Length tolerance +/-2mm

- TOP quality at fair prices

- High-quality products made to measure and cut to size

- Competent advice & service

Technical data:

| Brand: | Evek |

| Manufacturer number: | Not applicable |

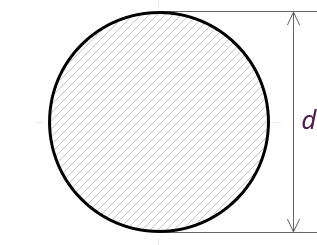

| Type: | rod, round rod |

| Material: | titanium |

| Operation area: | industrial area; Medical technology (surgical implants); Ultrasound technology (sonotrodes and various components); Marine; Engine technology (various components); Outdoor and sports (bicycles, racing vehicles, mountaineering equipment, etc.); Watch and jewelry industry |

| Standard classifications: | |

| Material number: | 3.7165 |

| US: | R56400 |

| EN: | Titanium grade 5 |

| ASTM: | B348 |

| Additional Information: | |

| Density: | 4.43 g/cm³ |

| Melting point: | 1650°C |

| Tensile strenght: | min. 895MPa |

| Stretch limit: | min. 828MPa |

| Strain: | min. 10% |

| Hernia constriction: | min. 25% |

| Thermal conductivity: | 7.1 W/m K |

| Electr. Resistance: | 1.71 Ω mm²/m |

| Surface: | smooth (may contain handling or storage marks) |

Description:

Titanium Grade 5 is the most commonly used titanium alloy. It consists of approx. 88.74 - 91.0% titanium, approximately 5.5 - 6.75% aluminum, approximately 3.5 - 4.5% vanadium and approx. 0.015% hydrogen together. The material has a material number 3.7165. In contrast to pure titanium, titanium 3.7165 can be hardened (up to thicknesses of 25 mm). The alloy has good hot formability and weldability. It is very resistant to various corrosive media as well as to sea and Sea water. The material 3.7165 is also characterized by high strength and good toughness with a low density. The quality also has very high resistance to crack initiation and crack propagation.

Titanium 3.7165 is normally used in industrial areas. Another industry where the material 3.7165 is widely used is medical technology (surgical implants). 3.7165 is also in high demand in the following areas:

- Ultrasound technology (sonotrodes and various components);

- Marine;

- Engine technology (various components);

- Outdoor and sports (bicycles, racing vehicles, mountaineering equipment, etc.);

- Watch and jewelry industry.

Titan 3.7165 is characterized by the following features:

- good hot formability and weldability;

- hardenable up to thicknesses of 25 mm;

- insensitive to sea or sea water;

- not susceptible to various corrosive media;

- high strength and good toughness;

- resistant to crack initiation and crack propagation.