【DE】4 Axis DDCS Expert Offline Stand Alone Motion CNC Controller PLC 1000Khz 24V for CNC Router Engraving Milling Machine

We will Ship from Germany warehouse to Below Europe Countries | ||||||

| Austria | Belgium | Bulgaria | Czech Republic | Croatia | Denmark | Estonia |

| Finland | France | Germany | Greece | Hungary | Ireland | Italy |

| Latvia | Lithuania | Luxembourg | Netherlands | Poland | Portugal | Romania |

| Slovakia | Slovenia | Spain | Sweden | UK | Malta | |

Package include:

- 1 x 4 Axis offline Motion Controller System DDCS EXPERT

- 1 x 4G USB Flash

- 1 x Cable

- English user manual

Descriptions:

4 Axis PLC Controller off-line (DDCS expert)

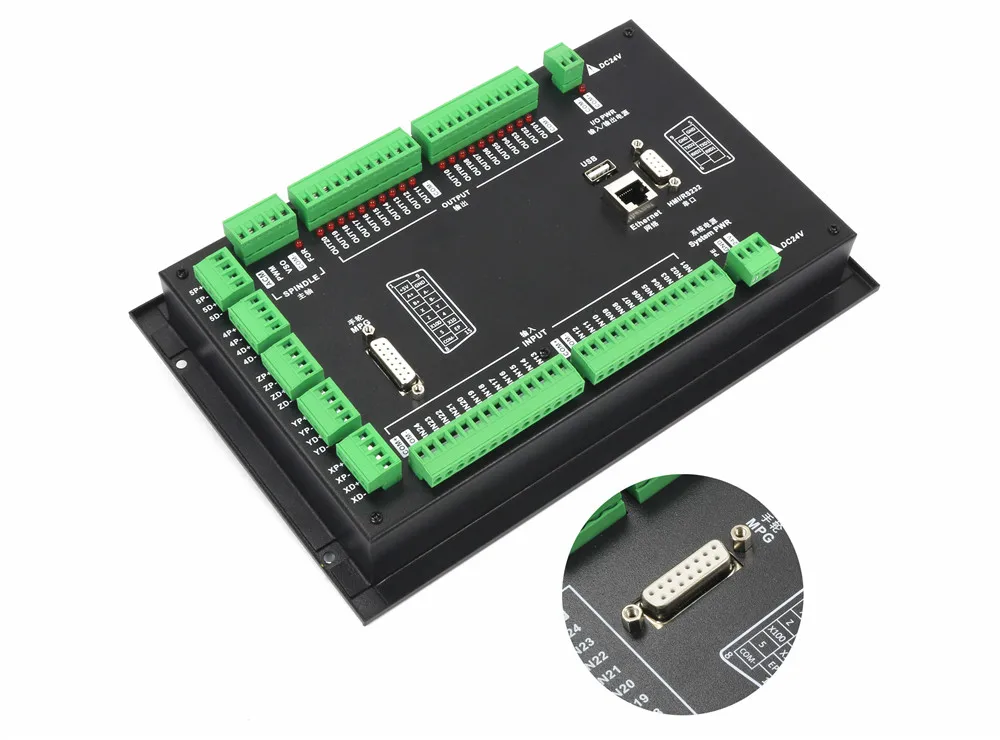

- Digital Dream is a numerical control company specializing in the research, developmentand production of various CNC (Computer Numerical Control) systems since 2008. Digital Dreamaims to combine high quality and high reliability with affffordability.The DDCS Expert is a 3~5 axes motion controller for open or close stepper and servo systemswith 7/10.2 full color display screen. The highest output pulse per axis is 1MHz. The users canself-defifine the functional keys. This controller supports multiple spindle mode, support straightTool Magazine, gantry type Magazine, disk type magazine. The Operation system interface eventhough very comprehensive, can be learned in very short time.The DDCS Expert numerical control system adopts the ARM+FPGA design framework. ARMcontrols the human-computer interface and code analysis and the FPGA provides the underlyingalgorithms and creates the control pulse. This guarantees reliable control and easy operation.The internal operating system is Linux based.The DDCS Expert can be used for many styles and types of CNC machines. Lathes, Routers,Pick&Place and Mills, lathe and cutters are just a few examples. The DDCS Expert operates as aStand Alone system without the need of a computer. This guarantees high precision, accuracyand reliability.

