Kubota Tractors

BX23S, LA340, BT603

Service Manual & Owner's Manual

YEAR: 2017 & Up

After Purchase A link will be sent to your eBay message to Download.

Note: PDF File not printed Material

Kubota service manual WSM Workshop Manual

Kubota owners' ops manual

Contents Below

INFORMATION

SAFETY FIRST

Safety first

Before you start service

Start safely

Operate safely

Protect against high pressure spray

Avoid hot exhaust

Exhaust filter cleaning

Prevent a fire

Keep a good airflow in the work area

Discard fluids correctly

Prevent acid burns

Prepare for emergencies

SAFETY LABEL

Safety labels for BX tractor

Safety labels for mower

Safety labels for loader

Safety labels for backhoe

SPECIFICATIONS

BX tractor specifications

Mower specifications

Bucket specifications

Dimensional specifications of loader

Operational specifications of loader

Backhoe dimensions

Backhoe lift capacity

TRAVELING SPEEDS

DIMENSIONS

GENERAL

IDENTIFICATION

Tractor identification

Checking serial number and hour meter

Cylinder number

Checking mower identification

Checking loader identification

Checking backhoe identification

GENERAL PRECAUTIONS

HANDLING PRECAUTIONS FOR ELECTRICAL PARTS AND WIRING

LUBRICANTS, FUEL AND COOLANT

BX tractor

Lubricants, fuel, and coolant

Fuel

Engine oil

Transmission oil

Overview of biodiesel fuel (BDF)

Mower

Lubricants

TIGHTENING TORQUES

General use screws, bolts and nuts

Stud bolts

Metric screws, bolts and nuts

American standard screws, bolts and nuts with UNC or UNF threads

Plugs

Adapters, elbows and others

MAINTENANCE CHECK LIST

BX tractor service intervals

Mower service intervals

CHECK AND MAINTENANCE

Periodic service

Opening bonnet

Daily check

Walk around inspection

Checking fuel gauge and refueling

Checking engine oil level

Checking transmission fluid level

Checking coolant level

Cleaning panel and radiator screen

Checking brake pedal

Checking gauges, meters, and Easy Checker™

Checking head light, hazard light, and tail light

Checking seat belt and ROPS

Checking and cleaning electrical wiring and battery cables

Checking movable parts

Check points of initial hours

Changing engine oil

Replacing engine oil filter

Replacing transmission oil filter

Changing transmission fluid

Cleaning transmission strainer

Check points of every hours

Greasing

Checking engine start system

Checking operator presence control (OPC) system

Checking wheel bolt torque

Cleaning lock lever shaft

Check points of every hours

Checking battery condition

Cleaning air cleaner element

Checking fuel filter

Adjusting fan belt tension

Adjusting HST neutral spring

Adjusting brake pedal

Check point of every hours

Replacing engine oil filter

Changing engine oil

Replacing transmission oil filter

Adjusting toe in

Check points of every hours

Adjusting front axle pivot

Changing transmission fluid

Cleaning transmission strainer

Changing front axle case oil

Replacing fuel filter element

Check points of every hours

Adjusting engine valve clearance

Check points of every hours or year

Replacing air cleaner element

Check points of every hours

Checking injection pressure of fuel injection nozzle

Check points of every hours or years

Flushing cooling system and changing coolant

Antifreeze

Check points of every hours

Checking injection pump

Check points of every year

Checking intake air line

Checking radiator hoses and hose clamps

Checking power steering line

Checking fuel lines

Checking engine breather hose

Check points of every years

Replacing radiator hose

Replacing fuel hose

Replacing power steering hose

Replacing intake air line

Replacing engine breather hose

Service as required

Bleeding fuel system

Replacing fuse

Replacing light bulb

Mower

Check points of daily or each use

Re tightening mower blade screw

Checking mower blade

Checking mower belt

Checking gear box oil level

Greasing spindle shafts, belt tension pivot and tension pulley

Greasing front and rear antiscalp rollers

Greasing universal joint

Check points of initial hours

Changing gear box oil

Check point of every hours

Changing gear box oil

Check points of every year

Checking gear box oil seal

Check point of every years

Replacing gear box oil seal

Front loader

Check points of daily or each use

Checking transmission fluid level

Checking hydraulic hoses

Check points of every hours

Greasing loader

Check points of every hours

Checking torque of main frame bolt and nut

Backhoe

Check points of daily or each use

Checking transmission fluid level

Checking hydraulic hoses

Checking backhoe mounting pin

Check points of every hours

Greasing backhoe

Check points of every hours

Checking torque sub frame bolt and nut

TIRES, WHEELS, AND BALLAST

Tires

Inflation pressure of tires

Dual tires

Wheel tread

Front wheels

Rear wheels

Ballast

Front ballast

Rear ballast

IMPLEMENT LIMITATIONS

Implement limitation tables

SPECIAL TOOLS

Special tools for engine

Special use puller set

Diesel engine compression tester (for injection nozzle)

Nozzle tester

Injection pump pressure tester

Valve guide replacing tool

Bushing replacing tool

Flywheel stopper

Crankshaft bearing replacing tool

Special tools for tractor

Tierod end lifter

Independent PTO clutch spring compression tool

Disassembling and assembling stand (/)

Disassembling and assembling stand (/)

