Solarbayer Wood Gasifier HVS 16 25 40 60 100 Kw Boiler Gasification

for environmentally friendly and CO2-neutral heating systems!

Solarbayer Wood gasification HVS ( EconomicLambda Control )

Environmentally friendly heating with wood

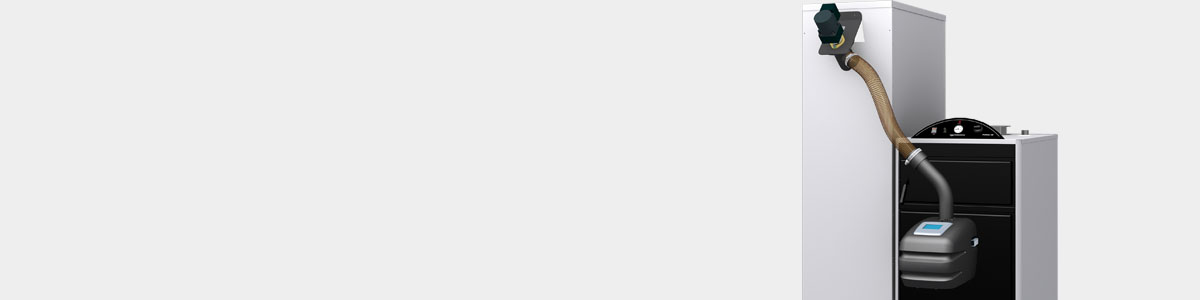

HVS Boilers are available for burning natural, split logs with log lengths of 33, 50, 70 to 100 cm (depending on the size of the boiler), optionally with or without lambda control with a nominal heat output of 16, 25, 40, 60 and 100 kW.

Solarbayer Log wood boiler HVS

With the log boilers from Solarbayer heat in an environmentally friendly, CO2-neutral and ecological way with maximum energy efficiency and an excellent price / performance ratio.

Brief description

- Very good price / performance ratio

- Easy installation and operation

- High efficiency and low exhaust emissions

- Robust and simple construction

- Technology that has proven itself over many years

- Excellent customer service even after the purchase

- Factory commissioning by Solarbayer customer service on request

- BAFA-eligible with up to 45% *

* Please note the BAFA funding criteria.

Product description

Little work from loading to cleaning!

Fill in wood, light and everything else runs automatically. The large filling space of the wood gasification boiler ensures a long burning time. The integrated fan guarantees a problem-free start even when the fireplace is cold. The fire flap and door lock prevent smoke from escaping. In addition, the fan stabilizes the combustion over the entire burning time and enables absolutely problem-free operation. Even our "smallest", the HVS 16 LC, is already excellently suited for heating a single-family home with a low-energy standard. From a boiler size of 25 kW, the large filling door can be used to comfortably heat with half-meter logs, whereby a certain excess length of the logs does not cause any problems due to the depth of the filling chamber. For larger buildings, the wood gasification boilers HVS 60 with 70 cm log length or HVS 100 with meter logs can be filled. The large filling volume results in long refilling intervals. The inside of the filling chamber is provided with a "hot air duct", which increases performance and achieves the best exhaust gas values.

Overview - admissions & funding

| Boiler type | Level 2 (1st BImSch-V.) | BAFA-Eligible |

| HVS 25 E. | ||

| HVS 40 E. | ||

| HVS 60 E | ||

| HVS 100 U | ||

| HVS 16 LC | ||

| HVS 25 LC | ||

| HVS 40 LC | ||

| HVS 60 LC | ||

| HVS 100 LC |

Take advantage of these advantages

- Wood central heating boiler with upper wood gasification and lower burnout

- Solid boiler construction and robot production guarantee a long service life

- Robust construction of the loading chamber

- All parts in contact with fire are made of special 6 mm thick boiler steel

- Consistent and tested boiler technology with innovative developments

- Exhaust gas turbulators for more power and lower exhaust gas temperatures

- Easy to use and easy to clean

- Fuel utilization with the same filling quantity up to 30% more effective than with standard wood boilers

- Modulation combustion, exhaust gas temperature control and optionally with HVS Lambda Control ) ensure compliance with the currently applicable limit values of the Federal Immission Control Ordinance

HVS LC Lambda Control

Combustion-optimized output and combustion control through permanent lambda monitoring (with lambda control)

In the wood gasification boilers of the HVS LC series, a modern and modular control concept with monitoring of the exhaust gas values through the standard built-in lambda probe ensures more output and, at the same time, low, environmentally friendly pollutant emissions. Based on the integrated boiler and flue gas logic, the intelligent control recognizes the power requirement. By means of the modulating air supply, the wood gasification HVS LC can react to excess power and ensure optimal and almost perfect fuel utilization. This offers you the best possible comfort and constant, even combustion for your wood. Optimal system efficiency can only be achieved with a perfect team. We therefore generally recommend our high-performance stratified storage SPS type SPS with a patented built-in stratification system for wood heating systems. The heat produced by the wood boiler can be optimally stored here. The heater then calls up the stored heat as required. This also protects the environment and keeps your fuel consumption as low as possible.

HVS E Economic

Performance-optimized and exhaust gas temperature-based control with system function monitoring (without lambda control)

The wood gasification HVS Economic achieves extremely clean emission values even without lambda control. By using the latest control technology, a product has been created that falls below the strict emissions standards that have already been set. With this boiler series you make the best possible use of the fuel and thus protect our environment. Each of these models is equipped with the electronic combustion control as standard. The permanent monitoring of the flue gas and boiler temperature means optimal comfort for you and constant, even combustion for your wood. The physics of the combustion process was copied from nature and integrated into our wood gasification boiler in an excellent way. The logical interplay of flue gas and boiler temperature rise in certain time sequences is used here to optimize the supply of combustion air.

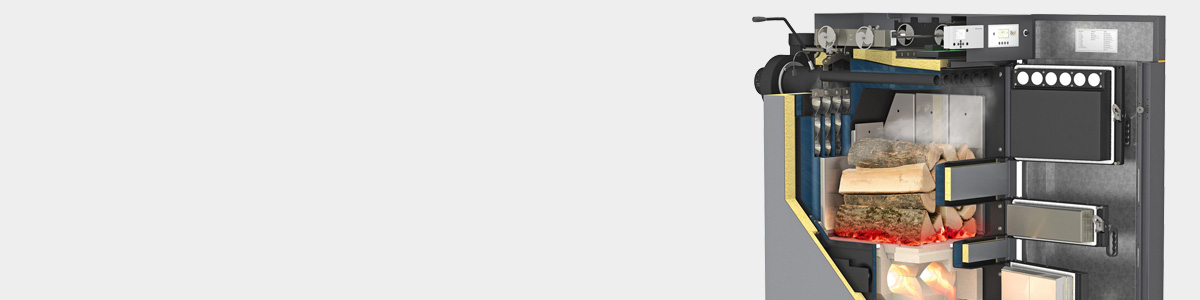

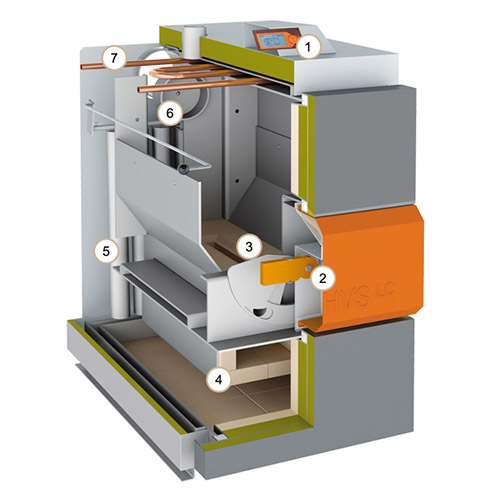

The construction of the Solarbayer wood gasification HVS

-

1. regulationGraphic display with permanent system function display

-

2. Pressure blowerThe amount of air required for optimal combustion is supplied by the standard built-in and continuously regulated pressure fan

-

3. Ceramic nozzle with secondary air ductCreates the optimal gas mixture and ensures a perfect wood gas flame directed downwards

-

4. Slide-in combustion chamberwith high-temperature-resistant fireclay bricks for complete burnout of the wood gases with a minimal amount of ash

-

5. Exhaust gas heat exchanger with turbulatorsFor the best possible transfer of the exhaust gas heat to the heating water

