TYPICAL USE AND APPLICATION

Wood Coating And Clear Sealer

Kayak, Canoe Stitch And Glue

Craft Decoupage Resin

Decorative And Protective Coating

Plaque Coatings

Clear Castings

Chemical Resistant Coatings

Constructed Using MAX CLR HP A/B

As A Wood Sealer And Fiberglass Impregnating Resin For Kayak And Canoes

5 Yards Of 7781 Fiberglass For This Resin System

https://www.ebay.com/itm/223508087559

AVAILABLE FIBERGLASS, CARBON FIBER, AND KEVLAR FABRICS

HEXCEL 120 1.5-OUNCE FIBERGLASS PLAIN WEAVE 5 YARDS | |

HEXCEL 120 1.5-OUNCE FIBERGLASS PLAIN WEAVE 10 YARDS | |

HEXCEL 7532 7-OUNCE FIBERGLASS PLAIN WEAVE 5 YARDS | |

STYLE 7500 10-OUNCE PLAIN WEAVE 5 YARDS | https://www.ebay.com/itm/223495621157 |

STYLE 7500 10-OUNCE PLAIN WEAVE 10 YARDS | |

Hexcel STYLE 3743 9-OUNCE 4 HARNESS SATIN WEAVE 5 YARDS | |

HEXCEL 1584 26 OUNCE FIBERGLASS SATIN WEAVE 3 YARDS | https://www.ebay.com/itm/311947365010 |

HEXCEL 1584 26 OUNCE FIBERGLASS SATIN WEAVE 5 YARDS | |

CARBON FIBER FABRIC 3K 2x2 TWILL WEAVE 6 OZ. 3 YARDS | |

CARBON FIBER FABRIC 3K PLAIN WEAVE 6 OZ 3 YARDS | |

|

|

KEVLAR 49 HEXCEL 351 PLAIN WEAVE FABRIC 2.2 OZ |

MAX CLR-HP A/B is an excellent resin system application where color stability and water clarity is crucial.

MAX CLR-HP COMPARED TO COMPETITIVE EPOXY SYSTEM CLAIMING CRYSTAL CLARITY

To Determine Coverage Or Amount Of Resin Needed Based On Area, Use This App To Calculate The Amount Needed

https://instacalc.com/35245/embed

Cut And Paste Link This Link:

Fluid Gallon Volume Conversion

1 Gallon = 3.7854 Liters

1 Gallon = 16 Cups

Fluid Gallon Mass Conventions

1 Gallon Of Mixed Unfilled Epoxy Resin = 9.23 Pounds

1 Gallon Of Mixed Unfilled Epoxy Resin = 4195 Grams

1 Gallon = 231 Cubic Inches

Typical Gallon Coverage

1 Gallon Of Resin Can Covers 1608 Square Feet

1 Mil Or 0.001 Inch Cured Coating Thickness

PHYSICAL PROPERTIES AND MECHANICAL PROPERTIES |

Density | 1.10 G/CC |

Form and Color | Clear Liquid |

Viscosity | 2,800 – 3,200 cPs @ 25ºC Mixed |

Mix Ratio | 50 Parts “B” to 100 Parts “A” By Weight |

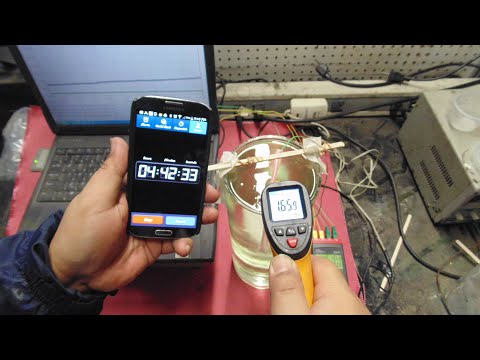

Working Time | 45 – 50 Minutes @ 25ºC (100 Gram Mass) |

Peak Exotherm | 70ºC (100 Gram Mass) |

Thin Film Set Time | 4 to 6 Hours |

Handle Time | 8 Hours |

Cure Time | 2 to 7 days @ 25ºC or 8 hours at room temperature plus 1 hours at 100ºC |

