Parcel include:- 1x 3 Axis/4 Axis/6 Axis Ethernet CNC Motion Control Card (CM300/CM400/CM600)

- 1x connection cable

- User manual and software

Product description:

- 【CM300 Introduction】CM300 motion control card, support 3-axis linkage interpolation, support one machine multi-card mode, users can use the extended G code to realize multi-card cooperative control. It is widely used in engraving machine, mold machine, machining center, precision engraving machine, automated assembly line equipment and other due fields.

- 【CM300 Specifications】System architecture: high performance processor + FPGA. Number of linked axes: 3 axis, maximum 1MHz pulse frequency. System power supply: 24V DC. Drive mode: pulse + direction, double pulse. IO: 12 inputs, 8 outputs. Spindle interface: 1 analog 0-10V, multisection speed, pulse. Handwheel interface: 5V, AB phase, 3 aixs selection, 3 speed multiplier, 1 emergency stop input. Network interface: 100Mbps EtherNet*1.

- 【CM400 Introduction】CM400 motion control card, support 4-axis linkage interpolation, support one machine multi-card mode, users can use the extended G code to realize multi-card cooperative control. It is widely used in engraving machine, mold machine, machining center, precision engraving machine, automated assembly line equipment and other due fields.

- 【CM400 Specifications】System architecture: high performance processor + FPGA. Number of linked axes: 4 axis, maximum 1MHz pulse frequency. System power supply: 24V DC. Drive mode: pulse + direction, double pulse. IO: 12 inputs, 8 outputs. Spindle interface: 1 analog 0-10V, multisection speed, pulse. Handwheel interface: 5V, AB phase, 4 axis selection, 3 speed multiplier, 1 emergency stop input. Network interface: 100Mbps EtherNet*1.

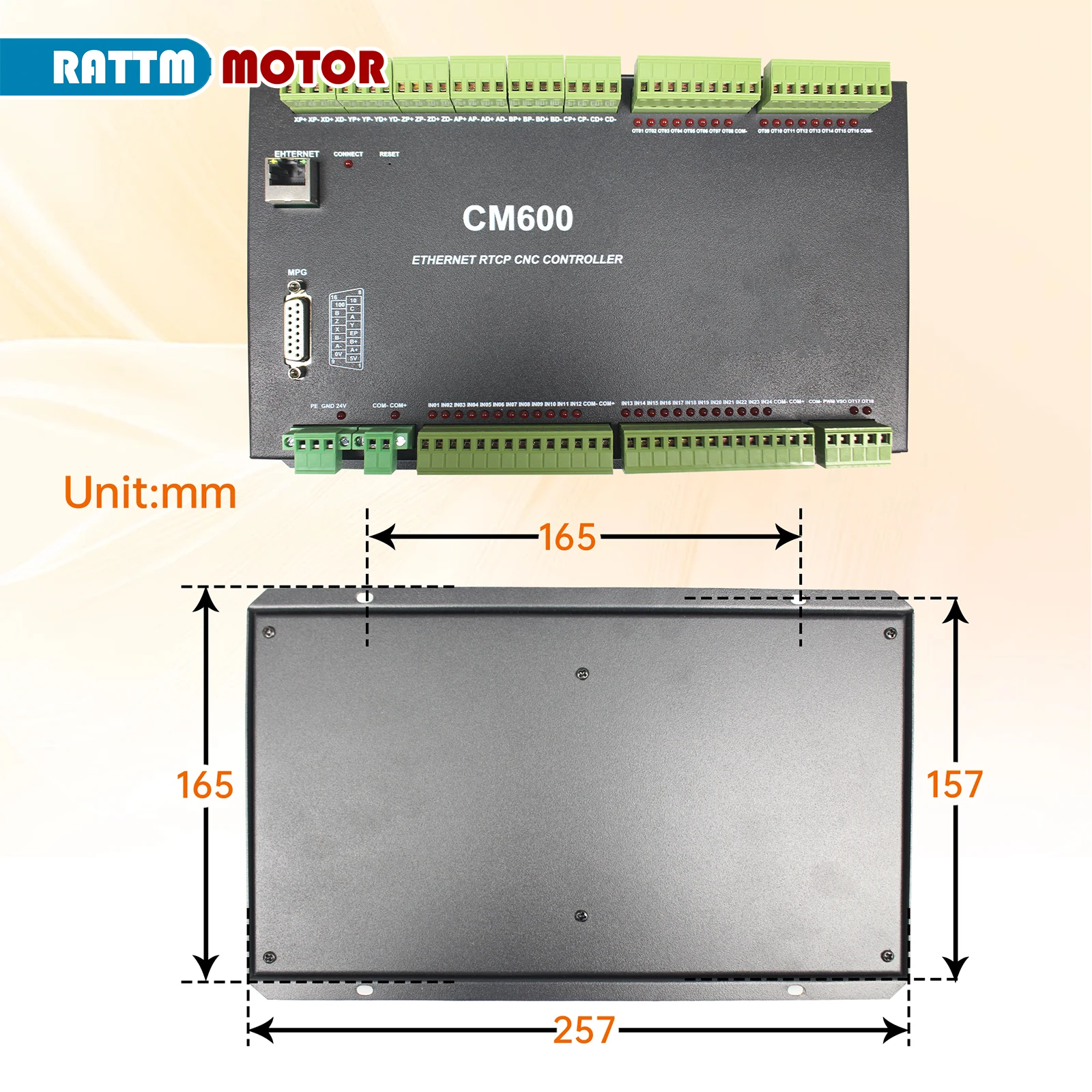

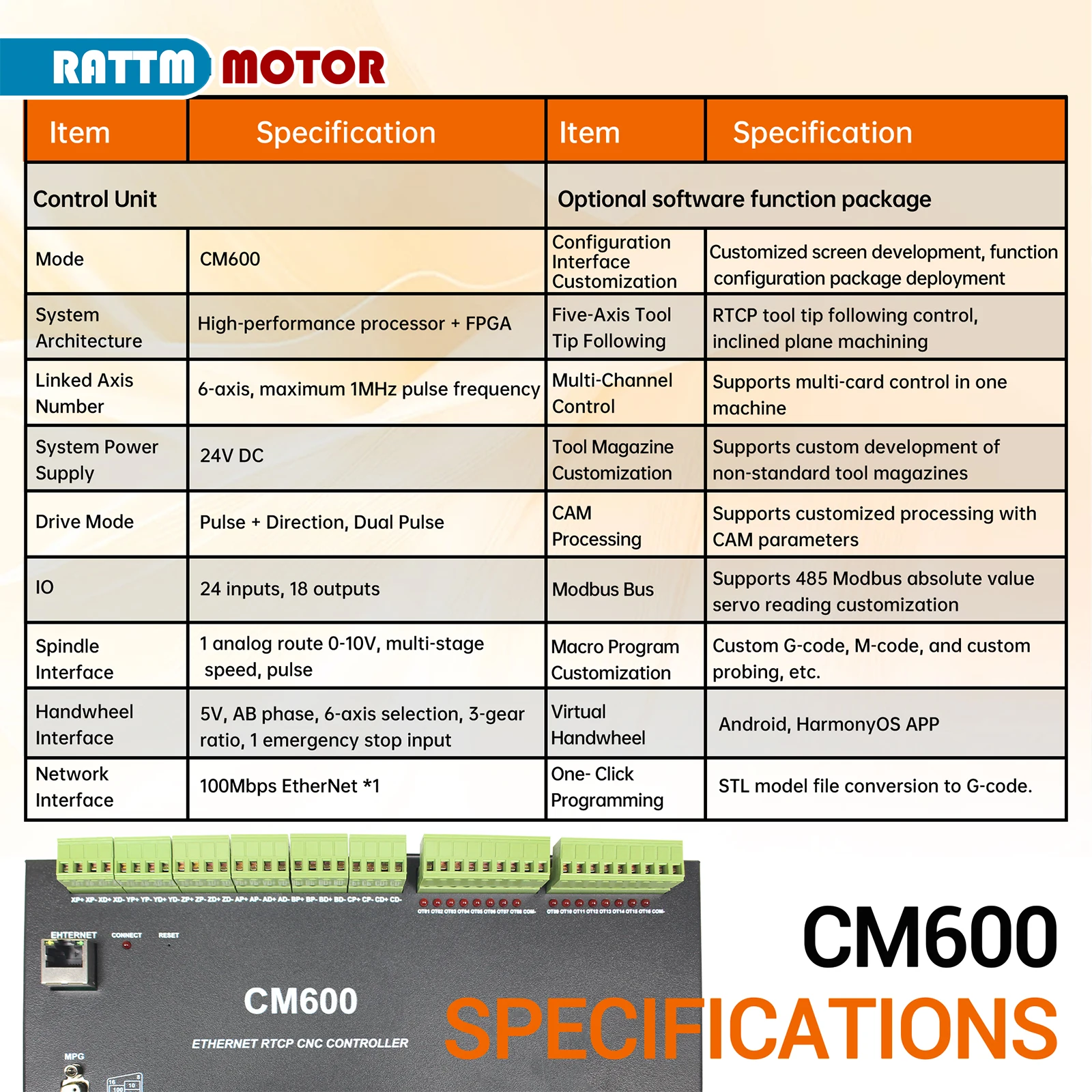

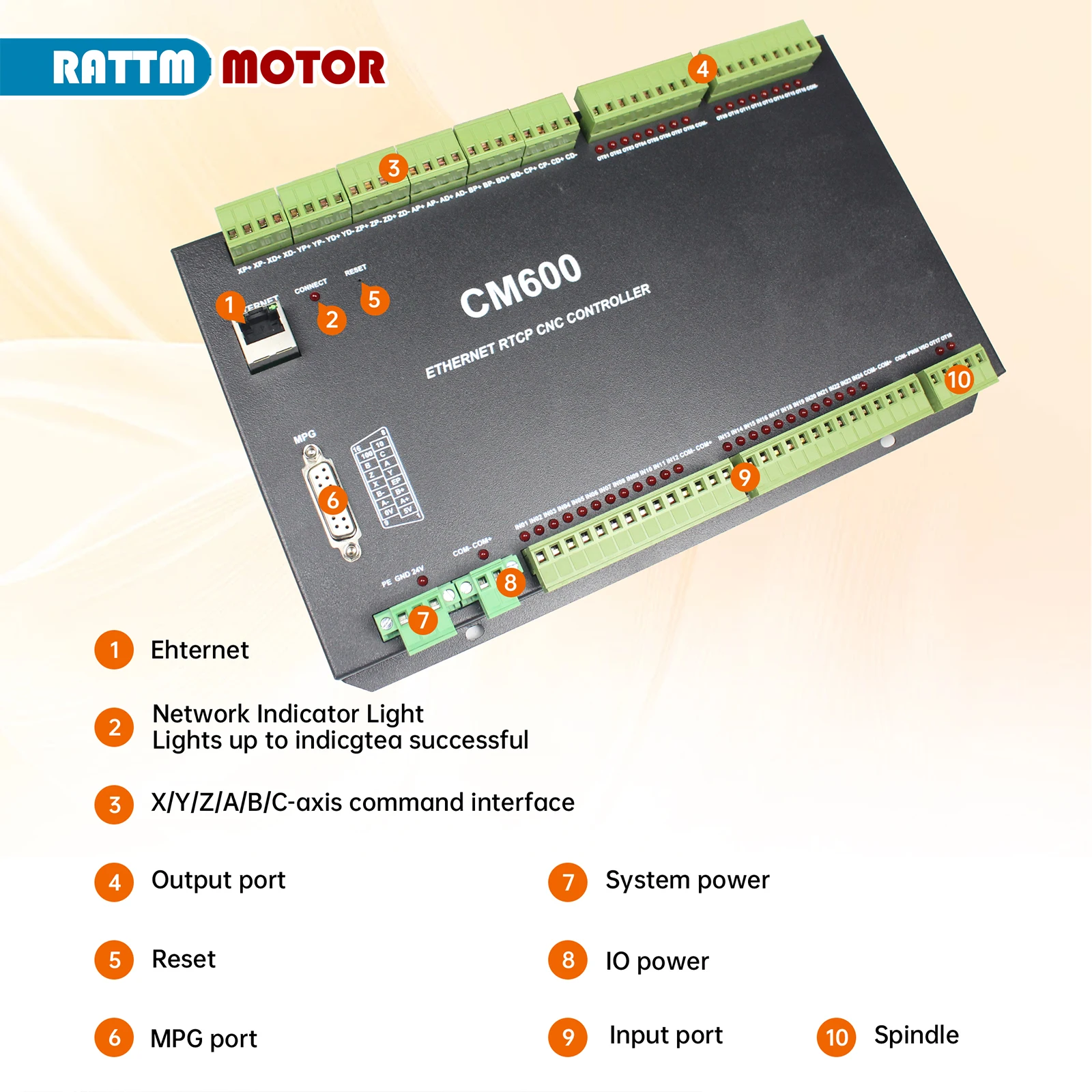

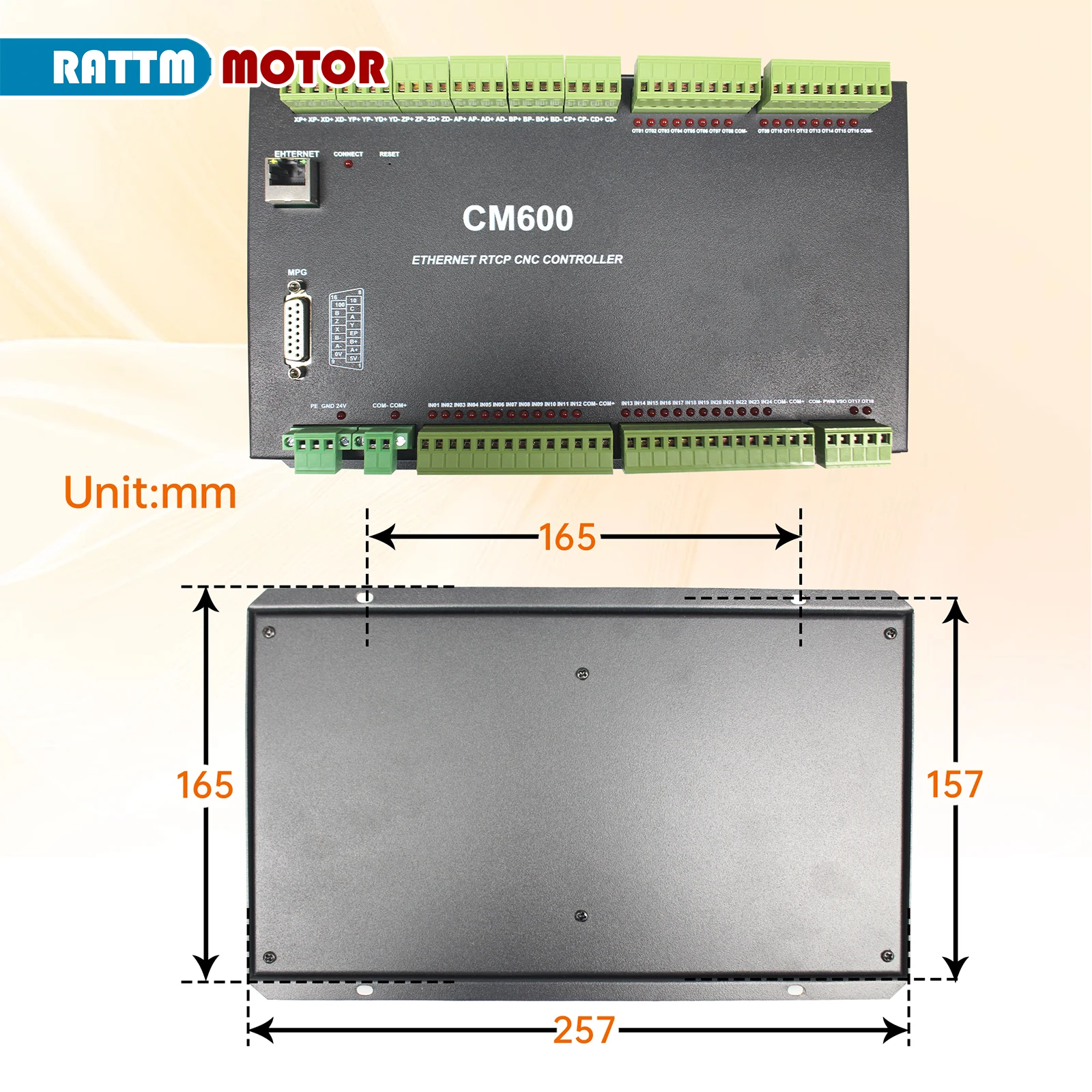