Check and high pressure relief valve assembly tool

ENGINE

MECHANISM

Engine body

Function of cylinder block

Function of closed breather

Function of halffloating head cover

Function of piston

Function of piston ring

Function of connecting rod

Function of crankshaft

Function of camshaft

Function of rocker arm

Function of flywheel

Function of timing gears

Lubricating system

Overview of lubricating system

Function of oil strainer

Function of oil pump

Function of oil filter

Function of relief valve

Function of oil pressure switch

Cooling system

Overview of cooling system

Function of water pump

Function of radiator

Function of radiator cap

Fuel system

Overview of fuel system

Function of fuel filter

Function of fuel feed pump

Function of injection nozzle

SERVICING

Troubleshooting for engine

Servicing specifications for engine

Tightening torques for engine

Checking and adjusting

Engine body

Checking compression pressure

Checking valve clearance

Lubricating system

Checking engine oil pressure

Cooling system

Checking fan belt tension

Checking fan belt damage and wear

Checking radiator cap air leakage

Checking radiator water leakage

Checking thermostat valve opening temperature

Fuel system

Checking injection timing

Checking fuel tightness of pump element

Checking fuel tightness of delivery valve

Checking nozzle spraying condition

Checking fuel injection pressure

Checking valve seat tightness

Checking nozzle holder

Disassembling and assembling

Separating engine

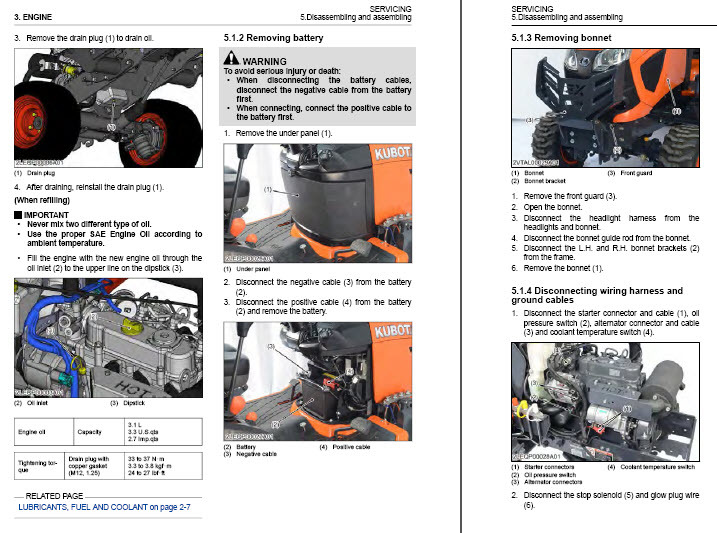

Draining engine oil

Removing battery

Removing bonnet

Disconnecting wiring harness and ground cables

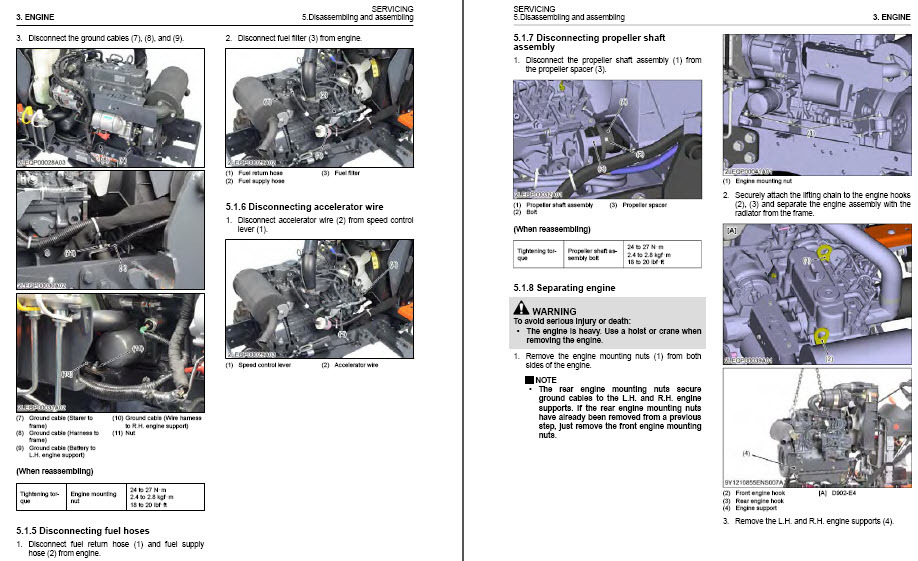

Disconnecting fuel hoses

Disconnecting accelerator wire

Disconnecting propeller shaft assembly

Separating engine

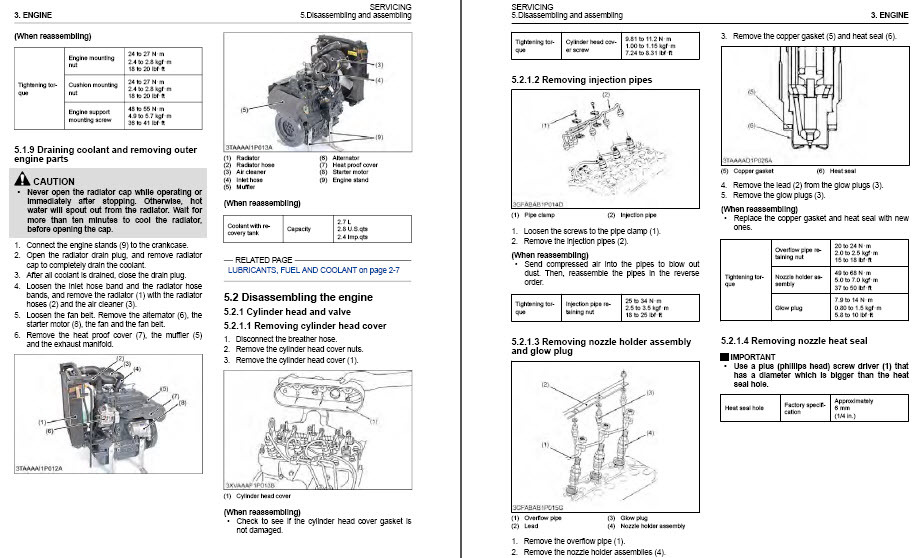

Draining coolant and removing outer engine parts

Disassembling the engine

Cylinder head and valve

Gear case and timing gears

Piston and connecting rod

Flywheel and crankshaft

Servicing

Cylinder head and valve

Checking top clearance

Checking cylinder head surface flatness

Checking cylinder head flaw

Checking valve recessing

Checking clearance between valve stem and valve guide

Replacing valve guide

Checking valve seating

Correcting valve

Correcting valve seat

Lapping valve

Checking free length and tilt of valve spring

Checking valve spring setting load

Checking oil clearance between rocker arm and rocker arm shaft

Checking push rod alignment

Checking oil clearance between tappet and tappet guide bore

Timing gears, camshaft and governor gear

Checking timing gear backlash

Checking idle gear side clearance

Checking camshaft side clearance

Checking camshaft alignment

Checking cam height

Checking oil clearance of camshaft journal

Checking oil clearance between idle gear shaft and idle gear bushing

Replacing idle gear bushing

Piston and connecting rod

Checking piston pin bore ID

Checking oil clearance between piston pin and small end bushing

Replacing small end bushing

Checking connecting rod alignment

Checking piston ring gap

Checking clearance between piston ring and piston ring groove

Crankshaft

Checking crankshaft side clearance

Checking crankshaft alignment

Checking oil clearance between crankpin and crankpin bearing

Checking oil clearance between crankshaft journal and crankshaft bearing

Replacing crankshaft bearing

Checking oil clearance between crankshaft journal and crankshaft bearing and crankshaft bearing

Cylinder

Checking cylinder wear

Correcting cylinder (Oversize)

Oil pump

Checking rotor lobe clearance

Checking clearance between outer rotor and pump body

Checking clearance between rotor and cover

Relief valve spring

Checking relief valve

TRANSAXLE

MECHANISM

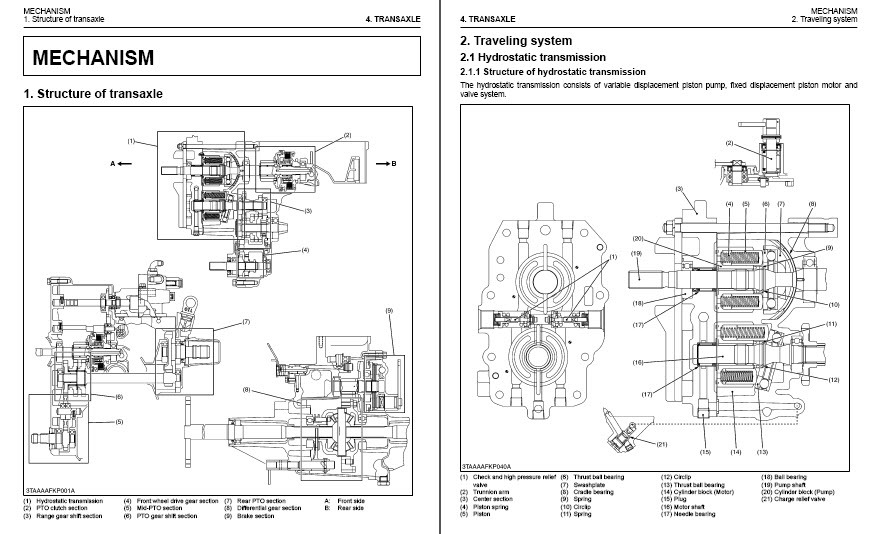

Structure of transaxle

Traveling system

Hydrostatic transmission

Structure of hydrostatic transmission

Oil flow of hydrostatic transmission

Structure of HST control linkage

Speed set linkage

Range gear shift section

Structure of range gear shift

Front wheel drive section

Structure of front wheel drive

Differential gear section

Structure of differential gears

Structure of differential lock

Brake section

Structure of brake system

PTO system

Structure of PTO system

Function of PTO clutch relief valve

Engaged function of PTO clutch

Disengaged function of PTO clutch

Structure of mid and rear PTO

Others

Hydraulic pump drive gear section

Structure of hydraulic pump drive gear

SERVICING

Troubleshooting for transaxle

Servicing specifications for transaxle

Tightening torques for transaxle

Checking and adjusting

Adjusting maximum speed

Adjusting HST neutral position

Checking and adjusting HST neutral spring (dynamic braking)

