About Us:

We are a family owned machine shop and engine testing facility located in the NE Indiana Tri-State region. Our shop foreman has more than 40 years experience building custom high-performance engines and out sales manager has more than 15 years hands on experience designing, assembling, and testing complicated high-end highly customized engines. Nearly all of our engines receive a custom designed camshaft matched to the flow charts of the cylinder heads and set up for the vehicle's exact intended use, along with a custom designed forged piston and other customized parts making our engines a better fit for most consumers.

PURCHASER TO RECEIVE:

One custom LS long block (complete from the bottom end up to the lifter valley cover and valve covers) built in the newly released DART NEXT iron severe duty engine block including custom designed billet camshaft, roller rocker arms, true roller timing set, custom forged pistons, forged crankshaft, forged connecting rods w/ ARP capscrew, with Total Seal moly rings and King X-treme bearings. We offer many add-ons and upgrades to this engine package. We can provide you with the correct oil pan assembly to fit your vehicle's chassis for as little as $300-- so do not let the custom oil pan deter you. We also offer these motors set up for the early earlier LS1/LS6 ECM and harness or later designs such as LS2, LS3, LS7, and LS9. We offer crank double keying, both wet sump and dry sump, and many other options. This engine can designed for the traditional intake and carburetor with or without coil packs or it can be designed and built for EFI, either natural aspiration or forced induction. We also off this engine package in an all aluminum Dart Next block.

The buy it now price is for an engine designed for up to 8 psi boost and ships with 4-Bolt GMPP CNC ported heads. We offer high boost upgrades that include 6-bolt heads, ARP studs, Cometic head gaskets, crank double key, (Inconel exhaust vavles for Turbo), heavy duty piston with upgraded wrist pin, and other mods. Inquire for details. Base crank and rods are 4340 forged and billet by Molnar Technologies and custom Piston by Racetec Piston. Other crank, rod, and cylinder head options are available subject to price increase.

NOTE: The oil pan assembly and oil pump pick-up are not included at the buy it now price!

WHY ARE WE QUALIFIED TO BUILD THE DART LS NEXT ENGINE PLAT FORM?

Beginning in January of 2013 our shop began R & D on the new Dart Next Block and received from Dart a Next block from Dart's very first production run. At this time, Dart had only produced 2 other blocks beforehand. One they cut up to measure and dissect and the other they assembled and dyno tested. After receiving the block, and after many hours of development over many months of time, we learned the requirements this new design LS block and what it commands to obtain a successful build and capitalize on the improved features of the block offered over the other LS blocks in the market place. Initially, it was thought that this block was almost fully compatible with the conventional parts usually used to build an LS motor other than requiring a custom oil pan (as this is how it was initially represented to us by Dart). However, we quickly discovered that there are several other area of this block that are not compatible and will catch the experienced LS engine builder off-guard---areas such as valve train geometry, cover fitment, head fastener challenges, rotating to block clearance changes and others hurdles. We have not only learned and over come these challenges and pit falls, we have standardized the DART Next platform and have put the engine package into full production.

IS IT WORTH IT?

You may be wondering why one would want to use the DART LS Next block considering it is more difficult and expensive to build as compared to the GMPP LSX race block or other plat forms, and if it is worth it? We can honestly say that for a person who is expecting to expose an engine to high levels of boost and or nitrous and/or high RPM operation that it is worth it from what we have learned from our hands on study of the block and use of it.

WHY IS IT WORTH IT?

