We will Ship from Germany warehouse to Below Europe Countries | ||||||

| Austria | Belgium | Bulgaria | Czech Republic | Croatia | Denmark | Estonia |

| Finland | France | Germany | Greece | Hungary | Ireland | Italy |

| Latvia | Lithuania | Luxembourg | Netherlands | Poland | Portugal | Romania |

| Slovakia | Slovenia | Spain | Sweden | UK | Malta | |

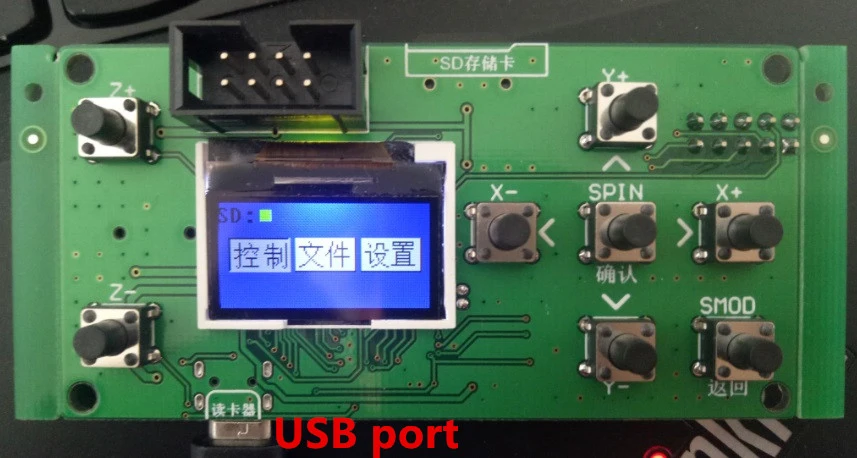

GRBL controller Function:

SD shows it is SD card condition, turn on power supply after insert SD card, otherwise, it won't work. SD card capacity 4G could be recognized.

Press X- or X+ button to switch

Control:Press confirmation button to access manually controlling page

File:Press confirmation button to access file page

Set:Press confirmation button to access setting page

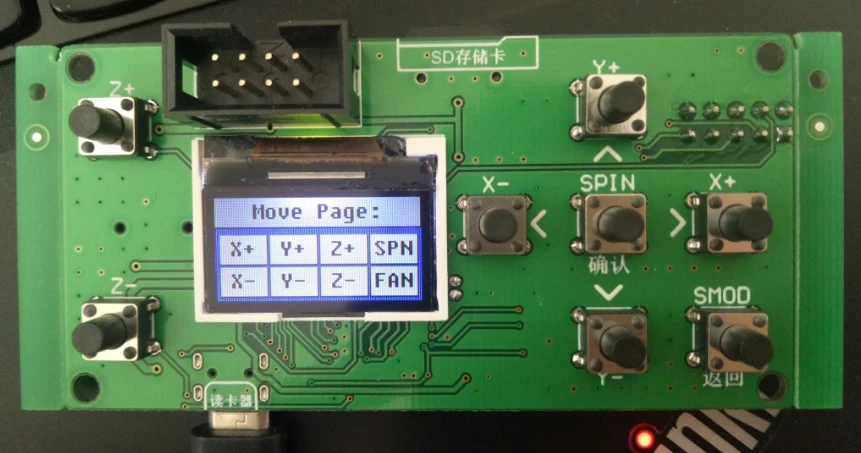

On the off-line controller, buttons control corresponding actions.

SPN is spindle controlling,should press SPIN.

Fan is fan controlling, should press SMOD.

Note: To exit this page, should press back button longly. after exit, save the current location as engraving starting point X0Y0Z0

Note: system can recognize max 100 available files one time (***.TXT***.txt***. NC***.nc***.CNC

***.cnc***.TAP***.tap could be recognized),not support files with long name.

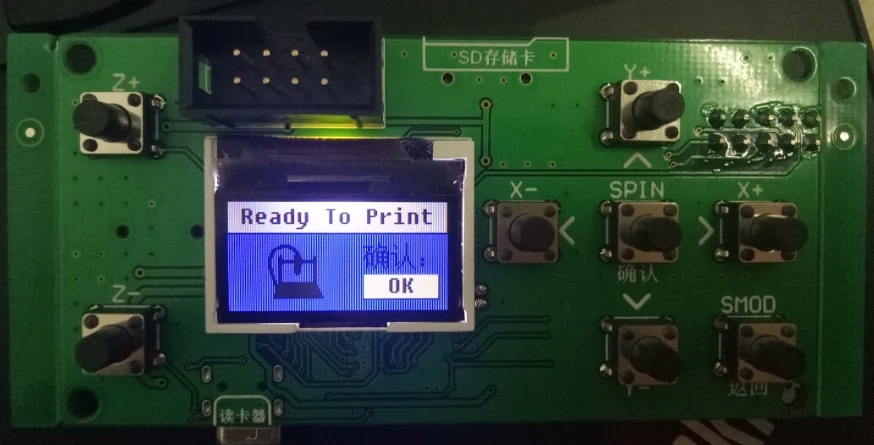

Press Y+ or Y- to choose files need to be engraved, press confirmation button to access engraving page.

Press ok to start engraving

If you want to stop during engraving, press back button longly, then back to the file selection page(machine will not stop at once, as GRBL controller has already saved a part of G code, will stop after carry out completely).

The left words show the machine moving distances every time you press the button on the condition of manually controlling, press Y+ or Y- to choose, default 1mm each time.

Press X- or X+ for switchover setting.

The right words show Communication baud rate setting, default 9600

After setting, press confirmation button to save, then press back button to exit setting page.

Note: the setting parameters can not be saved on the condition of electricity outage, it will be default value when turn on next time.

Problem&Feedback

Please give us the opportunity to resolve any problem when you have, we concern your problem and we will try our best to resolve it.

We are a new member in ebay now, and need understand both of sides

Pls email us before you want to leave any negative feedback

Refund

When you have the parcel, and not satisfied the goods or it is other problem like as broken,pls tell us the detail reason and provide the photos

Any reason required for all refund. Item must be in it's original condition and no physical damage. Buyer responsible for all shipping cost

Contact us

Welcome worldwide customer inquire and questions, we will try to do our best to feedback customer’s email within 1-2 business days,if not pls check the mail box again

Customer’s satisfaction is very important to us.

Problem&Feedback

Please give us the opportunity to resolve any problem when you have, we concern your problem and we will try our best to resolve it.

We are a new member in ebay now, and need understand both of sides

Pls email us before you want to leave any negative feedback

Refund

When you have the parcel, and not satisfied the goods or it is other problem like as broken,pls tell us the detail reason and provide the photos

Any reason required for all refund. Item must be in it's original condition and no physical damage. Buyer responsible for all shipping cost

Contact us

Welcome worldwide customer inquire and questions, we will try to do our best to feedback customer’s email within 1-2 business days,if not pls check the mail box again

Customer’s satisfaction is very important to us.