-

6. Heating flap with pull rodPrevents smoke from escaping when adding fuel

-

7. Safety heat exchangerTo cool the boiler down if it overheats

Technical specifications

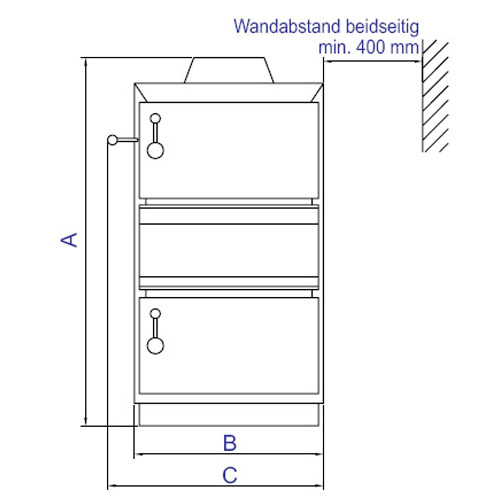

| measurements and weight | Type | 16 LC | 25 E. 25 LC |

40 E. 40 LC |

60 E 60 LC |

100 U 100 LC |

| A height | mm | 1155 | 1155 | 1390 | 1440 | 1440 |

| B width | mm | 590 | 590 | 590 | 760 | 760 |

| C width incl. Slider | mm | 645 | 645 | 645 | 785 | 785 |

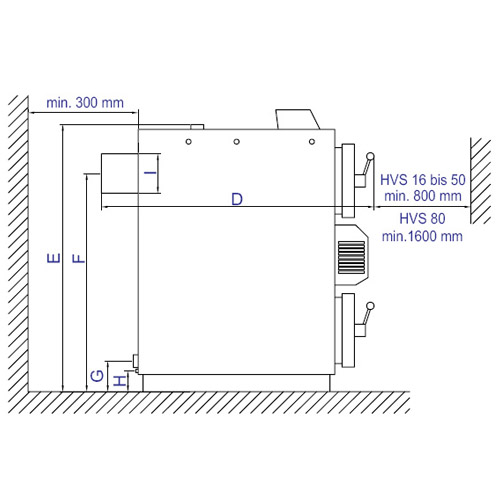

| D depth | mm | 840 | 1070 | 1070 | 1260 | 1650 |

| E Height of advance | mm | 1075 | 1075 | 1310 | 1400 | 1400 |

| F Height of exhaust pipe (center) | mm | 890 | 890 | 1110 | 1170 | 1170 |

| G Height of return | mm | 115 | 115 | 125 | 215 | 215 |

| H Height of emptying | mm | 55 | 55 | 70 | 135 | 135 |

| I Ø exhaust nozzle | mm | 159 | 159 | 196 | 196 | 196 |

| Ø boiler flow / boiler return | Rp | DN 50 (2 ″) | DN 50 (2 ″) | DN 50 (2 ″) | DN 50 (2 ″) | DN 50 (2 ″) |

| Ø Safety heat exchanger | G | DN 20 (¾ ″) | DN 20 (¾ ″) | DN 20 (¾ ″) | DN 20 (¾ ″) | DN 20 (¾ ″) |

| Ø Immersion sleeve for safety heat exchanger | Rp | DN 15 (½ ″) | DN 15 (½ ″) | DN 15 (½ ″) | DN 15 (½ ″) | DN 15 (½ ″) |

| Ø emptying | Rp | DN 15 (½ ″) | DN 15 (½ ″) | DN 15 (½ ″) | DN 20 (¾ ″) | DN 20 (¾ ") |

| Boiler weight | kg | 400 | 440 | 525 | 790 | 990 |

| Specifications | Type | 16 LC | 25 E. 25 LC |

40 E. 40 LC |

60 E 60 LC |

100 U 100 LC |

| Nominal heat output in kW | kW | 16 | 25 | 40 | 60 | 100 |

| Efficiency | % | 92.1 | 91.4 92.6 |

91.8 91.9 |

90.6 92.0 |

91.2 92.8 |

| Energy efficiency class | A + | A + | A + | A + | - | |

| Energy efficiency index EEI | 113 | 114 117 |

113 115 |

113 115 |

- | |

| Annual space heating efficiency | % | 82 | 82 83 |

82 83 |

81 82 |

- |

| Boiler water content | L. | 60 | 75 | 93 | 180 | 215 |

| Max. operating pressure | bar | 3 | 3 | 3 | 3 | 3 |

| Pressure loss at nominal load (Δt 10 K) | mbar | 9.35 | 9.75 | 10.48 | 12.77 | 11.5 |

| Pressure loss at nominal load (Δt 20 K) | mbar | 1.00 | 1.05 | 2.55 | 3.19 | 2.82 |