To be brief, we will focus on the key benefits of the block when used with moderate to excessive boost and/or nitrous and/or high RPM use. Dart has cast the cylinders of the Next block exceptionally thick at approximately .075 thicker than the GM LSX block at any given bore size. We do like and use at our shop the LSX block for certain builds but the cylinders are weaker. Not only due to thickness but also due to core shift. When a block is cast and poured from a mold plugs are used to locate the cylinders, and if the plugs do not hold the cylinder casting perfectly, core shift becomes an issue making one side of the cylinder effectively thicker than the other or at least a portion of one side if the cylinder casting is titled in the process. Dart has taken great precautions by using a greater number of plus to hold the cylinder casting still during the pouring and curing procedure so that core shift is nearly eliminated and they have followed up by sonic checking and cutting the block apart to ensure that their endeavor to avoid core shift has been successful. Other LS blocks (especially the LSX block) have been found to suffer from the negative effects of core shift weakening the block, especially at larger over bores. In GMs defense, there have been reports GM has redesigned the LSX block and reissued a new part number after customer's were breaking the cylinders on the LSX blocks under boost and at the larger over bore sizes, and we are certainly glad for this but even if the core shift concerns are no longer an issue, the Dart cylinder wall is still thicker and therefore stronger and a better fit for severe duty applications. On to the other features of the Dart block making it a good choice for the severe duty consumer: the cylinder barrels have been extended in the Dart block by .375 (almost 1/2 inch). All one has to do is enter on of the well known LS chat room forums on line such as LS1 Tech and many others and it will not take long to find many people advising not to go past a 4.000" stroke to avoid problems associated with the piston protruding out of the bottom of the shorter LS cylinders at bottom dead center, as reliability, oil consumption, and other concerns are raised. This is no longer an issue with the Dart block. Considering the cylinders are .375 longer, this effectively allows one to run up to a 4.375 stroke in the Dart Next block while maintaining the same level of piston stability as the 4.000" stroke. This is an important thing to mention because the larger stroke in the block allow for more torque and horsepower at a lower RPM giving the consumer a larger power base, and when power adders are introduced such as boost and or nitrous, the end result is exponentially more power! Darts main caps design is another important area to mention. Dart has designed into the Next block a very beefier and thicker billet main cap with larger diameter cap fasteners than found in other LS block plat forms. All one has to do is remove a Dart main cap and hold it in one's hand along with the conventional LSX or LS thinner main cap with smaller fasteners to understand. More importantly, Dart has introduced to its main cap design the tried and true splayed angle that severe duty racers have relied on for decades for optimum cap to block clamping. In addition to this, Dart has designed into the Next block and extremely beefy main web supporting the crank and main saddle of the block with exceptional strength attributes. The last two area or benefits of the Dart LS Next block we will mention is the blocks deck and the un-skirting of the block to reduce power robbing windage and exxcessive crank case pressure concerns. Dart has cast this block with an ultra thick .625 thick head deck surface eliminating the concern of the deck flexing or cracking with excessive boost and or nitrous that can cause poor cylinder head gasket seal or worse. Dart has also retained the good features of GM's LSX design such as 6-bolt head pattern for extra head clamping and LSX lifter valley design allowing for sight of lifters through the lifter valley and use of either LSX lifter trays or tie bar lifters. Lastly, Dart has totally redesigned the oiling system of the Next block for better oiling and less windage than the LS Y-Block design that robs power potential along with allowing for better crankcase evacuation and less crank case pressure concerns.

BASE ENGINE PACKAGE INCLUDED AT THE EBAY BUY IT NOW:

SPECS:

Engine Type: LS-Series Small-Block V-8

Displacement: Customer's Choice 364 - 454 cubic inch (larger displacements available at an additional charge).

