 15 ersatzteile komatsu pc15-2 mini excavator minibagger komatsu pc 15 r-8 komatsu pc15 r3 ricambi komatsu pc15 komatsu pc 15 rhs

Note: not printed material !!

500 !! PLUS PAGES PDF FORMAT mailed cd

Contents :

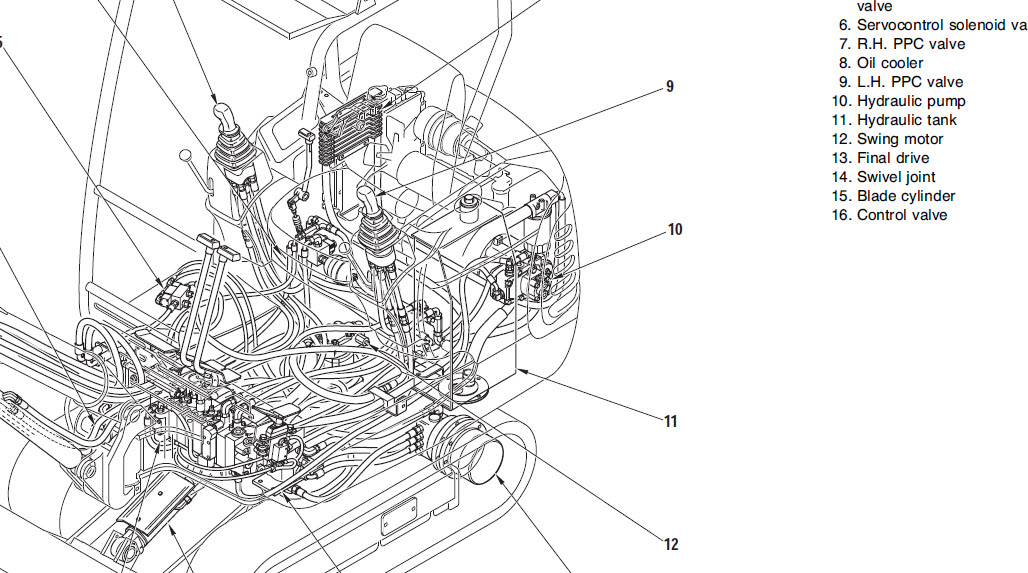

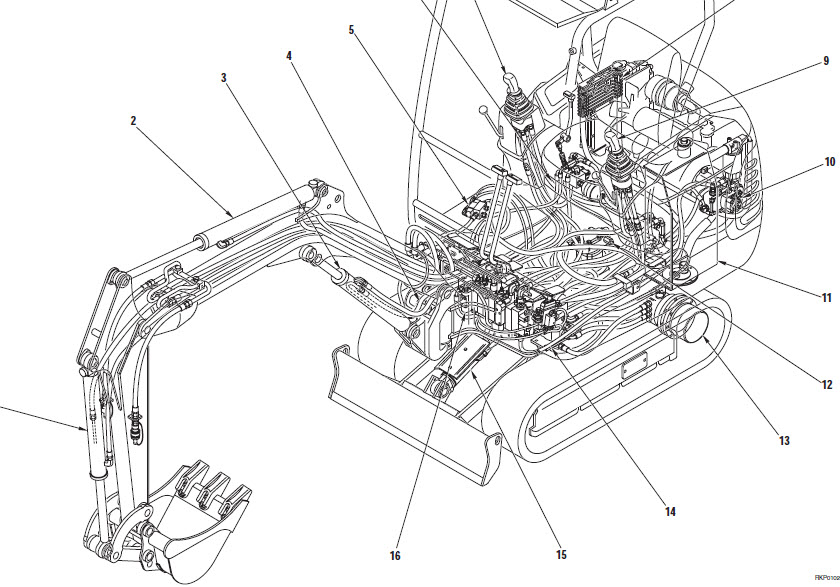

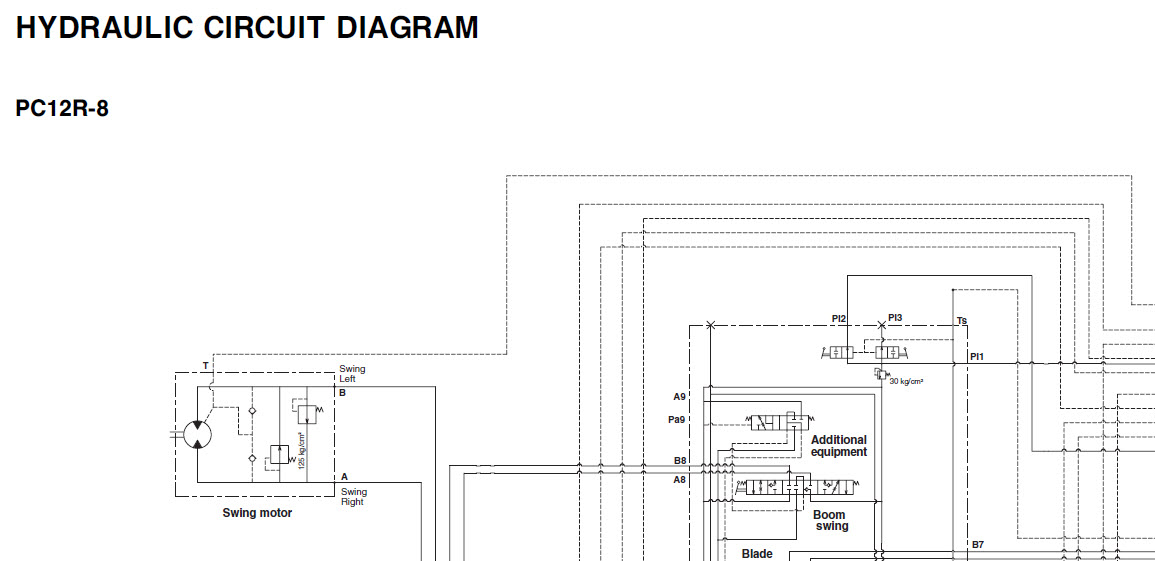

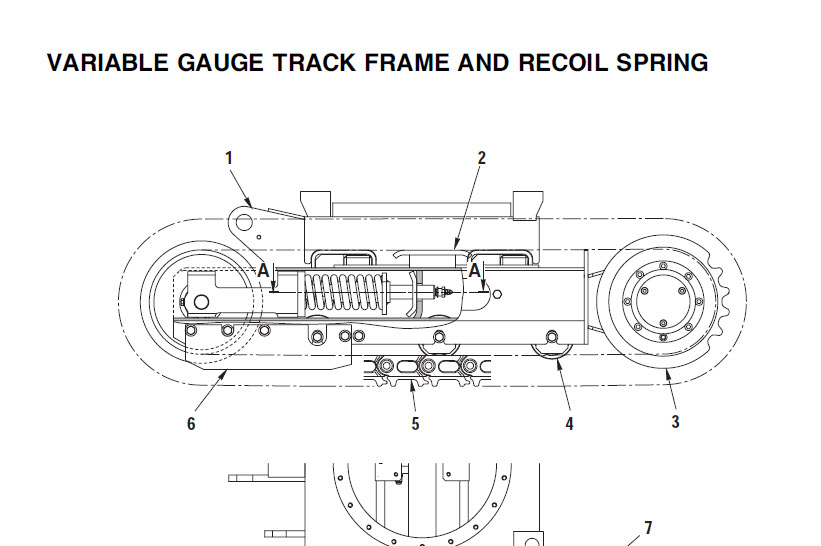

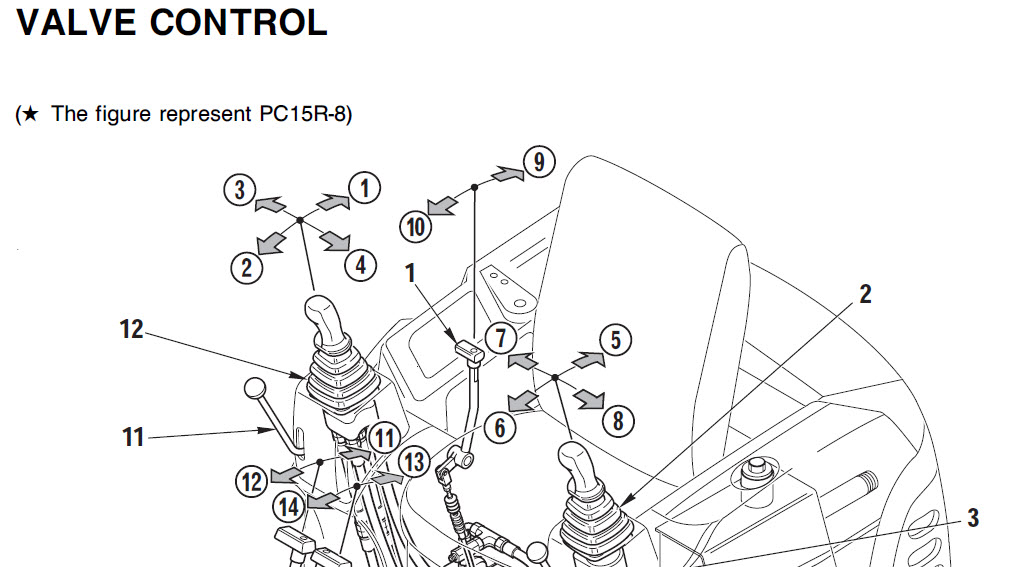

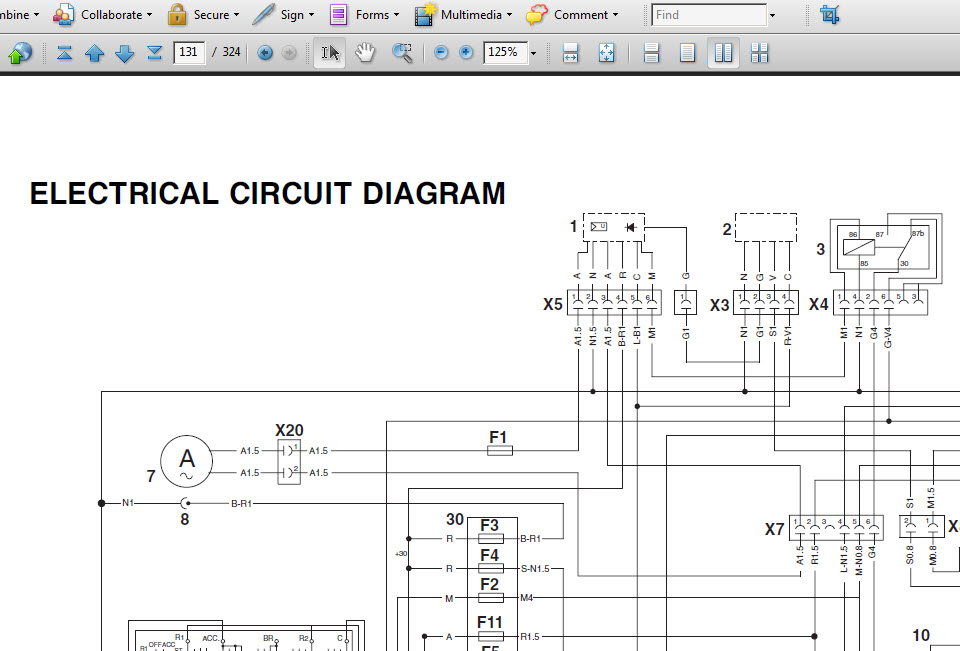

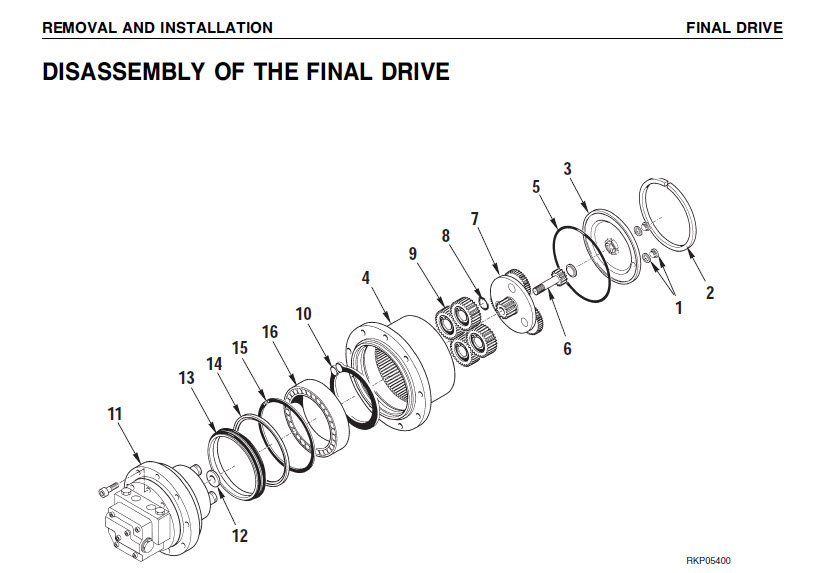

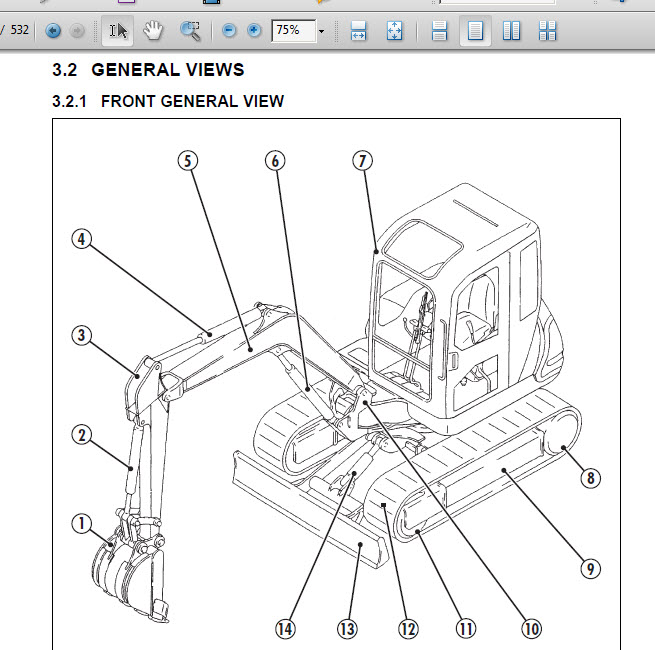

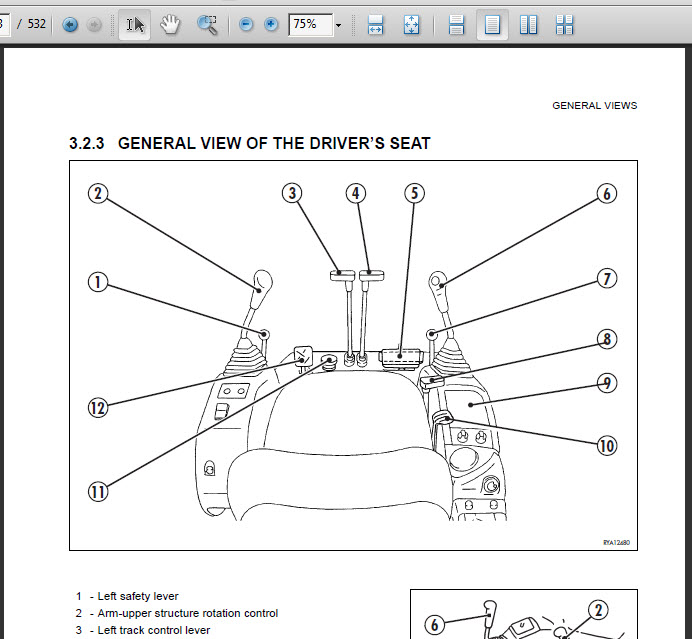

COVER CONTENTS LIST OF REVISED PAGES SAFETY FOREWORD HOW TO READ THE SHOP MANUAL HOISTING INSTRUCTIONS STANDARD TIGHTENING TORQUE COATING MATERIALS ELECTRIC WIRE CODE WEIGHT TABLE TABLE OF OIL AND COOLANT QUANTITIES 10.STRUCTURE AND FUNCTION POWER TRAIN SWING CIRCLE SWING MOTOR FINAL DRIVE TRACK FRAME AND RECOIL SPRING VARIABLE GAUGE TRACK FRAME AND RECOIL SPRING CARRIER ROLLER STEEL SHOE HYDRAULIC SYSTEM PC12R-8 HYDRAULIC SYSTEM PC15R-8 HYDRAULIC CIRCUIT DIAGRAM PC12R-8 HYDRAULIC CIRCUIT DIAGRAM PC12R-8 MISTRAL HYDRAULIC CIRCUIT DIAGRAM PC12R-8 HS HYDRAULIC CIRCUIT DIAGRAM PC12R-8 MISTRAL HS HYDRAULIC CIRCUIT DIAGRAM PC15R-8 HYDRAULIC CIRCUIT DIAGRAM PC15R-8 HS HYDRAULIC CIRCUIT DIAGRAM HYDRAULIC PUMP CONTROL VALVE PC12R-8 PC12R-8 MISTRAL CONTROL VALVE PC12R-8 HS PC12R-8 MISTRAL HS CONTROL VALVE PC15R-8 SWIVEL JOINT TRAVEL MOTOR CYLINDERS VALVE CONTROL ACCUMULATOR PPC VALVE PPC VALVE SOLENOID VALVE VARIABLE GAUGE UNDERCARRIAGE SERVOCONTROL SAFETY VALVE CUTTING SHOVEL CONTROL VALVE ELECTRICAL CIRCUIT DIAGRAM 20.TESTING AND ADJUSTMENTS NORMAL OR STANDARD TECHNICAL DATA SPECIAL TOOLS CHECKING THE ENGINE SPEED ADJUSTMENT OF VALVE CLEARANCE MEASUREMENT OF THE COMPRESSION PRESSURE CONTROL AND ADJUSTMENT OF THE TENSION OF THE FAN BELT CONTROL AND ADJUSTMENT OF THE INJECTION TIMING CONTROL AND ADJUSTMENT OF THE ACCELERATOR STROKE ADJUSTMENT OF THE STROKE OF THE BLADE COMMAND LEVER CONTROL AND ADJUSTMENT OF THE STROKE OF THE TRAVEL LEVER CENTERING ADJUSTMENT OF THE BOOM SWING COMMAND PEDAL ADJUSTMENT OF THE RUBBER PAD AND SAFETY MICROSWITCH FOR SERVO-CONTROL ENGAGEMENT CONTROL AND ADJUSTMENT OF THE TRACK-SHOE TENSION CONTROL AND REGULATION OF THE PRESSURE IN THE HYDRAULIC CIRCUITS (PC12R) CONTROL AND REGULATION OF THE PRESSURES IN THE HYDRAULIC CIRCUITS (PC15R) CONTROL AND REGULATION OF THE LS DIFFERENTIAL PRESSURE AND ADJUSTMENT OF THE LS VALVE REGULATION OF THE PC VALVE CONTROL AND REGULATION OF THE SERVO-CONTROL POWER SUPPLY (PC12R) CONTROL AND REGULATION OF THE SERVO-CONTROL POWER SUPPLY (PC15R) ELIMINATION OF RESIDUAL PRESSURES - PRESSURISATION OF THE TANK BLEEDING AIR FROM THE HYDRAULIC CIRCUITS CONTROL OF HYDRAULIC DRIFTS - ANALYSIS OF THE CAUSES OF A DRIFT CHECKING FOR ANY LEAKAGES INSIDE THE WORKING EQUIPMENT CYLINDERS CHECKING FOR ANY LEAKAGES INSIDE THE SWING MOTOR METHODS FOR TESTING FOR LEAKAGES INSIDE THE SWIVEL JOINT 30.REMOVAL AND INSTALLATION HOW TO READ THE MANUAL PRECAUTIONS TO BE TAKEN WHILE WORKING SPECIAL TOOLS STARTER MOTOR ALTERNATOR PUMP GROUP INJECTION NOZZLES CYLINDER HEAD OIL COOLER RADIATOR ENGINE HOOD CAB AND CANOPY HEATING FAN REAR COUNTERWEIGHT TOP COVER AND SIDE PANELS HYDRAULIC OIL TANK FUEL TANK ENGINE-PUMP GROUP PUMP ENGINE-PUMP COUPLING CONTROL VALVE RIGHT-HAND PPC VALVE (BOOM-BUCKET) LEFT-HAND PPC VALVE (ARM-BUCKET) SERVOCONTROL SOLENOID GROUP (PC12 WITHOUT TRAVEL INCREMENT) SERVOCONTROL SOLENOID GROUP (PC12 WITH TRAVEL INCREMENT - PC15R) SWIVEL JOINT SWING MOTOR REVOLVING FRAME SWING CIRCLE TRAVEL MOTOR RUBBER TRACK SHOES TRACK-SHOES SPROCKET WHEEL COMPLETE FINAL DRIVE FINAL DRIVE IDLER AND RECOIL SPRING ASSEMBLY IDLER SPRING RECOIL AND THRUST CYLINDER GROUPS TRACK ROLLERS BOOM CYLINDER ARM CYLINDER BUCKET CYLINDER BOOM SWING CYLINDER BLADE CYLINDER WORKING EQUIPMENT CYLINDER UPPER WORKING EQUIPMENT BUCKET ARM BOOM BOOM SWING SUPPORT BLADE 40.STANDARD MAINTENANCE SWING CIRCLE TRACK FRAME AND RECOIL SPRING VARIABLE GAUGE TRACK FRAME AND RECOIL SPRING IDLER FINAL DRIVE SPROCKET TRACK ROLLER TRACK SHOE HYDRAULIC PUMP CONTROL VALVE SWIVEL JOINT SWING MOTOR TRAVEL MOTOR CYLINDERS PC12R-8 CYLINDERS PC15R-8 WORK EQUIPMENT PC12R-8 WORK EQUIPMENT PC15R-8 Komatsu Excavator PC12R-8 PC15R-8 Operation Maintenance Manual FOREWORD INFORMATION ON SAFETY INTRODUCTION INTENDED USES IMPROPER OR UNAUTHORIZED USES MAIN CHARACTERISTICS RUNNING IN PRODUCT IDENTIFICATION MACHINE SERIAL