CLEAR LIQUID RESIN-HIGH PERFORMANCE

Epoxy Resin System

24 Fluid Ounces Combined Volume

16 Ounces of MAX CLR-HP PART A

AND

8 OUNCES of MAX CLR-HP PART B

PRODUCT DESCRIPTION

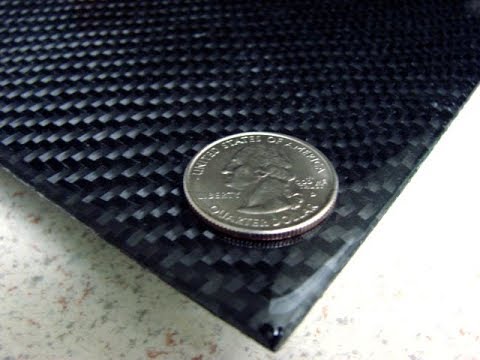

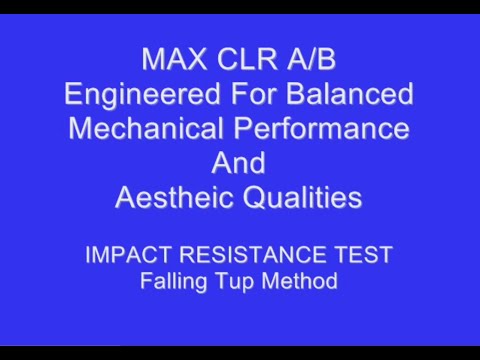

MAX CLR-HP A/B is a two-part epoxy-based system specially formulated as a High-Performance version of the MAX CLR resin system. It offers higher mechanical performance while maintaining crystal clarity, gloss, and other aesthetic qualities. MAX CLR-HP provides excellent performance at wider service temperature range, especially its retention of its mechanical hardness at elevated temperatures as well its durability when exposed to below freezing temperatures. It's none blushing performance, high gloss finish, excellent transparent clarity, color stability and ease of use make MAX CLR-HP an excellent choice as an impregnating resin for composite fabrics, protective coatings, casting resin and general fabricating applications.

MAX CLR-HP also offers high chemical resistance, structural adhesion and overall durability suitable for many protective coatings applications. MAX CLR-HP A/B performs well at room temperature use and can withstand cyclic exposure to temperatures from -40°C to 112°C with minimal loss of mechanical performance.

MAX CLR-HP A/B can be used as a transparent adhesive for bonding a variety of substrates such as composite materials, concrete and ceramic products, plastics, wood, glass, steel, aluminium and most soft metals used in jewelry applications. Upon Cure, MAX CLR-HP A/B resists extreme and repeated thermal shocks making it well suited for bonding substrates with dissimilar expansion coefficients.

MAX CLR-HP A/B is 100% solids.

It does not contain Ozone Depleting Chemicals (ODC), non-reactive plasticizers or solvent fillers.

IMPORTANT GUIDELINES FOR FOOD SAFE COATINGS APPLICATIONS

MAX CLR-HP A/B is thermoset polymer resin that cures crystal clear and demonstrates high chemical resistance to acidic and basic compounds. It is resistant to dilute grain alcohol and can withstand brief contact with hot fluids (up to 187 °F) such as coffee, tea, and soups.

The primary purpose of the MAX CLR-HP resin system is to facilitate a sanitizable coating that demonstrates low extractable of its chemical constituents during direct food contact. Equally, the objective goal of the cured coating is to create a durable barrier when applied onto a porous substrate (such as wood) that prevents absorption of fluids or organic compounds that allows bacterial colonization or microbial growth.

All components used to formulate the MAX CLR-HP resin system are listed in the Code of Federal Regulations, Title 21, Part 175 for resinous coatings/adhesive subject to direct and indirect food contact.

For Coatings Applications

https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=175.300

For Adhesives Application

https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=175.105

IMPORTANT GUIDELINES FOR FOOD CONTACT APPLICATIONS

For food contact applications, MAX CLR-HP A/B must be fully cured to ensure no chemical leaching can occur when foodstuffs come in contact with the cured resin system. Any uncured chemical compounds caused by improperly prepared MAX CLR-HP A/B may be extracted and cause cross-contamination or leaching during food contact. Please review the following and to avoid any curing problems.

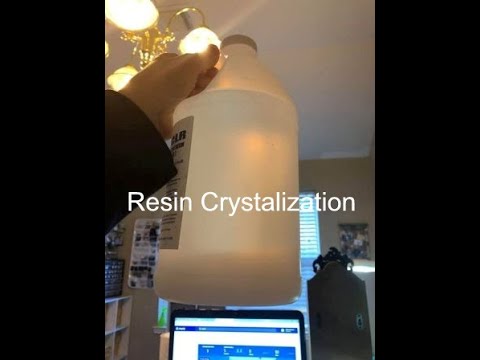

COLD TEMPERATURE CRYSTALLIZATION

The high purity nature of the resin formulation makes it prone to crystallizing when exposed to temperatures below 57 °F. During the colder season, the PART A resin component may crystallize during shipping. It can also occur after the container has been stored in an uncontrolled environment. Crystallized resin appears as an opaque white mass on the bottom of the bottle.

PROCESSING CRYSTALLIZED RESIN

With the cap securely in place, place the PART A container in a hot water bath (160°F) until the contents are revert back to its liquid state and optically transparent. Cool the PART A bottle to 75 def F and the mix the proper amount of PART B curing agent.

EPOXY RESIN CRYSTALLIZATION - Solidified Epoxy Resin Processing

Video will open in a new window

Using the eBay App? Paste link into a browser window:

STORAGE

Secure caps for both bottles and store above 65°F minimum temperature to prevent re-crystallization.

The resin system will remain viable for at least 12 months or longer.

USE AND APPLICATION

Precondition both bottles to 75°F and measure the components accurately at a 2:1 mix ratio; 100 parts resin to 50 parts curing agent. The use of a weighing scale is recommended over volumetric measuring. Any off-ratio excess of either the resin or curing agent can cause poor cure results and cause excessive chemical leaching that can transfer to the food or beverage.

The substrate must be suitable and prepared for the intended purpose of the application. Remove any contaminants that may interfere with the complete cure of the MAX CLR-HP A/B resin system. Exclude the use of materials and components not suitable for food contact (lead-based pigments, harsh cleaners and unsanitary conditions).

CURING PROCEDURE

Allow the applied resin to fully cure for a minimum of 48 hours at 75°F before exposing the coating to any foodstuffs. A short heat post-cure at 150°F for 60 to 90 minutes will ensure the resin is fully cured. Rinse the cured coating with warm water and mild detergent before allowing any food contact.

PRACTICAL GUIDE ON HOW TO USE THIS RESIN SYSTEM

Review All Published Data Regarding This Product.

Proper Usage Data And Other Detailed Information Are Posted At This Page.

Mix the Resin And Curing Agent Only After The Surface Is Prepared For Application.

STEP 1. SURFACE PREPARATION

The quality of adhesion of any coating or adhesive application is dependent on how well the surface is prepared. The resin system must be able to properly 'wet-out' the surface to form a continuous film. Surfaces demonstrating poor wettability prevents the liquid resin from forming a cohesive bond. Improper surface wetting yields poor adhesion and will delaminate during use.

Wetting is the ability of a liquid to interfaces or wet-out a solid surface; its dynamics is expressed as surface tension. A surface that demonstrates low surface tension, such as waxed surface, oily surface or slick plastics like Teflon will prevent the liquid resin to wet-out and cause poor adhesion.