Block : Dart Next cast iron with 6-bolt

Crankshaft : 4340 forged steel (Upgrades Available such as 100% American Chrome Nickle Moly)

Connecting Rods: 4340 forged steel w/ ARP (Upgrades Available to Billet or 100% Timkin American Steel w/ Custom Age 625 Faster (stronger than L19 without corrosion embrittlement concerns)

Pistons: (Custom): forged aluminum (Upgrades Available such as Gas Porting, Thick wall or Tool Steel wrist pin, added crown thickness, Thermal Coating & More)

Camshaft Type (Custom Comp Cam): Mechanical roller or Hydraulic

Camshaft Lift (in): .Custom Based On Head Flow and Intended Use Billet Roller (Other Custom Cam Designs Also Available)

Cylinder Heads: GM Performance with Lunati High-Lift Spring and Hollow Intake Valve "as cast" (Upgrade to brand of preference and or CNC porting and 6-bolt)

Compression Ratio: Purchasers Choice: Pump Gas, Race Gas, or Low Compression For Boost

Rocker Arms: GM Cagged Roller Trunnion or Fuller Roller (Upgrade to Shaft Mount)

Recommended Fuel: Race fuel (Dependent on Selected Compression Ratio)

Balanced: Internal

Please see our website and take our shop tour to see the kind of work we do. Thank you and look forward to hearing from you.

Jerry Long, Div Mngr

SAG Performance Group

Phone:

Fax: (877) 309-1271

Website: https:/www.sagperfomance

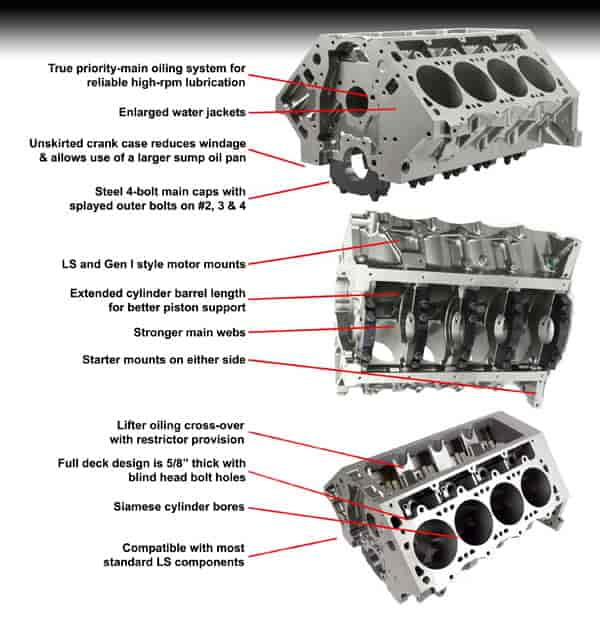

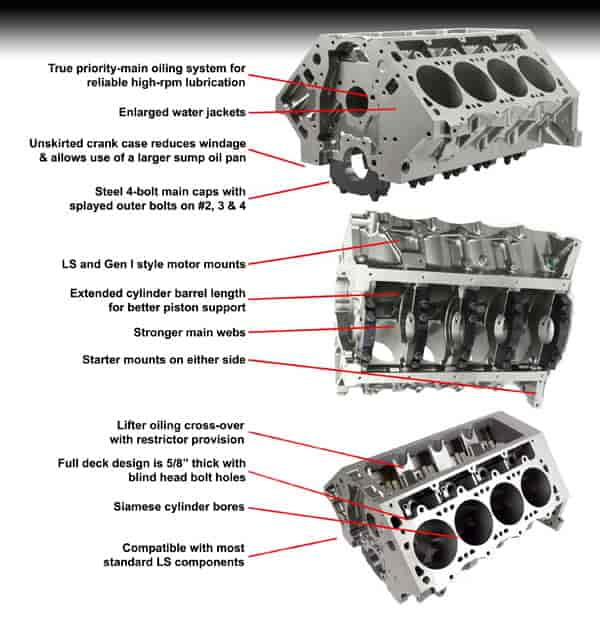

SEE BELOW FOR A WEALTH OF INFORMATION ON THE NEW DART NEXT BLOCK:

Features:

| Reduced windage and increased power

Extended cylinder barrel length

Siamese cylinder bores

Special RMR Iron Alloy

4.000'' or 4.125'' w/ 4.200'' Maximum Bore

4.200'' x 4.100'' Maximum Bore & Stroke

454 Cubic Inch Maximum

Stock LS Camshaft Position

Accepts Standard Camshaft Belt Drive or Chain Drive (Cloyes p/n 9-3658TX3)

