Please! Inform Film Type (NV-25, NV-35) when ordering by e-mail or invoice.

Please check with your country's customs office to determine what these additional costs will be prior to buying.

Benefits- Great heat rejection provides energy savings and improved comfort.

- A warm natural hue invites warmth and beauty to any room.

- Extends the life of furnishings by significantly reducing UV rays, the largest cause of fading.

- Low interior reflectivity, especially at night!

- 3M nano-technology enhances color stability.

- Reduces glare and eye discomfort.

- Comprehensive 3M manufacturer's warranty.

- Increases personal safety from flying glass.

- Scratch resistant coating.

1. SUMMARY

A. Section Includes: Abrasion-resistant, solar control, reflective window film. Film is designed to reduce gain of solar heat energy

through window by reflecting more to the exterior than interior. Traditional metalized films reflect equally both

inside and outside, where you need it, and less to the inside. The Night Vision line reflects more to the outside,

where you need it, and less to the inside, where you do not need it. 3M Night Vision, carbon impregnated

polyester layer provides outstanding heat rejection performance.

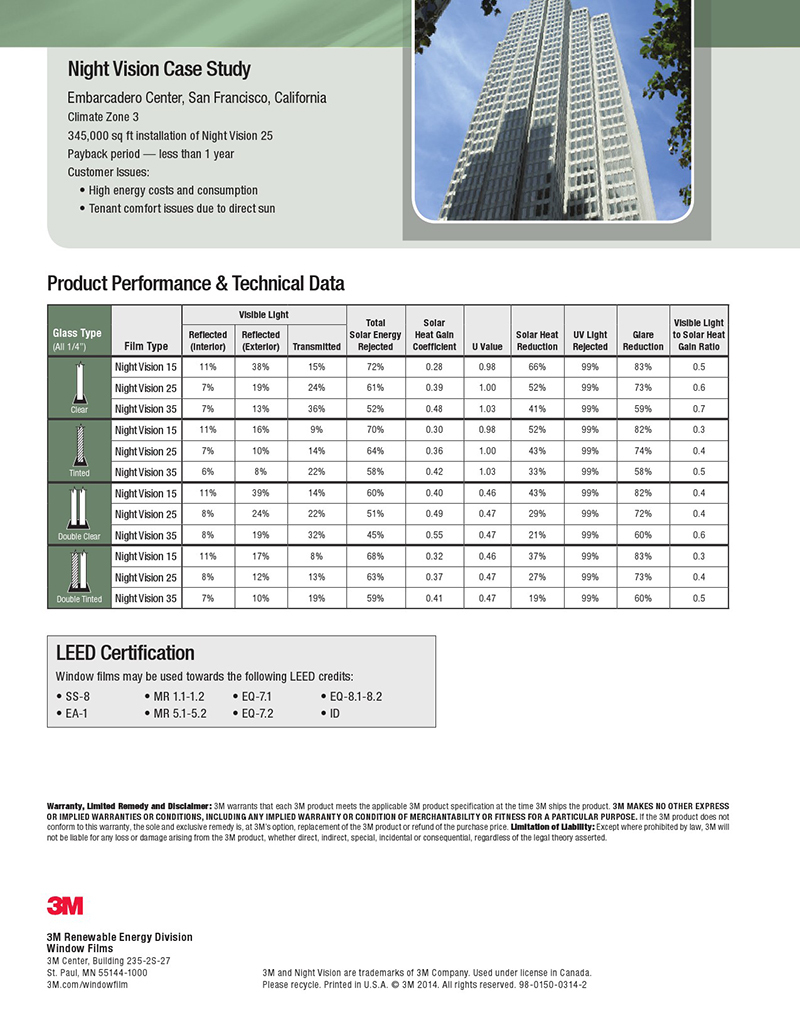

| 6mm Clear Glass | NV-15 | NV-25 | NV-35 |

Shading Coefficeint | 0.94 | 0.32 | 0.45 | 0.55 |

Visible Light Transmitted | 89% | 15% | 24% | 36% |

Visible Light External Reflected | 8% | 38% | 19% | 13% |

Visible Light Internal Reflected | 9% | 11% | 7% | 7% |

IR Reject | N/A | 83% | 72% | 56% |

U Value | 1.03 | 0.98 | 1.00 | 1.03 |

U Value (W/m2K) | 5.8 | 5.5 | 5.6 | 5.8 |

Heat Gain Reduction | N/A | 66% | 52% | 41% |

Heat Loss Reduction | N/A | 4% | 2% | 0% |

Glare Reduction | N/A | 83% | 73% | 59% |

UV Block | N/A | 99% | 99% | 99% |

TSER | 19% | 72% | 61% | 52% |

1. Adhesive System: Pressure sensitive, weatherable, acrylate adhesive applied uniformly over surface opposite abrasion

resistant coated surface.