Checking charge relief pressure

Checking high relief pressure (Forward)

Checking high relief pressure (Reverse)

Readjusting relief valve (When HST does not work due to its loose hexagon socket head screw)

Checking PTO clutch operating pressure

Adjusting brake pedal free travel

Disassembling and assembling

Separating transaxle

Draining transmission fluid

Removing battery

Removing lift rod and lower link

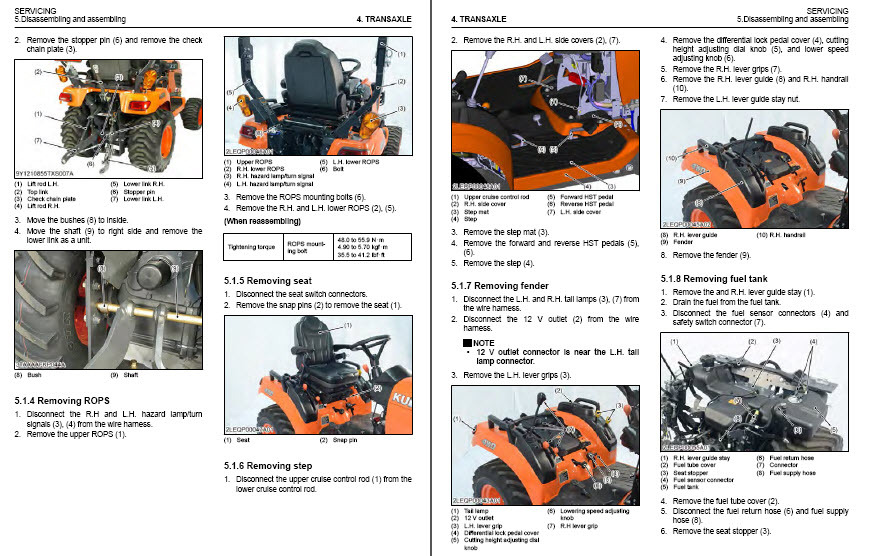

Removing ROPS

Removing seat

Removing step

Removing fender

Removing fuel tank

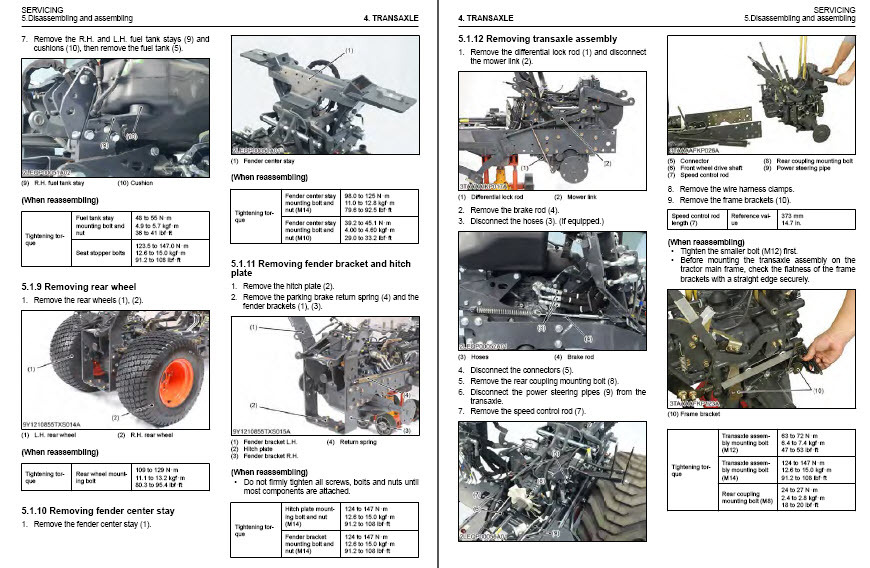

Removing rear wheel

Removing fender center stay

Removing fender bracket and hitch plate

Removing transaxle assembly

Removing brake pedal

Removing propeller shaft

Removing differential lock pedal

Removing speed control pedal, HST damper, and cruise rod

Hydrostatic transmission

Removing levers and mower lift arm

Removing PTO clutch valve

Removing oil cooler cover

Removing center section and valve plates

Removing check and high pressure relief valve plug

Checking check and high pressure relief valve

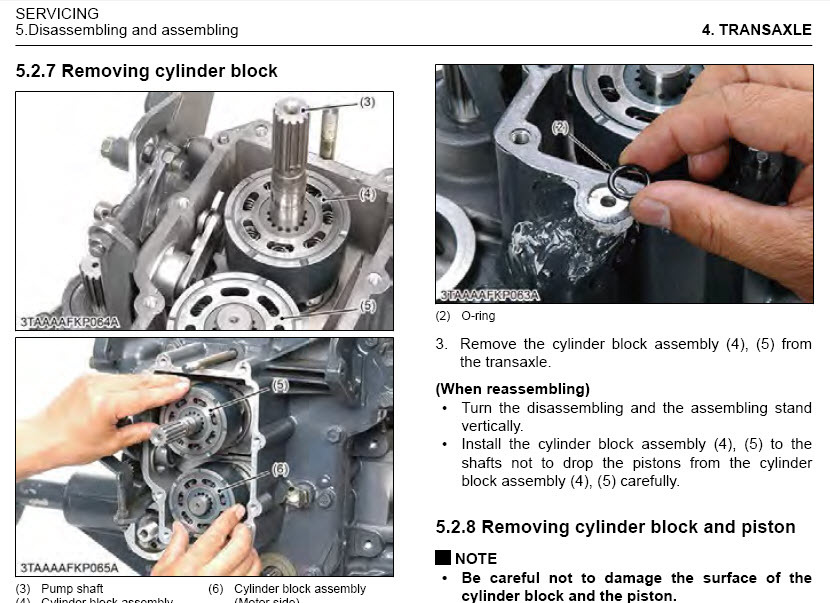

Removing cylinder block

Removing cylinder block and piston

Removing swashplate and trust roller bearing

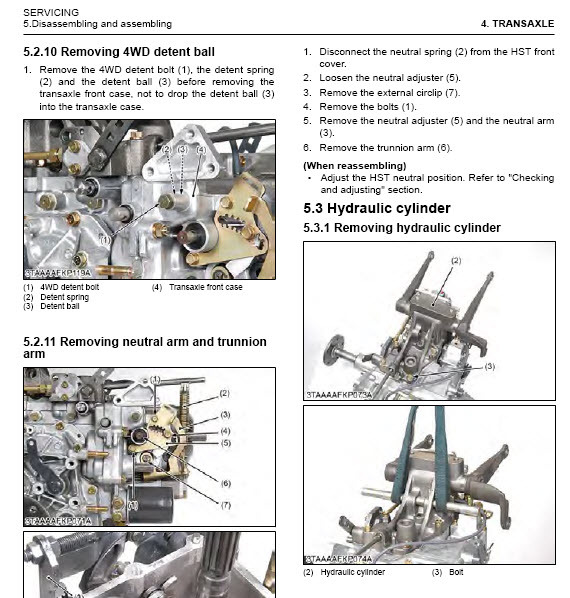

Removing WD detent ball

Removing neutral arm and trunnion arm

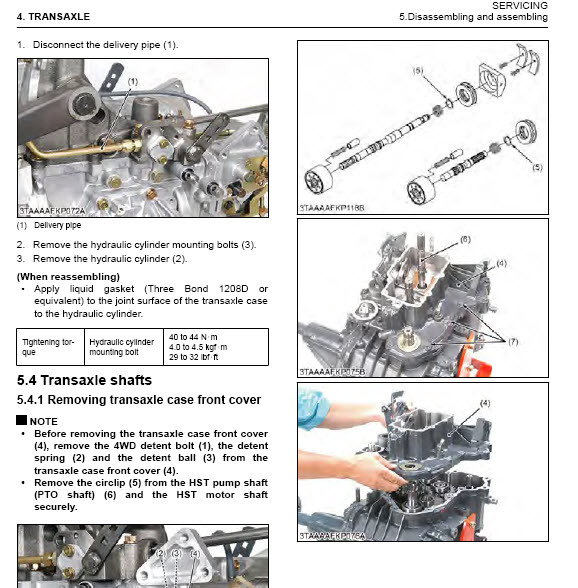

Hydraulic cylinder

Removing hydraulic cylinder

Transaxle shafts

Removing transaxle case front cover

Removing hydraulic pump assembly

Removing rear PTO cover assembly

Disassembling rear axle (LH)