| Perm. Pressure range safety device | bar | min. 1 to max. 4 | ||||

| Inlet water temperature overflow safety device | ° C | 4 to 15 | ||||

| Opening temperature overflow safety device | ° C | 95 | ||||

| Noise level | dB | 45.0 | 45.5 | 47.7 | 51.4 | 54.2 |

| Filling space / fuel | Type | 16 LC | 25 E. 25 LC |

40 E. 40 LC |

60 E 60 LC |

100 U 100 LC |

| permitted fuel | natural, split logs with residual moisture 16% ± 3% | |||||

| Maximum log length | mm | 330 | 500 | 500 | 700 | 1000 |

| Filling space depth | mm | 370 | 560 | 560 | 750 | 1085 |

| Filling space height | mm | 490 | 490 | 750 | 730 | 730 |

| Filling space width | mm | 440 | 440 | 440 | 575 | 575 |

| Dimensions of the filling opening W / H | mm | 435/255 | 435/255 | 435/255 | 575/318 | 575/318 |

| Combustion chamber content, volume liter approx. | L. | 80 | 116 | 180 | 310 | 455 |

| Max. Filling weight (beech) approx. | kg | 20 | 30 | 48 | 80 | 120 |

| Fuel consumption at nominal load (beech) approx. | kg / h | 4.5 | 7.1 | 11.2 | 17 | 25 |

| Burning time at nominal load (beech) approx. | Hours. | 4.4 | 4.2 | 4.3 | 4.5 | 4.5 |

| Chimney requirements / exhaust gas values | Type | 16 LC | 25 E. 25 LC |

40 E. 40 LC |

60 E 60 LC |

100 U 100 LC |

| Rec. at least Chimney cross section Ø | mm | 140 | 150 | 180 | 180 | 200 |

| Train requirement ± 15% | Pa | -13 ...- 15 | ||||

| Recommended effective chimney height | m | approx. 7 | ||||

| Exhaust gas mass flow | g / s | 10 | 16 | 25 | 38 | 64 |

| Modulating exhaust gas temperature | ° C | approx. 180 (± 30) | ||||

| Flue gas routing to the chimney | m | stretched length <1.5 m (max. 2 arches) | ||||

| Chimney draft regulator | Mandatory accessories (recommendation: ZUK 180) | |||||

| Electrical data | Type | 16 LC | 25 E. 25 LC |

40 E. 40 LC |

60 E 60 LC |

100 U 100 LC |

| Mains voltage / frequency | V / Hz | 230/50 | ||||

| Power consumption standby | W. | <0.3 | ||||

| Power consumption operation [ HVS E / HVS LC] | W. | 55 | 40/55 | 40/55 | 80/95 | 80/95 |

| Hydraulics | Type | 16 LC | 25 E. 25 LC |

40 E. 40 LC |

60 E 60 LC |

100 U 100 LC |

| Rec. Minimum buffer volume1) | l | 1000 | 1500 | 2200 | 3300 | 5500 |

| Manufacturer recommendation 1) | l | 1500 | 2000 | 3000 | 5000 | 6000 |

| Minimum pipe dimensioning (CU / precision steel pipe) Ø2) | mm | 28 | 28 | 35 | 42 | 54 |

| Minimum pipe dimensioning (steel pipe) 2) | DN 25 (1 ″) | DN 25 (1 ″) | DN 32 (1¼ ″) | DN 40 (1½ ″) | DN 50 (2 ″) | |

| Minimum boiler return temperature (target: boiler flow temp. 80 ° C) | ° C | 70 | 70 | 67 | 65 | 63 |

The pipe dimensions mentioned here are only intended as a suggestion and do not replace technical planning.

Emission values according to the test report based on dry exhaust gas and 13% by volume of oxygen;

Product information in accordance with the requirements of Regulation (EU) 2015/1189 regarding energy consumption labeling of solid fuel boilers

To 01. January 2020, BAFA significantly increased the subsidies for heating with renewable energies (solar thermal, biomass and heat pumps). The grants are no longer granted as a fixed amount subsidy, but as a share financing (percentage subsidy) on the basis of the eligible investment costs, so that the acquisition costs, assembly costs and many other costs can be recognized from now on. Further details on the eligible costs are available on request.