Hardness | 80 ± 5 Shore D, |

Tee-Peel Strength | 5.7 Lbs. per inch Width |

Tensile Shear Strength | 2,935 psi @ 25ºC |

1,970 psi @ -40ºC | |

1250 psi @ 100ºC | |

Elongation | 3.0% @ 25ºC |

Flexural Strength | 13,000 psi |

Flexural Modulus | 344,000 psi |

Heat Deflection Temp. | 110ºC |

CHEMICAL RESISTANCE PERFORMANCE

FULL IMMERSION at 30°C

MEASURED PERCENT CHANGE IN WEIGHT

REAGENT | 3 days | 28 days |

Deionized Water | 0.09% | .13% |

Sea Water | 0.11% | 0.18% |

Ethanol Grain Alcohol 80% | 0.63% | .61% |

Methanol | 3.98% | 10.28% |

Ammonia Quaternary Solution | 0.40% | 0.46% |

Xylene | 0.54% | 0.55% |

Butyl Cellosolve | 16.63% | 18.31% |

MEK | Destroyed | Destroyed |

10% Lactic Acid | 1.81% | 2.12% |

10% Acetic Acid | 0.11% | 0.15% |

70% Sulfuric Acid | 0.08% | 0.14% |

50% Sodium Hydroxide | 0.12% | 0.12% |

Sodium Hypochlorite -Bleach | 0.51% | 1.36% |

SPECIMEN CURE CYCLE 7 DAYS @ 25ºC PLUS 1 HOUR POST CURE @100ºC

1 CUBIC INCH SPECIMEN SIZE

IMPACT RESISTANCE OF MAX CLR-HP A/B

Epoxy based polymers are one of the most versatile thermoset resins that can be modified into a multitude of applications and fit a very specific task as demanded by the application. It offers ease of use and generally safer to handle over other types of thermoset resins which make it the choice material for many high-performance composites.

MECHANICAL PERFORMANCE TEST

Impact testing is one of the most revealing test methods that demonstrate a material's ability to resist and withstand a high-rate of pressure loading, its behavior during and after the impact can define its maximum mechanical property and conditional limits upon its destruction.

Why is Impact Testing Important?

The impact resistance of an object provides the ultimate measure of its resistance to its definitive destruction. Governed by the many laws and dynamics of physics, a skilled chemist or materials engineer can determine the design equilibrium and ultimate performance by careful analysis of the material’s disassociation and the manner of its destruction.

With this knowledge, other aspects of mechanical performance can be accurately derived and through skillful engineering, one can determine:

- The impact energies the part can be expected to see in its lifetime

- The type of impact that will deliver that energy, and then

- A material that will resist such assaults over the projected lifespan.

To Determine Coverage Or Amount Of Resin Needed Based On Area, Use This App To Calculate The Amount Needed

Cut And Paste Link This Link: instacalc.com/35245

MIXING TECHNIQUE OF EPOXY RESINS

MAX CLR-HP A/B FOR COATINGS APPLICATION

Prepare the surface to be coated or sealed by degreasing and removing any surface contaminants.

If coating a wood substrate as a base, pre-seal the wood with MAX CLR HP and dilute with 5% acetone or MEK by volume. This will create a low viscosity penetrating sealant to lock any grain raising. Allow curing overnight.

Upon cure, lightly sand the surface to remove any raised wood grain, sand off just enough to remove any gloss and then clean with a tack rag.

Repeat if necessary until a smooth surface is achieved. If embedding pictures or other items onto the tabletop, plaques or decoupage projects, secure the items using the MAX CLR-HP as an adhesive and allow to set-up before coating.

Pour the mixed MAX CLR HP into another container and mix for another minute (this ensures that no tacky spots caused by unmixed material will be applied) and pour or brush or foam roller (use foam roller for a lint-free application) coat apply onto the substrate to be sealed.

Allow the coating to flow out evenly and protect the surface from airborne dust and debris until it has set-up. If a thicker coating is desired, allow to set-up for at least 6 hours before applying subsequent coats. To remove stubborn surface bubbles, pass a flame from a propane torch over the surface very, very quickly and the air bubbles will pop. Allow the completed coating to cure for at least 24 hours before handling.

Optional step for a super high gloss finish

Upon full cure of the coating, lightly wet sand the surface using an 1800-grit, then a 2000 grit or finer polishing or rubbing compound and apply durable car polish.

MAX CLR-HP A/B FOR CASTING

Clean the mold and apply a good quality release agent such as wax mold release or PVA mold release.

Slowly pour the mixed MAX CLR HP into the on the corner of the mold cavity and allow the resin to fill the cavity allowing the entrapped air bubbles to rise to the surface.

Remove any surface air bubbles using the torch technique described above.

Allow curing at room temperature for 24 to 36 hours.

To use MAX CLR-HP A/B As An Electrical Potting Compound

Place the circuit board in the casing or cavity and secure all wiring leads to its desired position.

Pour the mixed MAX CLR-HP into one corner of the cavity and fill to the desired level. By pouring or filling the resin from the corner of the electronic casing any air voids is pushed away and reduce the possibility of "high-pots" that is caused by voids in the potting compound.

Cure at room temperature for at least 24 hours before putting in service.

Thick Casting Applications

Multi-Stage Pour 6-Inches Tall, 6-Inches Diameter

Total Mass Of 1200 Grams Mixed Resin Divided Into 3 Staged Pour

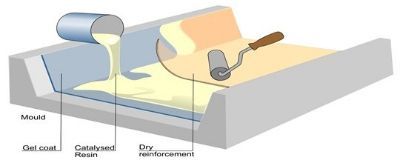

By resolute definition, a fabricated COMPOSITE material is a manufactured collection of two or more ingredients or products intentionally combined to form a new homogeneous material that is defined by its performance that should uniquely greater than the sum of its individual parts. This method is also defined as a SYNERGISTIC COMPOSITION.

COMPOSITE MATERIAL COMPOSITION

REINFORCING FABRIC & IMPREGNATING RESIN

'ENGINEERED PROCESS'

EQUALS

COMPOSITE LAMINATE WITH THE BEST WEIGHT TO STRENGTH PERFORMANCE

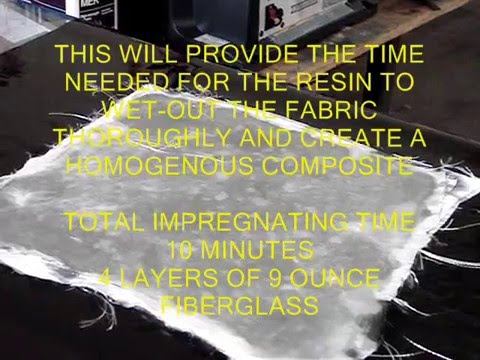

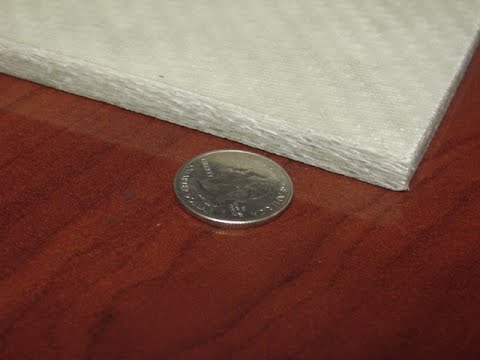

Note The Uniformity Between The Impregnating Resin And Fiberglass Fabric Making A Transparent Laminate

With respect to the raw materials selection -fabric and resin, the fabricating process and the and curing and test validation of composite part, these aspects must be carefully considered and in the engineering phase of the composite.

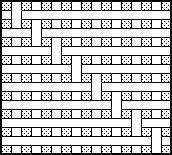

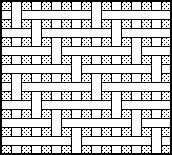

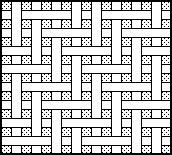

TYPES OF FABRIC WEAVE STYLE AND SURFACE FINISHING

FOR RESIN TYPE COMPATIBILITY

Fabrics are generally considered ”balanced” if the breaking strength is within 15% warp to fill and are best in bias applications on lightweight structures.

“Unbalanced” fabrics are excellent when a greater load is required one direction and a lesser load in the perpendicular direction.

- Tow: The bundle of individual carbon filaments used to weave carbon fabric. 50k tow means there are 48-50,000 carbon filaments in the tow. Smaller tow i.e. 12k, 6k, 3k and 1k are obtained by dividing the 50k tow into smaller bundles.

- Thread Count: The number of threads (tow in carbon and yarn in Aramid) per inch. The first number will be the warp count and the second will be the fill count.