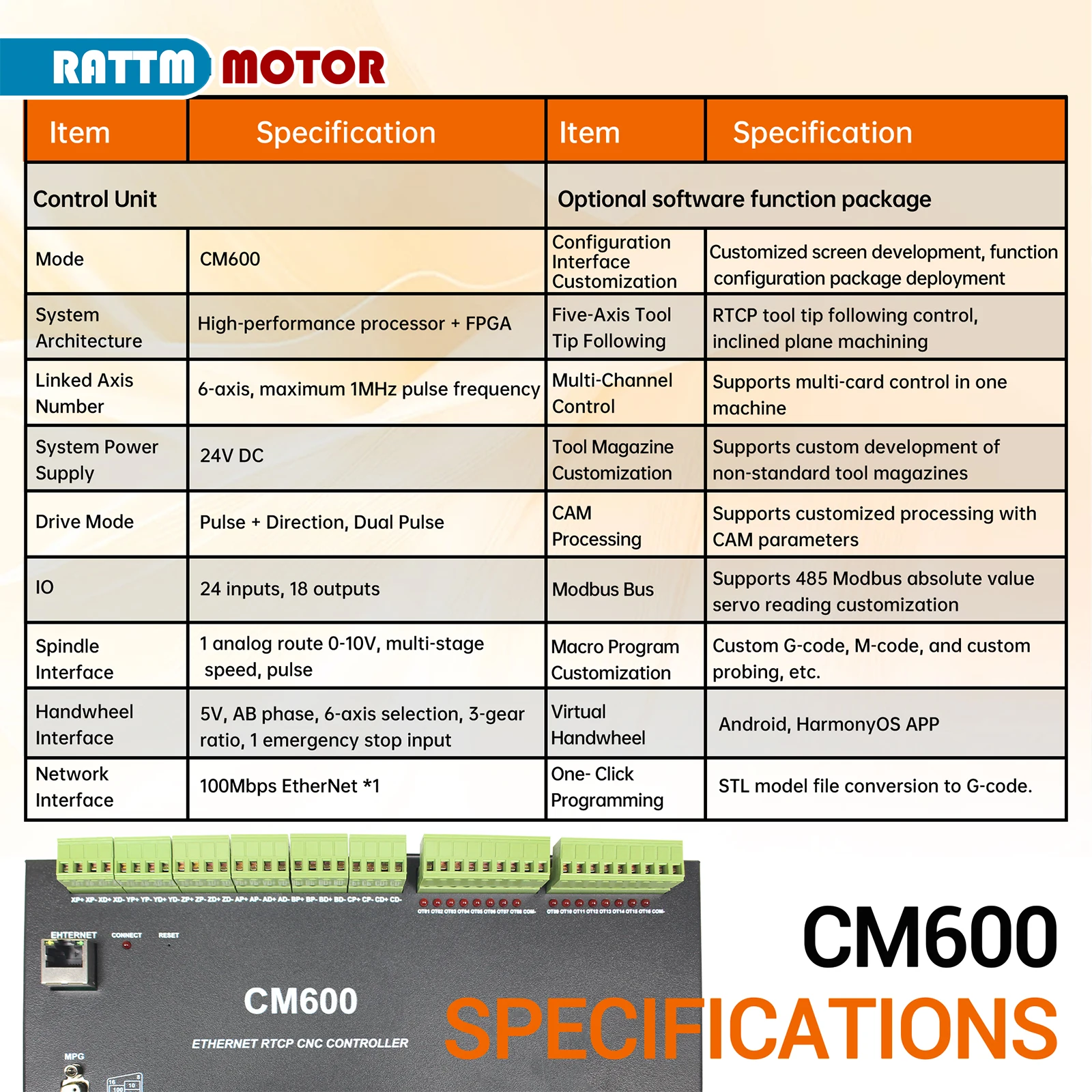

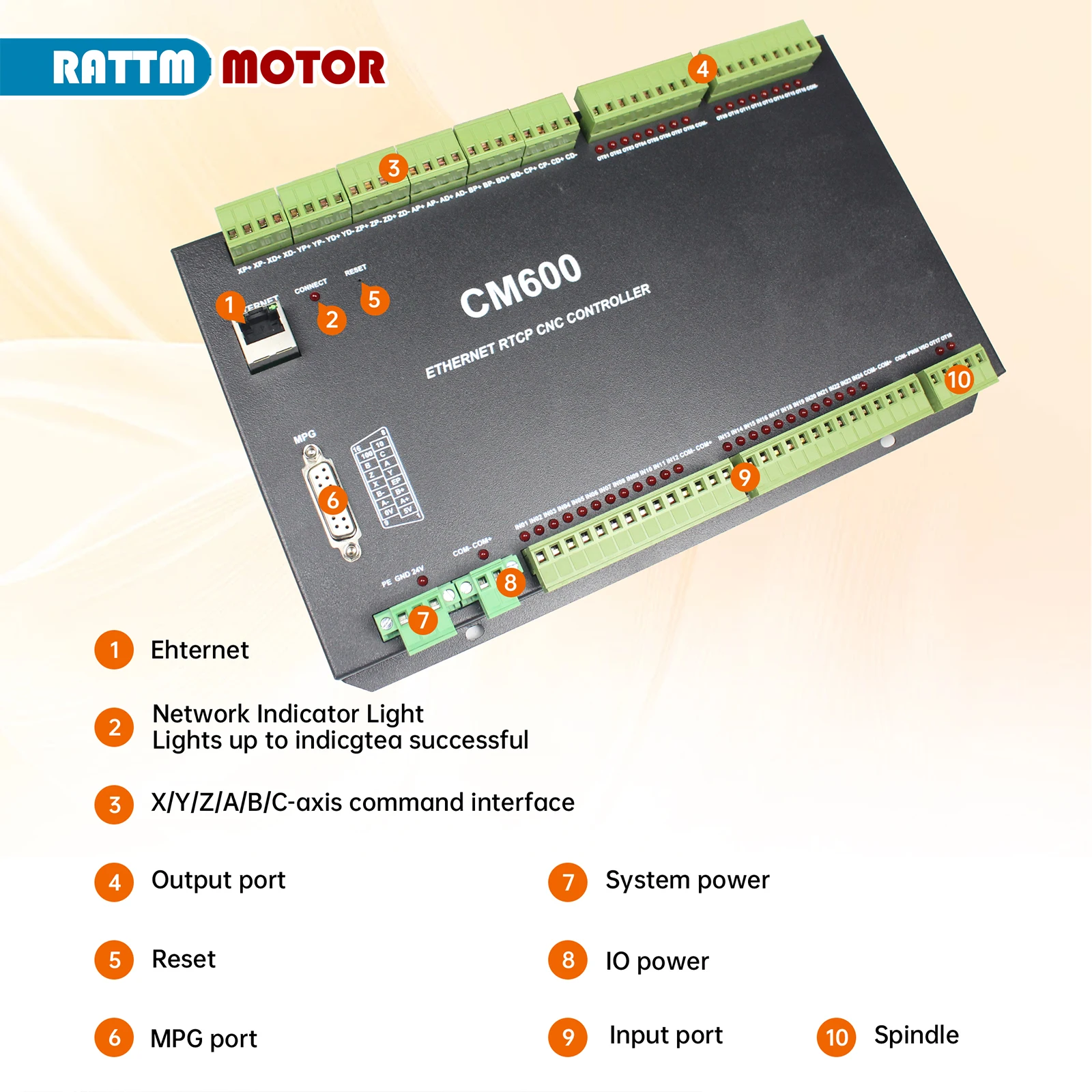

- 【CM600 Introduction】CM600 motion control card, support 6-axis linkage interpolation, support one machine multi-card mode, users can use the extended G code to realize multi-card cooperative control. It is widely used in engraving machine, mold machine, machining center, precision engraving machine, automated assembly line equipment and other due fields.

- 【CM600 Specifications】System architecture: high performance processor + FPGA. Number of linked axes: 6 axis, maximum 1MHz pulse frequency. System power supply: 24V DC. Drive mode: pulse + direction, double pulse. IO: 12 inputs, 8 outputs. Spindle interface: 1 analog 0-10V, multisection speed, pulse. Handwheel interface: 5V, AB phase, 6 axis selection, 3 speed multiplier, 1 emergency stop input. Network interface: 100Mbps EtherNet*1.

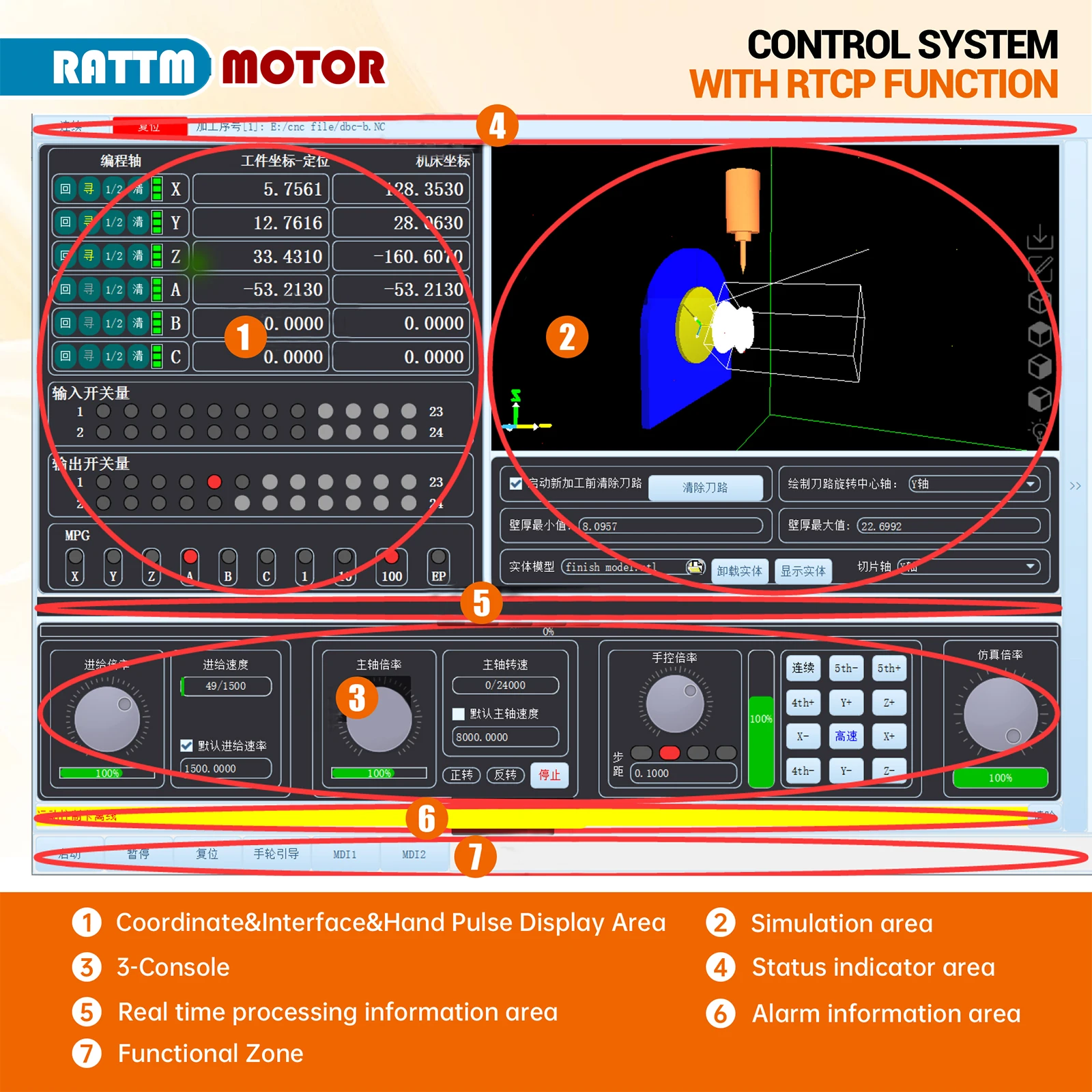

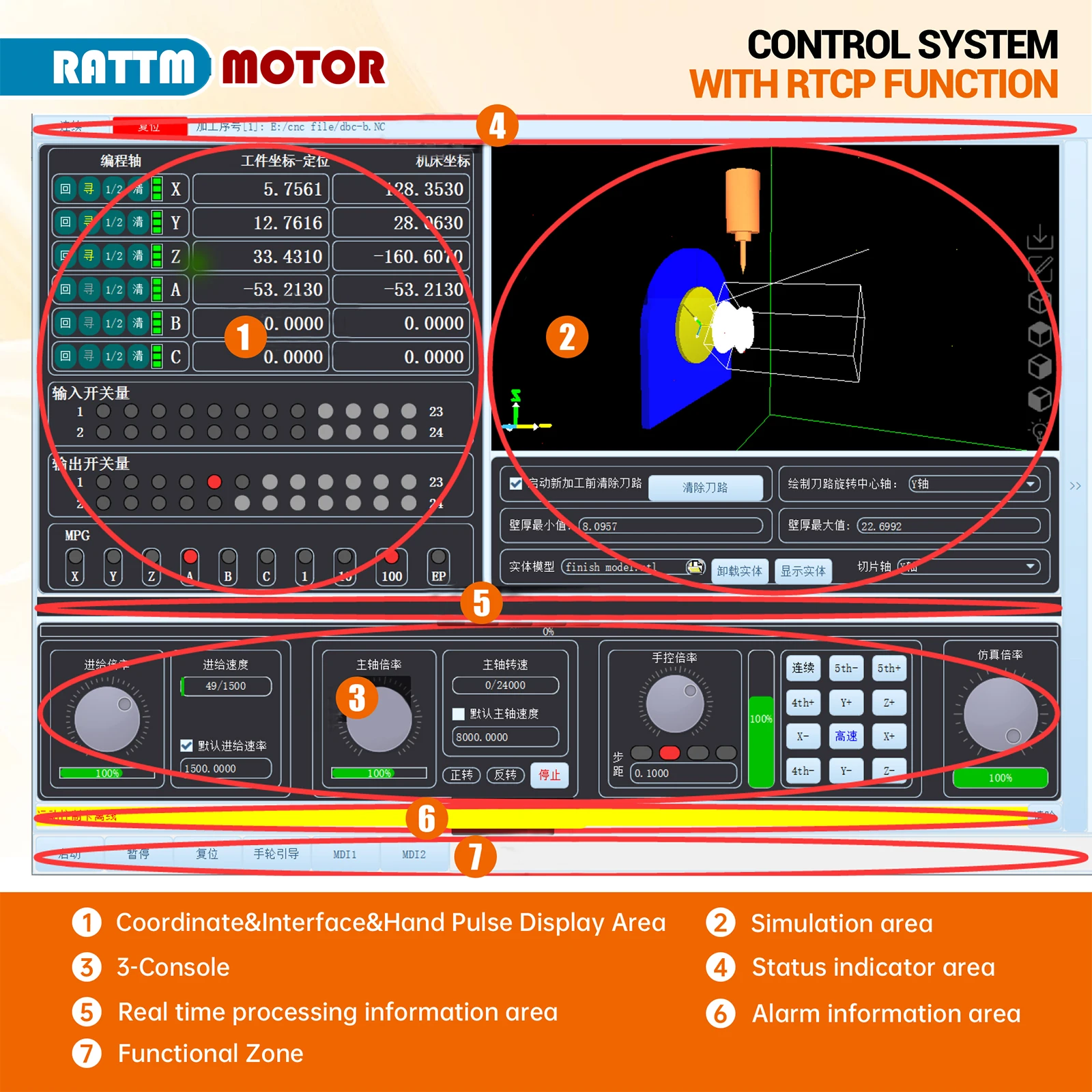

- 【Introduction to control systems with RTCP function】The control system with RTCP function is designed with configuration and has a strong scalability. In addition to supporting macro programming and customized setting of NC function parameters, it also supports 18 types of machine structure forms of 3-axis, 4-axis and 5-axis. It also has powerful toolpath preview and positioning functions, powerful and stable performance.

- 【Software Feature Pack Specifications】 5-axis tip-following, RTCP tip-following control for bevel machining. Tool magazine customization, support for flying scale tool magazine customization development.CAM processing, support for CAM parameterized processing customization.Modbus bus, support for 485modbus absolute value servo reading customization development. Macro program customization, custom G code, M code and custom probing, etc. Virtual handwheel, Android, Hongmeng APP.

- 【Customized support function】Support customized G code, support servo spindle, rigid tapping. Support customized function shortcut keys, universal input port can be configured shortcut function keys. Support user deep configuration customization, rapid secondary development of interface, automatic deployment of functional components. Support macro program customization.

- 【CM400 main advantages①】Supports 3D dynamic machining simulation function. Tool position and G-code can realize two-way positioning. 30,000 lines of super pre-reading processing function, support path forward planning. Tiny line segment wide smooth processing, better surface, good machining surface and high efficiency. Support handwheel guidance, all movements can be guided by handwheel, such as zero search, tool setting, tool magazine and so on. Supports the expansion of disk, in-line tool mag

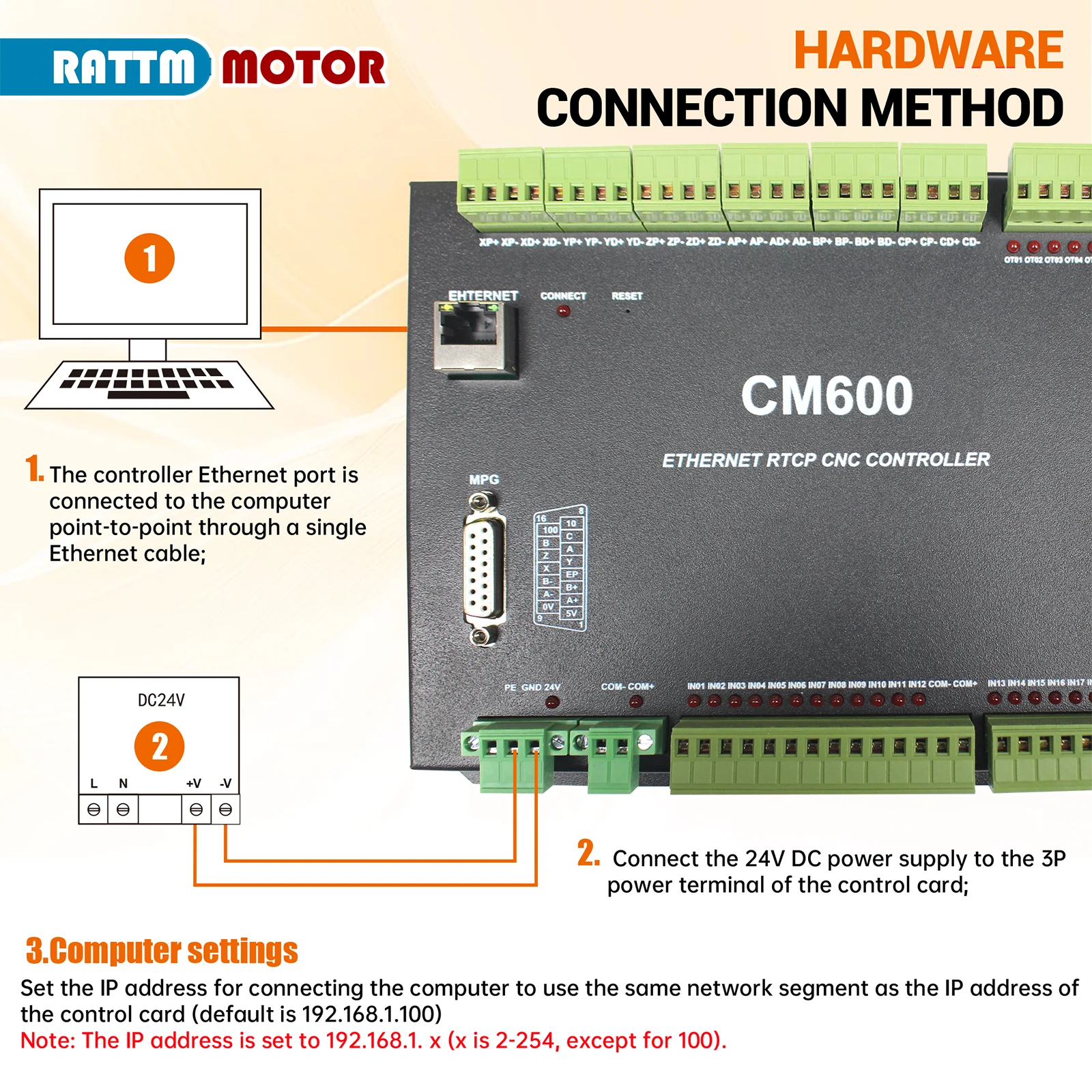

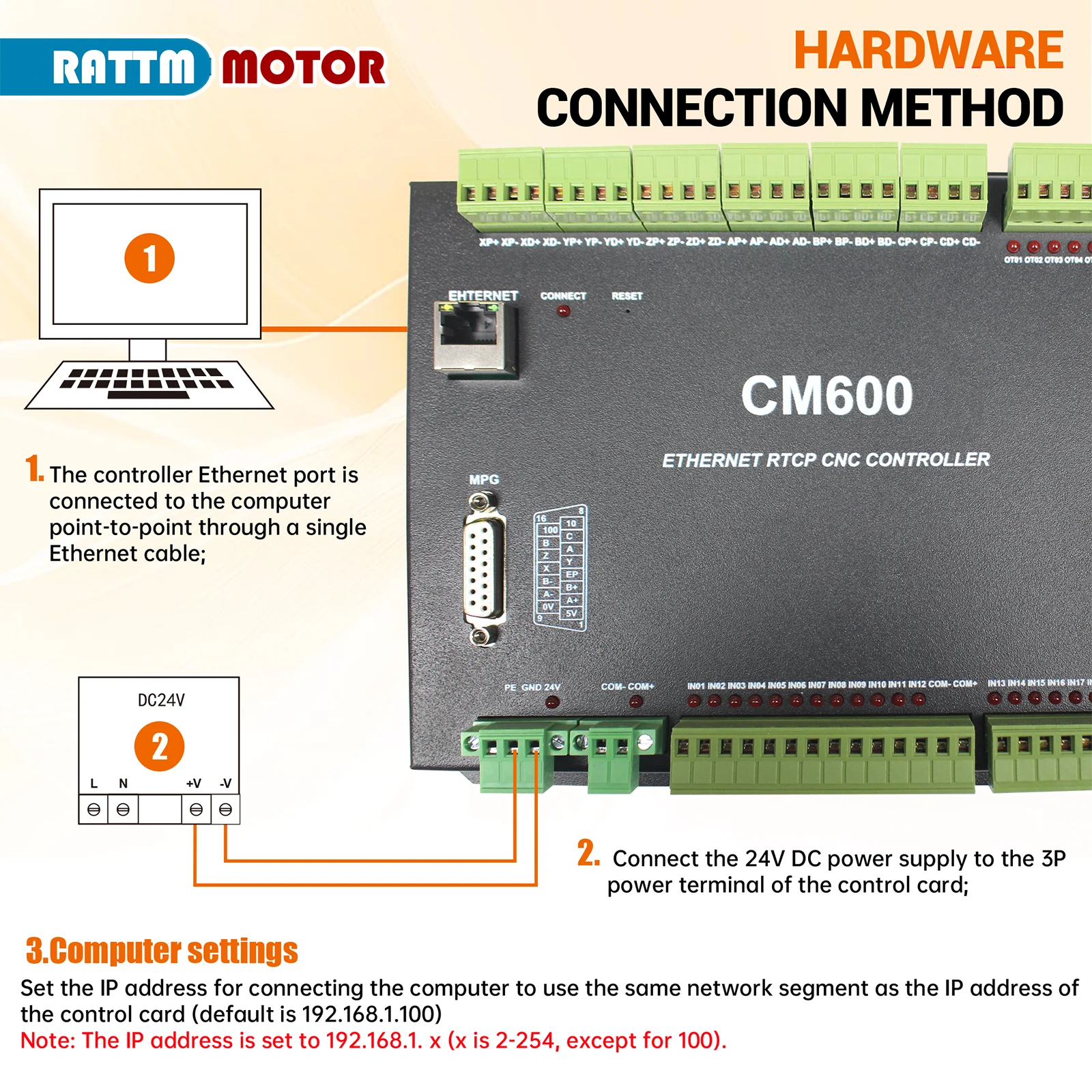

- 【Hardware Quick Connect and PC Setup】①The Ethernet port of the controller is connected point-to-point with the computer via an Ethernet cable. ② 24V DC power supply is connected to the 3P power terminal of the controller card. ③ Computer Setup: Set the IP address of the connected computer so that it is in the same network segment as the IP address of the controller card (default is 192.168.1.100). Note: Set the IP address to 192.168.1.x (x is 2-254, except 100).

Overview

This is a control system with RTCP function, which is powerful and stable in performance.

⚫ Adopting configuration design, it has strong scalability.

⚫ Supports 18 types of machine tool structures with three, four, and five axes.

⚫ Supports various five axis RTCP functions.

⚫ Support macro programming.

⚫ Support custom NC function parameters.

⚫ Powerful blade path preview and positioning function.

The most important highlight of this product is:

1. Support tool path display

2. Support mobile control

- 1x 3 Axis/4 Axis/6 Axis Ethernet CNC Motion Control Card (CM300/CM400/CM600)

- 1x connection cable

- User manual and software

Product description:

- 【CM300 Introduction】CM300 motion control card, support 3-axis linkage interpolation, support one machine multi-card mode, users can use the extended G code to realize multi-card cooperative control. It is widely used in engraving machine, mold machine, machining center, precision engraving machine, automated assembly line equipment and other due fields.

- 【CM300 Specifications】System architecture: high performance processor + FPGA. Number of linked axes: 3 axis, maximum 1MHz pulse frequency. System power supply: 24V DC. Drive mode: pulse + direction, double pulse. IO: 12 inputs, 8 outputs. Spindle interface: 1 analog 0-10V, multisection speed, pulse. Handwheel interface: 5V, AB phase, 3 aixs selection, 3 speed multiplier, 1 emergency stop input. Network interface: 100Mbps EtherNet*1.

- 【CM400 Introduction】CM400 motion control card, support 4-axis linkage interpolation, support one machine multi-card mode, users can use the extended G code to realize multi-card cooperative control. It is widely used in engraving machine, mold machine, machining center, precision engraving machine, automated assembly line equipment and other due fields.

- 【CM400 Specifications】System architecture: high performance processor + FPGA. Number of linked axes: 4 axis, maximum 1MHz pulse frequency. System power supply: 24V DC. Drive mode: pulse + direction, double pulse. IO: 12 inputs, 8 outputs. Spindle interface: 1 analog 0-10V, multisection speed, pulse. Handwheel interface: 5V, AB phase, 4 axis selection, 3 speed multiplier, 1 emergency stop input. Network interface: 100Mbps EtherNet*1.

- 【CM600 Introduction】CM600 motion control card, support 6-axis linkage interpolation, support one machine multi-card mode, users can use the extended G code to realize multi-card cooperative control. It is widely used in engraving machine, mold machine, machining center, precision engraving machine, automated assembly line equipment and other due fields.

- 【CM600 Specifications】System architecture: high performance processor + FPGA. Number of linked axes: 6 axis, maximum 1MHz pulse frequency. System power supply: 24V DC. Drive mode: pulse + direction, double pulse. IO: 12 inputs, 8 outputs. Spindle interface: 1 analog 0-10V, multisection speed, pulse. Handwheel interface: 5V, AB phase, 6 axis selection, 3 speed multiplier, 1 emergency stop input. Network interface: 100Mbps EtherNet*1.

- 【Introduction to control systems with RTCP function】The control system with RTCP function is designed with configuration and has a strong scalability. In addition to supporting macro programming and customized setting of NC function parameters, it also supports 18 types of machine structure forms of 3-axis, 4-axis and 5-axis. It also has powerful toolpath preview and positioning functions, powerful and stable performance.

- 【Software Feature Pack Specifications】 5-axis tip-following, RTCP tip-following control for bevel machining. Tool magazine customization, support for flying scale tool magazine customization development.CAM processing, support for CAM parameterized processing customization.Modbus bus, support for 485modbus absolute value servo reading customization development. Macro program customization, custom G code, M code and custom probing, etc. Virtual handwheel, Android, Hongmeng APP.

- 【Customized support function】Support customized G code, support servo spindle, rigid tapping. Support customized function shortcut keys, universal input port can be configured shortcut function keys. Support user deep configuration customization, rapid secondary development of interface, automatic deployment of functional components. Support macro program customization.

- 【CM400 main advantages①】Supports 3D dynamic machining simulation function. Tool position and G-code can realize two-way positioning. 30,000 lines of super pre-reading processing function, support path forward planning. Tiny line segment wide smooth processing, better surface, good machining surface and high efficiency. Support handwheel guidance, all movements can be guided by handwheel, such as zero search, tool setting, tool magazine and so on. Supports the expansion of disk, in-line tool mag

- 【Hardware Quick Connect and PC Setup】①The Ethernet port of the controller is connected point-to-point with the computer via an Ethernet cable. ② 24V DC power supply is connected to the 3P power terminal of the controller card. ③ Computer Setup: Set the IP address of the connected computer so that it is in the same network segment as the IP address of the controller card (default is 192.168.1.100). Note: Set the IP address to 192.168.1.x (x is 2-254, except 100).

Overview

This is a control system with RTCP function, which is powerful and stable in performance.

⚫ Adopting configuration design, it has strong scalability.

⚫ Supports 18 types of machine tool structures with three, four, and five axes.

⚫ Supports various five axis RTCP functions.

⚫ Support macro programming.

⚫ Support custom NC function parameters.

⚫ Powerful blade path preview and positioning function.

The most important highlight of this product is:

1. Support tool path display

2. Support mobile control

Problem&Feedback

Please give us the opportunity to resolve any problem when you have, we concern your problem and we will try our best to resolve it.

We are a new member in ebay now, and need understand both of sides

Pls email us before you want to leave any negative feedback

Refund

When you have the parcel, and not satisfied the goods or it is other problem like as broken,pls tell us the detail reason and provide the photos

Any reason required for all refund. Item must be in it's original condition and no physical damage. Buyer responsible for all shipping cost

Contact us

Welcome worldwide customer inquire and questions, we will try to do our best to feedback customer’s email within 1-2 business days,if not pls check the mail box again

Customer’s satisfaction is very important to us.