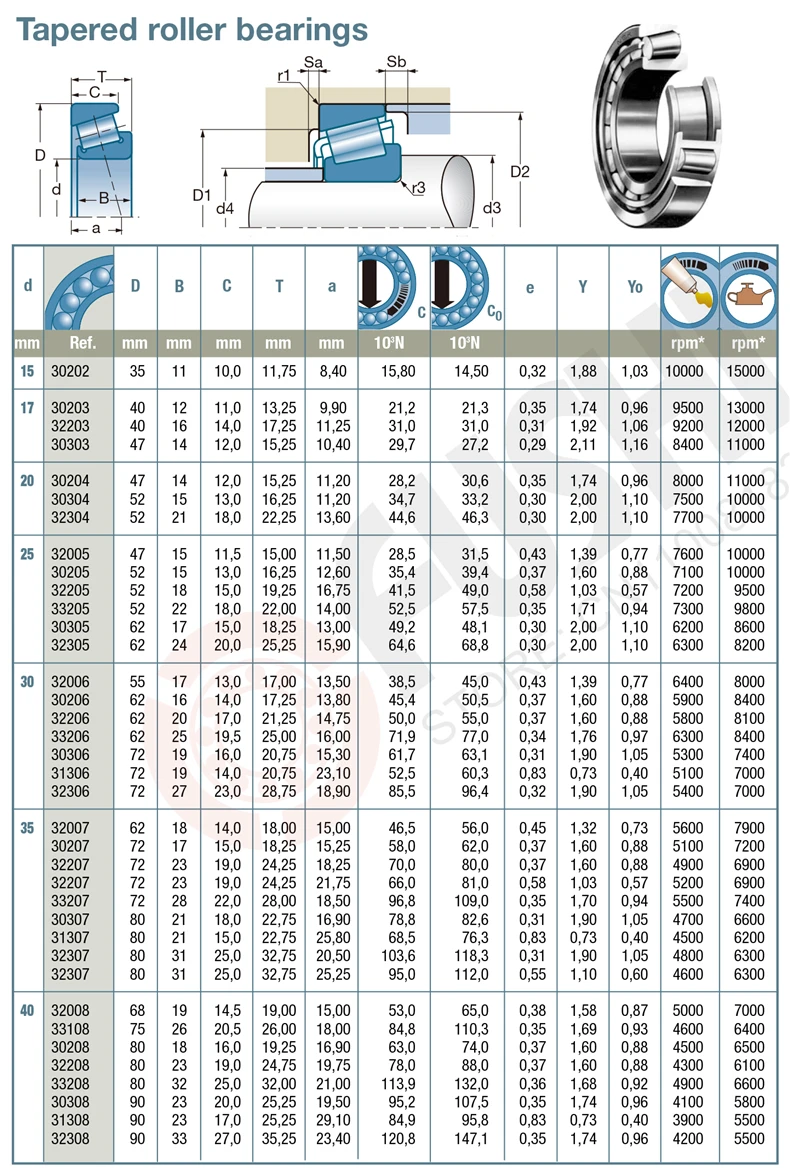

1.STRUCTURE OF TAPERED ROLLER BEARINGS

Tapered roller bearings consist of outer ring, inner ring,rollers and a cage. This bearing contains tapered rollers for its rolling element which are guided by the inner ring backface rib on the roller large end face.The raceway surfaces of inner ring and outer ring and the rolling contact surface of rollers are designed so that the respective apexes converge at a point on the bearing center line.Bearings are classified into standard, intermediate and steep types, in accordance with their contact angle (α).The larger the contact angle is, the greater the bearing resistance to axial load.

2.TAPERED ROLLER BEARING ADVANTAGES

Long Life Even In Contaminated Lubricant Durable Steel CageDimensionally Interchangeable With Other Bearing Manufacturers Typical Applications for Tapered Roller Bearings Tapered roller bearings are used for heavy-duty, moderate speed applications.

3.BEARING DESIGNATION & DIMENSIONS

Item: 38YM1/48Y1 Type: Taper Roller Bearing Steering bearings for motorcycle Lubrication: Need Grease Size: 30 x 48 x 12 mm Inner diameter: 30 mm Outer diameter: 48 mm Width: 12 mm

4.WHEN DO I NEED TO CHANGE BEARINGS

Wear comes from one of three things. - Good honest usage. - Long hours of riding in the bed of a truck or trailer. - Abuse and lack of maintenance.