Removing rear axle case (RH)

Removing T final gear

Removing rear axle case, RH and brake

Removing PTO clutch assembly

Assembling shafts

Assembling select arms and HST pump shaft (PTO clutch shaft)

Assembling front wheel drive shaft, shifter, spiral bevel pinion shaft and midPTO shaft

Servicing

Hydrostatic transmission

Checking center section

Checking charge relief valve

Checking check and high pressure relief valve

Checking cylinder block assembly

Checking thrust washer, thrust roller bearing, thrust plate and cradle bearing

Checking pump shaft (PTO clutch shaft)

Checking needle bearing

Transaxle case

Checking bearing

Checking PTO clutch disc wear

Checking separate plate and back plate wear

Checking flatness of clutch piston, pressure plate and steel plate

Checking clutch spring free length

Checking PTO brake disc wear

Checking PTO brake plate

Checking clearance between differential case and differential side gear

Checking clearance between differential pinion shaft and differential pinion

Checking backlash between differential pinion and differential side gear

Checking backlash between spiral bevel pinion gear and bevel gear

Checking brake cam lever movement

Checking flatness of actuator and bearing holder

Checking height of cam plate and ball

Checking brake disc and friction plate wear

FRONT AXLE

MECHANISM

Structure of front axle

Front wheel alignment

Camber of front axle

Kingpin angle of front axle

Caster of front axle

Toein of front axle

SERVICING

Troubleshooting for front axle

Servicing specifications for front axle

Tightening torques for front axle

Checking and adjusting

Adjusting toein

Adjusting front axle rocking force

Adjusting front wheel steering angle

Disassembling and assembling

Separating front axle assembly

Draining front axle case oil

Removing battery

Removing bonnet

Removing front wheel and propeller shaft cover

Disconnecting propeller shaft

Removing front axle assembly

Front axle assembly

Removing power steering cylinder

Removing bevel gear case and front gear case

Removing front gear case cover

Removing T bevel gear and front axle shaft

Removing front gear case and bevel gear case

Removing bevel pinion shaft and differential gear assembly

Removing differential gear

Servicing

Checking clearance between differential case and differential side gear

Checking clearance between differential pinion shaft and differential pinion

Checking backlash between differential pinion and differential side gear

Checking turning torque of bevel pinion shaft

Checking backlash between bevel pinion shaft and bevel gear

Checking backlash between T bevel gear and T bevel gear

Checking clearance between center pin and pin support bushing

STEERING

MECHANISM

Structure of steering system

Hydraulic circuit of steering

Steering controller

Structure of steering controller

Control valve

Metering device

Relief valve

Steering cylinder

Structure of steering cylinder

SERVICING

Troubleshooting for steering

Servicing specifications for steering

Tightening torques for steering

Checking and adjusting

Checking relief valve operating pressure

Disassembling and assembling

Power steering cylinder

Removing adapter and tierod

Disassembling steering cylinder

Separating power steering controller

Removing battery

Removing steering wheel

Removing upper panel

Removing steering controller

Separating power steering cylinder

Removing bonnet

Removing front axle assembly

Removing power steering cylinder

Servicing

Checking steering cylinder ID

Checking clearance between rod and guide

HYDRAULIC SYSTEM

MECHANISM

Structure of hydraulic system

Hydraulic circuit

Hydraulic pump

Outline of hydraulic pump

Structure of hydraulic pump

Specification of hydraulic pump

Control valve

Outline of control valve

Function of control valve

Control valve in neutral position

Control valve in lift position

Control valve in down position

Flow priority valve

Outline of flow priority valve

Structure of flow priority valve

Specification of flow priority valve

Relief valve

Outline of relief valve

Structure of relief valve

Function of relief valve

Specification of relief valve

Hydraulic cylinder

Structure of hydraulic cylinder

Hydraulic block type outlet

Structure of hydraulic block type outlet

Mower linkage

Structure of mower linkage

Front loader valve

Structure

Structure of front loader valve and pipe

Structure of front loader control valve

Front loader hydraulic circuit

Function of loader control valve

Loader control lever in neutral position

Loader control lever in up position

Loader control lever in down position

Loader control lever in floating position

Loader control lever in rollback position

Loader control lever in dump position

SERVICING

Troubleshooting for hydraulic system

Servicing specifications for hydraulic system

Tightening torques for hydraulic system

Checking and adjusting

Relief valve

Checking relief valve setting pressure

Pump and priority valve

Checking hydraulic pump oil flow

Checking power steering oil flow

Mower lift linkage

Adjusting mower lift linkage

Disassembling and assembling

Hydraulic pump

Removing battery

Removing lift rod and lower link

Removing ROPS

Removing seat

Removing step

Removing fender

Removing fuel tank

Removing fender center stay

Removing hydraulic pump

Hydraulic cylinder block

Removing battery

Removing lift rod and lower link

Removing ROPS

Removing step

Removing fender

Removing fuel tank

Removing fender center stay

Removing mower linkage and wire harness

Removing hydraulic cylinder block

Hydraulic cylinder and control valve

Removing control valve

Removing control valve lever

Removing lift arm, hydraulic arm shaft and hydraulic arm

Removing hydraulic piston

Removing lowering speed adjusting valve

Mower lift linkage

Disassembling mower linkage

Control valve (Front loader)

Removing battery

Removing ROPS

Removing seat

Removing step

Removing fender

Removing control valve

Disassembling control valve

Servicing

Hydraulic pump

Checking clearance between tip of gear tooth and casing

Checking clearance between bushing and shaft

Checking side plate thickness

Hydraulic cylinder

Checking hydraulic cylinder bore

Checking hydraulic arm shaft bushing

ELECTRICAL SYSTEM

MECHANISM

Wiring diagram of BX tractor

Electrical connector chart

Reading electrical circuit diagrams

How to read wiring diagram

Layout of connector diagrams

Precautions on handling electrical connectors

Starting system

Electrical circuit of starting system

Function of relay

Function of starter

Function of glow plug

Function of safety switch

Function of fuel pump

OPC (Operator Presence Control) system

Electrical circuit of OPC timer

Charging system

Electrical circuit for charging system

Function of IC regulator (P connector type)

Lighting system

Electrical circuit for lighting system

Gauges

Electrical circuit of gauge system

Meter panel

Function of hour meter

Function of tachometer

Function of fuel gauge

Function of coolant temperature gauge

Function of fuel level sensor

Function of coolant temperature sensor

Function of oil pressure switch

Others

Electrical circuit for accessory

Function of DC outlet

SERVICING

Troubleshooting for electrical system

Servicing specifications for electrical system

Tightening torques for electrical system

Checking and adjusting

Battery

Checking battery voltage

Checking battery terminal connection

Checking battery specific gravity

Main switch

Checking main switch connector voltage

Checking main switch continuity at off position

Checking main switch continuity at on position

Checking main switch continuity at preheat position

Checking main switch continuity at start position

Starter

Checking motor

Testing starter magnet switch (pullin, holding coils)