In the same respect, if the surface is coated from a previous application, the epoxy adhesion is limited to adhesion quality of the primary coating is applied over. Make sure to remove any loose or peeling old coating before application to avoid delamination. If possible remove the old coating by mechanical sanding or power washing so the applied epoxy is in direct contact with the base substrate. Applying a coating over oil-based stain should be avoided.

|

METALS AND CONCRETE Degrease Metals– Wipe surface with lint-free rag dampened with Methyl Ethyl Ketone (MEK) or acetone to remove all oil, dirt, and grease. Etch Metals – For optimum results, metal parts should be immersed in a chromic acid bath solution consisting of:

The solution is held at 160°F (71°C), and the parts left immersed for 5 to 7 minutes. Rinse – remove metal parts from etching bath and rinse with clean water. (distilled water is recommended). Etch Concrete- Use commercially sold concrete etching solution (hydrochloric acid based works best). Neutralized per instructions, rinse and allow to dry thoroughly. ALTERNATE PROCEDURE Degrease and dry – Degrease the surface as noted above, sand or sandblast the surface lightly but thoroughly. Rinse with acetone or Methyl Ethyl Ketone (MEK), and dry.

|

GLASS Degrease – With MEK as above, or with a strong boiling solution of a good grade household detergent. Etch – For optimum results, degreasing can be followed by the chromic acid bath outlined above.

WOOD

Sand – Bonding surfaces should be sanded lightly, but thoroughly to remove all external contamination. Clean – Carefully remove all dust, or particles of wood from sanded areas. A stiff and clean brush or compressed air can be used.

PLASTIC Clean – Remove all dirt, oil, or other surfaces contaminated with detergent soap or degreasing solvent and water, followed by thorough rinsing and drying. A solvent that does not have a detrimental effect may also be used. Sand – Surfaces to be bonded should be sanded lightly, but thoroughly to remove surface sheen. Clean – Carefully remove all dust or particles of plastic from the sanded area. A clean brush, lint-free cloth, or compressed air may be used. |

STEP 2. CHECK THE PART A OR RESIN BOTTLE FOR CRYSTALLIZATION

During the winter months, the PART A or RESIN component may crystallize and cause poor cure performance. Our MAX Epoxy Resins are formulated with high purity grade resin polymers which makes it prone to crystallization when exposed to temperatures below 57°F. Crystallization can also occur after the resin has been stored over a period. It will appear as a waxy white mass at the bottom of the bottle. The PART A or RESIN component must be in its liquid form to thoroughly mix with the PART B or curing agent to achieve full cure.DO NOT USE UNLESS PROCESSEDView the following video for identification and processing.

STEP 3. DETERMINE THE AMOUNT THE BATCH SIZE NEEDEDBlending amounts greater than 1000.0 grams or 1 quart in volume requires careful mixing and ensuring the mixed resin is applied and used within the established working time to prevent exothermic "run-away" reaction. Do not let the mixed resin to sit in mass greater than 10 minutes. The heat generated during polymerization will accelerate the chemical reaction and cause a 'run-away' reaction to occur that can generate temperatures above 300°F when allowed to react in mass. Mix the proper amount of resin and curing agent and apply within 10-15 minutes to avoid this from occurring.

Calculate the amount to be mixed by measuring the length x width x thickness of the area to be coated to obtain the cubic volume of the resin needed. Use These Factors To Convert Gallon Needed Into Volumetric Or Weight Measurements.

Fluid Gallon To Volume Conversion

1 Gallon = 231 Cubic Inches

1 Gallon = 128 Ounces

1 Gallon = 3.7854 Liters

1 Gallon = 4 Quarts

1 Gallon = 16 Cups

Fluid Gallon Mass Conversions

1 Gallon Of Mixed Unfilled Epoxy Resin = 9.23 Pounds

1 Gallon Of Mixed Unfilled Epoxy Resin = 4195 Grams

Applying the MAX CLR-HP A/B on a porous surface, such bare wood, take into account that the coating will be absorbed.

Mix a batch of the MAX CLR-HP A/B and apply it onto the bare wood, and allow to cure until it has set dry to the touch. This will seal the surface porosity as well as prevent air bubbles from outgassing and minimize entrapped air bubbles.

Allow to cure for 16 hours and lightly sand the surface to remove 'grain-raising'.

Clean off the surface to remove sanding debris and the surface is ready for the next coating application.

The coating thickness is a big factor that dictates resin coverage.

For protective coatings, a minimum coating thickness of 0.010-inch or 10 mils is recommended.

Thicker coating thickness up to 0.500 mils or 1/2 inch per can be applied, however consider the exothermic heat the resin produces when cured in a concentrated mass.

The larger the mass the higher the exothermic temperature is generatedTo calculate coating thickness of 0.010-inch or 10 mils is recommended

Calculation: 1608 / 10 = 160.8 Square Feet 1 Gallon Coverage

For high-build or thick casting of 1/2 inch (500.0 mils)Calculation: 1608 / 500 = 3.21 Square Feet 1 Gallon Coverage

STEP 4. MIXING PROCEDURE

Click Window To Watch Video Demonstration

How To Mix Epoxy Resin For Food Contact Coating. Avoid Tacky Spots, Minimize Air Bubble When Mixing - YouTube

Video will open in a new window

Using the eBay App? Paste link into a browser window:

Click Window To Watch Video Demonstration

STEP 5. APPLICATION DEMONSTRATIONS

Condition the ambient temperature to 75°F for best results. Ensure that the work area is dust free and well ventilated. MAX CLR-HP A/B is self-levelling and will continue to flow until it polymerization converts it to a solid phase. It can be applied by using a bristle or high-density foam brush/roller or poured into place. MAX CLR-HP A/B is self levelling, ensure the surface is level and secure any leaks by using tape to create a temporary patch and prevent leakage.

Multiple Pour Or Layering For Thick Coat Application

Click Window To Watch Video Demonstration

AIR BUBBLE REMOVAL TECHNIQUE

Click Window To Watch Video Demonstration

STEP 6. CURING

To achieve the best cure results, the ambient condition should be between 75°F to 85°F and the relative humidity is below 80%. The colder the temperature the longer takes to fully cure. Use an infrared lamp to warm the ambient temperature. Infrared lamps also work well for warming large work areas.

Post Curing at 150°F for 2 hours will accelerate full curing.

Rinse the surface with warm water and mild detergent before use.

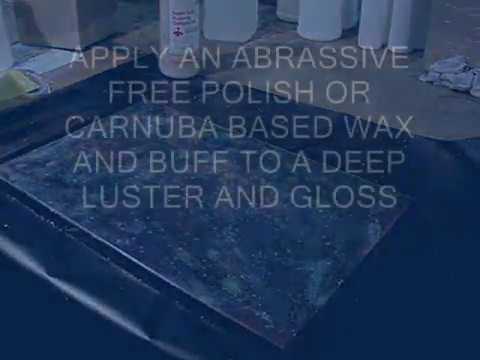

CUTTING AND POLISHING

Allow to fully cure for 48 hours before polishing or machining. MAX CLR-HP A/B can be cut, ground or CNC or lathe machined to shape. Polishing improves scratch resistance. The transparency is also restored after machining by wet sanding and then polish with abrasive free wax or polish.

Click On The Picture To View Test Video. The Video Will Open In A New Window

POLISHINGClick On The Picture To View Test Video. The Video Will Open In A New Window

DEGLOSSING

Once the

MAX CLR-HP A/Bfully cures, deglossing the surface to create a satin finish can be easily done using an abrasive pad. In this demonstration, a SCOTCHBRITE pad was used to de-gloss the surface. Note the dramatic decrease in gloss after a light polishing with the abrasive pad. Very-fine sandpaper (wet-sanding) also works well.