1.565'' O.D. Camshaft Snout

.275'' Cylinder Wall Thickness @ 4.185'' Bore

9.240'' Deck Height w / extended cylinder barrels .375'' at bottom

5/8'' (.625'') Deck Thickness

1.500'' Diameter Freeze Plugs

Cam retaining plate: Dart cam retaining plate / Cover. Dart 301-32226000

Billet Steel 4-Bolt Splayed Main Caps w/Center Thrust

.8427'' - .8437'' Lifter Bores (up to .937'' keyed w/ 1.062'' dia. bushing)

Low Volume Priority Main Oiling System w/Center Crossover

Melling or Stock LS Oil Pump

Must Use Remote Oil Filter

Special Oil Pan Required: Moroso, Canton and Stef's

Stock LS style Rear Main Seal with Factory Cover

Factory LS Starter w/Driver and Passenger Mounting Options

Main Bolts: Inners - 7/16'' x 3.600''; Outer - 7/16'' x 2.900''

Studs Holes: Head 10-bolt Pattern with 7/16'', 3/8'', and 8mm sizes

Stud Length in Block: 1.000'' Thread Depth

Factory LS Timing Cover and Front Seal

227 lbs w/Main Caps

100% Made in the USA! |

The New Dart LS Next Engine Blocks are designed to

eliminate the high RPM power loss and the problem of separate bays in

the crankcase associated with the ''Y-Block'' design of the LS engine

series. This has been accomplished by using the conventional style small

and big block Chevy 4-bolt steel main caps with 7/16" bolts, full main

webbing and crank barrel around a standard LS rotating assembly for

maximum bottom end strength!

The cylinder barrels are extended by .375" at the bottom, providing the

effective equivalent of a 9.615" deck height in terms of potential

supported piston travel, while maintaining a standard 9.240" actual deck

height for maximum compatibility with available components. This

equates to greater piston support with long stroke combinations and

allows for better piston designs to increase stability. While extra

thick Siamese cylinder bores allow for large displacement capacity!

The oiling system has also been revised the stock internal main oil

galley has been eliminated and a revised low restriction priority main

oiling system is utilized. A pro-stock / pro-mod big block style stepped

main oil galley measuring 9/16"-1/2"-7/16" is employed and increases

volume but most importantly there is no loss of pressure or velocity at

the front of the block!

At the top end of the block a 5/8" thick full deck design with six head

bolts per cylinder is utilized to provide secure clamping strength and

versatility for power adder applications. LSX style lifter bosses and

guides are utilized while the provisions for oil restrictors in the

lifter valley simplify the installation and removal of restrictors!

Dart’s LS Next Block Performs Well In Oil-system Tests

Dart’s new LS Next iron cylinder block is one step closer to hitting

the market following a series of oil-system tests. The block was first

shown at the SEMA show last November, and it’s designed to take

advantage of the LS engine’s positive attributes while removing the

negatives from the equation. Basically, the new block supports LS

cylinder heads and other major components but replaces the troublesome

Y-block side skirts with Gen I-style main caps and oil-pan rails. The

result is less crank windage and stronger main web.

The

oiling system was the most critical issue that company founder Richard

Maskin and his team tackled during the block’s development. The first

test used an external pump and a modified Moroso Rocket-block pan core.

The second test utilized a stock LS oil pump, which was modified with a

weaker pressure spring, and a Moroso LS oil pan with pan rail spacers to

make up the difference in the skirt length. These adjustments

maintained the oil desired oil pressure in the engine without the

excessive volume that the LS often requires.

The

oiling system was the most critical issue that company founder Richard

Maskin and his team tackled during the block’s development. The first

test used an external pump and a modified Moroso Rocket-block pan core.