Glow plug

Checking glow plug lead terminal voltage

Checking glow plug continuity

Safety switch

Checking PTO shift lever switch continuity

Checking HST neutral switch continuity

Operator presence control (OPC) system

Checking seat switch and seat turnover switch continuity

Checking OPC timer

Fuel pump

Checking fuel pump connector voltage

Checking fuel pump continuity

Engine stop solenoid

Testing engine stop solenoid

Timer relay

Checking timer relay connector voltage

Testing timer relay

Charging system

Checking battery charging current

Combination switch

Removing combination switch

Checking combination switch connector voltage

Checking head light switch continuity when setting switch at OFF position

Checking head light switch continuity when setting switch at ON position

Checking turn signal light switch continuity when setting switch knob at OFF position

Checking turn signal light switch continuity when setting switch knob at RIGHT position

Checking turn signal light switch continuity when setting switch knob at LEFT position

Checking hazard switch continuity when setting switch knob at OFF position

Checking hazard switch continuity when setting switch knob at ON position

Checking flasher unit connector voltage

Testing flasher unit actuation

Gauge

Checking charge lamp (charging circuit)

Checking engine oil pressure lamp

Checking engine oil pressure switch continuity

Checking fuel level sensor continuity

Checking coolant temperature sensor connector voltage

Checking coolant temperature sensor continuity

Checking hour meter and tachometer

Accessory

Checking DC outlet connector voltage

Checking DC outlet continuity

Meter panel

Checking connector voltage, sensor resistance and switch

Disassembling and assembling

Starter

Disassembling starter motor

Removing magnet switch

Removing plunger

Alternator

Removing pulley

Removing rear end cover

Removing brush holder

Removing IC regulator

Removing rectifier

Removing rear end frame

Removing rotor

Removing retainer plate

Removing bearing on drive end side

Removing bearing at slip ring side

Servicing

Starter

Checking overrunning clutch

Checking commutator and mica

Checking brush wear

Checking brush holder

Checking armature coil

Checking field coil

Alternator

Checking bearing

Checking stator

Checking rotor

Checking slip ring

Checking brush wear

Checking rectifier

MOWER

MECHANISM

Structure of power transmission of mower

Structure of lifting mechanism of mower

SERVICING

Troubleshooting for mower

Servicing specifications for mower

Tightening torques for mower

Setting up mower [RCKDBX and RCKDBX]

Assembling mower

Setting mower

Mounting front link

Mounting frame link

Setting tractor

Mounting mower

Checking and adjusting

Mower adjustment

Adjusting mower link

Adjusting front and rear cutting height

Adjusting left and right cutting height

Adjusting cutting height

Checking mower blade and belt

Checking mower blade

Checking mower belt

Disassembling and assembling

Removing ramps and belt covers

Removing mower blades

Removing blade boss

Removing gear box and mower belt

Disassembling gear box

Removing center pulley holder

Removing outer pulley and blade shaft

Servicing

Adjusting turning torque of pinion shaft

Adjusting backlash between bevel gears

FRONT LOADER

MECHANISM

Hydraulic circuit

Front remote hydraulic control system (if equipped)

Operating control lever

Boom cylinder and bucket cylinder

Structure of boom cylinder and bucket cylinder

One touch front loader

Outline of one touch front loader

One lever quick touch lines coupler

Structure of one lever quick touch lines coupler

Auto lock attachment and detachment

Outline of auto lock attachment and detachment

Function of auto lock attachment and detachment

Mechanical loader frame standing mechanism

Structure of mechanical loader frame standing mechanism

rd function valve (If equipped)

Structure of rd function valve

Function of rd function valve

Activation switch in off position

Activation switch in on position

SERVICING

Troubleshooting for front loader

Tightening torques for front loader

Checking and adjusting

Loader stand

Adjusting height of loader stand

Front hydraulic valve main switch and relay

Checking front hydraulic valve main switch continuity

Checking connector voltage of front hydraulic valve main switch

Checking relay

rd function solenoid valve

Checking rd function solenoid valve continuity

Checking connector voltage of rd function solenoid valve

Disassembling and assembling

Removing loader

Reinstalling loader

Bucket, boom and hydraulic cylinders

Attaching attachments

Removing attachments

Removing bucket cylinder

Removing boom cylinder and hydraulic tubes

Removing piston rod assembly

Removing cylinder head, piston and nut

Removing piston seal and Oring

Installing Oring and piston seal

Side frames, front guard and main frames

Removing side frames

Removing front guard

Removing main frames

rd function valve (If equipped)

Removing rd function valve

Removing hydraulic tubes of rd function

Servicing

Piston rod

Checking piston rod bend

BACKHOE

MECHANISM

Hydraulic circuit

Control valve

Structure of backhoe control valve

Function of backhoe control valve

Backhoe control valve in neutral position

Backhoe control valve in swing right position

Backhoe control valve in swing left position

Backhoe control valve in boom up position

Backhoe control valve in boom down position

Backhoe control valve in LH stabilizer shrink position

Backhoe control valve in LH stabilizer extend position

Backhoe control valve in RH stabilizer shrink position

Backhoe control valve in RH stabilizer extend position

Backhoe control valve in dipperstick crowd position

Backhoe control valve in dipperstick extend position

Backhoe control valve in bucket rollback position

Backhoe control valve in bucket dump position

Structure of overload relief valve

Function of relief position

Function of anticavitation position

Structure of hydraulic cylinder

SERVICING

Troubleshooting for backhoe

Servicing specifications for backhoe

Tightening torques for backhoe

Checking and adjusting

Checking relief valve setting pressure

Checking control lever operation force

Checking stabilizer control lever operation force

Disassembling and assembling

Removing backhoe

Preparing to remove backhoe

Releasing mounting pins

Disconnecting hydraulic hoses

Removing backhoe

Installing backhoe

Preparing to install backhoe

Connecting hydraulic hoses

Setting mounting pins

Installing backhoe

Disassembling backhoe

Removing bucket

Removing dipperstick and bucket cylinder

Removing dipperstick cylinder, boom, boom cylinder, and hoses

Removing swing frame

Removing swing cylinder

Removing stabilizers and stabilizer cylinder

Removing lever support and control valve

Removing backhoe main frame

Disassembling control valve

Disassembling cylinder (Boom, dipperstick, bucket, swing, stabilizer)

Removing cylinder rod assembly

Removing cylinder head, piston, and nut

Checking cylinder adaptor angle

Removing piston seal and Oring

Installing Oring and piston seal

Servicing

Checking clearance between pin and bushing

Checking thrust washer wear

Checking piston rod bend

SAFETY FIRST

Safety first

Before you start service

Start safely

Operate safely

Protect against high pressure spray

Avoid hot exhaust

Exhaust filter cleaning

Prevent a fire

Keep a good airflow in the work area

Discard fluids correctly

Prevent acid burns

Prepare for emergencies

SAFETY LABEL

Safety labels for BX tractor

Safety labels for mower

Safety labels for loader

Safety labels for backhoe

SPECIFICATIONS

BX tractor specifications

Mower specifications

Bucket specifications

Dimensional specifications of loader

Operational specifications of loader

Backhoe dimensions

Backhoe lift capacity

TRAVELING SPEEDS

DIMENSIONS

GENERAL

IDENTIFICATION

Tractor identification

Checking serial number and hour meter

Cylinder number

Checking mower identification

Checking loader identification

Checking backhoe identification

GENERAL PRECAUTIONS

HANDLING PRECAUTIONS FOR ELECTRICAL PARTS AND WIRING

LUBRICANTS, FUEL AND COOLANT

BX tractor

Lubricants, fuel, and coolant

Fuel

Engine oil

Transmission oil

Overview of biodiesel fuel (BDF)

Mower

Lubricants

TIGHTENING TORQUES

General use screws, bolts and nuts

Stud bolts

Metric screws, bolts and nuts

American standard screws, bolts and nuts with UNC or UNF threads

Plugs

Adapters, elbows and others

MAINTENANCE CHECK LIST

BX tractor service intervals

Mower service intervals

CHECK AND MAINTENANCE

Periodic service

Opening bonnet

Daily check

Walk around inspection

Checking fuel gauge and refueling

Checking engine oil level

Checking transmission fluid level

Checking coolant level

Cleaning panel and radiator screen

Checking brake pedal

Checking gauges, meters, and Easy Checker™

Checking head light, hazard light, and tail light

Checking seat belt and ROPS

Checking and cleaning electrical wiring and battery cables

Checking movable parts

Check points of initial hours

Changing engine oil

Replacing engine oil filter

Replacing transmission oil filter

Changing transmission fluid

Cleaning transmission strainer

Check points of every hours

Greasing

Checking engine start system

Checking operator presence control (OPC) system

Checking wheel bolt torque

Cleaning lock lever shaft

Check points of every hours

Checking battery condition

Cleaning air cleaner element

Checking fuel filter

Adjusting fan belt tension

Adjusting HST neutral spring

Adjusting brake pedal

Check point of every hours

Replacing engine oil filter

Changing engine oil

Replacing transmission oil filter

Adjusting toe in

Check points of every hours

Adjusting front axle pivot

Changing transmission fluid

Cleaning transmission strainer

Changing front axle case oil

Replacing fuel filter element

Check points of every hours

Adjusting engine valve clearance

Check points of every hours or year

Replacing air cleaner element

Check points of every hours

Checking injection pressure of fuel injection nozzle

Check points of every hours or years

Flushing cooling system and changing coolant

Antifreeze

Check points of every hours

Checking injection pump

Check points of every year

Checking intake air line

Checking radiator hoses and hose clamps

Checking power steering line

Checking fuel lines

Checking engine breather hose

Check points of every years

Replacing radiator hose

Replacing fuel hose

Replacing power steering hose

Replacing intake air line

Replacing engine breather hose

Service as required

Bleeding fuel system

Replacing fuse

Replacing light bulb

Mower

Check points of daily or each use

Re tightening mower blade screw

Checking mower blade

Checking mower belt

Checking gear box oil level

Greasing spindle shafts, belt tension pivot and tension pulley

Greasing front and rear antiscalp rollers

Greasing universal joint

Check points of initial hours

Changing gear box oil

Check point of every hours

Changing gear box oil

Check points of every year

Checking gear box oil seal

Check point of every years

Replacing gear box oil seal

Front loader

Check points of daily or each use

Checking transmission fluid level

Checking hydraulic hoses

Check points of every hours

Greasing loader

Check points of every hours

Checking torque of main frame bolt and nut

Backhoe

Check points of daily or each use

Checking transmission fluid level

Checking hydraulic hoses

Checking backhoe mounting pin

Check points of every hours

Greasing backhoe

Check points of every hours

Checking torque sub frame bolt and nut

TIRES, WHEELS, AND BALLAST

Tires

Inflation pressure of tires

Dual tires

Wheel tread

Front wheels

Rear wheels

Ballast

Front ballast

Rear ballast

IMPLEMENT LIMITATIONS

Implement limitation tables

SPECIAL TOOLS

Special tools for engine

Special use puller set

Diesel engine compression tester (for injection nozzle)

Nozzle tester

Injection pump pressure tester

Valve guide replacing tool

Bushing replacing tool

Flywheel stopper

Crankshaft bearing replacing tool

Special tools for tractor

Tierod end lifter

Independent PTO clutch spring compression tool

Disassembling and assembling stand (/)

Disassembling and assembling stand (/)

Check and high pressure relief valve assembly tool

ENGINE

MECHANISM

Engine body

Function of cylinder block

Function of closed breather

Function of halffloating head cover

Function of piston

Function of piston ring

Function of connecting rod

Function of crankshaft

Function of camshaft

Function of rocker arm

Function of flywheel

Function of timing gears

Lubricating system

Overview of lubricating system

Function of oil strainer

Function of oil pump

Function of oil filter

Function of relief valve

Function of oil pressure switch

Cooling system

Overview of cooling system

Function of water pump

Function of radiator

Function of radiator cap

Fuel system

Overview of fuel system

Function of fuel filter

Function of fuel feed pump

Function of injection nozzle

SERVICING

Troubleshooting for engine

Servicing specifications for engine

Tightening torques for engine

Checking and adjusting

Engine body

Checking compression pressure

Checking valve clearance

Lubricating system

Checking engine oil pressure

Cooling system

Checking fan belt tension

Checking fan belt damage and wear

Checking radiator cap air leakage

Checking radiator water leakage

Checking thermostat valve opening temperature

Fuel system

Checking injection timing

Checking fuel tightness of pump element

Checking fuel tightness of delivery valve

Checking nozzle spraying condition

Checking fuel injection pressure

Checking valve seat tightness

Checking nozzle holder

Disassembling and assembling

Separating engine

Draining engine oil

Removing battery

Removing bonnet

Disconnecting wiring harness and ground cables

Disconnecting fuel hoses

Disconnecting accelerator wire

Disconnecting propeller shaft assembly

Separating engine

Draining coolant and removing outer engine parts

Disassembling the engine

Cylinder head and valve

Gear case and timing gears

Piston and connecting rod

Flywheel and crankshaft

Servicing

Cylinder head and valve

Checking top clearance

Checking cylinder head surface flatness

Checking cylinder head flaw

Checking valve recessing

Checking clearance between valve stem and valve guide

Replacing valve guide

Checking valve seating

Correcting valve

Correcting valve seat

Lapping valve

Checking free length and tilt of valve spring

Checking valve spring setting load

Checking oil clearance between rocker arm and rocker arm shaft

Checking push rod alignment

Checking oil clearance between tappet and tappet guide bore

Timing gears, camshaft and governor gear

Checking timing gear backlash

Checking idle gear side clearance

Checking camshaft side clearance

Checking camshaft alignment

Checking cam height

Checking oil clearance of camshaft journal

Checking oil clearance between idle gear shaft and idle gear bushing

Replacing idle gear bushing

Piston and connecting rod

Checking piston pin bore ID

Checking oil clearance between piston pin and small end bushing

Replacing small end bushing

Checking connecting rod alignment

Checking piston ring gap

Checking clearance between piston ring and piston ring groove

Crankshaft

Checking crankshaft side clearance

Checking crankshaft alignment

Checking oil clearance between crankpin and crankpin bearing

Checking oil clearance between crankshaft journal and crankshaft bearing

Replacing crankshaft bearing

Checking oil clearance between crankshaft journal and crankshaft bearing and crankshaft bearing

Cylinder

Checking cylinder wear

Correcting cylinder (Oversize)

Oil pump

Checking rotor lobe clearance

Checking clearance between outer rotor and pump body

Checking clearance between rotor and cover

Relief valve spring

Checking relief valve

TRANSAXLE

MECHANISM

Structure of transaxle

Traveling system

Hydrostatic transmission

Structure of hydrostatic transmission

Oil flow of hydrostatic transmission

Structure of HST control linkage

Speed set linkage

Range gear shift section

Structure of range gear shift

Front wheel drive section

Structure of front wheel drive

Differential gear section

Structure of differential gears

Structure of differential lock

Brake section

Structure of brake system

PTO system

Structure of PTO system

Function of PTO clutch relief valve

Engaged function of PTO clutch

Disengaged function of PTO clutch

Structure of mid and rear PTO

Others

Hydraulic pump drive gear section

Structure of hydraulic pump drive gear

SERVICING

Troubleshooting for transaxle

Servicing specifications for transaxle

Tightening torques for transaxle

Checking and adjusting

Adjusting maximum speed

Adjusting HST neutral position

Checking and adjusting HST neutral spring (dynamic braking)