NUMBER MACHINE IDENTIFICATION PLATE ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE TRAVEL REDUCTION GEAR SERIAL NUMBER SWING REDUCTION GEAR SERIAL NUMBER CAB SERIAL NUMBER SERIAL NUMBERS AND DEALER’S ADDRESS TABLE OF CONTENTS FOREWORD INFORMATION ON SAFETY INTRODUCTION INTENDED USES IMPROPER OR UNAUTHORIZED USES MAIN CHARACTERISTICS RUNNING IN PRODUCT IDENTIFICATION MACHINE SERIAL NUMBER MACHINE IDENTIFICATION PLATE ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE TRAVEL REDUCTION GEAR SERIAL NUMBER SWING REDUCTION GEAR SERIAL NUMBER CAB SERIAL NUMBER SERIAL NUMBERS AND DEALER’S ADDRESS SAFETY, NOISE AND VIBRATION PLATES POSITION OF THE SAFETY PLATES PICTOGRAMS AND RELEVANT MEANINGS POSITION OF THE NOISE PLATES ON MACHINES WITH CAB POSITION OF THE NOISE PLATES ON MACHINES WITH CANOPY VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED GENERAL PRECAUTIONS GENERAL SAFETY RULES SAFETY DEVICES AND GUARDS CLOTHING AND PERSONAL PROTECTION ITEMS UNAUTHORIZED MODIFICATIONS LEAVING THE OPERATOR’S SEAT GETTING ON AND OFF THE MACHINE PREVENTING FIRES DUE TO FUEL AND OIL PREVENTING BURNS PREVENTING DAMAGE DUE TO ASBESTOS POWDER PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT FIRE EXTINGUISHERS AND FIRST AID KIT PRECAUTIONS CONCERNING THE CAB STRUCTURE PRECAUTIONS CONCERNING THE EQUIPMENT PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE SAFETY ON THE WORK SITE FIRE PREVENTION PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB ROOM VENTILATION PRECAUTIONS TO BE TAKEN FOR THE LIGHTS CLEANING THE WINDOWS WINDSHIELD WIPER BLADES PRECAUTIONS TO BE TAKEN WHEN WORKING STARTING THE ENGINE CHECK THE DIRECTION BEFORE STARTING THE MACHINE CHECKS FOR TRAVELLING IN REVERSE MOVING THE MACHINE MOVING ON SLOPES WORKING ON SLOPES UNAUTHORIZED OPERATIONS PREVENTING ELECTROCUTION VISIBILITY WORKING ON ICY OR SNOW COVERED SURFACES PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT WORKING ON LOOSE GROUND PARKING THE MACHINE TRANSPORTING THE MACHINE ON MOTOR VEHICLES LOADING AND UNLOADING TRANSPORT BATTERY PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY STARTING WITH BOOSTER CABLES PRECAUTIONS FOR THE REMOVAL PRECAUTIONS FOR MAINTENANCE WARNING PLATES TOOLS PERSONNEL EQUIPMENT WORKING UNDER THE MACHINE CLEANING THE MACHINE USE OF THE ENGINE DURING MAINTENANCE OPERATIONS PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP COOLANT LEVEL IN THE RADIATOR USING LAMPS PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR PRECAUTIONS CONCERNING THE STARTER HANDLING HIGH PRESSURE PIPES PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH PRESSURE OIL PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE COOLING FAN AND BELT WASTE MATERIALS PRECAUTIONS FOR THE USE OF THE synthetic biodegradable oil type HEES SAFETY LOCKS MACHINE LOCKS GENERAL VIEWS FRONT GENERAL VIEW GENERAL VIEW OF THE MACHINE WITH CANOPY GENERAL VIEW OF THE DRIVER’S SEAT INSTRUMENTS AND CONTROLS INSTRUMENTS WARNING LIGHTS SWITCHES AND PUSH BUTTONS ELECTRICAL ACCESSORIES MACHINE CONTROLS FUSES AND RELAYS FUSES RELAYS GUARDS AND DRIVER’S SEAT ENGINE HOOD CANOPY CAB SLIDING DOOR FRONT OPENING WINDSHIELD FRONT WINDSHIELD (LOWER PART) SIDE OPENING WINDOW VENTILATION AND HEATING SEAT SAFETY BELT EMERGENCY EXIT TECHNICAL DOCUMENTATION CASE FIRE EXTINGUISHER FIRST AID KIT USE OF THE MACHINE CHECKS BEFORE STARTING THE ENGINE VISUAL CHECKS DAILY CHECKS OPERATIONAL CHECKS STARTING THE ENGINE STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES STARTING WITH COLD ENGINE OR IN COLD CLIMATES WARMING THE ENGINE HEATING THE HYDRAULIC OIL HOW TO MOVE THE MACHINE STEERING (CHANGING DIRECTION) MOVING ON SLOPES MAXIMUM IMMERSION DEPTH PARKING THE MACHINE PARKING ON LEVEL GROUND PARKING ON SLOPES STOPPING THE ENGINE TRANSPORTING THE MACHINE ON MOTOR VEHICLES LOADING AND UNLOADING THE MACHINE TRANSPORT LIFTING THE MACHINE PRECAUTIONS TO BE TAKEN IN THE COLD SEASON FUEL AND LUBRICANTS COOLANT BATTERY OTHER PRECAUTIONS PRECAUTIONS TO BE TAKEN AT THE END OF WORK PRECAUTIONS TO BE TAKEN IN THE WARM SEASON USING THE WORK EQUIPMENT ORGANIZING THE WORK AREA POSITIONING THE MACHINE FOR DIGGING OPERATIONS DIGGING METHOD BUCKET USING THE MACHINE WITH VARIABLE TRACK GAUGE HOW TO USE THE VARIABLE TRACK GAUGE ADJUSTING THE BLADE LONG PERIODS OF INACTIVITY BEFORE THE PERIOD OF INACTIVITY DURING THE PERIOD OF INACTIVITY AFTER THE PERIOD OF INACTIVITY TROUBLESHOOTING OCCURRENCES THAT ARE NOT FAILURES HOW TO REMOVE THE