- Fill: The threads that run the width of the roll or bolt and perpendicular to the warp threads.

- Warp: The threads that run the length of the roll or bolt and perpendicular to the fill threads.

- Finish: The chemical treatment to fiberglass making it compatible with resin systems, therefore improving the bond between the fiber and the resin. Finishing fiberglass typically decreases the fiber strength by as much as 50%. Both Silane and Volan finishes are epoxy compatible. Historically, Volan has been considered a softer finish for a more pliable fabric, but recent advances have yielded some excellent soft Silane finishes.

- Thickness: Measured in fractions of an inch. The thicker the fabric the more resin required to fill the weave to obtain a surface-smooth finished part.

Weaves:

- Plain weave means the warp and fill threads cross alternately. This is the most common weave.

- 4 Harness (4 HS Satin or crowfoot) weave means the fill thread floats over three warp threads, then under one warp thread. This weave is more pliable than the plain weave, therefore conforms to complex curves more easily.

- 8 Harness (8 HS Satin) weave means the fill thread floats over seven warp threads, then under one warp thread. This weave is the most pliable of the standard fiberglass weaves.

- 2 x 2 Twill weave means the fill thread floats over two warp threads, then fewer than two warp threads. This weave is found most commonly in carbon fabrics and is more pliable than plain weave.

Most fabrics are stronger in the warp than the fill because higher tension is placed on the warp fiber keeping it straighter during the weaving process. Rare exceptions occur when a larger, therefore stronger thread is used in the fill direction than the warp direction.

All of our fiberglass fabrics is woven By HEXCEL COMPOSITES, a leading manufacturer of composite materials engineered for high-performance applications in marine, aerospace for commercial and military, automotive, sporting goods and other application-critical performance. These fabrics are 100% epoxy-compatible and will yield the best mechanical properties when properly fabricated.

AVAILABLE FIBERGLASS, CARBON FIBER, AND KEVLAR FABRICS

HEXCEL 120 1.5-OUNCE FIBERGLASS PLAIN WEAVE 5 YARDS | |

HEXCEL 120 1.5-OUNCE FIBERGLASS PLAIN WEAVE 10 YARDS | |

HEXCEL 7532 7-OUNCE FIBERGLASS PLAIN WEAVE 5 YARDS | |

FIBERGLASS 45+/45- DOUBLE BIAS 3 YARDS | |

|

|

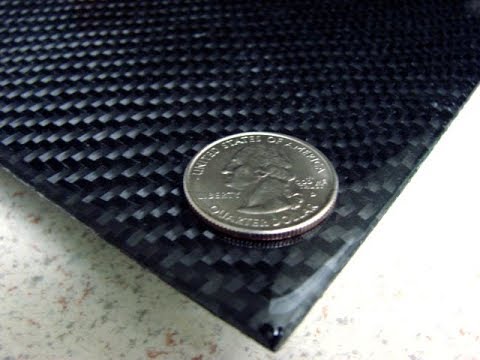

CARBON FIBER FABRIC 3K 2x2 TWILL WEAVE 6 OZ. 3 YARDS | |

CARBON FIBER FABRIC 3K PLAIN WEAVE 6 OZ 3 YARDS | |

|

|

KEVLAR 49 HEXCEL 351 PLAIN WEAVE FABRIC 2.2 OZ |

MAX BOND LOW VISCOSITY A/B

Marine Grade

|

MAX BOND LOW VISCOSITY 32-Ounce Kit |

|

|

MAX BOND LOW VISCOSITY 64-Ounce

Kit |

|

|

MAX

BOND LOW VISCOSITY 1-Gallon Kit |

|

|

MAX

BOND LOW VISCOSITY 2-Gallon kit |

|

|

MAX

BOND LOW VISCOSITY 10-Gallon Kit |

MAX 1618 A/B

Crystal Clear, High Strength, Lowest Viscosity (Thin), Durability & Toughness, Excellent Wood Working Resin

MAX 1618 A/B 48-Ounce Kit | |

MAX 1618 A/B 3/4-Gallon Kit | |

MAX 1618 A/B 3/4-Gallon Kit | |

MAX 1618 A/B 1.5-Gallon Kit |

MAX CLR A/B

Water Clear Transparency, Chemical Resistance, FDA Compliant For Food Contact, High Impact, Low Viscosity

MAX CLR A/B 24-Ounce Kit | |

MAX CLR A/B 48-Ounce Kit | |

MAX CLR A/B 96-Ounce Kit | |

MAX CLR A/B 96-Ounce Kit | |

MAX CLR A/B 1.5-Gallon Kit |

MAX GRE A/B

GASOLINE RESISTANT EPOXY RESIN

Resistant To Gasoline/E85 Blend, Acids & Bases, Sealing, Coating, Impregnating Resin

MAX GRE A/B 48-Ounce Kit | |

MAX GRE A/B 96-Ounce Kit |

MAX HTE A/B

HIGH-TEMPERATURE EPOXY

Heat Cured Resin System For Temperature Resistant Bonding, Electronic Potting, Coating, Bonding

MAX HTE A/B 80-Ounce Kit | |

MAX HTE A/B 40-Ounce Kit |

Step Three:

Proper Lay-Up Technique -Putting It All Together

Pre-lay-up notes

- Lay out the fabric and pre-cut to size and set aside

- Avoid distorting the weave pattern as much as possible

- For fiberglass molding, ensure the mold is clean and adequate mold release is used

- View our video presentation above "MAX EPOXY RESIN MIXING TECHNIQUE"

- Mix the resin only when all needed materials and implements needed are ready and within reach

Mix the proper amount of resin needed and be accurate proportioning the resin and curing agent. Adding more curing agent than the recommended mix ratio will not promote a faster cure. Over saturation or starving the fiberglass or any composite fabric will yield poor mechanical performance. When mechanical load or pressure is applied to the composite laminate, the physical strength of the fabric should bear the stress and not the resin. If the laminate is over saturated with the resin it will most likely to fracture or shatter instead of rebounding and resist damage.

Don’t how much resin to use to go with the fiberglass?

A good rule of thumb is to maintain a minimum of 30 to 35% resin content by weight.

This is the optimum ratio used in high-performance prepreg (or pre-impregnated fabrics) typically used in aerospace and high-performance structural application.

For general hand lay-ups, calculate using 60% fabric weight to 40% resin weight as a safety factor.

This will ensure that the fabricated laminate will be below 40% resin content depending on the waste factor accrued during fabrication.

Place the entire pre-cut fiberglass to be used on a digital scale to determine the fabric to resin weight ratio. Measuring by weight will ensure accurate composite fabrication and repeatability, rather than using OSY (ounces per square yard) or GSM ( grams per meter square) data.

THE USE OF A WEIGHING SCALE IS HIGHLY RECOMMENDED

Purchase this scale with any of our product offering and the shipping cost of the scale is free.

https://www.ebay.com/itm/222630300203

A good rule of thumb is to maintain a minimum of 30 to 35% resin content by weight, this is the optimum ratio used in high-performance prepreg (or pre-impregnated fabrics) typically used in aerospace and high-performance structural application. For general hand lay-ups, calculate using 60% fabric weight to 40% resin weight as a safety factor. This will ensure that the fabricated laminate will be below 40% resin content depending on the waste factor accrued during fabrication.

Place the entire pre-cut fiberglass to be used on a digital scale to determine the fabric to resin weight ratio. Measuring by weight will ensure accurate composite fabrication and repeatability, rather than using OSY data.

Typical fabric weight regardless of weave pattern

1 ounce per square yard is equal to 28.35 grams

1 square yard equals to 1296 square inches (36 inches x 36 inches)

FOR EXAMPLE

1 yard of 8-ounces per square yard (OSY) fabric weighs 226 grams

1 yard of 10-ounces per square yard (OSY) fabric weighs 283 grams

Ounces per square yard or OSY is also known as aerial weight, which is the most common unit of measurement for composite fabrics. To determine how much resin is needed to adequately impregnate the fiberglass, use the following equation:

(Total Weight of Fabric divided by 60%)X( 40%)= weight of mixed resin needed

OR

fw= fabric weight

rc= target resin content

rn=resin needed

MASTER EQUATION

(fw/60%)x(40%)=rn

FOR EXAMPLE

1 SQUARE YARD OF 8-OSY FIBERGLASS FABRIC WEIGHS 226 GRAMS

(226 grams of dry fiberglass / 60%) X 40% = 150.66 grams of resin needed

So for every square yard of 8-ounce fabric, it will need 150.66 grams of mixed resin.

Computing For Resin And Curing Agent Amount

150.66 grams of resin needed

MIX RATIO OF RESIN SYSTEM IS 2:1 OR

50 PHR (per hundred resin)

2 = 66.67% (2/3)

+

1 = 33.33%(1/3)

=

(2+1)=3 or (66.67%+33.33%)=100% or (2/3+1/3)= 3/3

150.66 x 66.67%= 100.45 grams of Part A RESIN

150.66 x 33.33%= 50.21 grams of Part B CURING AGENT

100.45 + 50.21 = 150.66 A/B MIXTURE

GENERAL LAY-UP PROCEDURE

Apply the mixed resin onto the surface and then lay the fabric and allow the resin to saturate through the fabric.

NOT THE OTHER WAY AROUND

This is one of the most common processing error that yields sub-standard laminates. By laying the fiberglass onto a layer of the prepared resin, less air bubbles are entrapped during the wetting-out stage. Air is pushed up and outwards instead of forcing the resin through the fabric which will entrap air bubbles. This technique will displace air pockets unhindered and uniformly disperse the impregnating resin throughout the fiberglass.

Eliminating air entrapment or void porosity in an epoxy/fiberglass lay-up process

Vacuum Infusion Process is also known in the composites industry as

Vacuum Assisted Resin Transfer Molding or VARTM.

Similar to the Vacuum Bagging Process where the negative pressure is used to apply consolidation force to the laminate while the resin cures, the resin is infused into the fabric lay-up by sucking the impregnating resin and thus forming the composite laminate.

The VARTM Process produces parts that require less secondary steps, such as trimming, polishing or grinding with excellent mechanical properties. However, the vacuum infusion requires more additional or supplemental related equipment and expendable materials. So the pros and cons of each presented composite fabrication process should be carefully determined to suit the user's capabilities and needs.

Please view the following video demonstration which explains the process of Vacuum Infusion or VARTM process.

CARBON FIBER VACUUM INFUSION WITH EPOXY RESIN - VACUUM BAGGING WITH MAX 1618 EPOXY RESIN

Video will open in a new window

MAX 1618 A/B VACUUM ASSISTED RESIN TRANSFER MOLDING PROCESS

VACUUM INFUSION VIDEO

Step Four: Proper Curing Although we have formulated all of our MAX EPOXY RESIN SYSTEM product line to be resistant to amine-blush, it is recommended not to mix any resin systems in high humidity conditions, greater than 60%. Always make sure that the substrate or material the epoxy resin system is being applied to is well prepared as possible to ensure the best-cured performance.

Always review the published data and information for proper usage, application, and general safety information.

Our expert staff of engineers is always available for consultation and assistance.

Allow the lay-up to cure for a minimum of 24 to 36 hours before handling. Optimum cured properties can take up to 7 days depending on the ambient cure condition. The ideal temperature cure condition of most room temperature epoxy resin is 22 to 27 degrees Celsius at 20% relative humidity. Higher ambient curing temperatures will promote faster polymerization and development of cured mechanical properties. Improving mechanical performance via post heat cure A short heat post cure will further improve the mechanical performance of most epoxy resins. Allow the applied resin system to cure at room temperature until for 18 to 24 hours and if possible, expose heat cure it in an oven or other sources of radiant heat (220°F to 250°F) for45 minute to an hour. You can also expose it to direct sunlight but place a dark colored cover, such as a tarp or cardboard to protect it from ultraviolet exposure. In general room temperature cured epoxy resin has a maximum operating temperature of 160°F or lower. A short heat post cure will ensure that the mixed epoxy system is fully cured, especially for room temperature cure system that can take up to 7 days to achieve 100% cure Some darkening or yellowing of the epoxy resin may occur if overexposed to high temperature (>250 F).

AMINE BLUSH The affinity of an amine compound (curing agent) to moisture and carbon dioxide creates a carbonate compound and forms what is called amine blush. Amine blush is a wax-like layer that forms as most epoxies cure. If the epoxy system is cured in extreme humidity (>70%). It will be seen as a white and waxy layer that must be removed by physical sanding of the surface followed by an acetone wipe.

OTHER TYPES OF EPOXY RESIN CURE MECHANISM LATENT CURING SYSTEMS Latent epoxy resins are systems that are mixed together at room temperature and will begin polymerization but it will not achieve full cure unless it is exposed to a heat cure cycle. In general, these are high-performance systems that demonstrate exceptional performance under extreme conditions such as high mechanical performance under heat and cryogenic temperatures, chemical resistance or any environment that epoxy room temperature system perform marginally or poorly. Upon the mixing of the resin and curing agent polymerization will begin and will only achieve a partial cure. Some resins may appear cured or dry to the touch, this state is called 'B-Stage Cure', but upon application of force will either be gummy or brittle almost glass-like and will dissolve in most solvents. The semi-cured resin must be exposed to an elevated temperature for it to continue polymerization and achieve full cure.

TESTING THE COMPOSITE DETERMINATION OF THE FABRIC-RESIN RATIO DON'T FORGET OUR EPOXY MIXING KITClick The Link To Add To Order

https://www.ebay.com/itm/222623932456

EVERYTHING YOU NEED TO MEASURE, MIX, DISPENSE OR APPLY

Proportioning the correct amount is equally as important to attain the intended cured properties of the resin system. The container in which the epoxy and curing agent is mixed is an important consideration when mixing an epoxy resin system. The container must withstand the tenacity of the chemical and must be free of contamination. Most epoxy curing agent has a degree of corrosivity, as a general practice, protective gloves should be worn when handling chemicals of the same nature.

MIXING KIT CONTENTS 1 Each Digital Scale -Durable, Accurate Up To 2000.0 Grams

4 Each 32-ounce (1 Quart) Clear HDPE Plastic Mix Cups

4 Each 16-ounce (1 Pint) Clear HDPE Plastic Mix Cups

One Size Fits All Powder-Free Latex Gloves

2 Each Graduated Syringes

Wooden Stir Sticks

Foam Brush

PLEASE CHECK OUT OTHER AVAILABLE RESIN SYSTEMS AT OUR eBay STORE For our complete listing, please Visit our eBay store!

IMPORTANT NOTICE Your purchase constitutes the acceptance of this disclaimer. Please review before purchasing this product. The user should thoroughly test any proposed use of this product and independently conclude satisfactory performance in the application. Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval. The information contained herein is based on data believed to be accurate at the time of publication. Data and parameters cited have been obtained through published information, PolymerProducts laboratories using materials under controlled conditions. Data of this type should not be used for a specification for fabrication and design. It is the user's responsibility to determine this Composites fitness for use. There is no warranty of merchantability of fitness for use, nor any other express implied warranty. The user's exclusive remedy and the manufacturer's liability are limited to refund of the purchase price or replacement of the product within the agreed warranty period. PolymerProducts and its direct representative will not be liable for incidental or consequential damages of any kind. Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether there is any infringement of patents is the sole liability of the user.

Always review the published data and information for proper usage, application, and general safety information.

Our expert staff of engineers is always available for consultation and assistance.

Click The Link To Add To Order

https://www.ebay.com/itm/222623932456

EVERYTHING YOU NEED TO MEASURE, MIX, DISPENSE OR APPLY

1 Each Digital Scale -Durable, Accurate Up To 2000.0 Grams

4 Each 32-ounce (1 Quart) Clear HDPE Plastic Mix Cups

4 Each 16-ounce (1 Pint) Clear HDPE Plastic Mix Cups

One Size Fits All Powder-Free Latex Gloves

2 Each Graduated Syringes

Wooden Stir Sticks

Foam Brush

Your purchase constitutes the acceptance of this disclaimer. Please review before purchasing this product. The user should thoroughly test any proposed use of this product and independently conclude satisfactory performance in the application. Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval. The information contained herein is based on data believed to be accurate at the time of publication. Data and parameters cited have been obtained through published information, PolymerProducts laboratories using materials under controlled conditions. Data of this type should not be used for a specification for fabrication and design. It is the user's responsibility to determine this Composites fitness for use. There is no warranty of merchantability of fitness for use, nor any other express implied warranty. The user's exclusive remedy and the manufacturer's liability are limited to refund of the purchase price or replacement of the product within the agreed warranty period. PolymerProducts and its direct representative will not be liable for incidental or consequential damages of any kind. Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether there is any infringement of patents is the sole liability of the user.