Checking charge relief pressure

Checking high relief pressure (Forward)

Checking high relief pressure (Reverse)

Readjusting relief valve (When HST does not work due to its loose hexagon socket head screw)

Checking PTO clutch operating pressure

Adjusting brake pedal free travel

Disassembling and assembling

Separating transaxle

Draining transmission fluid

Removing battery

Removing lift rod and lower link

Removing ROPS

Removing seat

Removing step

Removing fender

Removing fuel tank

Removing rear wheel

Removing fender center stay

Removing fender bracket and hitch plate

Removing transaxle assembly

Removing brake pedal

Removing propeller shaft

Removing differential lock pedal

Removing speed control pedal, HST damper, and cruise rod

Hydrostatic transmission

Removing levers and mower lift arm

Removing PTO clutch valve

Removing oil cooler cover

Removing center section and valve plates

Removing check and high pressure relief valve plug

Checking check and high pressure relief valve

Removing cylinder block

Removing cylinder block and piston

Removing swashplate and trust roller bearing

Removing WD detent ball

Removing neutral arm and trunnion arm

Hydraulic cylinder

Removing hydraulic cylinder

Transaxle shafts

Removing transaxle case front cover

Removing hydraulic pump assembly

Removing rear PTO cover assembly

Disassembling rear axle (LH)

Removing rear axle case (RH)

Removing T final gear

Removing rear axle case, RH and brake

Removing PTO clutch assembly

Assembling shafts

Assembling select arms and HST pump shaft (PTO clutch shaft)

Assembling front wheel drive shaft, shifter, spiral bevel pinion shaft and midPTO shaft

Servicing

Hydrostatic transmission

Checking center section

Checking charge relief valve

Checking check and high pressure relief valve

Checking cylinder block assembly

Checking thrust washer, thrust roller bearing, thrust plate and cradle bearing

Checking pump shaft (PTO clutch shaft)

Checking needle bearing

Transaxle case

Checking bearing

Checking PTO clutch disc wear

Checking separate plate and back plate wear

Checking flatness of clutch piston, pressure plate and steel plate

Checking clutch spring free length

Checking PTO brake disc wear

Checking PTO brake plate

Checking clearance between differential case and differential side gear

Checking clearance between differential pinion shaft and differential pinion

Checking backlash between differential pinion and differential side gear

Checking backlash between spiral bevel pinion gear and bevel gear

Checking brake cam lever movement

Checking flatness of actuator and bearing holder

Checking height of cam plate and ball

Checking brake disc and friction plate wear

FRONT AXLE

MECHANISM

Structure of front axle

Front wheel alignment

Camber of front axle

Kingpin angle of front axle

Caster of front axle

Toein of front axle

SERVICING

Troubleshooting for front axle

Servicing specifications for front axle

Tightening torques for front axle

Checking and adjusting

Adjusting toein

Adjusting front axle rocking force

Adjusting front wheel steering angle

Disassembling and assembling

Separating front axle assembly

Draining front axle case oil

Removing battery

Removing bonnet

Removing front wheel and propeller shaft cover

Disconnecting propeller shaft

Removing front axle assembly

Front axle assembly

Removing power steering cylinder

Removing bevel gear case and front gear case

Removing front gear case cover

Removing T bevel gear and front axle shaft

Removing front gear case and bevel gear case

Removing bevel pinion shaft and differential gear assembly

Removing differential gear

Servicing

Checking clearance between differential case and differential side gear

Checking clearance between differential pinion shaft and differential pinion

Checking backlash between differential pinion and differential side gear

Checking turning torque of bevel pinion shaft

Checking backlash between bevel pinion shaft and bevel gear

Checking backlash between T bevel gear and T bevel gear

Checking clearance between center pin and pin support bushing

STEERING

MECHANISM

Structure of steering system

Hydraulic circuit of steering

Steering controller

Structure of steering controller

Control valve

Metering device

Relief valve

Steering cylinder

Structure of steering cylinder

SERVICING

Troubleshooting for steering

Servicing specifications for steering

Tightening torques for steering

Checking and adjusting

Checking relief valve operating pressure

Disassembling and assembling

Power steering cylinder

Removing adapter and tierod

Disassembling steering cylinder

Separating power steering controller

Removing battery

Removing steering wheel

Removing upper panel

Removing steering controller

Separating power steering cylinder

Removing bonnet

Removing front axle assembly

Removing power steering cylinder

Servicing

Checking steering cylinder ID

Checking clearance between rod and guide

HYDRAULIC SYSTEM

MECHANISM

Structure of hydraulic system

Hydraulic circuit

Hydraulic pump

Outline of hydraulic pump

Structure of hydraulic pump

Specification of hydraulic pump

Control valve

Outline of control valve

Function of control valve

Control valve in neutral position

Control valve in lift position

Control valve in down position

Flow priority valve

Outline of flow priority valve

Structure of flow priority valve

Specification of flow priority valve

Relief valve

Outline of relief valve

Structure of relief valve

Function of relief valve

Specification of relief valve

Hydraulic cylinder

Structure of hydraulic cylinder

Hydraulic block type outlet

Structure of hydraulic block type outlet

Mower linkage

Structure of mower linkage

Front loader valve

Structure

Structure of front loader valve and pipe

Structure of front loader control valve

Front loader hydraulic circuit

Function of loader control valve

Loader control lever in neutral position

Loader control lever in up position

Loader control lever in down position

Loader control lever in floating position

Loader control lever in rollback position

Loader control lever in dump position

SERVICING

Troubleshooting for hydraulic system

Servicing specifications for hydraulic system

Tightening torques for hydraulic system

Checking and adjusting

Relief valve

Checking relief valve setting pressure

Pump and priority valve

Checking hydraulic pump oil flow

Checking power steering oil flow

Mower lift linkage

Adjusting mower lift linkage

Disassembling and assembling

Hydraulic pump

Removing battery

Removing lift rod and lower link

Removing ROPS

Removing seat

Removing step

Removing fender

Removing fuel tank

Removing fender center stay

Removing hydraulic pump

Hydraulic cylinder block

Removing battery

Removing lift rod and lower link

Removing ROPS

Removing step

Removing fender

Removing fuel tank

Removing fender center stay

Removing mower linkage and wire harness

Removing hydraulic cylinder block

Hydraulic cylinder and control valve

Removing control valve

Removing control valve lever

Removing lift arm, hydraulic arm shaft and hydraulic arm

Removing hydraulic piston

Removing lowering speed adjusting valve

Mower lift linkage

Disassembling mower linkage

Control valve (Front loader)

Removing battery

Removing ROPS

Removing seat

Removing step

Removing fender

Removing control valve

Disassembling control valve

Servicing

Hydraulic pump

Checking clearance between tip of gear tooth and casing

Checking clearance between bushing and shaft

Checking side plate thickness

Hydraulic cylinder

Checking hydraulic cylinder bore

Checking hydraulic arm shaft bushing

ELECTRICAL SYSTEM

MECHANISM

Wiring diagram of BX tractor

Electrical connector chart

Reading electrical circuit diagrams

How to read wiring diagram

Layout of connector diagrams

Precautions on handling electrical connectors

Starting system

Electrical circuit of starting system

Function of relay

Function of starter

Function of glow plug

Function of safety switch

Function of fuel pump

OPC (Operator Presence Control) system

Electrical circuit of OPC timer

Charging system

Electrical circuit for charging system

Function of IC regulator (P connector type)

