THE AWARD WINNING BRICK BRACE SAFETY SYSTEM

HALF SET

Includes, Six Brick Brace Safety tools, Six hooks, 4 couplers, Anchor Bolts, a correct procedure, guidance, Brick Brace masonry weight awareness chart, VAT & free delivery anywhere within the UK.

(Scaffold tube not included)

Providing the tools, training, skills and knowledge to stabilise a structure and to safely manage alterations.

BRICK BRACE BENEFITS

Providing further temporary support options

–

Keyhole surgery for face brickwork remedial & repair works

–

Instructions & help-line are provided with every order

–

Use at any height, high or low

–

Stabilises lime & weak mortar masonry, no lost or falling masonry & minimal making good

–

The only temporary masonry support equipment fully tested in multiples on brickwork

–

Guaranteed superior finish to a task

–

No voids/traps in scaffolds

–

Re-instates a load point to safely reduce the weight of the load

–

Pays for itself within two applications

–

Minimal Repair time

–

Ensures future generations are taught correctly

-

Versatile & Lightweight, Easy To Store/ Fits in a tool bag

–

Reduced carbon footprint

–

Designed & Manufactured in Great Britain

–

Superior results and time saved, GUARANTEED!

Brick Brace Sets Available at

Brickbracedotcom

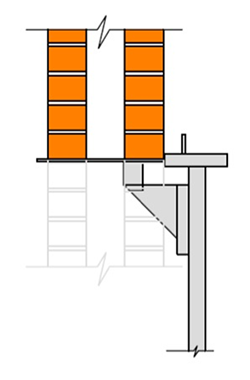

Half set

All Opening sizes up to 3,150 mm (14 brick lengths), supporting all 91 bricks within the triangle of masonry above the opening at any height, high or low, with full access to the task.

-

Full Set

The Brick Brace safety system allows openings up to 5400mm when using an aluminium scaffold beam, see photo no9.

&

Use as a safety belt above wider openings when propping to reduce the weight of the load to avoid collapse from overloading.

The Brick Brace safety system shares the load equally across the opening to reduce the risk of minor collapse in-between props and minimising the risk of an Acrow prop curving during a task.

Purchase and use with confidence after reading our ebay feedback, with a full money back guarantee to anyone that doesn't benefit from its use!

GUIDANCE

The stability & lateral strength of a brick structure is unpredictable & varies upon each project; this depends on the length of the opening, the mortar mix, the age & the quality of the masonry. Lime mortar masonry having minimal lateral strength, if any.

The Brick Brace is the only temporary support equipment designed to increase stability where totally neglected in the past.

A tongued prop attachment was

designed in the mid 1980’s when openings were smaller and a cavity only 50mm

but due to changes in construction design a typical cavity has now doubled to

100mm and 150mm+ upon newer properties for further thermal value and open plan

living accommodation has also vastly increased the opening and steel sizes

within a typical residential extension.

–

The safe working load is reduced to an unknown quantity by over extending further from the wall to gain more

fitting space when attempting tasks which require longer and wider steels with

welded top/bottom plates for wider cavities when still only using the tongued prop attachment.

-

We have studied temporary

masonry support for many years, more than anyone before us. Our fully patented

method of strengthening masonry before alterations take place is the further

preparation required for safer and superior results, GUARANTEED!

-

–

A tongued prop attachment misuses an Acrow prop & changes the direction of the load onto the side of the Acrow props inner tube of which is only designed for vertical loads (from the head plate down to the foot plate).

An eccentrically loaded Acrow prop curves

and loses height when overloaded or over tightened which is the legal

duty of the user not to overload and to work with an Acrow prop fitted

with an attachment in a safe, professional & competent manner even though

no warning of this is in place.

-

The fully tested Brick Brace safety tool

increases the unknown strength of lime & cement mortar masonry by creating

a force of 40Nm which through testing is proven to be strong and stable enough

to prevent collapse during alterations.

-

Now in our Twelfth year of business with tens

of thousands of Brick Brace safety tools being sold and used worldwide every

year!

–

Brick Brace

safety tools are fitted three bricks apart in a cement mortar mix, a maximum of

two and a half bricks apart in a weak/ lime mortar mix and within every

perpendicular joint upon Block work.

-

Drill out the required perpendicular

joint/s with a 10mm masonry drill bit. Insert the Brick Brace safety

tool/s and engage fully to the angled plate. Tighten the centre screw with

a 19mm socket spanner; the masonry is now reinforced and ready for safer

alterations and superior results, guaranteed.

-

WHY USE THE BRICK BRACE?

The theory behind a tongued prop attachment

is to use fewer Acrow props and to reduce masonry damage and is marketed within

that manner, which certainly is not the case when the maximum safe working load

is only a fraction (1/5) of the correct propping and needling method (if used

correctly) and when maintaining the 340kg safe working load the hole within

both sides of the cavity wall or a 9″ wall is actually larger than fitting a

needle and with at least five times more fitting holes required than one needle.

-

The misleading instructions have increased

the risk of the user to underestimate the weight of the load and induces the

risk of the user to overload the equipment through further eccentricities and

has also suppressed the true level of knowledge required to safely

tackle the many different tasks of altering masonry.