The second test utilized a stock LS oil pump, which was modified with a

weaker pressure spring, and a Moroso LS oil pan with pan rail spacers to

make up the difference in the skirt length. These adjustments

maintained the oil desired oil pressure in the engine without the

excessive volume that the LS often requires.

“According to my sources, the stock LS7 uses somewhere around 18

gallons per minute revved up, while our design uses much less and still

provides more-than-adequate oiling across the board,” explains Maskin.

“So far, we’ve created two blocks – the first one was cut up for

inspection, and the block used for this test was number two. Now that

the initial testing has been run, we plan to pour 25 production blocks

next week, which will be available for purchase on or about the first of

May.

“We’ve got two more tests to run,” continues Maskin. “The first being

a Pro Stock dry-sump system with 25 inches or more of vacuum to see

what power potential is really in the oiling system. For the second

test, we’ll be going back to the stock pump with an all-out, baffled,

screened, wet-sump oil pan.”

More power than expected

The test engine was fitted with Dart’s CNC-machined LS1 heads, a “reasonably small” solid-roller cam, GM intake and 850cfm carb.

“As far as performance goes, there are plenty of performance parts

out there – heads, manifolds, etc. that are much better than what we

used in this engine,” says Maskin. “We were just trying to prove that

the block worked as it was designed to work.”

Experts at Lingenfelter Performance and Nickens Racing Engines had

earlier suggested to Maskin that the engine with those parts would make

about 640 to 660 horsepower. As indicated by the dyno results below, the

engine hit a peak of 740 horsepower and averaged 701 horsepower from

5,600 to 8,000 rpm.

Dart’s

new LS Next block features 4-bolt steel main caps with 7/16-inch bolts

and full main webbing for maximum bottom-end strength. The cylinder

barrels are .375-inch longer for better piston support and ring seal. It

comes with a 9.240-inch deck height and 5/8-inch deck thickness. The

siamesed cylinder bores can be opened up to 4.200 inches, allowing for

large-displacement options.

Dart’s

new LS Next block features 4-bolt steel main caps with 7/16-inch bolts

and full main webbing for maximum bottom-end strength. The cylinder

barrels are .375-inch longer for better piston support and ring seal. It

comes with a 9.240-inch deck height and 5/8-inch deck thickness. The

siamesed cylinder bores can be opened up to 4.200 inches, allowing for

large-displacement options.

The block also features blind head bolts: four 7/16-inch head bolts,

one 3/8-inch and one stock-sized inner hole per cylinder to improve

clamp force in power-adder applications. There are provisions for oil

restrictors in the lifter valley to complement the low-volume, priority

main oiling system. LSX-style lifter bosses and dog-bone provisions are

also included with the LS Next block – it will easily accommodate

1.060-inch bushings with .937-inch lifters. The block also features a

Pro Stock/Pro Mod-type big-block style stepped main oil galley. Lastly,

the water jacket around the No. 1 cylinder has been expanded as well as

around the outside of each cylinder barrel for additional cooling

capacity.

Test Engine Specs:

Test Engine Specs:

- Bore: 4.155 inch

- Stroke: 4.00 inch

- Rod Length: 6.125 inch

- Compression Ratio: 12.5:1

- Pistons: Mahle flat top

- Engine Bearings: Clevite

- Camshaft: Mechanical roller 255/265 duration, .670-inch lift

- Rocker: Harland Sharp Roller

- Heads: Dart w/ 2.08-inch I/1.60-inch E

- Intake: Chevy Performance single plane

- Carburetor: Demon 850cfm

- Ignition: HEI, with 30 degrees timing

- Oil Pump: Moroso external, Melling stock replacement

- Oil Pan: Moroso

- Headers: Hedman

Check out this interview with Richard Maskin from the 2012 PRI show as he discusses the LS Next block.

https://www.enginelabs.com/news/darts-ls-next-block-performs-well-in-oil-system-tests/