Lighting system

Electrical circuit for lighting system

Gauges

Electrical circuit of gauge system

Meter panel

Function of hour meter

Function of tachometer

Function of fuel gauge

Function of coolant temperature gauge

Function of fuel level sensor

Function of coolant temperature sensor

Function of oil pressure switch

Others

Electrical circuit for accessory

Function of DC outlet

SERVICING

Troubleshooting for electrical system

Servicing specifications for electrical system

Tightening torques for electrical system

Checking and adjusting

Battery

Checking battery voltage

Checking battery terminal connection

Checking battery specific gravity

Main switch

Checking main switch connector voltage

Checking main switch continuity at off position

Checking main switch continuity at on position

Checking main switch continuity at preheat position

Checking main switch continuity at start position

Starter

Checking motor

Testing starter magnet switch (pullin, holding coils)

Glow plug

Checking glow plug lead terminal voltage

Checking glow plug continuity

Safety switch

Checking PTO shift lever switch continuity

Checking HST neutral switch continuity

Operator presence control (OPC) system

Checking seat switch and seat turnover switch continuity

Checking OPC timer

Fuel pump

Checking fuel pump connector voltage

Checking fuel pump continuity

Engine stop solenoid

Testing engine stop solenoid

Timer relay

Checking timer relay connector voltage

Testing timer relay

Charging system

Checking battery charging current

Combination switch

Removing combination switch

Checking combination switch connector voltage

Checking head light switch continuity when setting switch at OFF position

Checking head light switch continuity when setting switch at ON position

Checking turn signal light switch continuity when setting switch knob at OFF position

Checking turn signal light switch continuity when setting switch knob at RIGHT position

Checking turn signal light switch continuity when setting switch knob at LEFT position

Checking hazard switch continuity when setting switch knob at OFF position

Checking hazard switch continuity when setting switch knob at ON position

Checking flasher unit connector voltage

Testing flasher unit actuation

Gauge

Checking charge lamp (charging circuit)

Checking engine oil pressure lamp

Checking engine oil pressure switch continuity

Checking fuel level sensor continuity

Checking coolant temperature sensor connector voltage

Checking coolant temperature sensor continuity

Checking hour meter and tachometer

Accessory

Checking DC outlet connector voltage

Checking DC outlet continuity

Meter panel

Checking connector voltage, sensor resistance and switch

Disassembling and assembling

Starter

Disassembling starter motor

Removing magnet switch

Removing plunger

Alternator

Removing pulley

Removing rear end cover

Removing brush holder

Removing IC regulator

Removing rectifier

Removing rear end frame

Removing rotor

Removing retainer plate

Removing bearing on drive end side

Removing bearing at slip ring side

Servicing

Starter

Checking overrunning clutch

Checking commutator and mica

Checking brush wear

Checking brush holder

Checking armature coil

Checking field coil

Alternator

Checking bearing

Checking stator

Checking rotor

Checking slip ring

Checking brush wear

Checking rectifier

MOWER

MECHANISM

Structure of power transmission of mower

Structure of lifting mechanism of mower

SERVICING

Troubleshooting for mower

Servicing specifications for mower

Tightening torques for mower

Setting up mower [RCKDBX and RCKDBX]

Assembling mower

Setting mower

Mounting front link

Mounting frame link

Setting tractor

Mounting mower

Checking and adjusting

Mower adjustment

Adjusting mower link

Adjusting front and rear cutting height

Adjusting left and right cutting height

Adjusting cutting height

Checking mower blade and belt

Checking mower blade

Checking mower belt

Disassembling and assembling

Removing ramps and belt covers

Removing mower blades

Removing blade boss

Removing gear box and mower belt

Disassembling gear box

Removing center pulley holder

Removing outer pulley and blade shaft

Servicing

Adjusting turning torque of pinion shaft

Adjusting backlash between bevel gears

FRONT LOADER

MECHANISM

Hydraulic circuit

Front remote hydraulic control system (if equipped)

Operating control lever

Boom cylinder and bucket cylinder

Structure of boom cylinder and bucket cylinder

One touch front loader

Outline of one touch front loader

One lever quick touch lines coupler

Structure of one lever quick touch lines coupler

Auto lock attachment and detachment

Outline of auto lock attachment and detachment

Function of auto lock attachment and detachment

Mechanical loader frame standing mechanism

Structure of mechanical loader frame standing mechanism

rd function valve (If equipped)

Structure of rd function valve

Function of rd function valve

Activation switch in off position

Activation switch in on position

SERVICING

Troubleshooting for front loader

Tightening torques for front loader

Checking and adjusting

Loader stand

Adjusting height of loader stand

Front hydraulic valve main switch and relay

Checking front hydraulic valve main switch continuity

Checking connector voltage of front hydraulic valve main switch

Checking relay

rd function solenoid valve

Checking rd function solenoid valve continuity

Checking connector voltage of rd function solenoid valve

Disassembling and assembling

Removing loader

Reinstalling loader

Bucket, boom and hydraulic cylinders

Attaching attachments

Removing attachments

Removing bucket cylinder

Removing boom cylinder and hydraulic tubes

Removing piston rod assembly

Removing cylinder head, piston and nut

Removing piston seal and Oring

Installing Oring and piston seal

Side frames, front guard and main frames

Removing side frames

Removing front guard

Removing main frames

rd function valve (If equipped)

Removing rd function valve

Removing hydraulic tubes of rd function

Servicing

Piston rod

Checking piston rod bend

BACKHOE

MECHANISM

Hydraulic circuit

Control valve

Structure of backhoe control valve

Function of backhoe control valve

Backhoe control valve in neutral position

Backhoe control valve in swing right position

Backhoe control valve in swing left position

Backhoe control valve in boom up position

Backhoe control valve in boom down position

Backhoe control valve in LH stabilizer shrink position

Backhoe control valve in LH stabilizer extend position

Backhoe control valve in RH stabilizer shrink position

Backhoe control valve in RH stabilizer extend position

Backhoe control valve in dipperstick crowd position

Backhoe control valve in dipperstick extend position

Backhoe control valve in bucket rollback position

Backhoe control valve in bucket dump position

Structure of overload relief valve

Function of relief position

Function of anticavitation position

Structure of hydraulic cylinder

SERVICING

Troubleshooting for backhoe

Servicing specifications for backhoe

Tightening torques for backhoe

Checking and adjusting

Checking relief valve setting pressure

Checking control lever operation force

Checking stabilizer control lever operation force

Disassembling and assembling

Removing backhoe

Preparing to remove backhoe

Releasing mounting pins

Disconnecting hydraulic hoses

Removing backhoe

Installing backhoe

Preparing to install backhoe

Connecting hydraulic hoses

Setting mounting pins

Installing backhoe

Disassembling backhoe

Removing bucket

Removing dipperstick and bucket cylinder

Removing dipperstick cylinder, boom, boom cylinder, and hoses

Removing swing frame

Removing swing cylinder

Removing stabilizers and stabilizer cylinder

Removing lever support and control valve

Removing backhoe main frame

Disassembling control valve

Disassembling cylinder (Boom, dipperstick, bucket, swing, stabilizer)

Removing cylinder rod assembly

Removing cylinder head, piston, and nut

Checking cylinder adaptor angle

Removing piston seal and Oring

Installing Oring and piston seal

Servicing

Checking clearance between pin and bushing

Checking thrust washer wear

Checking piston rod bend

After Purchase A link will be sent to your eBay message to Download.

Note: PDF File not printed Material