The funding overview from 01.01.2020

Here we give you a brief overview of the possible subsidies (investment grants) from BAFA:

The funding rate for a biomass system (wood, pellet or wood chip boiler) or heat pump system is

-

- in the building stock: 35% (1)

- in the building stock with exchange bonus (*) of the old oil heating: 45% (1)

- in new buildings: 35% (1)

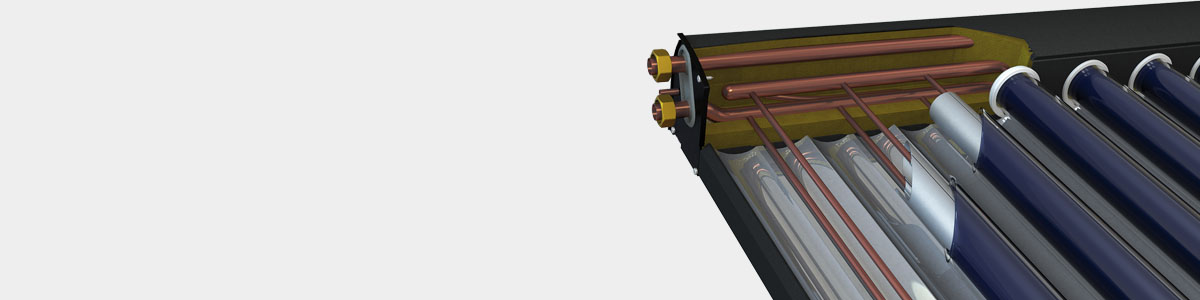

The funding rate for a solar collector system / solar thermal system (2) amounts to

-

- in the building stock: 30% (1)

- in new buildings: 30% (1)

The subsidy rate for a renewable energy hybrid heating system (EE hybrid) (3) amounts to

-

- in the building stock: 35% (1)

- in the building stock with exchange bonus (*) of the old oil heating: 45% (1)

- in new buildings: 35% (1)

The subsidy rate for a gas condensing boiler combined with renewable heat generation (gas hybrid heating) is

-

- in the building stock: 30% (5)

- in the building stock with exchange bonus (*) of the old oil heating: 40% (5)

DANGER

Better act now before it's too late!Because if your old boiler is affected by the obligation to replace it, funding can no longer be applied for!

If you have any questions, please contact us!

(*) The exchange bonus is only possible if there is no legal obligation to exchange the old oil boiler!1) The funding rates refer to the eligible costs for the requested measure

2) Since a solar collector system can never carry the entire heating load of a building on its own, no exchange bonus is granted here.

3) Combination of a biomass, heat pump and / or solar collector system

4) Renewable Ready: A gas condensing boiler with storage and control and regulation technology is installed for the subsequent integration of a renewable heat generator.

5) Applies to the entire eligible system, incl. renewable heat generator. Status: 17. January 2020 - Please note the BAFA funding requirements, further information can be found at bafa.de - Subject to technical changes and errors.

Please send us a copy of your letterhead and a copy of your business registration. After checking your data, you will receive your access data for the specialist area as well as a complete product folder with a net purchase price list for resellers.

The headquarters of Solarbayer GmbH is located in the Eichstätt district in the region north of Ingolstadt in the heart of Bavaria. In the exhibition rooms, you can use cutaway models to gain an insight into the sophisticated technology. Storage tanks, wood boilers, etc. are located on over 12,000 m² of storage space. Our own design office with development department, as well as state-of-the-art production facilities at various locations in Europe, guarantee the highest quality.

If you have some time to spare, just drop by us. Of course we look forward to your visit at any time.

| Parcel costs Germany |

Price € (1 package) |

| Parcel up to 30 kg (parcel dimensions max. 60 x 60 x 120 cm) | 8.50 |

| Bulky goods up to 30 kg (package dimensions over 60 x 60 x 120 cm) | 28.00 |

| Freight costs Germany (within mainland Germany) |

Price € (1 pallet) |

Price € (2 pallets) |

| Storage 100 to 1000 liters | 83.00 | 120.00 |

| Storage 1250 to 1500 liters | 107.00 | 185.00 |

| Storage 2200 to 2500 liters | 155.00 | 250.00 |

| Storage 3000 to 5000 liters | 240.00 | 430.00 |

| Wood boilers / pellet boilers up to 45 kW | 120.00 | 185.00 |

| Wood boilers / pellet boilers over 45 kW | 170.00 | 240.00 |

| Heat pump | 145.00 | 215.00 |

| Collector pallet (solar package) | 145.00 | 215.00 |

| Small pallet | 50.00 | 72.00 |

| Betriebsform | Holzvergaser |

| Marke | Solarbayer |

| Hersteller | Solarbayer |

| Energieeffizienzklasse | A+ |

| Herstellernummer | nicht zutreffend |

| Typ | Kessel |