MACHINE AFTER THE FUEL HAS RUN OUT IF THE BATTERY IS DOWN STARTING WITH BOOSTER CABLES OTHER TROUBLES ELECTRICAL CIRCUIT HYDRAULIC SYSTEM ENGINE GUIDE TO MAINTENANCE MAINTENANCE NOTES NOTES REGARDING THE ENGINE ENGINE OIL COOLANT FUEL NOTES REGARDING THE HYDRAULIC SYSTEM NOTES REGARDING THE ELECTRICAL SYSTEM NOTES REGARDING LUBRICATION PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING FUEL, COOLANT AND LUBRICANTS SYNTHETIC BIODEGRADABLE LUBRICANTS DRIVING TORQUES FOR SCREWS AND NUTS STANDARD DRIVING TORQUES SPECIFIC DRIVING TORQUES LUBRICATION LUBRICATION DIAGRAM PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY CRITICAL PARTS FOR SAFETY MAINTENANCE PLAN WHEN REQUIRED WASHING THE COOLING CIRCUIT DRAINING THE FUEL TANK ELECTRICAL SYSTEM STEEL TRACK TENSION RUBBER TRACKS RUBBER TRACK TENSION RUBBER TRACK LUBRICATING THE ARTICULATIONS MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER (BREAKER) HYDRAULIC OIL FILTER HYDRAULIC OIL CHECKS BEFORE STARTING VARIOUS CHECKS COOLANT LEVEL FUEL LEVEL ENGINE OIL LEVEL OIL LEVEL IN THE HYDRAULIC CIRCUIT MAINTENANCE AFTER THE FIRST HOURS OF OPERATION MAINTENANCE EVERY HOURS OF OPERATION LUBRICATING THE JOINTS AND THE BALL BEARING RING LUBRICATING THE VARIABLE TRACK GAUGE SLIDING GUIDES ( HS – HS) CLEANING THE AIR CLEANER CARTRIDGE MAINTENANCE AFTER THE FIRST HOURS OF OPERATION MAINTENANCE EVERY HOURS OF OPERATION ADJUSTING THE FAN BELT TENSION BATTERY ELECTROLYTE LEVEL OIL LEVEL IN THE TRAVEL REDUCTION GEARS HYDRAULIC SYSTEM OIL FILTER ENGINE OIL MAINTENANCE AFTER THE FIRST HOURS OF OPERATION MAINTENANCE EVERY HOURS OF OPERATION ENGINE OIL FILTER FUEL FILTER FUEL PUMP PRECLEANER AIR CLEANER CARTRIDGE CLEANING THE OUTSIDE OF THE RADIATORS DRAINING THE HYDRAULIC OIL TANK (Only for machines in which the synthetic biodegradable o MAINTENANCE EVERY HOURS OF OPERATION OIL IN THE TRAVEL REDUCTION GEARS MAINTENANCE EVERY HOURS OF OPERATION HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER COOLANT CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE ALTERNATOR AND THE STARTER TECHNICAL DATA STANDARD OVERALL DIMENSIONS TECHNICAL CHARACTERISTICS STANDARD OVERALL DIMENSIONS HS (VARIABLE TRACK GAUGE) TECHNICAL CHARACTERISTICS HS (VARIABLE TRACK GAUGE) STANDARD OVERALL DIMENSIONS TECHNICAL CHARACTERISTICS STANDARD OVERALL DIMENSIONS HS (VARIABLE TRACK GAUGE) TECHNICAL CHARACTERISTICS HS (VARIABLE TRACK GAUGE) LIFTING CAPACITY WITH RAISED BLADE LIFTING CAPACITY WITH LOWERED BLADE PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT CHARACTERISTICS OF THE OPTIONAL EQUIPMENT ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER) DESCRIPTION AND CONTROL USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED INSTALLING AND REMOVING THE DEMOLITION HAMMER INSTALLING THE HAMMER REMOVING THE HAMMER MAINTENANCE SAFETY, NOISE AND VIBRATION PLATES POSITION OF THE SAFETY PLATES PICTOGRAMS AND RELEVANT MEANINGS POSITION OF THE NOISE PLATES ON MACHINES WITH CAB POSITION OF THE NOISE PLATES ON MACHINES WITH CANOPY VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED GENERAL PRECAUTIONS GENERAL SAFETY RULES SAFETY DEVICES AND GUARDS CLOTHING AND PERSONAL PROTECTION ITEMS UNAUTHORIZED MODIFICATIONS LEAVING THE OPERATOR’S SEAT GETTING ON AND OFF THE MACHINE PREVENTING FIRES DUE TO FUEL AND OIL PREVENTING BURNS PREVENTING DAMAGE DUE TO ASBESTOS POWDER PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT FIRE EXTINGUISHERS AND FIRST AID KIT PRECAUTIONS CONCERNING THE CAB STRUCTURE PRECAUTIONS CONCERNING THE EQUIPMENT PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE SAFETY ON THE WORK SITE FIRE PREVENTION PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB ROOM VENTILATION PRECAUTIONS TO BE TAKEN FOR THE LIGHTS CLEANING THE WINDOWS WINDSHIELD WIPER BLADES PRECAUTIONS TO BE TAKEN WHEN WORKING STARTING THE ENGINE CHECK THE DIRECTION BEFORE STARTING THE MACHINE CHECKS FOR TRAVELLING IN REVERSE MOVING THE MACHINE MOVING ON SLOPES WORKING ON SLOPES UNAUTHORIZED OPERATIONS PREVENTING ELECTROCUTION VISIBILITY WORKING ON ICY OR SNOW COVERED SURFACES PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT WORKING ON LOOSE GROUND PARKING THE MACHINE TRANSPORTING THE MACHINE ON MOTOR VEHICLES LOADING AND UNLOADING TRANSPORT BATTERY PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY STARTING WITH BOOSTER CABLES PRECAUTIONS FOR THE REMOVAL PRECAUTIONS FOR MAINTENANCE WARNING PLATES TOOLS PERSONNEL EQUIPMENT WORKING UNDER THE MACHINE