Examples

A

9″ brickwork can weigh over 600kg per

square metre, (120 bricks plus mortar) which would require at least five Acrow props and attachments per linear metre (at 167mm centre’s) on a larger opening on a

typical two storey residential property, which could weigh 1,440kg per linear

metre without roof loads and making the use of such products unsuitable &

obsolete for that task.

B

The traditional tongued prop attachment

was designed in the mid 1980’s when a typical cavity was only 50mm but due to

changes in construction design a cavity has now trebled to 150mm with open plan

living accommodation has increased opening sizes.

Attempting tasks which require wider

steels with welded top or bottom plates for large cavities and still only using

tongues is where more problems of overloading through over extending further

from the wall arise.

C

The new instructions updated Nov’ 2015

strangely suggest that propping an older style 9″ wall by over 300mm

eccentricity from the centre line of the wall to the centre line of the Acrow

prop is acceptable even when the safe working load is reduced to an unknown

quantity and when to avoid collapse the tongued attachment is totally dependent

on the unknown lateral strength of the lime mortar masonry.

D

The majority of tasks require far more

fitting work space than tongued prop attachments can safely offer when still

maintaining the maximum 340kg safe working load and when not dangerously

removing the opening down to the full finished level without the permanent

support being fitted as this increases the risk of collapse through accidental

removal of loaded Acrow props during the demolition of the masonry. To reduce

the risk of minor and major collapse only a few courses of masonry should be

carefully removed to allow for the safe fitting of the permanent support. Once

the permanent support is in the final position and cured, the rest of the

opening can then be removed down to the full finished depth.

–

The Brick Brace, guidance, correct

procedures, weight charts and proven strategies address all the main causes of

collapse during masonry alterations and ensures future generations are taught

safely & correctly.

–

The force required upon the safety tools is estimated at 700N, for a safety factor of x 3 the force is 2.1kN.

A recommended torque of 40Nm produces a force of 3.28kN which is more than adequate even allowing for some fall off in force as the tool beds in.

This torque is also readily achievable on site and was also used in the test via a ratchet spanner. It also provides a force well below that to crush the end faces of the brick. When bricks were removed from below there was no distress whatsoever, no visible movement or cracking which suggested that the calculations are very reasonable.

-

The fully tested Brick Brace safety tool increases the unknown variable strength of masonry by creating a force of 40Nm which through testing is proven to be strong and stable enough to prevent collapse.

-

The main cause of collapse during masonry alterations is overloading equipment due to underestimating the weight of the load & over extending Acrow props fitted with tongued prop attachments from the wall to avoid internal 1st floor wall damage and/or attempting to gain further fitting access, as over extending greatly affects the Acrow props safe working load.

The Maximum Safe Working Loads

(S.W.L)

–

An Acrow prop, 3,400Kg.

–

An Acrow prop used within the props and needles method, 1,700Kg.

–

When fitted with a tongued prop attachment an Acrow props safe working load is severely reduced by at least 90%, from 3,400kg down to the maximum 340kg and can even reduce down to 0kg of which depends on the size & the working height of the Acrow prop, how plumb, how tightly fitted and how far the Acrow prop is positioned from the centre of the wall.

To maintain the maximum 340kg safe working load the tongue must fully penetrate the internal skin when supporting a cavity wall, as seen in the drawing below.

–

BRICK BRACE FEEDBACK

-

Mr S. Dunaway

(Builder From Surrey)

Top quality product.

After taking the time to read and understand what the Brick Brace has to offer, I can now appreciate the impact this system can have on improving the safety of structural alterations.

After all, structural alterations are the only general construction based procedures where NO training or advice is offered to any tradesman.

For me, Brick Brace is not just a product; it has provided an understanding of the task, with clear guidance on the limitations of all the equipment.

I also received very helpful advice and instructions from the guys at brick brace regarding my own project.

I challenge you all to find another company so invested in your own safety when it comes to structural alterations!

-

EXCELLENT, A+, GREAT, 100% POSITIVE, 5 STARS,

QUALITY ITEM, THIS IS A BRILLIANT BIT OF KIT

"Great item, all info & weight charts etc A+"

"Very pleased, did exactly as the instructions said and watched video. Brill"

"This product is simply brilliant!!! Turned a difficult job into an easy one...A1".

“Great product, made life so easy, I had no dropped bricks whatsoever” A+++

Excellent thank you, very fast service, can't recommend company or product enough.

Extremely good seller - brick brace works so well and so quick to implement.

Fast delivery brilliant tool - don't be frightened of technology!!

Fantastic product

Good kit. fast delivery 5*.

Truly fantastic bit of kit, genuine seller and great communication.

Great labour saving device.

Brilliant piece of kit. Well worth the money. Thank you.

Brilliant. Top job. 10/10.

Cracking device, should be in every builders tool kit.

Goods as described, works well, very quick delivery, recommended 5*seller.

Absolutely superb. works exactly as described.

first class product top ebayer.

Fast Delivery, Fantastic product. Thank You A++++.

great......!!!!!!!!!!!!!!!!!!

Great item fast response, well packaged, recommended seller !

5****** Highly recommend.

2023 Propping Guide available via our website

THANK YOU FOR READING

Brickbracedotcom

01895-546405

KEEP IT SAFE

BRICK BRACE