a. Viewing film from a distance of 10 feet (3 m) at angles up to 45 degrees from either side of glass, film shall not appear

distorted.

2. Flammability: Class A Interior Finish for Buildings Materials for both Flame Spread Index and Smoke Development Values per

ASTM E84.

3. Abrasion Resistance: Surface coating resistant to abrasion, with less than 5 percent increase of transmitted light haze

resulting per ASTM D1044 using 100 cycles, 500 grams of weight, and CS10F Calbrase Wheel.

film.

Provide films with acrylic abrasion-resistant coating over surface of film for enhanced durability.

1. Film Color: Derived from metal coating and/or components, and product will not contain conventional dyed polyester.

2. Provide uniform film, without noticeable pin holes, streaks, thin spots, scratches, banding, or other optical defects. Variation in

total transmission across width, at any portion along length, shall not exceed 2 percent over average. Density of film across

web is not to exceed plus or minus 2 percent. Provide film with no evidence of coating voids.

A. Use protective tarps and drop cloths to cover interior finishes near window.

B. Turn off or cover heating and air conditioning ventilation ducts.

C. Clean window and window framing thoroughly with cleaning solution consisting of 90 percent water and 10 percent ammonia.

Blade inside surface of window glass with industrial razors to insure removal of foreign contaminants.

1. Tape and seal cracked and deteriorating window sealant.

D. Place towel or other absorbent material on window sill or sash to absorb moisture accumulation generated by film application.

E. Thoroughly rinse glass from top to bottom with pressure spray tank.

F. Squeegee entire glass surface.

G. Dry glass edges and window frames using a lint-free towel.

5. INSTALLATION

A. Install in accordance with manufacturer's instructions.

B. Cut film edges neatly and square at a uniform distance of 1/8 inch (3 mm) to 1/16 inch (1.5 mm) of window sealant.

Use new blade tips after 3 to 4 cuts.

C. Spray the slip solution, composed of one capful of baby shampoo or dishwashing liquid to 1 gallon of water,

on window glass and adhesive to facilitate proper positioning of film.

D. Apply film to glass and lightly spray film with slip solution.

E. Squeegee from top to bottom of window. Spray slip solution to film and squeegee a second time.

F. Bump film edge with lint-free towel wrapped around edge of a 5-way tool.

G.Upon completion of film application, allow 30 days for moisture from film installation to dry thoroughly,

and to allow film to dry flat with no moisture dimples when viewed under normal viewing conditions.

H. If completing an exterior application, check with the manufacturer as to whether edge sealing is required.

6. CLEANING AND PROTECTION

A. Remove left over material and debris from Work area. Use necessary means to protect film before, during,

and after installation.

B. Touch-up, repair or replace damaged products before Substantial Completion.

C. After application of film, wash film using common window cleaning solutions, including ammonia solutions,

30 days after application. Do not use abrasive type cleaning agents and bristle brushes to avoid scratching film.

Use synthetic sponges or soft cloths.

INFORMATION

Shipping

We ship your orders almost within 2 business days after your payment.

It will arrive almost within 2~55 business days.

Customs & Duties

Import duties, taxes and charges are not included in the item price or shipping charges. Buyers are responsible for these charges. Please check with your country's customs office to determine what these additional costs will be prior to bidding/buying.

Returns

We carefully inspect the item before shipping.

If you received the wrong item, please let us know it through “My Message”, we will exchange it to the correct item.

Feedback

Your opinion is very important to us.

Satisfied with our service, please give me a 5 star positive feedback.

Please DO NOT leave a neutral or negative feedback without contacting us first to get a better solution. A better solution for you is better than any other neutral or negative feedback. (A seller of anyone with star scores below 3 can no longer sell.)