CLEANING THE MACHINE USE OF THE ENGINE DURING MAINTENANCE OPERATIONS PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP COOLANT LEVEL IN THE RADIATOR USING LAMPS PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR PRECAUTIONS CONCERNING THE STARTER HANDLING HIGH PRESSURE PIPES PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH PRESSURE OIL PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE COOLING FAN AND BELT WASTE MATERIALS PRECAUTIONS FOR THE USE OF THE synthetic biodegradable oil type HEES SAFETY LOCKS MACHINE LOCKS GENERAL VIEWS FRONT GENERAL VIEW GENERAL VIEW OF THE MACHINE WITH CANOPY GENERAL VIEW OF THE DRIVER’S SEAT INSTRUMENTS AND CONTROLS INSTRUMENTS WARNING LIGHTS SWITCHES AND PUSH BUTTONS ELECTRICAL ACCESSORIES MACHINE CONTROLS (STANDARD PEDAL) (OPTIONAL PEDAL) FUSES AND RELAYS FUSES RELAYS GUARDS AND DRIVER’S SEAT ENGINE HOOD CANOPY CAB SLIDING DOOR FRONT OPENING WINDSHIELD FRONT WINDSHIELD (LOWER PART) SIDE OPENING WINDOW VENTILATION AND HEATING SEAT SAFETY BELT EMERGENCY EXIT TECHNICAL DOCUMENTATION CASE FIRE EXTINGUISHER FIRST AID KIT USE OF THE MACHINE CHECKS BEFORE STARTING THE ENGINE VISUAL CHECKS DAILY CHECKS OPERATIONAL CHECKS STARTING THE ENGINE STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES STARTING WITH COLD ENGINE OR IN COLD CLIMATES WARMING THE ENGINE HEATING THE HYDRAULIC OIL HOW TO MOVE THE MACHINE STEERING (CHANGING DIRECTION) CHANGING DIRECTION WHEN THE MACHINE IS NOT MOVING MOVING ON SLOPES MAXIMUM IMMERSION DEPTH PARKING THE MACHINE PARKING ON LEVEL GROUND PARKING ON SLOPES STOPPING THE ENGINE TRANSPORTING THE MACHINE ON MOTOR VEHICLES LOADING AND UNLOADING THE MACHINE TRANSPORT LIFTING THE MACHINE PRECAUTIONS TO BE TAKEN IN THE COLD SEASON FUEL AND LUBRICANTS COOLANT BATTERY OTHER PRECAUTIONS PRECAUTIONS TO BE TAKEN AT THE END OF WORK PRECAUTIONS TO BE TAKEN IN THE WARM SEASON USING THE WORK EQUIPMENT ORGANIZING THE WORK AREA POSITIONING THE MACHINE FOR DIGGING OPERATIONS DIGGING METHOD BUCKET USING THE MACHINE WITH VARIABLE TRACK GAUGE HOW TO USE THE VARIABLE TRACK GAUGE ADJUSTING THE BLADE LONG PERIODS OF INACTIVITY BEFORE THE PERIOD OF INACTIVITY DURING THE PERIOD OF INACTIVITY AFTER THE PERIOD OF INACTIVITY TROUBLESHOOTING OCCURRENCES THAT ARE NOT FAILURES HOW TO REMOVE THE MACHINE AFTER THE FUEL HAS RUN OUT IF THE BATTERY IS DOWN STARTING WITH BOOSTER CABLES OTHER TROUBLES ELECTRICAL CIRCUIT HYDRAULIC SYSTEM ENGINE GUIDE TO MAINTENANCE MAINTENANCE NOTES NOTES REGARDING THE ENGINE ENGINE OIL COOLANT FUEL NOTES REGARDING THE HYDRAULIC SYSTEM NOTES REGARDING THE ELECTRICAL SYSTEM NOTES REGARDING LUBRICATION PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING FUEL, COOLANT AND LUBRICANTS LUBRICATION WITH GREASE DRIVING TORQUES FOR SCREWS AND NUTS STANDARD DRIVING TORQUES SPECIFIC DRIVING TORQUES LUBRICATION LUBRICATION DIAGRAM PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY MAINTENANCE PLAN WHEN REQUIRED WASHING THE COOLING CIRCUIT DRAINING THE FUEL TANK ELECTRICAL SYSTEM STEEL TRACK TENSION RUBBER TRACKS RUBBER TRACK TENSION RUBBER TRACK LUBRICATING THE ARTICULATIONS MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER (BREAKER) HYDRAULIC OIL FILTER HYDRAULIC OIL CHECKS BEFORE STARTING VARIOUS CHECKS COOLANT LEVEL FUEL LEVEL ENGINE OIL LEVEL OIL LEVEL IN THE HYDRAULIC CIRCUIT MAINTENANCE AFTER THE FIRST HOURS OF OPERATION MAINTENANCE EVERY HOURS OF OPERATION LUBRICATING THE JOINTS AND THE BALL BEARING RING LUBRICATING THE VARIABLE TRACK GAUGE SLIDING GUIDES CLEANING THE AIR CLEANER CARTRIDGE MAINTENANCE AFTER THE FIRST HOURS OF OPERATION MAINTENANCE EVERY HOURS OF OPERATION ADJUSTING THE FAN BELT TENSION BATTERY ELECTROLYTE LEVEL OIL LEVEL IN THE TRAVEL REDUCTION GEARS HYDRAULIC SYSTEM OIL FILTER ENGINE OIL MAINTENANCE AFTER THE FIRST HOURS OF OPERATION MAINTENANCE EVERY HOURS OF OPERATION ENGINE OIL FILTER FUEL FILTER FUEL PUMP PRECLEANER AIR CLEANER CARTRIDGE CLEANING THE OUTSIDE OF THE RADIATORS DRAINING THE HYDRAULIC OIL TANK OIL IN THE TRAVEL REDUCTION GEARS HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER COOLANT CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE ALTERNATOR AND THE STARTER TECHNICAL DATA STANDARD OVERALL DIMENSIONS TECHNICAL CHARACTERISTICS LIFTING CAPACITY WITH RAISED BLADE AUTHORIZED OPTIONAL EQUIPMENT PRECAUTIONS REGARDING SAFETY PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT CHARACTERISTICS OF THE OPTIONAL EQUIPMENT ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER) DESCRIPTION AND CONTROL USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED FOR A CORRECT USE, IT IS NECESSARY TO: ALWAYS AVOID THE FOLLOWING INCORRECT USES: INSTALLING AND REMOVING THE DEMOLITION HAMMER INSTALLING THE HAMMER REMOVING THE HAMMER MAINTENANCE