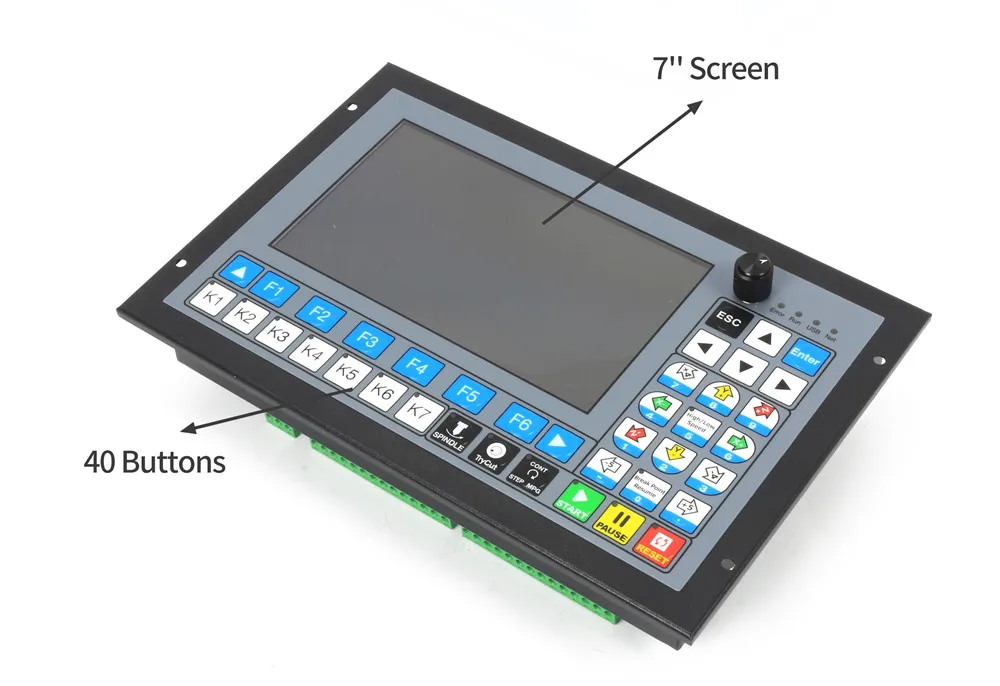

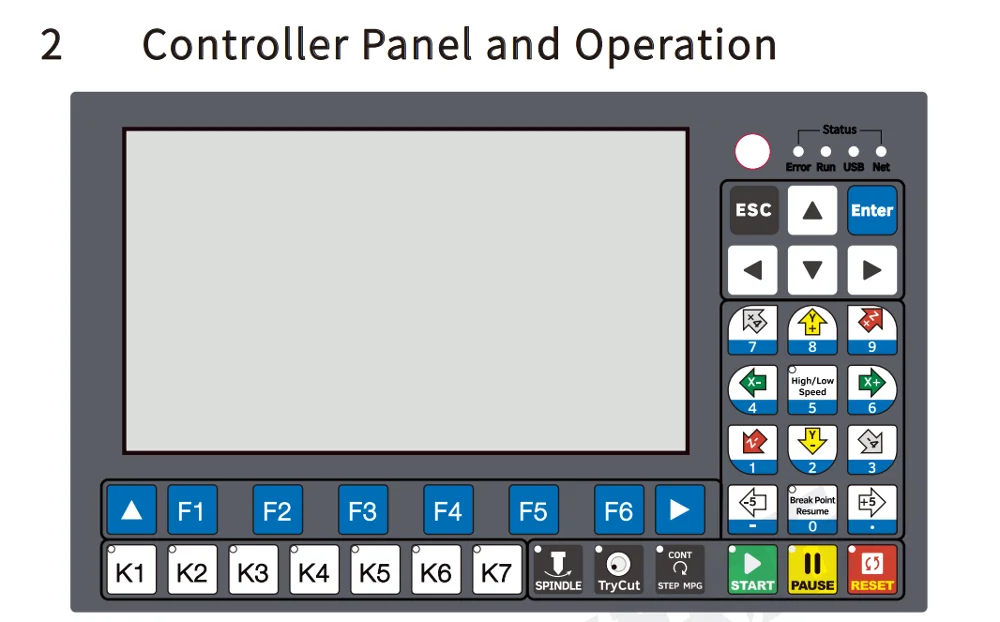

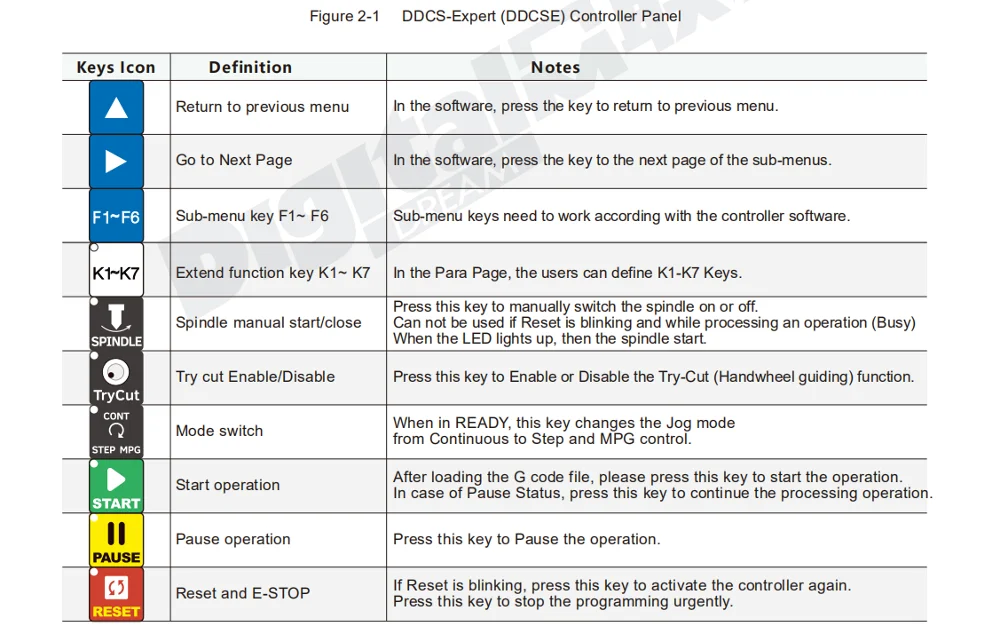

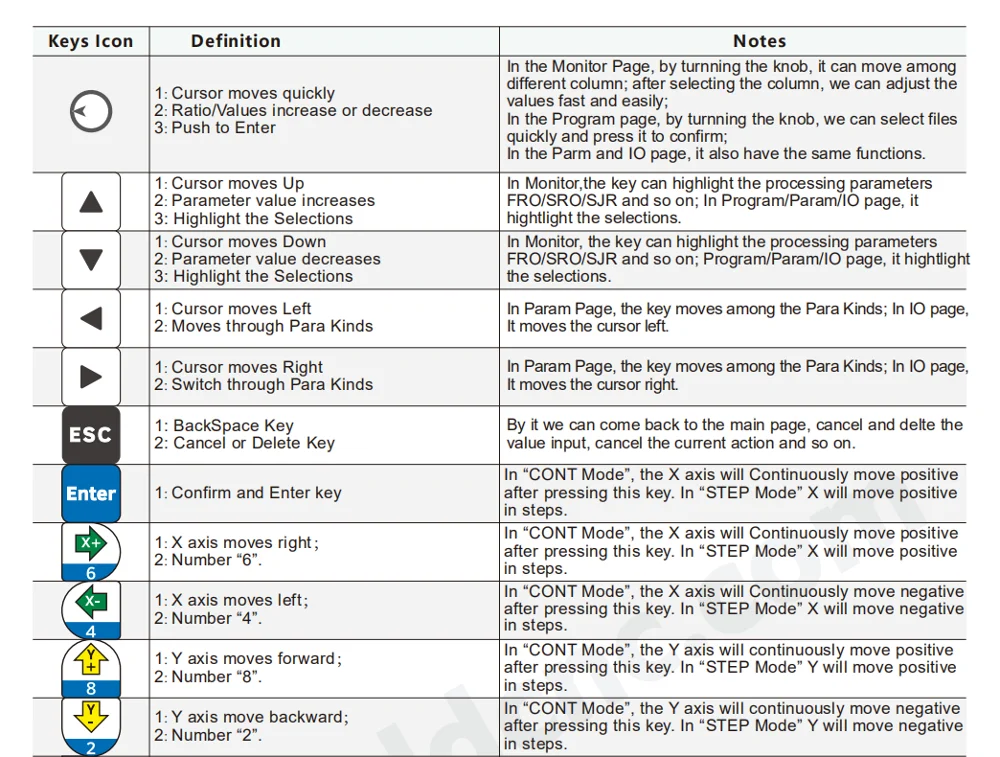

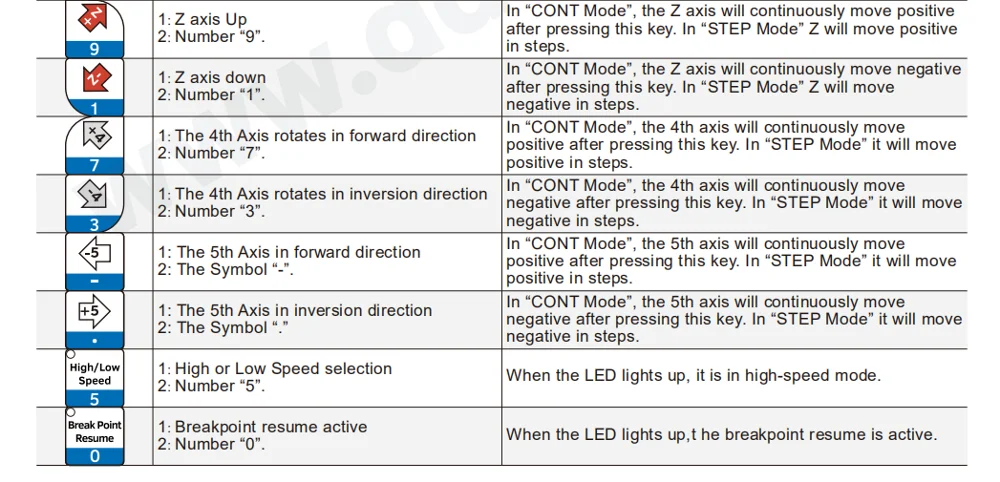

♞【Product】Model Number:DDCS EXPERT ; 1M Hz output frequency for each axis; 7 inch full color display screen; resolution ratio: 1024*600, 40 operation keys - ♞【Introduction】The DDCS Expert numerical control system adopts the ARM+FPGA design framework. ARM controls the human-computer interface and code analysis and the FPGA provides the underlying algorithms and creates the control pulse. This guarantees reliable control and easy operation.The internal operating system is Linux based.

- ♞【Compatible G Code】Compatible with standard G-code,support popular CAD/CAM software, such as ArtCam, MasterCam, ProE, JDSoft SurfMill, Aspire, Fusion 360 and so on;

- ♞【Power Supply】The Power Supply for the controller is 24VDC, minimum Current is 0.5A

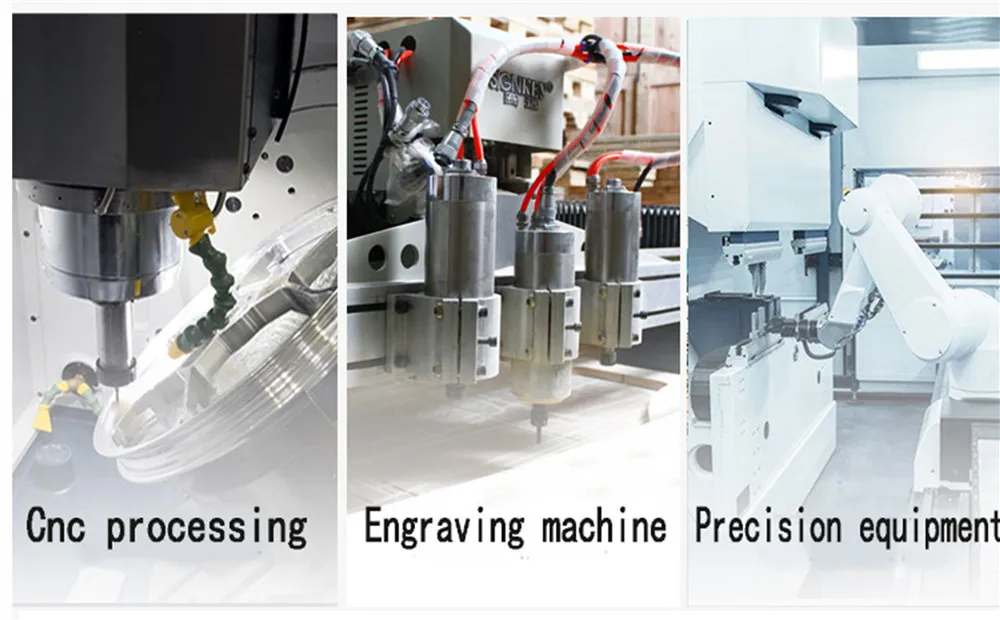

- ♞【Applications】The DDCS Expert can be used for many styles and types of CNC machines. Lathes, CNC Routers,Pick&Place and Milling Machine, lathe and cutters are just a few examples.

Shipping:

All items will be sent out with tracking within 1-2 business day after the payment received,may be a delay on weekends;

Return&Refund:

1.Any reason required for all refund.Item must be in it's original condition and no physical damage,buyer responsible for all shipping cost.

2.When you have the parcel,and not satisfied the goods or it is other problem like as broken,pls tell us the detail reason and provide the photos,we will help you to solve any problems.