PHYSICAL AND MECHANICAL PROPERTIES

|

Viscosity Density Form and Color |

800 – 1,200 cPS @ 25°C Mixed 1.10 g/cc Clear Transparent Liquid |

|

Mix Ratio |

100 Parts to 50 Parts A By Weight or by Volume |

|

Working Time |

45 Minutes @25°C (77°F 100-gram mass) |

|

Peak Exotherm |

70°C (158°F, 100-gram mass) |

|

Handle Time Full Cure Time |

5.5 Hours 36 Hours minimum @ 25°C (75°F) |

|

Hardness |

72± 5 Shore |

|

Tee-Peel Strength |

5.7 Lbs per inch Width |

|

Tensile Shear Strength |

1,300 psi @ 25°C (77°F) |

|

|

800 psi @ -80°C (-112°F) |

|

|

550 psi @ 100°C (212°F) |

|

Elongation |

9.0% @ 25°C (77°F) |

|

Compressive Strength |

2,200 psi |

|

Heat Distortion Temp |

80°C (176°F) |

|

PHYSICAL PROPERTIES AND MECHANICAL PROPERTIES |

|

Density |

1.10 G/CC |

|

Form and Color |

Clear Liquid |

|

Viscosity |

2,800 – 3,200 cPs @ 25ºC Mixed |

|

Mix Ratio |

50 Parts “B” to 100 Parts “A” By Weight |

|

Working Time |

45 – 50 Minutes @ 25ºC (100 Gram Mass) |

|

Peak Exotherm |

70ºC (100 Gram Mass) |

|

Thin Film Set Time (Dry to the Touch) |

4 to 6 Hours |

|

Handle Time (Green Strength) |

8 Hours |

|

Full Cure Time |

5 to 7 days @ 25ºC |

| Accelerated Cure Time | 8 hours at 25ºC plus 1 hour at 100ºC |

|

Hardness |

80 ± 5 Shore D@ 25ºC |

|

Tee-Peel Strength |

5.7 Lbs. per inch Width @ 25ºC |

| Tensile Shear Strength | 8412 psi - 58 MPa @ 25ºC |

| Tensile Modulus | 348,000 psi - 2.4 GPa @ 25ºC |

| Compressive Strength | 8992 psi- 62 MPa @ 25ºC |

| Compressive Modulus | 203,053 - 1.4 GPa @ 25ºC |

|

Elongation |

3.0% @ 25ºC |

|

Flexural Strength |

12,100 psi - 84 MPa @ 25ºC |

|

Flexural Modulus |

406,000 psi- GPa @ 25ºC |

|

Heat Deflection Temp. |

90ºC |

CHEMICAL RESISTANCE PERFORMANCE

FULL IMMERSION at 30°C MEASURED PERCENT CHANGE IN WEIGHT

SPECIMEN CURE CYCLE 7 days @ 25ºC plus 1 hour at 100ºC -1 CUBIC INCH SPECIMEN SIZE

|

REAGENT |

3 days |

28 days |

|

Deionized Water |

0.09 |

.10 |

|

Sea Water |

0.11 |

0.11 |

|

Methanol |

7.93 |

-2.41 |

|

Ethanol 50% |

1.98 |

2.18 |

|

Toluene |

0.40 |

2.86 |

|

Xylene |

0.04 |

0.05 |

|

Butyl Cellosolve |

16.63 |

5.31 |

|

MEK |

Destroyed |

Destroyed |

|

10% Lactic Acid |

1.81 |

5.42 |

|

10% Acetic Acid |

0.11 |

0.45 |

|

70% Sulfuric Acid |

0.08 |

0.14 |

|

50% Sodium Hydroxide |

0 |

0 |

|

10% Sodium Hypochlorite |

0.51 |

1.36 |

IMPACT RESISTANCE OF MAX CLR-HP A/B

IMPORTANT NOTICE

The user should thoroughly test any proposed use of this product and independently conclude the satisfactory performance in the application. Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval.

The information contained herein is based on data believed to be accurate at the time of publication. Data and parameters cited have been obtained through published information, PolymerProducts and Polymer Composites Inc. laboratories using materials under controlled conditions. Data of this type should not be used for a specification for fabrication and design. It is the user's responsibility to determine this Composites fitness for use.

There is no warranty of merchantability for fitness of use, nor any other express implied warranty. The user's exclusive remedy and the manufacturer's liability are limited to refund of the purchase price or replacement of the product within the agreed warranty period. PolymerProducts and its direct representative will not be liable for incidental or consequential damages of any kind. Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether there is any infringement of patents is the sole liability of the user.