COVER CONTENTS LIST OF REVISED PAGES SAFETY FOREWORD HOW TO READ THE SHOP MANUAL HOISTING INSTRUCTIONS STANDARD TIGHTENING TORQUE COATING MATERIALS ELECTRIC WIRE CODE WEIGHT TABLE TABLE OF OIL AND COOLANT QUANTITIES 10.STRUCTURE AND FUNCTION POWER TRAIN SWING CIRCLE SWING MOTOR FINAL DRIVE TRACK FRAME AND RECOIL SPRING VARIABLE GAUGE TRACK FRAME AND RECOIL SPRING CARRIER ROLLER STEEL SHOE HYDRAULIC SYSTEM PC12R-8 HYDRAULIC SYSTEM PC15R-8 HYDRAULIC CIRCUIT DIAGRAM PC12R-8 HYDRAULIC CIRCUIT DIAGRAM PC12R-8 MISTRAL HYDRAULIC CIRCUIT DIAGRAM PC12R-8 HS HYDRAULIC CIRCUIT DIAGRAM PC12R-8 MISTRAL HS HYDRAULIC CIRCUIT DIAGRAM PC15R-8 HYDRAULIC CIRCUIT DIAGRAM PC15R-8 HS HYDRAULIC CIRCUIT DIAGRAM HYDRAULIC PUMP CONTROL VALVE PC12R-8 PC12R-8 MISTRAL CONTROL VALVE PC12R-8 HS PC12R-8 MISTRAL HS CONTROL VALVE PC15R-8 SWIVEL JOINT TRAVEL MOTOR CYLINDERS VALVE CONTROL ACCUMULATOR PPC VALVE PPC VALVE SOLENOID VALVE VARIABLE GAUGE UNDERCARRIAGE SERVOCONTROL SAFETY VALVE CUTTING SHOVEL CONTROL VALVE ELECTRICAL CIRCUIT DIAGRAM 20.TESTING AND ADJUSTMENTS NORMAL OR STANDARD TECHNICAL DATA SPECIAL TOOLS CHECKING THE ENGINE SPEED ADJUSTMENT OF VALVE CLEARANCE MEASUREMENT OF THE COMPRESSION PRESSURE CONTROL AND ADJUSTMENT OF THE TENSION OF THE FAN BELT CONTROL AND ADJUSTMENT OF THE INJECTION TIMING CONTROL AND ADJUSTMENT OF THE ACCELERATOR STROKE ADJUSTMENT OF THE STROKE OF THE BLADE COMMAND LEVER CONTROL AND ADJUSTMENT OF THE STROKE OF THE TRAVEL LEVER CENTERING ADJUSTMENT OF THE BOOM SWING COMMAND PEDAL ADJUSTMENT OF THE RUBBER PAD AND SAFETY MICROSWITCH FOR SERVO-CONTROL ENGAGEMENT CONTROL AND ADJUSTMENT OF THE TRACK-SHOE TENSION CONTROL AND REGULATION OF THE PRESSURE IN THE HYDRAULIC CIRCUITS (PC12R) CONTROL AND REGULATION OF THE PRESSURES IN THE HYDRAULIC CIRCUITS (PC15R) CONTROL AND REGULATION OF THE LS DIFFERENTIAL PRESSURE AND ADJUSTMENT OF THE LS VALVE REGULATION OF THE PC VALVE CONTROL AND REGULATION OF THE SERVO-CONTROL POWER SUPPLY (PC12R) CONTROL AND REGULATION OF THE SERVO-CONTROL POWER SUPPLY (PC15R) ELIMINATION OF RESIDUAL PRESSURES - PRESSURISATION OF THE TANK BLEEDING AIR FROM THE HYDRAULIC CIRCUITS CONTROL OF HYDRAULIC DRIFTS - ANALYSIS OF THE CAUSES OF A DRIFT CHECKING FOR ANY LEAKAGES INSIDE THE WORKING EQUIPMENT CYLINDERS CHECKING FOR ANY LEAKAGES INSIDE THE SWING MOTOR METHODS FOR TESTING FOR LEAKAGES INSIDE THE SWIVEL JOINT 30.REMOVAL AND INSTALLATION HOW TO READ THE MANUAL PRECAUTIONS TO BE TAKEN WHILE WORKING SPECIAL TOOLS STARTER MOTOR ALTERNATOR PUMP GROUP INJECTION NOZZLES CYLINDER HEAD OIL COOLER RADIATOR ENGINE HOOD CAB AND CANOPY HEATING FAN REAR COUNTERWEIGHT TOP COVER AND SIDE PANELS HYDRAULIC OIL TANK FUEL TANK ENGINE-PUMP GROUP PUMP ENGINE-PUMP COUPLING CONTROL VALVE RIGHT-HAND PPC VALVE (BOOM-BUCKET) LEFT-HAND PPC VALVE (ARM-BUCKET) SERVOCONTROL SOLENOID GROUP (PC12 WITHOUT TRAVEL INCREMENT) SERVOCONTROL SOLENOID GROUP (PC12 WITH TRAVEL INCREMENT - PC15R) SWIVEL JOINT SWING MOTOR REVOLVING FRAME SWING CIRCLE TRAVEL MOTOR RUBBER TRACK SHOES TRACK-SHOES SPROCKET WHEEL COMPLETE FINAL DRIVE FINAL DRIVE IDLER AND RECOIL SPRING ASSEMBLY IDLER SPRING RECOIL AND THRUST CYLINDER GROUPS TRACK ROLLERS BOOM CYLINDER ARM CYLINDER BUCKET CYLINDER BOOM SWING CYLINDER BLADE CYLINDER WORKING EQUIPMENT CYLINDER UPPER WORKING EQUIPMENT BUCKET ARM BOOM BOOM SWING SUPPORT BLADE 40.STANDARD MAINTENANCE SWING CIRCLE TRACK FRAME AND RECOIL SPRING VARIABLE GAUGE TRACK FRAME AND RECOIL SPRING IDLER FINAL DRIVE SPROCKET TRACK ROLLER TRACK SHOE HYDRAULIC PUMP CONTROL VALVE SWIVEL JOINT SWING MOTOR TRAVEL MOTOR CYLINDERS PC12R-8 CYLINDERS PC15R-8 WORK EQUIPMENT PC12R-8 WORK EQUIPMENT PC15R-8 Komatsu Excavator PC12R-8 PC15R-8 Operation Maintenance Manual FOREWORD INFORMATION ON SAFETY INTRODUCTION INTENDED USES IMPROPER OR UNAUTHORIZED USES MAIN CHARACTERISTICS RUNNING IN PRODUCT IDENTIFICATION MACHINE SERIAL NUMBER MACHINE IDENTIFICATION PLATE ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE TRAVEL REDUCTION GEAR SERIAL NUMBER SWING REDUCTION GEAR SERIAL NUMBER CAB SERIAL NUMBER SERIAL NUMBERS AND DEALER’S ADDRESS TABLE OF CONTENTS FOREWORD INFORMATION ON SAFETY INTRODUCTION INTENDED USES IMPROPER OR UNAUTHORIZED USES MAIN CHARACTERISTICS RUNNING IN PRODUCT IDENTIFICATION MACHINE SERIAL NUMBER MACHINE IDENTIFICATION PLATE ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE TRAVEL REDUCTION GEAR SERIAL NUMBER SWING REDUCTION GEAR SERIAL NUMBER CAB SERIAL NUMBER SERIAL NUMBERS AND DEALER’S ADDRESS SAFETY, NOISE AND VIBRATION PLATES POSITION OF THE SAFETY PLATES PICTOGRAMS AND RELEVANT MEANINGS POSITION OF THE NOISE PLATES ON MACHINES WITH CAB POSITION OF THE NOISE PLATES ON MACHINES WITH CANOPY VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED GENERAL PRECAUTIONS GENERAL SAFETY RULES SAFETY DEVICES AND GUARDS CLOTHING AND PERSONAL PROTECTION ITEMS UNAUTHORIZED MODIFICATIONS LEAVING THE OPERATOR’S SEAT GETTING ON AND OFF THE MACHINE PREVENTING FIRES DUE TO FUEL AND OIL PREVENTING BURNS PREVENTING DAMAGE DUE TO ASBESTOS POWDER PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT FIRE EXTINGUISHERS AND FIRST AID KIT PRECAUTIONS CONCERNING THE CAB STRUCTURE PRECAUTIONS CONCERNING THE EQUIPMENT PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE SAFETY ON THE WORK SITE FIRE PREVENTION PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB ROOM VENTILATION PRECAUTIONS TO BE TAKEN FOR THE LIGHTS CLEANING THE WINDOWS WINDSHIELD WIPER BLADES PRECAUTIONS TO BE TAKEN WHEN WORKING STARTING THE ENGINE CHECK THE DIRECTION BEFORE STARTING THE MACHINE CHECKS FOR TRAVELLING IN REVERSE MOVING THE MACHINE MOVING ON SLOPES WORKING ON SLOPES UNAUTHORIZED OPERATIONS PREVENTING ELECTROCUTION VISIBILITY WORKING ON ICY OR SNOW COVERED SURFACES PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT WORKING ON LOOSE GROUND PARKING THE MACHINE TRANSPORTING THE MACHINE ON MOTOR VEHICLES LOADING AND UNLOADING TRANSPORT BATTERY PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY STARTING WITH BOOSTER CABLES PRECAUTIONS FOR THE REMOVAL PRECAUTIONS FOR MAINTENANCE WARNING PLATES TOOLS PERSONNEL EQUIPMENT WORKING UNDER THE MACHINE CLEANING THE MACHINE USE OF THE ENGINE DURING MAINTENANCE OPERATIONS PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP COOLANT LEVEL IN THE RADIATOR USING LAMPS PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR PRECAUTIONS CONCERNING THE STARTER HANDLING HIGH PRESSURE PIPES PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH PRESSURE OIL PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE COOLING FAN AND BELT WASTE MATERIALS PRECAUTIONS FOR THE USE OF THE synthetic biodegradable oil type HEES SAFETY LOCKS MACHINE LOCKS GENERAL VIEWS FRONT GENERAL VIEW GENERAL VIEW OF THE MACHINE WITH CANOPY GENERAL VIEW OF THE DRIVER’S SEAT INSTRUMENTS AND CONTROLS INSTRUMENTS WARNING LIGHTS SWITCHES AND PUSH BUTTONS ELECTRICAL ACCESSORIES MACHINE CONTROLS FUSES AND RELAYS FUSES RELAYS GUARDS AND DRIVER’S SEAT ENGINE HOOD CANOPY CAB SLIDING DOOR FRONT OPENING WINDSHIELD FRONT WINDSHIELD (LOWER PART) SIDE OPENING WINDOW VENTILATION AND HEATING SEAT SAFETY BELT EMERGENCY EXIT TECHNICAL DOCUMENTATION CASE FIRE EXTINGUISHER FIRST AID KIT USE OF THE MACHINE CHECKS BEFORE STARTING THE ENGINE VISUAL CHECKS DAILY CHECKS OPERATIONAL CHECKS STARTING THE ENGINE STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES STARTING WITH COLD ENGINE OR IN COLD CLIMATES WARMING THE ENGINE HEATING THE HYDRAULIC OIL HOW TO MOVE THE MACHINE STEERING (CHANGING DIRECTION) MOVING ON SLOPES MAXIMUM IMMERSION DEPTH PARKING THE MACHINE PARKING ON LEVEL GROUND PARKING ON SLOPES STOPPING THE ENGINE TRANSPORTING THE MACHINE ON MOTOR VEHICLES LOADING AND UNLOADING THE MACHINE TRANSPORT LIFTING THE MACHINE PRECAUTIONS TO BE TAKEN IN THE COLD SEASON FUEL AND LUBRICANTS COOLANT BATTERY OTHER PRECAUTIONS PRECAUTIONS TO BE TAKEN AT THE END OF WORK PRECAUTIONS TO BE TAKEN IN THE WARM SEASON USING THE WORK EQUIPMENT ORGANIZING THE WORK AREA POSITIONING THE MACHINE FOR DIGGING OPERATIONS DIGGING METHOD BUCKET USING THE MACHINE WITH VARIABLE TRACK GAUGE HOW TO USE THE VARIABLE TRACK GAUGE ADJUSTING THE BLADE LONG PERIODS OF INACTIVITY BEFORE THE PERIOD OF INACTIVITY DURING THE PERIOD OF INACTIVITY AFTER THE PERIOD OF INACTIVITY TROUBLESHOOTING OCCURRENCES THAT ARE NOT FAILURES HOW TO REMOVE THE MACHINE AFTER THE FUEL HAS RUN OUT IF THE BATTERY IS DOWN STARTING WITH BOOSTER CABLES OTHER TROUBLES ELECTRICAL CIRCUIT HYDRAULIC SYSTEM ENGINE GUIDE TO MAINTENANCE MAINTENANCE NOTES NOTES REGARDING THE ENGINE ENGINE OIL COOLANT FUEL NOTES REGARDING THE HYDRAULIC SYSTEM NOTES REGARDING THE ELECTRICAL SYSTEM NOTES REGARDING LUBRICATION PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING FUEL, COOLANT AND LUBRICANTS SYNTHETIC BIODEGRADABLE LUBRICANTS DRIVING TORQUES FOR SCREWS AND NUTS STANDARD DRIVING TORQUES SPECIFIC DRIVING TORQUES LUBRICATION LUBRICATION DIAGRAM PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY CRITICAL PARTS FOR SAFETY MAINTENANCE PLAN WHEN REQUIRED WASHING THE COOLING CIRCUIT DRAINING THE FUEL TANK ELECTRICAL SYSTEM STEEL TRACK TENSION RUBBER TRACKS RUBBER TRACK TENSION RUBBER TRACK LUBRICATING THE ARTICULATIONS MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER (BREAKER) HYDRAULIC OIL FILTER HYDRAULIC OIL CHECKS BEFORE STARTING VARIOUS CHECKS COOLANT LEVEL FUEL LEVEL ENGINE OIL LEVEL OIL LEVEL IN THE HYDRAULIC CIRCUIT MAINTENANCE AFTER THE FIRST HOURS OF OPERATION MAINTENANCE EVERY HOURS OF OPERATION LUBRICATING THE JOINTS AND THE BALL BEARING RING LUBRICATING THE VARIABLE TRACK GAUGE SLIDING GUIDES ( HS – HS) CLEANING THE AIR CLEANER CARTRIDGE MAINTENANCE AFTER THE FIRST HOURS OF OPERATION MAINTENANCE EVERY HOURS OF OPERATION ADJUSTING THE FAN BELT TENSION BATTERY ELECTROLYTE LEVEL OIL LEVEL IN THE TRAVEL REDUCTION GEARS HYDRAULIC SYSTEM OIL FILTER ENGINE OIL MAINTENANCE AFTER THE FIRST HOURS OF OPERATION MAINTENANCE EVERY HOURS OF OPERATION ENGINE OIL FILTER FUEL FILTER FUEL PUMP PRECLEANER AIR CLEANER CARTRIDGE CLEANING THE OUTSIDE OF THE RADIATORS DRAINING THE HYDRAULIC OIL TANK (Only for machines in which the synthetic biodegradable o MAINTENANCE EVERY HOURS OF OPERATION OIL IN THE TRAVEL REDUCTION GEARS MAINTENANCE EVERY HOURS OF OPERATION HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER COOLANT CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE ALTERNATOR AND THE STARTER TECHNICAL DATA STANDARD OVERALL DIMENSIONS TECHNICAL CHARACTERISTICS STANDARD OVERALL DIMENSIONS HS (VARIABLE TRACK GAUGE) TECHNICAL CHARACTERISTICS HS (VARIABLE TRACK GAUGE) STANDARD OVERALL DIMENSIONS TECHNICAL CHARACTERISTICS STANDARD OVERALL DIMENSIONS HS (VARIABLE TRACK GAUGE) TECHNICAL CHARACTERISTICS HS (VARIABLE TRACK GAUGE) LIFTING CAPACITY WITH RAISED BLADE LIFTING CAPACITY WITH LOWERED BLADE PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT CHARACTERISTICS OF THE OPTIONAL EQUIPMENT ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER) DESCRIPTION AND CONTROL USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED INSTALLING AND REMOVING THE DEMOLITION HAMMER INSTALLING THE HAMMER REMOVING THE HAMMER MAINTENANCE SAFETY, NOISE AND VIBRATION PLATES POSITION OF THE SAFETY PLATES PICTOGRAMS AND RELEVANT MEANINGS POSITION OF THE NOISE PLATES ON MACHINES WITH CAB POSITION OF THE NOISE PLATES ON MACHINES WITH CANOPY VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED GENERAL PRECAUTIONS GENERAL SAFETY RULES SAFETY DEVICES AND GUARDS CLOTHING AND PERSONAL PROTECTION ITEMS UNAUTHORIZED MODIFICATIONS LEAVING THE OPERATOR’S SEAT GETTING ON AND OFF THE MACHINE PREVENTING FIRES DUE TO FUEL AND OIL PREVENTING BURNS PREVENTING DAMAGE DUE TO ASBESTOS POWDER PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT FIRE EXTINGUISHERS AND FIRST AID KIT PRECAUTIONS CONCERNING THE CAB STRUCTURE PRECAUTIONS CONCERNING THE EQUIPMENT PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE SAFETY ON THE WORK SITE FIRE PREVENTION PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB ROOM VENTILATION PRECAUTIONS TO BE TAKEN FOR THE LIGHTS CLEANING THE WINDOWS WINDSHIELD WIPER BLADES PRECAUTIONS TO BE TAKEN WHEN WORKING STARTING THE ENGINE CHECK THE DIRECTION BEFORE STARTING THE MACHINE CHECKS FOR TRAVELLING IN REVERSE MOVING THE MACHINE MOVING ON SLOPES WORKING ON SLOPES UNAUTHORIZED OPERATIONS PREVENTING ELECTROCUTION VISIBILITY WORKING ON ICY OR SNOW COVERED SURFACES PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT WORKING ON LOOSE GROUND PARKING THE MACHINE TRANSPORTING THE MACHINE ON MOTOR VEHICLES LOADING AND UNLOADING TRANSPORT BATTERY PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY STARTING WITH BOOSTER CABLES PRECAUTIONS FOR THE REMOVAL PRECAUTIONS FOR MAINTENANCE WARNING PLATES TOOLS PERSONNEL EQUIPMENT WORKING UNDER THE MACHINE CLEANING THE MACHINE USE OF THE ENGINE DURING MAINTENANCE OPERATIONS PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP COOLANT LEVEL IN THE RADIATOR USING LAMPS PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR PRECAUTIONS CONCERNING THE STARTER HANDLING HIGH PRESSURE PIPES PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH PRESSURE OIL PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE COOLING FAN AND BELT WASTE MATERIALS PRECAUTIONS FOR THE USE OF THE synthetic biodegradable oil type HEES SAFETY LOCKS MACHINE LOCKS GENERAL VIEWS FRONT GENERAL VIEW GENERAL VIEW OF THE MACHINE WITH CANOPY GENERAL VIEW OF THE DRIVER’S SEAT INSTRUMENTS AND CONTROLS INSTRUMENTS WARNING LIGHTS SWITCHES AND PUSH BUTTONS ELECTRICAL ACCESSORIES MACHINE CONTROLS (STANDARD PEDAL) (OPTIONAL PEDAL) FUSES AND RELAYS FUSES RELAYS GUARDS AND DRIVER’S SEAT ENGINE HOOD CANOPY CAB SLIDING DOOR FRONT OPENING WINDSHIELD FRONT WINDSHIELD (LOWER PART) SIDE OPENING WINDOW VENTILATION AND HEATING SEAT SAFETY BELT EMERGENCY EXIT TECHNICAL DOCUMENTATION CASE FIRE EXTINGUISHER FIRST AID KIT USE OF THE MACHINE CHECKS BEFORE STARTING THE ENGINE VISUAL CHECKS DAILY CHECKS OPERATIONAL CHECKS STARTING THE ENGINE STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES STARTING WITH COLD ENGINE OR IN COLD CLIMATES WARMING THE ENGINE HEATING THE HYDRAULIC OIL HOW TO MOVE THE MACHINE STEERING (CHANGING DIRECTION) CHANGING DIRECTION WHEN THE MACHINE IS NOT MOVING MOVING ON SLOPES MAXIMUM IMMERSION DEPTH PARKING THE MACHINE PARKING ON LEVEL GROUND PARKING ON SLOPES STOPPING THE ENGINE TRANSPORTING THE MACHINE ON MOTOR VEHICLES LOADING AND UNLOADING THE MACHINE TRANSPORT LIFTING THE MACHINE PRECAUTIONS TO BE TAKEN IN THE COLD SEASON FUEL AND LUBRICANTS COOLANT BATTERY OTHER PRECAUTIONS PRECAUTIONS TO BE TAKEN AT THE END OF WORK PRECAUTIONS TO BE TAKEN IN THE WARM SEASON USING THE WORK EQUIPMENT ORGANIZING THE WORK AREA POSITIONING THE MACHINE FOR DIGGING OPERATIONS DIGGING METHOD BUCKET USING THE MACHINE WITH VARIABLE TRACK GAUGE HOW TO USE THE VARIABLE TRACK GAUGE ADJUSTING THE BLADE LONG PERIODS OF INACTIVITY BEFORE THE PERIOD OF INACTIVITY DURING THE PERIOD OF INACTIVITY AFTER THE PERIOD OF INACTIVITY TROUBLESHOOTING OCCURRENCES THAT ARE NOT FAILURES HOW TO REMOVE THE MACHINE AFTER THE FUEL HAS RUN OUT IF THE BATTERY IS DOWN STARTING WITH BOOSTER CABLES OTHER TROUBLES ELECTRICAL CIRCUIT HYDRAULIC SYSTEM ENGINE GUIDE TO MAINTENANCE MAINTENANCE NOTES NOTES REGARDING THE ENGINE ENGINE OIL COOLANT FUEL NOTES REGARDING THE HYDRAULIC SYSTEM NOTES REGARDING THE ELECTRICAL SYSTEM NOTES REGARDING LUBRICATION PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING FUEL, COOLANT AND LUBRICANTS LUBRICATION WITH GREASE DRIVING TORQUES FOR SCREWS AND NUTS STANDARD DRIVING TORQUES SPECIFIC DRIVING TORQUES LUBRICATION LUBRICATION DIAGRAM PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY MAINTENANCE PLAN WHEN REQUIRED WASHING THE COOLING CIRCUIT DRAINING THE FUEL TANK ELECTRICAL SYSTEM STEEL TRACK TENSION RUBBER TRACKS RUBBER TRACK TENSION RUBBER TRACK LUBRICATING THE ARTICULATIONS MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER (BREAKER) HYDRAULIC OIL FILTER HYDRAULIC OIL CHECKS BEFORE STARTING VARIOUS CHECKS COOLANT LEVEL FUEL LEVEL ENGINE OIL LEVEL OIL LEVEL IN THE HYDRAULIC CIRCUIT MAINTENANCE AFTER THE FIRST HOURS OF OPERATION MAINTENANCE EVERY HOURS OF OPERATION LUBRICATING THE JOINTS AND THE BALL BEARING RING LUBRICATING THE VARIABLE TRACK GAUGE SLIDING GUIDES CLEANING THE AIR CLEANER CARTRIDGE MAINTENANCE AFTER THE FIRST HOURS OF OPERATION MAINTENANCE EVERY HOURS OF OPERATION ADJUSTING THE FAN BELT TENSION BATTERY ELECTROLYTE LEVEL OIL LEVEL IN THE TRAVEL REDUCTION GEARS HYDRAULIC SYSTEM OIL FILTER ENGINE OIL MAINTENANCE AFTER THE FIRST HOURS OF OPERATION MAINTENANCE EVERY HOURS OF OPERATION ENGINE OIL FILTER FUEL FILTER FUEL PUMP PRECLEANER AIR CLEANER CARTRIDGE CLEANING THE OUTSIDE OF THE RADIATORS DRAINING THE HYDRAULIC OIL TANK OIL IN THE TRAVEL REDUCTION GEARS HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER COOLANT CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE ALTERNATOR AND THE STARTER TECHNICAL DATA STANDARD OVERALL DIMENSIONS TECHNICAL CHARACTERISTICS LIFTING CAPACITY WITH RAISED BLADE AUTHORIZED OPTIONAL EQUIPMENT PRECAUTIONS REGARDING SAFETY PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT CHARACTERISTICS OF THE OPTIONAL EQUIPMENT ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER) DESCRIPTION AND CONTROL USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED FOR A CORRECT USE, IT IS NECESSARY TO: ALWAYS AVOID THE FOLLOWING INCORRECT USES: INSTALLING AND REMOVING THE DEMOLITION HAMMER INSTALLING THE HAMMER REMOVING THE HAMMER MAINTENANCE