I've seen worn steering bearings that tended to keep the steering in one place. You could turn the handlebars to the right or left OK, but with the handlebars straight forward there is a definite "Groove" that the steering sort of "Falls" into. I've seen this on high mileage street bikes with roller bearings. I've also seen it on dirt bikes with ball bearings which have spent many hours riding in the back of pickup trucks. To get rid of this the bearing must be replaced.

If rust or dirt has gotten into the bearings they should be replaced. Sometimes you can clean the rust or dirt out, regrease the bearing and everything will work OK. You will have to decide on a case by case basis. If possible, it is best to replace the bearings.

5.TAPERED ROLLER BEARINGS APPLICATION

Typical applications that will benefit from these durable bearings include: Agriculture, Construction and Mining Equipment Various Axle Systems Conveyance Vehicles Gear Box, Engine Motors, Reducers

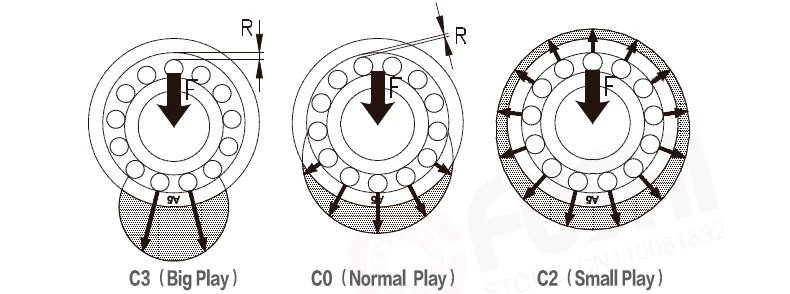

1. WHY DO THE BEARINGS I RECEIVED HAVE SHAKING?

The clearance of the bearing is related to the play. The default is the standard C0 clearance, which is usually 3-18um. The corresponding principle is shown in the figure below. If you don't need to shake, please choose C2 small clearance bearing. If you have any questions, please contact us before purchasing.

2. DO I STILL NEED TO ADD GREASE TO THE BEARINGS?

Yes, this is the taper roller steering bearing, When assembling, you need to apply grease, Grease has the effect of rust protection and lubrication. If you have special using requirements, please operate under the guidance of a professional.

3.WHAT IS THE ACCURACY OF ABEC-1?

ABEC is the American ANSI standard. The corresponding German DIN standard and international ISO standard are as follows:

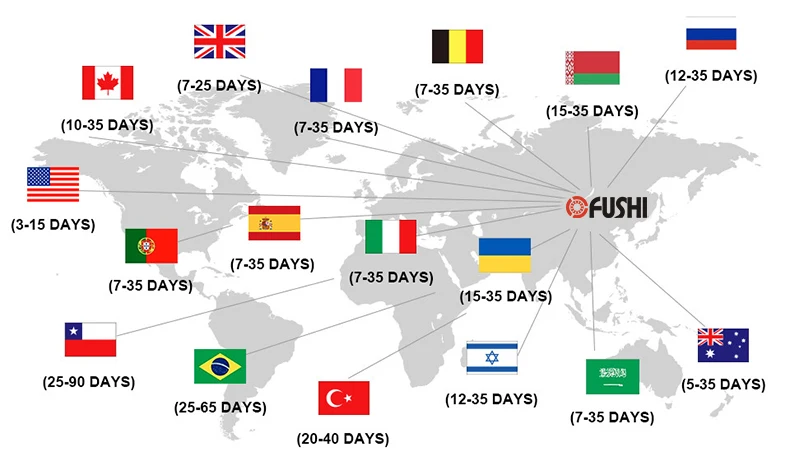

4.DO YOU PROVIDE LOGISTICS TRACKING INFORMATION?

Yes, all our products provide full logistics tracking. And the products you buy are all new. We will buy transportation insurance for you. If the product is damaged or lost during transportation, you can get paid.

On Nov-18-19 at 05:16:13 PST, seller added the following information: