CBN sharpening stones combined bond, on blank,

Poltava plant of diamond tools

200 х 30 х 8 x 3 x 5

Length: 200 mm = 8 inch

Width: 3 mm x = 1.2 inch

Total thickness: 8 mm = 0.32 inch

CBN thickness: 3 mm = 0.12 inch

Blank thickness: 5 mm = 0.2 inch

Trademark: Aldim. These next generation stones were developed on the basis of our experience in sharpening business:

- solid support plate (thicker aluminum blank: 4 mm vs competitors' 3 mm);

- appropriate bonds (selected, depending on grain size)

- combination of long life, delicate sharpening, and excellent performance of combined (metal-resin) bond.

Material: CBN - cubic boron nitride. It has the best cost/productivity ratio for processing of STEEL, comparing to diamond and cheaper materials. CBN is a generic name, there are also other names of this material, depending on manufacturer: borazon, elbor, cubonite, etc.

CBN grit: any, please select from the list.

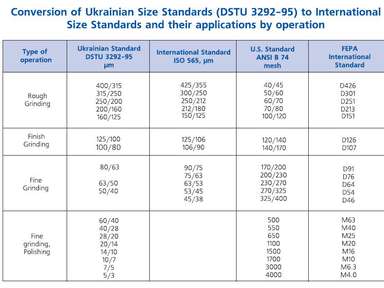

Please refer grain size conversion chart below.

There's "Leather on aluminum blank", polished Italian leather, to apply paste (https://www.ebay.com/itm/284796231990) on final operations, dimensions 160x25x7.

Because this product is relatively cheap, comparing to shipping costs, I sell Leather on aluminum blank, if you buy a stone.

Bond: combined bonds to ensure the best performance.

Grain sizes: 0.5/0- 5/3 - resin bond BP50 for polishing;

Grain sizes 5/3 - 63/50 - resin bond BP44 for grinding;

Grain sizes 80/63 - 125/100 - wear resistant metal-resin bond BP08 for grinding

Grain sizes 160/125 - 315/250 - roughing metal-resin bond BP05 for grinding

Concentration 100%.

Do not waste your money on cheaper stones with lower/unknown concentrations.

Flat solid block, CBN grains are distributed evenly across the volume of the 3 mm thick stone.

Preparation

Unlike other sharpening stones, most of these combined bond stones do not need preparation, except stones with grits finer 1 microns (<Grit 15000). Ultrafine grains (1/0, 0.5/0) form agglomerates in a bond, so you may need to dress them with abrasive powders/pastes, or they will be self-polished after sharpening of 30-50 knives.

1. SiC powders on glass plate, polish the stone with each grain size for 5 min. Refer SiC selection table below. Cheap and simple method.

2. CBN pastes on 3 iron plates. One iron plate for each grit size set (60/40 and 28/20, 14/10 and 7/5, 3/2 and 1/0), total working time 1 hour. This method is more expensive, but more effective.

You may buy Set of SiC powders for stone preparation (F400, F800, F1200), 100 gr. of each, total weight 300 gr.

Use and cleaning

Use any comfortable oil (baby, olive..) to prevent glazing. If glazed - clean with alcohol and toothbrush.

Maintenance (in 1-2 year), flattening/revitalization:

- resin bond stones - with silicon (silica) carbide powders on glass plate,

- metal bond stones - with silica powders or with FeCl.

You may buy 100 gr. of FeCl in grain selection window. I sell it if you buy a stone.

Please review presentation and how-to-prepare video:

CBN sharpening stones, combined bond. Presentation and preparation for first use

Video will open in a new window

Using the eBay App? Paste link into a browser window:

Sharpening with Poltava diamond and cubic boron nitride stones

Sharpening with Poltava diamond and CBN stones

Video will open in a new window

Using the eBay App? Paste link into a browser window:

Selection of SiC powders for dressing of sharpening stones

| Stone | Starting grit | Finishing grit |

| 500/400 μ = 35/40= D501 | F16 (1230 μ) | F24 (745 μ) |

| 400/315 μ = 40/45= D426 | F16 (1230 μ) | F46 (370 μ) |

| 315/250 μ = 50/60= D301 | F24 (745 μ) | F46 (370 μ) |

| 250/200 μ = 60/70= D251 | F24 (745 μ) | F60 (260 μ) |

| 200/160 μ = 70/80= D213 | F36 (525 μ) | F60 (260 μ) |

| 160/125 μ = 100/120= D151 | F46 (370 μ) | F80 (180 μ) |

| 125/100 μ = 120/140= D126 | F60 (260 μ) | F100 (129 μ) |

| 100/80 μ = 140/170= D107 | F60 (260 μ) | F120 (109 μ) |

| 80/63 μ = 170/200= D91 | F80 (180 μ) | F150 (82 μ) |

| 63/50 μ = 230/270= D64 | F100 (129 μ) | F180 (69 μ) |

| 50/40 μ = 270/325= D54 | F120 (109 μ) | F220 (58 μ) |

| 40/28 μ = 550= M40 | F150 (82 μ) | F240 (46 μ) |

| 28/20 μ = 650= M25 | F180 (69 μ) | F320 (30 μ) |

| 20/14 μ = 1100= M20 | F240 (46 μ) | F400 (18 μ) |

| 14/10 μ = 1500= M16 | F320 (30 μ) | F400 (18 μ) |

| 10/7 μ = 1700= M10 | F400 (18 μ) | F600 (10 μ) |

| 7/5 μ = 3000= M6.3 | F600 (10 μ) | F800 (6,7 μ) |

| 5/3 μ = 4000= M4 | F600 (10 μ) | F800 (6,7 μ) |

| 3/2 μ = 6000= M1.5 | F800 (6,7 μ) | F1200 (3 μ) |

| 2/1 μ = 10000 | F800 (6,7 μ) | F1200 (3 μ) |

| 1/0 μ | F800 (6,7 μ) | F1200 (3 μ) |

| 0.5/0 μ | F800 (6,7 μ) | F1200 (3 μ) |

My listings of Poltava sharpening/honing stones (Length x Width x Abrasive Thickness, mm):

Diamond sharpening stones: not recommended for steels with high carbon content, but perform well with hard steels, like CPM S90V.

CBN sharpening stones: standard for steels.

Combined bond: next generation bond, combines delicacy of resin bond on fine grains, and wear resistance of metal bonds on coarse grain sizes.

Sets: preselected stones to make your choice easier: metal and combined bond sharpening stones on blanks.

Pro 200% - professional stones with concentration 200% (standard stones are 100% concentration), which means higher productivity and longer tool's life.

Economy: cost saving solution for most sharpening applications.

"Pro" and "Economy" are the only nicknames I use for stones and I suppose it's clear why. No pathetic nicknames and brands. Just product as it should be, from trusted Poltava seller.

"Pro" and "Economy" are the only nicknames I use for stones and I suppose it's clear why. No pathetic nicknames and brands. Just product as it should be, from trusted Poltava seller.

30000 grit = 0.5/0 μ - fine polishing

15000 grit = 1/0 μ - fine polishing

10000 grit = 2/1 μ - fine polishing

5000 grit = 3/2 μ - fine polishing

4000 grit = 5/3 μ - polishing

3000 grit = 7/5 μ - polishing

1700 grit = 10/7 μ - polishing

1500 grit = 14/10 μ - polishing

1100 grit = 20/14 μ - polishing

650 grit = 28/20 μ - polishing

550 grit = 40/28 μ - fine grinding

325 grit = 50/40 μ - fine grinding

285 grit = 63/50 μ - fine grinding

240 grit = 80/63 μ - fine grinding

225 grit = 100/80 μ - fine grinding

160 grit = 125/100 μ - grinding

100 grit = 160/125 μ - grinding

80 grit = 200/165 μ - sharpening / rough grinding

Recommended set of these stones for steel (microns from coarse to fine):

200/160

125/100

63/50

40/28

20/14

10/7

5/3

2/1

CBN paste 0.5/0 (https://www.ebay.com/itm/284796231990) on leather blank

Made in Ukraine, by Poltava plant of diamond tools.

Shipping:

Ukrainian post (ukrposhta.ua), registered mail with tracking number; delivery time to US, Europe - 2-4 weeks.

Tracking will be available on your local post website when order arrives to your country; it is advisable to track on specialized sites like trackitonline, etc.

All orders do arrive if address is correct, but delivery time of some parcels may be delayed up to 2 months because of logistics or customs issues. Please contact me first before opening case.

International Buyers – Please Note:

Import duties, taxes, and charges are not included in the item price or shipping cost. These charges are the buyer's responsibility.

Please check with your country's customs office to determine what these additional costs will be prior to bidding or buying.

Import duties, taxes, and charges are not included in the item price or shipping cost. These charges are the buyer's responsibility.

Please check with your country's customs office to determine what these additional costs will be prior to bidding or buying.

Catalog of diamond and CBN tools

Video will open in a new window

Using the eBay App? Paste link into a browser window: