MAX GRE A/B is electrically non-conductive, shielding the metal substrate making the metal less suceptable to coorosion.

MAX GRE A/B also is also acid resistant thus reducing oxidation or rusting of the metal tank.

Both steel(Fe) or aluminum(Al) tanks metal tanks are more susceptable to oxidation or corrosion

It is a premium grade resin system for repairs and restoration of fuel tanks made from steel, aluminum, copper and FRP materials.

MAX GRE A/B is 100% solids and does not contain non-reactive components that affects chemical resistance and stability.

Upon cure, it is resistant to swelling, softening, loss of adhesion from immersion and direct contact to modern gasoline and diesel fuels.

MAX GRE A/B is used as a barrier coating for metal and FRP fuel cells.

It provides a high degree of chemical-resistance against petroleum-based gasoline, diesel, and ethanol fuel blends (E85).

MAX GRE A/B is an anti-corrosion coating for steel substrates, and prevents oxidation on aluminum and copper metals.

MAX GRE A/B works well as an impregnating resin for fiberglass, carbon fiber fabrics for patching, reinforcing and fabricating FRP composite fuel cells.

MAX GRE A/B is used as a strong adhesive for bonding metals, FRP composites, and most porous substrates.

Corrosion Of Aluminum Fuel Tanks From Ethanol Blended Fuels

To learn more about alcoholate corrosion of aluminum, please perform a web search on "Ethanol Tank Corrosion".

Surface Preparation Prior To Application

The efficacy of any product used for similar applications is dependent on how well the surface is prepared to ensure a strong bond.

For repairing or coating used or old tanks, the substrate requires degreasing to remove lubricants and fuel additive residue.

The strength of adhesion is dependent on how well the substrate is prepared.

This critical step applies to both metal and composite tanks.

View The Following Video Demonstration Regarding Surface Tension.

The video demonstrates how the surface tension of a solid surface affects the wettability of the applied liquid.

The liquid can be an adhesive coating, colored paints or printing inks.

Good substrate wetting yields good adhesion, may it be for coating applications, composites fabrication, or general bonding use.

The substrate, metal or otherwise must be cleaned appropriately to remove oily residue by chemical degreasing.

Use acetone to degrease the surface and ensure that the substrate is dry and free from contamination before application.

Do not use rubbing alcohol or denature alcohol; acetone works best for degreasing and removing surface residue that affects adhesion.

Remove loose or flaking rust, and for the best adhesion performance, abrade or sandblast so the MAX GRE A/B coating is in direct contact with the metal substrate.

For aluminum substrates, chromic acid etching or sanding to bare metal is recommended for bonding and coating applications.

An aluminum etching solution formulation is posted below.

Use the same water bead test to determine the wettability of the substrate.

If the water does not form a continuous film as demonstrated in the video, the surface requires more surface modification, until the surface yields good wetting.

The Following Surface Preparation Procedures Are Recommended.

METALS AND CONCRETE Degrease Metals– Wipe surface with lint-free rag dampened with Methyl Ethyl Ketone (MEK) or acetone to remove all oil, dirt, and grease. Etch Metals – For optimum results, metal parts should be immersed in a chromic acid bath solution consisting of:

The solution is held at 160°F (71°C), and the parts left immersed for 5 to 7 minutes. Rinse – remove metal parts from etching bath and rinse with clean water. (distilled water is recommended). Etch Concrete- Use commercially sold concrete etching solution (hydrochloric acid based works best). Neutralized per instructions, rinse and allow to dry thoroughly. ALTERNATE PROCEDURE Degrease and dry – Degrease the surface as noted above, sand or sandblast the surface lightly but thoroughly. Rinse with acetone or Methyl Ethyl Ketone (MEK), and dry. | GLASS Degrease – With MEK as above, or with a strong boiling solution of a good grade household detergent. Etch – For optimum results, degreasing can be followed by the chromic acid bath outlined above. WOOD Sand – Bonding surfaces should be sanded lightly, but thoroughly to remove all external contamination. Clean – Carefully remove all dust, or particles of wood from sanded areas. A stiff and clean brush or compressed air can be used. PLASTIC Clean – Remove all dirt, oil, or other surfaces contaminated with detergent soap or degreasing solvent and water, followed by thorough rinsing and drying. A solvent that does not have a detrimental effect may also be used. Sand – Surfaces to be bonded should be sanded lightly, but thoroughly to remove surface sheen. Clean – Carefully remove all dust or particles of plastic from the sanded area. A clean brush, lint-free cloth, or compressed air may be used. |

Mixing And Application

Precaution: As with industrial chemicals of the same nature, avoid direct skin contact using protective gloves and eyewear.

Ensure the work area is well ventilated and extinguish any flame source to prevent fuel vapors accidental ignition vapor fuels.

Always practice safety first.

The Use Of A Weighing Scale Is Highly Recommended For Measuring The Resin To Curing Agent Mix Ratio.

Purchase this scale with any of our offering &the shipping cost of the scale is free.

https://www.ebay.com/itm/222630300203

Shipping overpayments are refunded back after completion of sale

MAX GRE A/B is mixed 2:1 by weight or by volume and offers a 35 to 45 minute working time.

Use a scale to measure the proper mix ratio accurately, which dramatically affects cured chemical resistance, especially when mixing small batch sizes.

The mixed consistency is similar to cooking oil. MAX GRE is self-leveling and will continue to flow until the MAX GRE resin gels or converts to a solid.

The ideal coating thickness to create a hermetic barrier is 0.015-inch or 15 mils and may require several applications to achieve the target coating thickness. Allow the first coat to cure for 5 to 6 hours at 75°F and repeat the application directly on top of the previous application. Once the desired thickness is achieved, allow the MAX GRE to fully cure 36 to 48 hours at 25°C to 30°C before use.

To use the MAX GRE as an adhesive, prepare the substrates to its bare condition so the MAX GRE is directly applied and in full contact with the base substrate. Ensure bond foot-print is relative to the amount of force that is expected.

Mix the proper amount of the resin and curing agent for the application.

Bondline control media such as ‘Potter’s Glass Bead’ is typically mixed with the MAX GRE to meter the ideal bondline thickness of 5 to 7 mils. Apply the mixed MAX GRE on both substrates to be bonded and assemble. Apply sufficient clamping force to ensure both substrates are mated until the MAX GRE cures. Allow to cure for 12 to 18 hours at room temperature for the the MAX GRE to be tack-free and handleable. Allow the MAX GRE to fully cure for 36 to 48 hours at 25°C to 30°C before use with fuels.

Potting Compound: MAX GRE A/B Is Self Leveling And Suitable For Thick Potting Or Casting Application

MAX GRE also works well as a potting compound for encapsulating fuel level sensors. It is suitable up to a ¾-inch thick casting or embedding. Upon cure, MAX GRE is non-conductive and provides electrical insulation for low voltage signals for gauges and meters. MAX GRE bonds well to copper wires and holds connections in place. It is resistant to pull-outs from expansion and contraction coefficients and mechanical vibration from average use and environment.

Impregnating Resin For Fiberglass Or Carbon Fiber

As an impregnating resin for composite fabrication, use silane or volan treated fabrics for the best epoxy resin compatibility and wet-out.

Saturate the fabric with the mixed MAX GRE at 33 percent resin content.

Allow to fully cure for 48 hours at 25°C to 30°C before use.

Observe composite fabricating guidelines for making fuel cells.

Review COMPOSITE FABRICATING BASICS Below For More Details

MAX GRE Chemical Resistance Test

Cured MAX GRE Specimens in E85 Gasoline Continuous Immersion Test

Specimens have been in complete immersion in E85 gasoline and diesel E85 fuel since 06/15/2009 with no change in is cured properties.

The stability in weight or hardness (Shore Durometer) of the MAX GRE demonstrates its superior chemical resistance to modern fuels.

No Change In Weight Or Durometer Hardness Demonstrating Its Chemical Resistance Properties.

Hardness Test After Continuous Immersion In Fuel

Testing the Shore Durometer Hardness of the specimens determines if the cures resin is being affected by the gasoline immersion.

The weights and Durometer Hardness of the specimens were measure before and after the immersion test and any changes in are recorded.

After several years of continuous gasoline immersion, the MAX GRE test specimens exhibits no change in weight or hardness.

Poor chemicals resistance will bloat the specimens, increasing in mass and reduce in Shore Durometer Hardness.

MAX GRE A/B has proven its excellent resistance against various petroleum fuels.

Testing For Weight Change, Durometer Hardness After Continuous Gasoline Immersion.

June 2009 | Start Date |

March 2014 | No appreciable change in dimension, weight, Durometer Hardness |

February 2017 | No appreciable change in dimension, weight, Durometer Hardness |

November 2019 | No appreciable change in dimension, weight, Durometer Hardness |

November 2020 | No appreciable change in dimension, weight, Durometer Hardness |

48 Ounce Kit Coverage At 0.030 Inch Coating Thickness = 20 Square Feet

48 Ounce Kit Coverage With 10 Ounce Per Square Yard Fiberglass Cloth With 70/30 Fabric To Resin Ratio By Weight =

6.5 Square Yards Of 10 Ounce Fiberglass Per This 48 Fluid Ounce Kit.

Best Style Fabric For Patching; 7781 Style 8 Harness Satin Weave

Free Shipping!

https://www.ebay.com/itm/223385247088

Use this satin weave style fiberglass fabric that offers excellent draping over curved and corners.

This weave style is also much tighter and has less opening between the fiberglass yarn.

Once impregnated with the MAX GRE resin, the laminate is impermeable and provides better hermetic sealing.

PHYSICAL PROPERTIES & MECHANICAL PROPERTIES |

Density | 1.10 G/CC |

Form and Color | Clear Liquid |

Viscosity | 2500-3000 cPs @ 25ºC Mixed |

Mix Ratio | 2:1 |

Working Time | 45 – 50 Minutes @ 25°C (100 Gram Mass) |

Peak Exotherm | 70°C (100 Gram Mass) |

Thin Film Set Time | 4 to 6 Hours |

Handle Time | 8 Hours |

Cure Time | 2 to 7 days @ 25°C |

Accelerated Cure Time | 8 hours at room temperature plus 1 hours at 100 |

Hardness | 80 ± 5 Shore D |

Tee-Peel Strength | 3.4 Lbs. per inch Width |

Tensile Shear Strength | 2,935 psi @ 25°C |

1,970 psi @ -40°C | |

1250 psi @ 100°C | |

Elongation | 3.0% @ 25°C |

Flexural Strength | 13,000 psi |

Flexural Modulus | 344,000 psi |

Heat Deflection Temp. | 70°C |

CHEMICAL RESISTANCE PERFORMANCE

Full Immersion At 15°C to 30°C

MEASURED PERCENT CHANGE IN WEIGHT

REAGENT | 10 Days | 100 Days |

Deionized Water | 0.09 % | 0.03 % |

Sea Water | 0.01 % | 0.08 % |

Methanol 15% | 3.93 % | Destroyed |

Ethanol 50% | 0.98 % | 0.82 % |

Toluene | 0.40 % | 2.86 % |

Xylene | 0.24 % | 2.55 % |

Gasoline (E85 Blend) | 0.10 % | 0.03 % |

MEK | 2.96% | Destroyed |

10% Lactic Acid | 0.81 % | 0.42 % |

10% Acetic Acid | 0.11 % | 0.45 % |

70% Sulfuric Acid | 0.08 % | 0.14 % |

50% Sodium Hydroxide | 0.00 % | 0.10 % |

10% Sodium Hypochlorite | 0.51 % | 1.36 % |

ELECTRICAL AND THERMAL CONDUCTIVITY PROPERTIES

Volume Resistivity | 4.7 X 1013 Ohms-Cm |

Dielectric Strength | 510 Volts/Mil 60 Cycles |

Dielectric Constant | 4.0 (10 kHz) |

Dissipation Factor | 0.014 (10 kHz) |

Thermal Conductivity (Unfilled) 40°-45°C | 0.25 W F/mK |

During the colder season, use and infrared lamp to increase the ambient temperature to minimize slow cure due to the colder temperatures.

IR Lamps works best for warming large areas.

Best Style Fabric For Patching And Fabricating Fuel Tanks

Weave Style 7781 8 Harness Satin Weave

https://www.ebay.com/itm/223669319695

Use this satin weave style fiberglass fabric that offers excellent draping over curved and corners.

This weave style is also much tighter and has less opening between the fiberglass yarn.

Once impregnated with the MAX GRE resin, the laminate is impermeable and provides hermetic sealing.

Carbon Fiber Motorcycle Gas Tank Fabricated With MAX GRE A/B

COMPOSITE FABRICATING BASIC GUIDELINES

By definition, a fabricated COMPOSITE material is a manufactured collection of two or more products intentionally combined to form a new homogeneous material that is uniquely greater than the sum of its individual parts.

This method is also defined as a SYNERGISTIC COMPOSITION.

COMPOSITE MATERIAL COMPOSITION

REINFORCING FABRIC & IMPREGNATING RESIN

'ENGINEERED PROCESS'

EQUALS

COMPOSITE LAMINATE WITH THE BEST WEIGHT TO STRENGTH PERFORMANCE

With respect to the raw materials selection -fabric and resin, the fabricating process and the and curing and test validation of composite part,

these aspects must be carefully considered and in the engineering phase of the composite.

Step One: Fabric Selection TYPES OF FABRIC WEAVE STYLE AND SURFACE FINISHING

FOR RESIN TYPE COMPATIBILITY

Fabrics are generally considered ”balanced” if the breaking strength is within 15% warp to fill and are best in bias applications on lightweight structures. “Unbalanced” fabrics are excellent when a greater load is required one direction and a lesser load in the perpendicular direction.

Weaves:

Plain weave means the warp and fill threads cross alternately. This is the most common weave.

4 Harness (4 HS Satin or crowfoot) weave means the fill thread floats over three warp threads, then under one warp thread.

This weave is more pliable than the plain weave, therefore conforms to complex curves more easily.

8 Harness (8 HS Satin) weave means the fill thread floats over seven warp threads, then under one warp thread.

his weave is the most pliable fiberglass weaves.

2 x 2 Twill weave means the fill thread floats over two warp threads, then fewer than two warp threads.

This weave is found most commonly in carbon fabrics and is more pliable than plain weave.Most fabrics are stronger in the warp than the fill because higher tension is placed on the warp fiber keeping it straighter during the weaving process.

Rare exceptions occur when a larger, therefore stronger thread is used in the fill direction than the warp direction.

PLAIN WEAVE

Is a very simple weave pattern and the most common style. The warp and fill yarns are interlaced over and under each other in alternating fashion. Plain weave provides good stability, porosity and the least yarn slippage for a given yarn count.

8 HARNESS SATIN WEAVE

The eight-harness satin is similar to the four-harness satin except that one filling yarn floats over seven warp yarns and under one.

This is a very pliable weave and is used for forming over curved surfaces.

4 HARNESS SATIN WEAVE

The four-harness satin weave is more pliable than the plain weave and is easier to conform to curved surfaces typical in reinforced plastics. In this weave pattern, there is a three by one interfacing where a filling yarn floats over three warp yarns and under one.

2x2 TWILL WEAVE

Twill weave is more pliable than the plain weave and has better drivability while maintaining more fabric stability than a four or eight harness satin weave. The weave pattern is characterized by a diagonal rib created by one warp yarn floating over at least two filling yarns.

SATIN WEAVE TYPE CONFORMITY UNTO CURVED SHAPES

Plain Weaves, Bi-axial, Unidirectional Styles For Directional High Strength Parts Use this weave style cloth when high strength parts are desired. It is ideal for reinforcement, mold making, aircraft and auto parts tooling, marine, and other composite lightweight applications. FIBERGLASS FINISHING FOR RESIN COMPATIBILITY

Finishing Cross Reference And Resin Type Compatibility RESIN COMPATIBILITY

Burlington

ClarkSchwebel

J.P Stevens

Uniglass Industries

Epoxy, Polyester

VOLAN A

VOLAN A

VOLAN A

VOLAN A

Epoxy, Polyester

I-550

CS-550

S-550

UM-550

Phenolic, Melamine

I-588

A1100

A1100

A1100

Epoxy, Polyimide

I-589

Z6040

S-920

UM-675

Epoxy

I-399

CS-272A

S-935

UM-702

Epoxy

CS-307

UM-718

Epoxy

CS-344

UM-724

Silicone

112

112

n-pH (neutral pH)

AVAILABLE FIBERGLASS, CARBON FIBER, AND KEVLAR FABRICS

Style 120 1.5-OUNCE FIBERGLASS PLAIN WEAVE 5 YARDS

Style 120 1.5-OUNCE FIBERGLASS PLAIN WEAVE 10 YARDS

Style 7532 7-OUNCE FIBERGLASS PLAIN WEAVE 5 YARDS

Style 7500 10 OUNCE FIBERGLASS PLAIN WEAVE 3 YARDS

Style 7500 10 OUNCE FIBERGLASS PLAIN WEAVE 5 YARDS

Style 3582 14 OUNCE FIBERGLASS SATIN WEAVE 5 YARDS

Style 3582 14 OUNCE FIBERGLASS SATIN WEAVE 10 YARDS

HEXCEL 1584 26 OUNCE FIBERGLASS SATIN WEAVE 3 YARDS

HEXCEL 1584 26 OUNCE FIBERGLASS SATIN WEAVE 5 YARDS

FIBERGLASS 45+/45- DOUBLE BIAS 3 YARDS

CARBON FIBER FABRIC 3K 2x2 TWILL WEAVE 6 OZ. 3 YARDS

CARBON FIBER FABRIC 3K PLAIN WEAVE 6 OZ 3 YARDS

KEVLAR 49 HEXCEL 351 PLAIN WEAVE FABRIC 2.2 OZ

Step Two:

The epoxy resin used in fabricating a laminate will dictate how the FRP will perform when load or pressure is implied on the part. To choose the proper resin system, consider the following factors that is crucial to a laminate's performance. SIZE AND CONFIGURATION OF THE PART (NUMBER OF PLIES AND CONTOURED, FLAT OR PROFILED) CONSOLIDATING FORCE (FREE STANDING DRY OR HAND LAY-UP, VACUUM BAG OR PLATEN PRESS CURING) CURING CAPABILITIES (HEAT CURED OR ROOM TEMPERATURE CURED) LOAD PARAMETERS (SHEARING FORCE, TORSIONAL AND DIRECTIONAL LOAD, BEAM STRENGTH)ENVIRONMENTAL EXPOSURE The principal role of the resin is to bind the fabric into a homogeneous rigid substrate (OPERATING TEMPERATURE, AMBIENT CONDITIONS, CHEMICAL EXPOSURE, CYCLIC FORCE LOADING) MATERIAL AND PRODUCTION COST(BUYING IN BULK WILL ALWAYS PROVIDE THE BEST OVERALL COSTS)

These factors will dictate the design and the composition of the part and must be carefully considered during the design and engineering phase of the fabrication.

TOP SELLING IMPREGNATING RESIN SYSTEM MAX BOND LOW VISCOSITY A/B

Marine Grade Boat Building

MAX BOND LOW VISCOSITY 32-Ounce kit

MAX BOND LOW VISCOSITY 64-Ounce Kit

MAX BOND LOW VISCOSITY 1-Gallon Kit

MAX BOND LOW VISCOSITY 2-Gallon kit

MAX BOND LOW VISCOSITY 10-Gallon Kit

MAX 1618 A/B

Crystal Clear, High Strength, Lowest Viscosity (Thin), Durability & Toughness, Excellent Wood Working Resin

MAX 1618 A/B 48-Ounce Kit

MAX 1618 A/B 3/4-Gallon Kit

MAX 1618 A/B 3/4-Gallon Kit

MAX 1618 A/B 1.5-Gallon Kit

MAX CLR A/B

Water Clear Transparency, Chemical Resistance, FDA Compliant For Food Contact, High Impact, Low Viscosity

MAX CLR A/B 24-Ounce Kit

MAX CLR A/B 48-Ounce Kit

MAX CLR A/B 96-Ounce Kit

MAX CLR A/B 96-Ounce Kit

MAX CLR A/B 1.5-Gallon Kit

MAX GRE A/B

GASOLINE RESISTANT EPOXY RESIN

Resistant To Gasoline/E85 Blend, Acids & Bases, Sealing, Coating, Impregnating Resin

MAX GRE A/B 48-Ounce Kit

MAX GRE A/B 96-Ounce Kit

MAX HTE A/B

HIGH-TEMPERATURE EPOXY

Heat Cured Resin System For Temperature Resistant Bonding, Electronic Potting, Coating, Bonding

MAX HTE A/B 80-Ounce Kit

MAX HTE A/B 40-Ounce Kit

Step Three:

Pre-lay-up notesLay out the fabric and pre-cut to size and set asideAvoid distorting the weave pattern as much as possibleFor fiberglass molding, ensure the mold is clean and an adequate mold release is usedView our video presentation above "MAX EPOXY RESIN MIXING TECHNIQUE"Mix the resin only when all needed materials and implements needed are ready and within reach Mix the proper amount of resin needed and be accurate proportioning the resin and curing agent.

Adding more curing agent than the recommended mix ratio will not promote a faster cure.

Over saturation or starving the fiberglass or any composite fabric will yield poor mechanical performance.

When mechanical load or pressure is applied to the composite laminate, the physical strength of the fabric should bear the stress and not the resin.

If the laminate is over saturated with the resin it will most likely to fracture or shatter instead of rebounding and resist damage.

Don’t how much resin to use to go with the fiberglass?

A good rule of thumb is to maintain a minimum of 30 to 35% resin content by weight,

this is the optimum ratio used in high-performance prepreg (or pre-impregnated fabrics) typically used in aerospace and high-performance structural application.

For general hand lay-ups, calculate using 60% fabric weight to 40% resin weight as a safety factor.

This will ensure that the fabricated laminate will be below 40% resin content depending on the waste factor accrued during fabrication.

Place the entire pre-cut fiberglass to be used on a digital scale to determine the fabric to resin weight ratio.

Measuring by weight will ensure accurate composite fabrication and repeatability, rather than using OSY (ounce per square yard) data.

THE USE OF A WEIGHING SCALE IS HIGHLY RECOMMENDED

Purchase this scale with any of our product offering and the shipping cost of the scale is free.

https://www.ebay.com/itm/222630300203

A good rule of thumb is to maintain a minimum of 30 to 35% resin content by weight.

This is the optimum ratio used in high-performance prepreg (or pre-impregnated fabrics) typically used in aerospace and high-performance structural application.

For general hand lay-ups, calculate using 60% fabric weight to 40% resin weight as a safety factor.

This will ensure that the fabricated laminate will be below 40% resin content depending on the waste factor accrued during fabrication.

Place the entire pre-cut fiberglass to be used on a digital scale to determine the fabric to resin weight ratio.

Measuring by weight will ensure accurate composite fabrication and repeatability, rather than using OSY data.

1 ounce per square yard is equal to 28.35 grams

1 square yard equals to 1296 square inches (36 inches x 36 inches)

FOR EXAMPLE

1 yard of 8-ounces per square yard (OSY) fabric weighs 226 grams

1 yard of 10-ounces per square yard (OSY) fabric weighs 283 grams

Ounces per square yard or OSY is also known as aerial weight, which is the most common unit of measurement for composite fabrics.

To determine how much resin is needed to adequately impregnate the fiberglass, use the following equation:

(Total Weight of Fabric divided by 60%)X( 40%)= weight of mixed resin needed

MASTER EQUATION

(fw/60%)x(40%)= RN

FOR EXAMPLE

1 SQUARE YARD OF 8-OSY FIBERGLASS FABRIC WEIGHS 226 GRAMS

(226 grams of dry fiberglass / 60%) X 40% = 150.66 grams of resin needed

So for every square yard of 8-ounce fabric, it will need 150.66 grams of mixed resin.

Computing For Resin And Curing Agent Amount

150.66 grams of resin needed

MIX RATIO OF RESIN SYSTEM IS 2:1 OR 50 PHR (per hundred resin)

2 = 66.67% (2/3) + 1 = 33.33%(1/3)

(2+1)=3 or (66.67%+33.33%)=100% or (2/3+1/3)= 3/3

150.66 x 66.67%= 100.45 grams of Part A RESIN

150.66 x 33.33%= 50.21 grams of Part B CURING AGENT

100.45 + 50.21 = 150.66 A/B MIXTURE

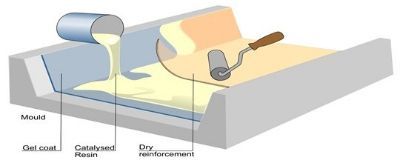

GENERAL LAY-UP PROCEDURE

Apply the mixed resin onto the surface and then lay the fabric and allow the resin to saturate through the fabric.

NOT THE OTHER WAY AROUND

This is one of the most common processing error that yields sub-standard laminates.

By laying the fiberglass onto a layer of the prepared resin, fewer air bubbles are entrapped during the wetting-out stage.

Air is pushed up and outwards instead of forcing the resin through the fabric which will entrap air bubbles.

This technique will displace air pockets unhindered and uniformly disperse the impregnating resin throughout the fiberglass.

Eliminating air entrapment or void porosity in an epoxy/fiberglass lay-up process

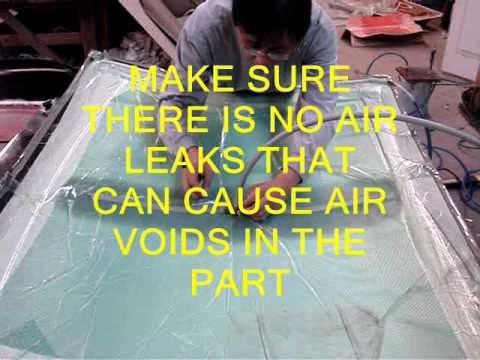

VACUUM BAGGING PROCESS

For performance critical application used in aerospace vehicles, composite framing for automotive vehicles and marine vessels, a process called 'Vacuum Bagging' is employed to ensure the complete consolidation of every layer of fabric.

The entire lay-up is encased in an airtight envelope or bagging.

A high-efficiency vacuum pump is used to draw out the air within the vacuum bag to create a negative atmospheric pressure. Once a full vacuum (29.9 Inches of Mercury) is achieved, the negative pressure applies a compacting force of 14.4 pounds per square inch.

(maximum vacuum pressure at sea level) is applied to the vacuum bag transferring the force to the entire surface area of the laminate.

Vacuum pressure is maintained until the resin cures to a solid.

For room temperature curing resin system, the vacuum pump is left in operation for a minimum of 18 hours. External heat can be applied to the entire lay-up, thus accelerating the cure of the resin system.

The vacuum force also removes any entrapped air bubble between the layers of fabric and eliminate what is called, porosity or air voids. Porosity within a laminate creates weak spots in the structure where mechanical failure originates when force or load is applied to the structure.

The standard atmosphere (symbol: atm) is a unit of pressure defined as 1 01325 Pa (1.01325 bar), equivalent to 760 mm Mercury or 29.92 inches Mercury or 14.696 pounds per square inch of pressure.

AUTOCLAVE CURING PROCESS

Autoclave curing processing is the most common method used in large-scale production of composite products. The aerospace industry, which includes space exploration rockets and vehicles, satellites, and military airplane utilizes this composite fabrication process due to the critical nature of the application. The mechanical demands of the composite are often pushed to the upper limits and autoclaved process yields composites with the best weight to strength ratio. BASIC OPERATION OF THE AUTOCLAVE PROCESS In the autoclave process, high pressure and heat are applied to the part through the autoclave atmosphere, with a vacuum bag used to apply additional pressure and protect the laminate from the autoclave gases. The cure cycle for a specific application is usually determined empirically and, as a result, several cure cycles may be developed for a single material system, to account for differences in laminate thickness or to optimize particular properties in the cured part. The typical autoclave cure cycle is a two-step process. First, vacuum and pressure are applied while the temperature is ramped up to an intermediate level and held there for a short period of time. The heat reduces the resin viscosity, allowing it to flow and making it easier for trapped air and volatiles to escape. The resin also begins wetting the fibers at this stage.

In the second ramp up, the temperature is raised to the final cure temperature and held for a sufficient length of time to complete the cure reaction. During this step, the viscosity continues to drop, but preset temperature ramp rates and hold times then stabilize viscosity at a level that permits adequate consolidation and fiber wetting, while avoiding excessive flow and subsequent resin starvation. These control factors also slow the reaction rate, which prevents excessive heat generation from the exothermic polymerization process. Upon completion, the cured mechanical performance of the composite is often much stronger and lighter compared to a hand lay-up, or vacuum bagged composite laminate.

VACUUM INFUSION PROCESS

Best Style Fabric For Patching And Fabricating Fuel Tanks  Use this satin weave style fiberglass fabric that offers excellent draping over curved and corners. This weave style is also much tighter and has less opening between the fiberglass yarn. Once impregnated with the MAX GRE resin, the laminate is impermeable and provides hermetic sealing. By definition, a fabricated COMPOSITE material is a manufactured collection of two or more products intentionally combined to form a new homogeneous material that is uniquely greater than the sum of its individual parts. This method is also defined as a SYNERGISTIC COMPOSITION.

REINFORCING FABRIC & IMPREGNATING RESIN 'ENGINEERED PROCESS' EQUALS COMPOSITE LAMINATE WITH THE BEST WEIGHT TO STRENGTH PERFORMANCE

With respect to the raw materials selection -fabric and resin, the fabricating process and the and curing and test validation of composite part, these aspects must be carefully considered and in the engineering phase of the composite. TYPES OF FABRIC WEAVE STYLE AND SURFACE FINISHING Weaves: This weave is more pliable than the plain weave, therefore conforms to complex curves more easily. 8 Harness (8 HS Satin) weave means the fill thread floats over seven warp threads, then under one warp thread. his weave is the most pliable fiberglass weaves. 2 x 2 Twill weave means the fill thread floats over two warp threads, then fewer than two warp threads. This weave is found most commonly in carbon fabrics and is more pliable than plain weave. Most fabrics are stronger in the warp than the fill because higher tension is placed on the warp fiber keeping it straighter during the weaving process.

SATIN WEAVE TYPE CONFORMITY UNTO CURVED SHAPES Finishing Cross Reference And Resin Type Compatibility

AVAILABLE FIBERGLASS, CARBON FIBER, AND KEVLAR FABRICS

(SHEARING FORCE, TORSIONAL AND DIRECTIONAL LOAD, BEAM STRENGTH) ENVIRONMENTAL EXPOSURE (OPERATING TEMPERATURE, AMBIENT CONDITIONS, CHEMICAL EXPOSURE, CYCLIC FORCE LOADING) MATERIAL AND PRODUCTION COST (BUYING IN BULK WILL ALWAYS PROVIDE THE BEST OVERALL COSTS) These factors will dictate the design and the composition of the part and must be carefully considered during the design and engineering phase of the fabrication. TOP SELLING IMPREGNATING RESIN SYSTEM MAX BOND LOW VISCOSITY A/B

MAX 1618 A/B

MAX CLR A/B

MAX GRE A/B

MAX HTE A/B

Step Three: Pre-lay-up notes Lay out the fabric and pre-cut to size and set aside Avoid distorting the weave pattern as much as possible For fiberglass molding, ensure the mold is clean and an adequate mold release is used View our video presentation above "MAX EPOXY RESIN MIXING TECHNIQUE" Mix the resin only when all needed materials and implements needed are ready and within reach Mix the proper amount of resin needed and be accurate proportioning the resin and curing agent. A good rule of thumb is to maintain a minimum of 30 to 35% resin content by weight, Measuring by weight will ensure accurate composite fabrication and repeatability, rather than using OSY (ounce per square yard) data. THE USE OF A WEIGHING SCALE IS HIGHLY RECOMMENDED

Purchase this scale with any of our product offering and the shipping cost of the scale is free. A good rule of thumb is to maintain a minimum of 30 to 35% resin content by weight. Place the entire pre-cut fiberglass to be used on a digital scale to determine the fabric to resin weight ratio. FOR EXAMPLE 1 yard of 8-ounces per square yard (OSY) fabric weighs 226 grams MASTER EQUATION MIX RATIO OF RESIN SYSTEM IS 2:1 OR 50 PHR (per hundred resin) GENERAL LAY-UP PROCEDURE NOT THE OTHER WAY AROUND This is one of the most common processing error that yields sub-standard laminates. Eliminating air entrapment or void porosity in an epoxy/fiberglass lay-up process  A high-efficiency vacuum pump is used to draw out the air within the vacuum bag to create a negative atmospheric pressure. (maximum vacuum pressure at sea level) is applied to the vacuum bag transferring the force to the entire surface area of the laminate. For room temperature curing resin system, the vacuum pump is left in operation for a minimum of 18 hours.  |

Vacuum Infusion Process is also known in the composites industry as

Vacuum Assisted Resin Transfer Molding or VARTM.

Similar to the Vacuum Bagging Process where the negative pressure is used to apply consolidation force to the laminate while the resin cures,

the resin is infused into the fabric lay-up by sucking the impregnating resin and thus forming the composite laminate.

The VARTM Process produces parts that require less secondary steps, such as trimming, polishing or grinding with excellent mechanical properties.

However, the vacuum infusion requires more additional or supplemental related equipment and expendable materials.

So the pros and cons of each presented composite fabrication process should be carefully determined to suit the user's capabilities and needs.

Please view the following video demonstration which explains the process of Vacuum Infusion or VARTM process.

MAX 1618 A/B VACUUM ASSISTED RESIN TRANSFER MOLDING PROCESS

Step Four: Proper Curing MAX EPOXY RESIN SYSTEM product line is resistant to amine-blush, however,it is recommended not to mix any resin systems in high humidity conditions, greater than 60%. Always make sure that the substrate or material the epoxy resin system is being applied to is well prepared as possible to ensure the best-cured performance.

Always review the published data and information for proper usage, application, and general safety information.

Our expert staff of engineers is always available for consultation and assistance.

Allow the lay-up to cure for a minimum of 24 to 36 hours before handling. Optimum cured properties can take up to 7 days depending on the ambient cure condition. The ideal temperature cure condition of most room temperature epoxy resin is 22°C - 27°C at 20% relative humidity. Higher ambient curing temperatures will promote faster polymerization and development of cured mechanical properties.

Improving mechanical performance via post heat cure A short heat post cure will further improve the mechanical performance of most epoxy resins. Allow the applied resin system to cure at room temperature until for 18 to 24 hours and if possible, expose heat cure it in an oven or other sources of radiant heat (220°F to 250°F) for 45 minute to an hour. You can also expose it to direct sunlight but place a dark colored cover, such as a plastic tarp or cardboard to protect it from ultraviolet exposure. In general room temperature cured epoxy resin has a maximum operating temperature of 160°F or lower. A short heat post cure will ensure that the mixed epoxy system is fully cured, especially for room temperature cure system that can take up to 7 days to achieve 100% cure Some darkening or yellowing of the epoxy resin may occur if overexposed to high temperature (>250°F).

AMINE BLUSH The affinity of an amine compound (curing agent) to moisture and carbon dioxide creates a carbonate compound and forms what is called amine blush. Amine blush is a wax-like layer that forms as most epoxies cure. If the epoxy system is cured in extreme humidity (>70%). It will be seen as a white and waxy layer that must be removed by physical sanding of the surface followed by an acetone wipe.

OTHER TYPES OF EPOXY RESIN CURE MECHANISM LATENT CURING SYSTEMS Latent epoxy resins are systems that are mixed together at room temperature and will begin polymerization, but it will not achieve full cure unless it is exposed to a heat cure cycle.

In general, these are high-performance systems that demonstrate exceptional performance under extreme conditions such as high mechanical performance under heat and cryogenic temperatures, chemical resistance or any environment that epoxy room temperature system perform marginally or poorly. Upon the mixing of the resin and curing agent polymerization will begin and will only achieve a partial cure. Some resins may appear cured or dry to the touch, this state is called 'B-Stage Cure', but upon application of force will either be gummy or brittle almost glass-like and will dissolve in most solvents. The semi-cured resin must be exposed to an elevated temperature for it to continue polymerization and achieve full cure.

HEAT ACTIVATED CURING SYSTEMS This type of epoxy system will not polymerize unless it is exposed to the activation temperature of the curing agent which can be as low as 200°F and as high as 400°F. In most instances, our MAX EPOXY SYSTEMS epoxy system can be stored at room temperature and remain liquid for up to six months and longer.

TESTING THE COMPOSITE DETERMINATION OF THE FABRIC-RESIN RATIO ULTIMATE COMPRESSIVE STRENGTH

6500 Pounds To Failure Mechanical Load

Divided By 0.498 Square Inch = 13,052 psi Maximum Compressive Strength.

Determination Of the Fabric To Resin (FTR) Ratio

The specimen test was weighed and burned to obtain the fiberglass weight.

The difference in weight before and after the resin burnout can be used to calculate FTR ratio.

************************************************************

Always review the published data and information for proper usage, application, and general safety information.

Our expert staff of engineers is always available for consultation and assistance.

ULTIMATE COMPRESSIVE STRENGTH

6500 Pounds To Failure Mechanical Load

Divided By 0.498 Square Inch = 13,052 psi Maximum Compressive Strength.

Determination Of the Fabric To Resin (FTR) Ratio

The specimen test was weighed and burned to obtain the fiberglass weight.

The difference in weight before and after the resin burnout can be used to calculate FTR ratio.

************************************************************

DON'T FORGET OUR EPOXY MIXING KIT

Click The Link To Add To Order https://www.ebay.com/itm/222623932456

EVERYTHING YOU NEED TO MEASURE, MIX, DISPENSE OR APPLY

Proportioning the correct amount is equally as important to attain the intended cured properties of the resin system. The container in which the epoxy and curing agent is mixed is an important consideration when mixing an epoxy resin system. The container must withstand the tenacity of the chemical and must be free of contamination. Most epoxy curing agent has a degree of corrosivity, as a general practice, protective gloves should be worn when handling chemicals of the same nature.

MIXING KIT CONTENTS 1 Each Digital Scale -Durable, Accurate Up To 2000.0 Grams

4 Each 32-ounce (1 Quart) Clear HDPE Plastic Mix Cups

4 Each 16-ounce (1 Pint) Clear HDPE Plastic Mix Cups

One Size Fits All Powder-Free Latex Gloves

2 Each Graduated Syringes

Wooden Stir Sticks

Assorted Size Foam Brush

IMPORTANT NOTICE

Your purchase constitutes the acceptance of this disclaimer. Please review before purchasing this product.

The user should thoroughly test any proposed use of this product and independently conclude the satisfactory performance in the application. Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval.

The information contained herein is based on data believed to be accurate at the time of publication. Data and parameters cited have been obtained through published information, PolymerProducts and Polymer Composites Inc. laboratories using materials under controlled conditions. Data of this type should not be used for a specification for fabrication and design. It is the user's responsibility to determine this Composites fitness for use.

There is no warranty of merchantability for fitness of use, nor any other express implied warranty.

The user's exclusive remedy and the manufacturer's liability are limited to refund of the purchase price or replacement of the product within the agreed warranty period. Polymer Composites Inc. and its direct representative will not be liable for incidental or consequential damages of any kind.

Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether there is any infringement of patents is the sole liability of the user.

DON'T FORGET OUR EPOXY MIXING KIT

Click The Link To Add To Order https://www.ebay.com/itm/222623932456

EVERYTHING YOU NEED TO MEASURE, MIX, DISPENSE OR APPLY

1 Each Digital Scale -Durable, Accurate Up To 2000.0 Grams

4 Each 32-ounce (1 Quart) Clear HDPE Plastic Mix Cups

4 Each 16-ounce (1 Pint) Clear HDPE Plastic Mix Cups

One Size Fits All Powder-Free Latex Gloves

2 Each Graduated Syringes

Wooden Stir Sticks

Assorted Size Foam Brush

IMPORTANT NOTICE

Your purchase constitutes the acceptance of this disclaimer. Please review before purchasing this product.

The user should thoroughly test any proposed use of this product and independently conclude the satisfactory performance in the application. Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval.

The information contained herein is based on data believed to be accurate at the time of publication. Data and parameters cited have been obtained through published information, PolymerProducts and Polymer Composites Inc. laboratories using materials under controlled conditions. Data of this type should not be used for a specification for fabrication and design. It is the user's responsibility to determine this Composites fitness for use.

There is no warranty of merchantability for fitness of use, nor any other express implied warranty.

The user's exclusive remedy and the manufacturer's liability are limited to refund of the purchase price or replacement of the product within the agreed warranty period. Polymer Composites Inc. and its direct representative will not be liable for incidental or consequential damages of any kind.

Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether there is any infringement of patents is the sole liability of the user.